Method for preparing double-layer zinc oxide nanowire array by chemical vapor deposition

A zinc oxide nanowire and chemical vapor deposition technology, which is applied in the field of preparation of zinc oxide nanowire arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

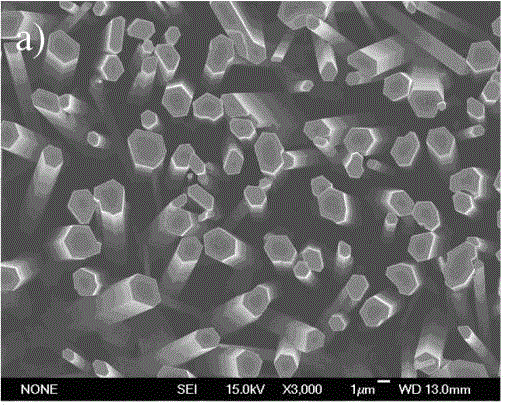

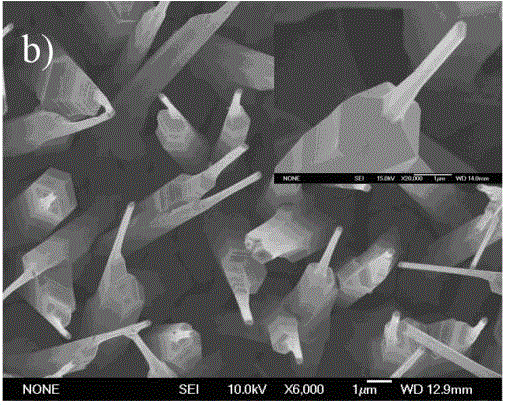

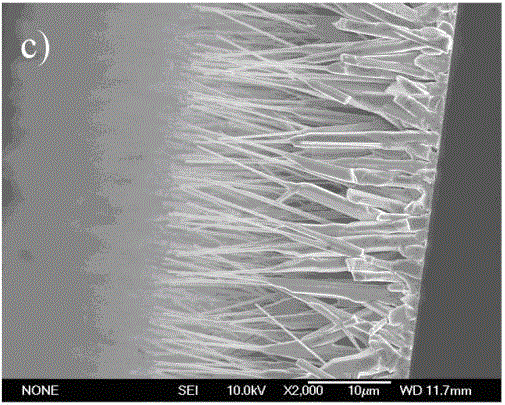

[0028] Example 1: Preparation of double-layer ZnO nanowire array

[0029] Concrete preparation steps of the present invention are as follows:

[0030] (1) Put the silicon wafer N(100) polished on one side into ethanol and acetone solutions and ultrasonically for 0.5 hours each to remove organic matter on the surface of the silicon wafer, and then put it into a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 3:1) , Heated at 80°C for 1 hour to remove oxides and metal impurities on the silicon surface. Put the treated silicon wafer into ultrapure water for 0.5 hours and ultrasonically remove the residual acid on the surface;

[0031] (2) Weigh 0.1098 g of zinc acetate dihydrate and add it to 25 mL of ethanol solution, stir until completely dissolved. Spin-coat the zinc acetate ethanol solution on the silicon wafer several times, and dry it in a 100°C drying oven for 20 minutes after each spin-coating;

[0032] (3) Weigh 0.5 g of graphite powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com