Field emission element

A field emission and component technology, which is applied to electrical components, parts of discharge tubes/lamps, discharge tubes, etc., can solve the problems of uneven and uneven top of carbon nanotube arrays, and the difficulty of CVD growth process for large-area uniformity, etc. Achieve the effect of improving field emission performance and reducing non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

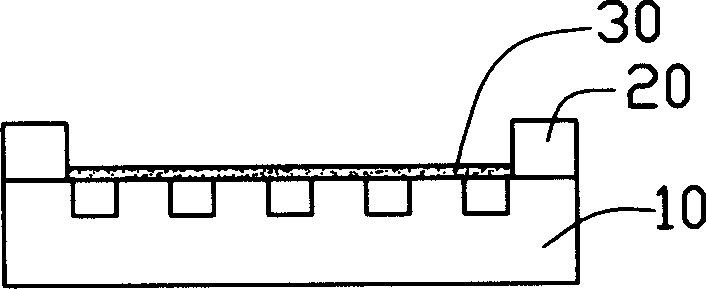

[0018] Combine below Figure 1-7 Introduce the manufacturing method of the field emission element of the present invention

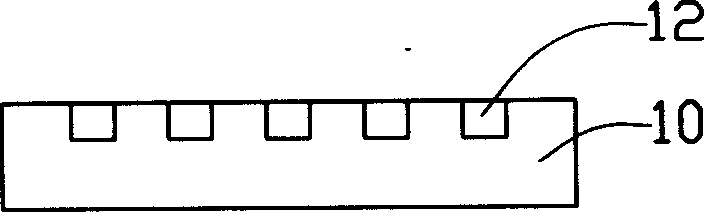

[0019] see figure 1 Firstly, a working template 10 is provided, and the working template 10 has tiny air holes 12, and the tiny air holes 12 can ensure that the working template 10 is easily desorbed in subsequent processes. The surface flatness of the working template 10 is required to be below 1 μm, and the material is required to withstand the growth temperature of carbon nanotubes at about 700° C. In this embodiment, porous silicon is selected as the working template 10 .

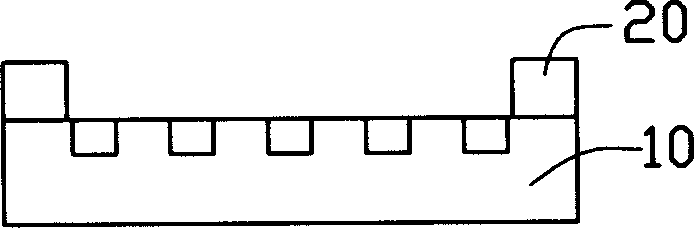

[0020] see figure 2 1. Make an insulating spacer 20 on the working template 10. In this embodiment, the mode of coating is used to make the insulating spacer 20 with a thickness of 200 μm. The method of making the insulating spacer 20 can also be printed or printed in addition to the coating method. The off-the-shelf thin plate is directly used, and the flatness of the side f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com