One-bath dyeing and anti-mosquito finishing method of aramid fiber disperse dye

A technology of dyeing and disperse dyes in the same bath, applied in the direction of dyeing method, fiber treatment, textile and papermaking, etc., can solve the problems of toxic dyeing carrier, unfavorable environmental protection, low dyeing rate, etc., and achieve bright colors, good practical effects, The effect of high dye uptake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment implements according to the following steps:

[0042] (1) Submerge the meta-aramid fiber in a solution consisting of 5 g / L sodium hydroxide and 2 g / L degreasing agent CY-1113 (Chuangxin Demei Chemical Industry Co., Ltd.), bath ratio 1:20, and boil it 30 minutes, then wash and dry with hot water and cold water in turn;

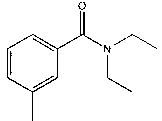

[0043] (2) Same-bath dyeing and anti-mosquito finishing of aramid fiber, immerse the aramid fiber in 2% disperse blue 2BLN based on fabric weight, 5 g / L finishing agent (N,N-diethyl m-toluene Amide 80%, Nongru 600 accounted for 14%, AES 2%, triethanolamine dodecylbenzenesulfonate 4%, put them into the stirring tank in turn, and stir at a temperature of 20-30°C for 5-10 min After cooling and standing to prepare the finishing solution), the water temperature is 70°C, the bath ratio is 1:20, and the temperature is raised to 130°C at 2°C / min. After 40 minutes of heat preservation treatment, the aramid fiber is taken out and washed with water...

Embodiment 2

[0048] This embodiment implements according to the following steps:

[0049] (1) Submerge the meta-aramid fabric in a solution consisting of 10 g / L sodium hydroxide and 5 g / L degreasing agent CY-1113 (Chuangxin Demei Chemical Industry Co., Ltd.), bath ratio 1:20, and boil it 30 minutes, then wash and dry with hot water and cold water in turn;

[0050] (2) For the same-bath dyeing and mosquito-proof finishing of aramid fiber, immerse the aramid fiber in 2% dispersed golden E-3RL, 10 g / L finishing agent (N,N-diethyl-m-methyl 80% of benzamide, 14% of Nongru 600, 2% of AES, and 4% of dodecylbenzenesulfonate triethanolamine salt are put into the stirring tank in turn, and stirred at a temperature of 20-30°C for 5- After cooling for 10 minutes, the finishing liquid was prepared as finishing agent). The water temperature was 70°C, the bath ratio was 1:20, and the temperature was raised to 140°C at 2°C / min. After 60 minutes of heat preservation, the aramid fiber was taken out Squeez...

Embodiment 3

[0055] This embodiment implements according to the following steps:

[0056] (1) Immerse the para-aramid fiber in a solution consisting of 10 g / L sodium hydroxide and 3 g / L degreasing agent CY-1113 (Chuangxin Demei Chemical Industry), bath ratio 1:20, boil for 30 Minutes, then wash and dry with hot water and cold water in turn;

[0057] (2) Same-bath dyeing and anti-mosquito finishing of aramid fiber, immerse the aramid fiber in 2% disperse blue 2BLN based on fabric weight, 10g / L finishing agent (N, N-diethyl m-toluamide 80%, Nongru 600 accounted for 14%, AES 2%, triethanolamine dodecylbenzenesulfonate 4%, put them into the stirring tank in turn, and stir for 5-10 minutes at a temperature of 20-30°C Cooling and standing to prepare the finishing solution), the water temperature is 70 °C, the bath ratio is 1:20, the temperature is raised to 130 °C at 2 °C / min, after 50 min of heat preservation treatment, the aramid fiber is taken out, washed and squeezed Dry;

[0058] (3) Red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com