Preparation method for carbon nanotube array cathode on Fe-based metal alloy substrate

A carbon nanotube array and alloy substrate technology, applied in the field of carbon nanotubes, can solve the problems of carbon nanotube growth termination, different catalyst particle sizes, uneven distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

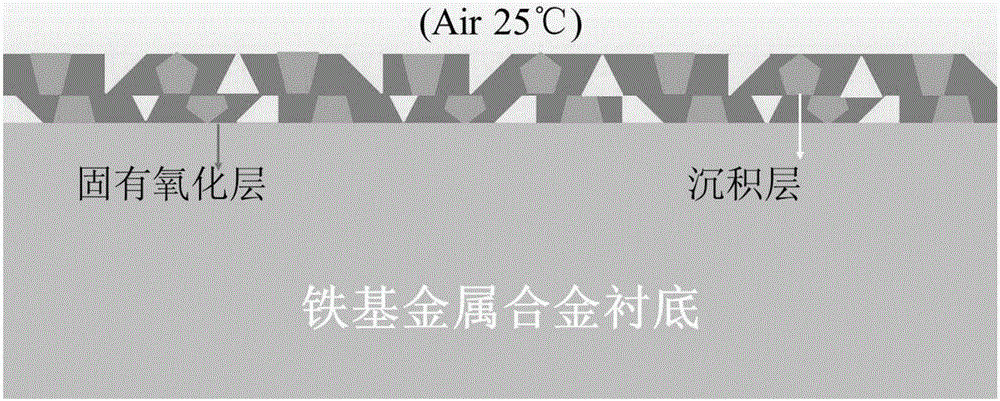

[0026] The method for preparing a carbon nanotube array cathode on an iron-based metal alloy substrate of the present invention includes the following steps: Step 1. The iron-based metal alloy substrate used in the present invention is ultrasonically cleaned with acetone, absolute ethanol and deionized water 20-30min to remove surface organic pollutants and other impurities, and then blow dry with dry compressed nitrogen.

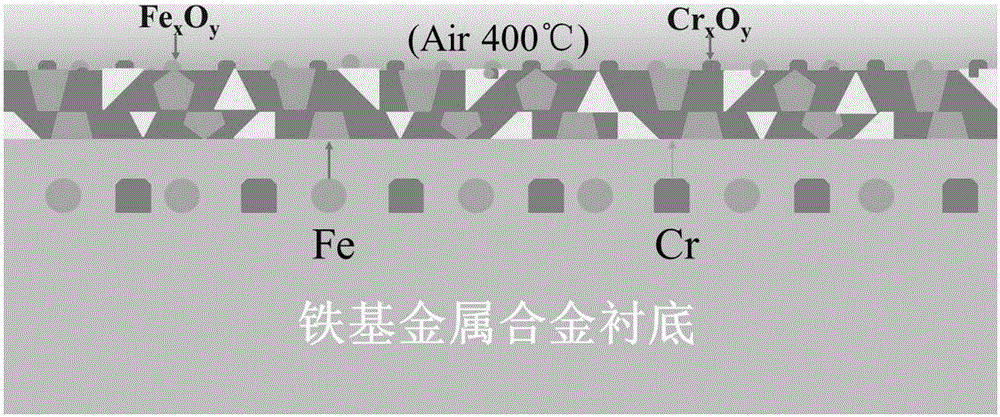

[0027] Step 2: Place the cleaned iron-based metal alloy substrate on the sample stage in the physical vapor deposition chamber, and use a combination of mechanical pump and turbo molecular pump to pump the chamber pressure to 10 -4 Pa, while introducing 40-50sccm argon gas, and using magnetron sputtering equipment under high bias conditions (200V) to deposit a layer of different element composition on the surface of iron-based metal alloy substrate by sputtering iron and chromium targets at the same time Thickness of the iron-chromium composite layer, and stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com