Preparation method of high-elasticity and high-strength double-crosslinked porous hydrogel

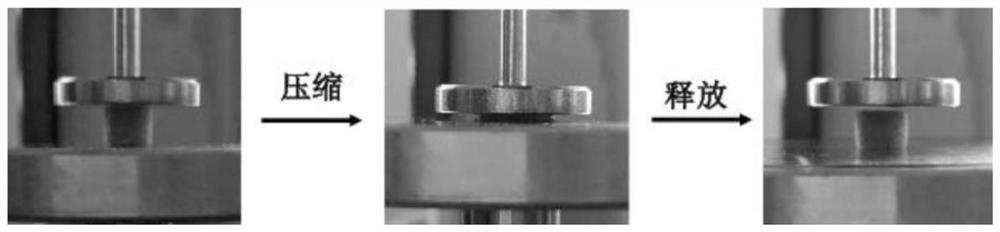

A porous hydrogel and double cross-linking technology, applied in the field of hydrogel materials, can solve problems such as poor mechanical properties, reduced solid content of the material body, unsatisfactory mechanical properties, etc., and achieve simple production equipment, good resistance to swelling, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh 10.17g of N-isopropylacrylamide, 0.648g of acrylic acid, 0.108g of ammonium persulfate, and 15mg of methylene bisacrylamide to prepare a 30mL solution with dimethyl sulfoxide as a solvent, and mix them uniformly to obtain a prepolymer solution;

[0036] (2) The obtained pre-polymerization solution is transferred to a 50mL centrifuge tube and NaCl particles are added thereto until the particles fill the solution;

[0037] (3) Transfer the saturated pre-polymerization solution filled with NaCl to a glass mold with a thickness of 2mm or a centrifuge tube of 5mL, and then irradiate it with a 36W ultraviolet lamp with a wavelength of 365nm for 2 hours at room temperature to obtain a chemically cross-linked hydrogel ;

[0038] (4) Soak the chemically cross-linked hydrogel in 250 mL of iron ion solution with a concentration of 0.10 mol / L for 18 hours to remove porogens and organic solvents and carry out physical cross-linking. Repeat twice and take out to obtain doub...

Embodiment 2

[0041] (1) Weigh 10.17g of N-isopropylacrylamide, 0.970g of acrylic acid, 0.111g of ammonium persulfate, and 16mg of methylene bisacrylamide to prepare a 30mL solution with dimethyl sulfoxide as a solvent, and mix well to obtain a prepolymer solution ;

[0042] (2) The obtained pre-polymerization solution is transferred to a 50mL centrifuge tube and NaCl particles are added thereto until the particles fill the solution;

[0043] (3) Transfer the saturated pre-polymerization solution filled with NaCl to a glass mold with a thickness of 2mm or a centrifuge tube of 5mL, and then irradiate it with a 36W ultraviolet lamp with a wavelength of 365nm for 2 hours at room temperature to obtain a chemically cross-linked hydrogel ;

[0044](4) Soak the chemically cross-linked hydrogel in 250 mL of iron ion solution with a concentration of 0.10 mol / L for 18 hours to remove porogens and organic solvents and carry out physical cross-linking. Repeat twice and take out to obtain double Cross...

Embodiment 3

[0047] (1) Weigh 10.17g of N-isopropylacrylamide, 1.94g of acrylic acid, 0.123g of ammonium persulfate, and 18mg of methylene bisacrylamide to prepare a 30mL solution with dimethyl sulfoxide as a solvent, and mix well to obtain a prepolymer solution ;

[0048] (2) The obtained pre-polymerization solution is transferred to a 50mL centrifuge tube and NaCl particles are added thereto until the particles fill the solution;

[0049] (3) Transfer the saturated pre-polymerization solution filled with NaCl to a glass mold with a thickness of 2mm or a centrifuge tube of 5mL, and then irradiate it with a 36W ultraviolet lamp with a wavelength of 365nm for 2 hours at room temperature to obtain a chemically cross-linked hydrogel ;

[0050] (4) Soak the chemically cross-linked hydrogel in 250 mL of iron ion solution with a concentration of 0.10 mol / L for 18 hours to remove porogens and organic solvents and carry out physical cross-linking. Repeat twice and take out to obtain double Cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

