Milling tools and cutting elements for milling tools

A technology of cutting elements and tools, applied in milling cutting inserts, tools for milling machines, workpieces, etc., can solve problems such as damage to positioning accuracy, deterioration of cutting edge positioning repeatability, etc., and achieve the effect of simplifying positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

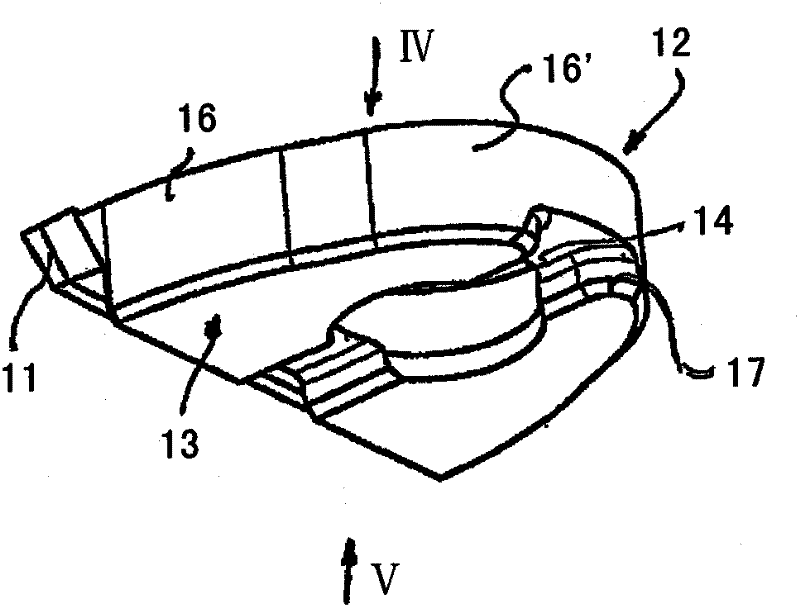

[0056] The milling tool comprises a carrier body 3 with a cutting element 1 inserted into a recess 2 of the carrier body and screwed to the carrier body 3 by countersunk screws 6 . In front of each cutting element 1 there is provided a chip space 4 for receiving chips generated during machining of a workpiece. From figure 1 It can be seen that the outer cutting element 1 is arranged in the axially open recess 2 and is not guided on its axial circumferential wall. The cutting element 1 is arranged such that a helical overall cutting edge is formed by the individual cutting edges 11 . The milling tool can be connected to a drive shaft (not shown in detail here) of a machining tool via an axial bore 5 provided in the carrier body 3 .

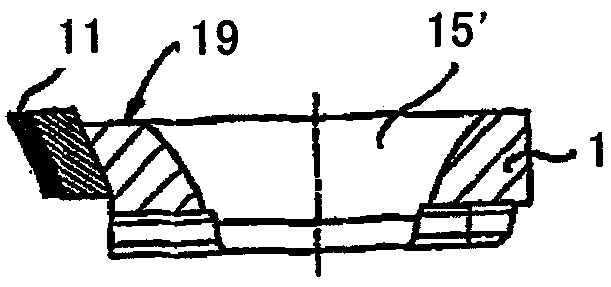

[0057] Each cutting element 1 has a symmetrical shape, which tapers toward the side opposite the cutting edge 11 (cutting edge) and is substantially triangular in design. The region 12 lying opposite the cutting edge 11 is rounded with a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com