Forming section

A forming section and forming shoe technology, which is applied in the wet section of paper machines, textiles, papermaking, paper machines, etc., can solve the problems of high cost of negative pressure system and high energy consumption of negative pressure system operation, and achieve less splashing and excellent quality and intensity characteristics, flexible and variable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

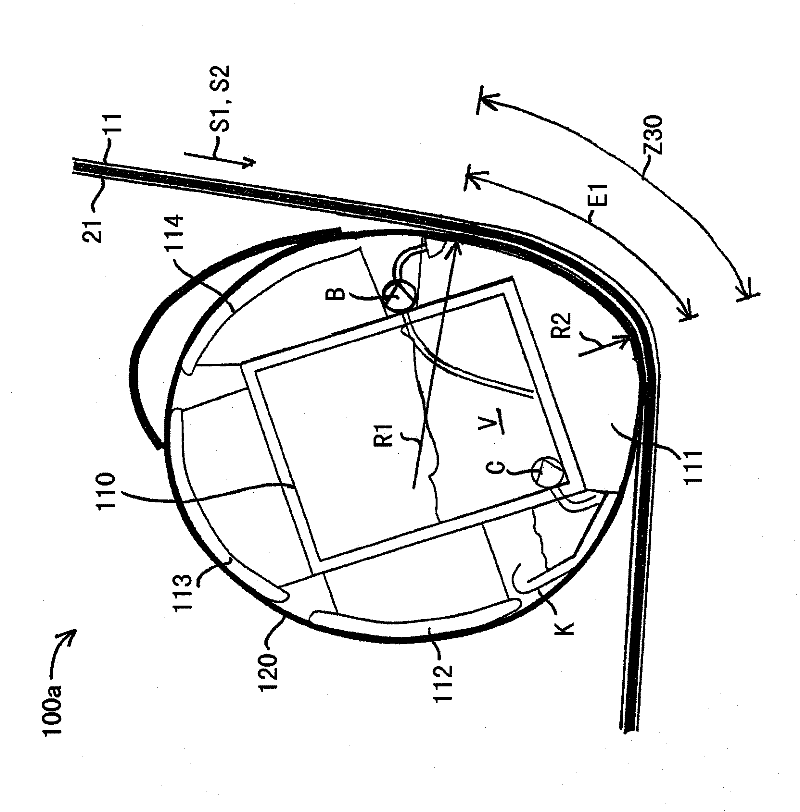

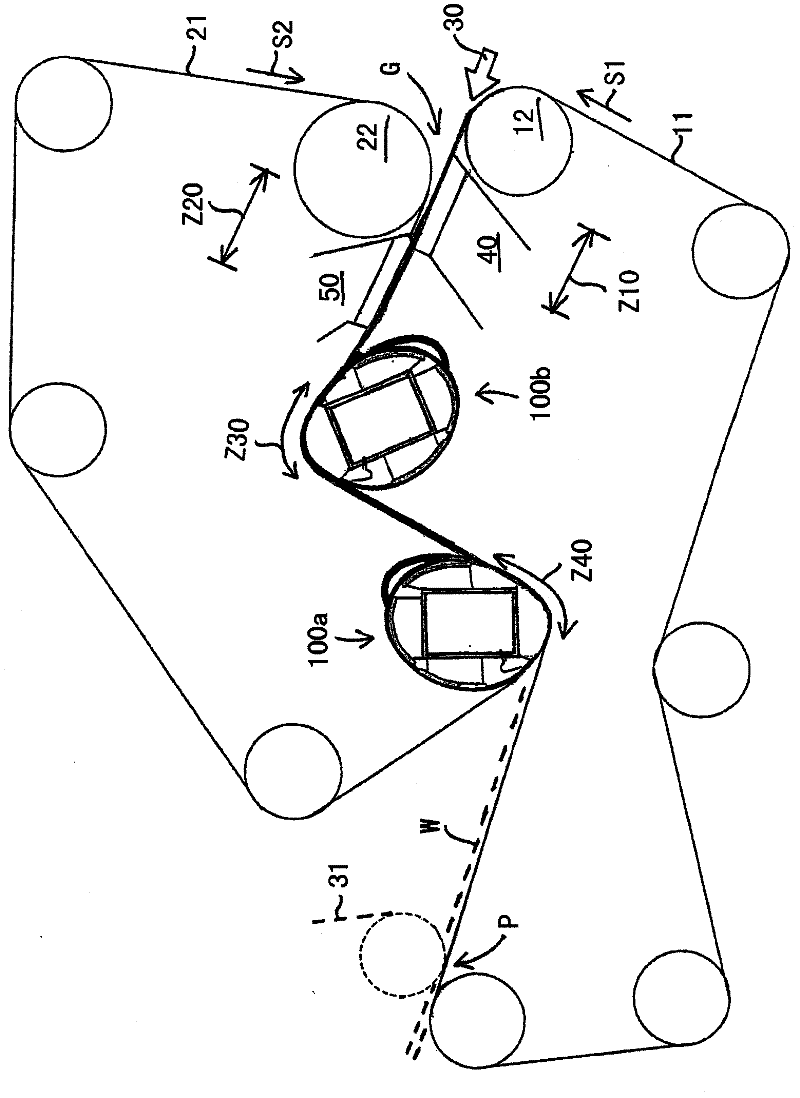

[0025] figure 1 A schematic side view of a forming part according to the invention is shown.

[0026] The forming section comprises a first wire loop 11 looped around a forming roll 12a and a second wire loop 21 looped around a first guide roll 22a. The direction of travel of the first web 11 is indicated by arrow S1 and the direction of travel of the second web 21 is indicated by arrow S2. The first wire 11 and the second wire 21 form a meeting gap G so that the wires 11, 21 meet in the area of the forming roll 12a. The headbox 30 feeds a jet of pulp suspension into this gap G between the wires 11 , 21 . After passing the meeting point, the wires 11, 21 travel in a specific section on the outer surface of the forming roll 12a on which a first dewatering zone Z1 formed by a curve is formed. Following this first dewatering zone Z1 formed by a curve is an essentially straight twin-wire section with two dewatering zones Z2, Z3 thereon. The second dehydration zone Z2 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com