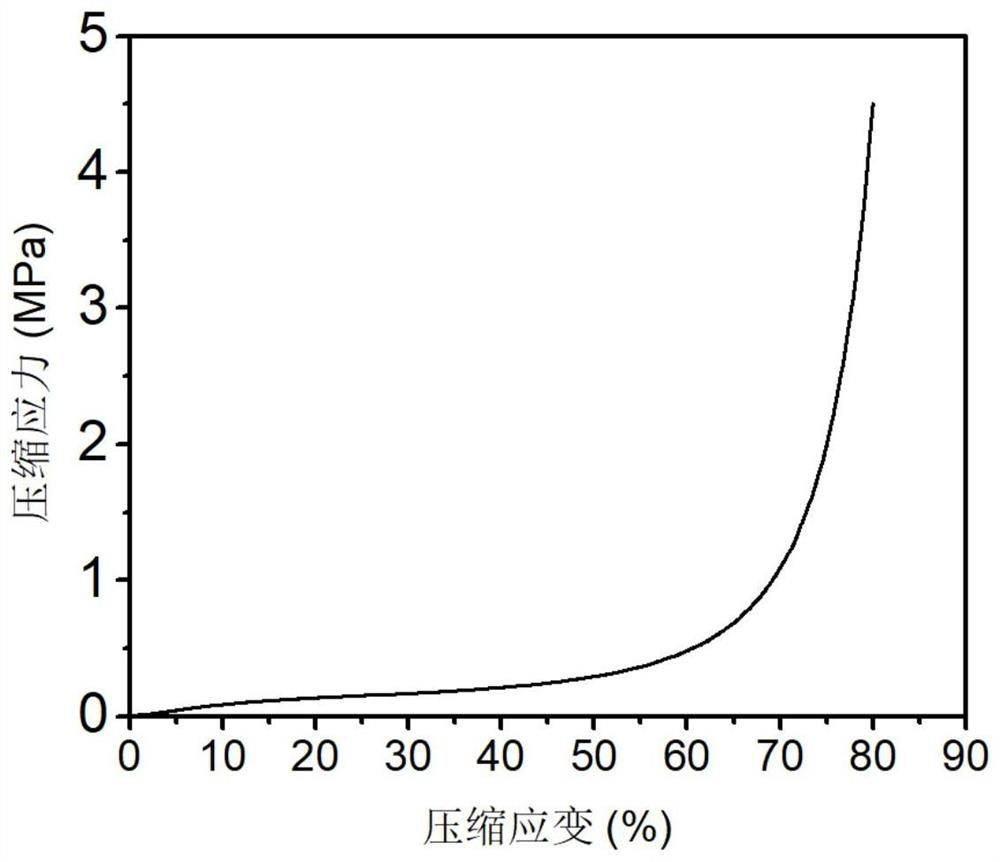

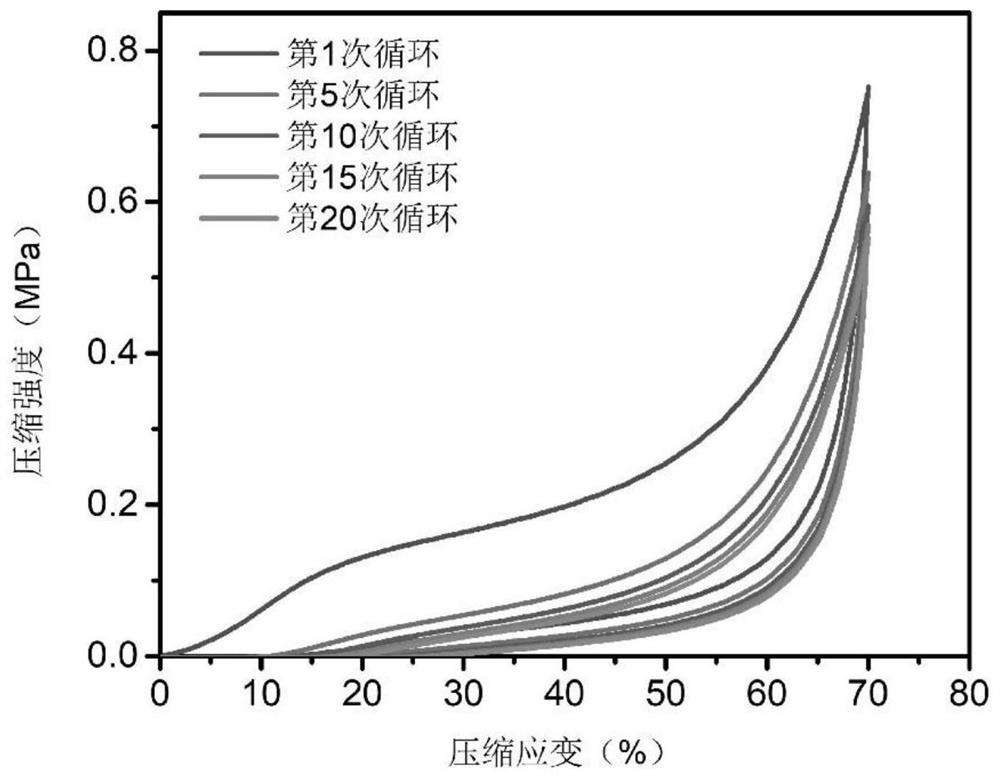

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com