Internally-arranged angle sensor all-in-one ultrasonic motor servo control system

A servo control system, angle sensor technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. It solves the problems of servo control system, closed-loop control of difficult hollow ultrasonic motor, etc., to avoid high-precision machining and assembly process requirements, ensure electrical performance, and improve internal space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

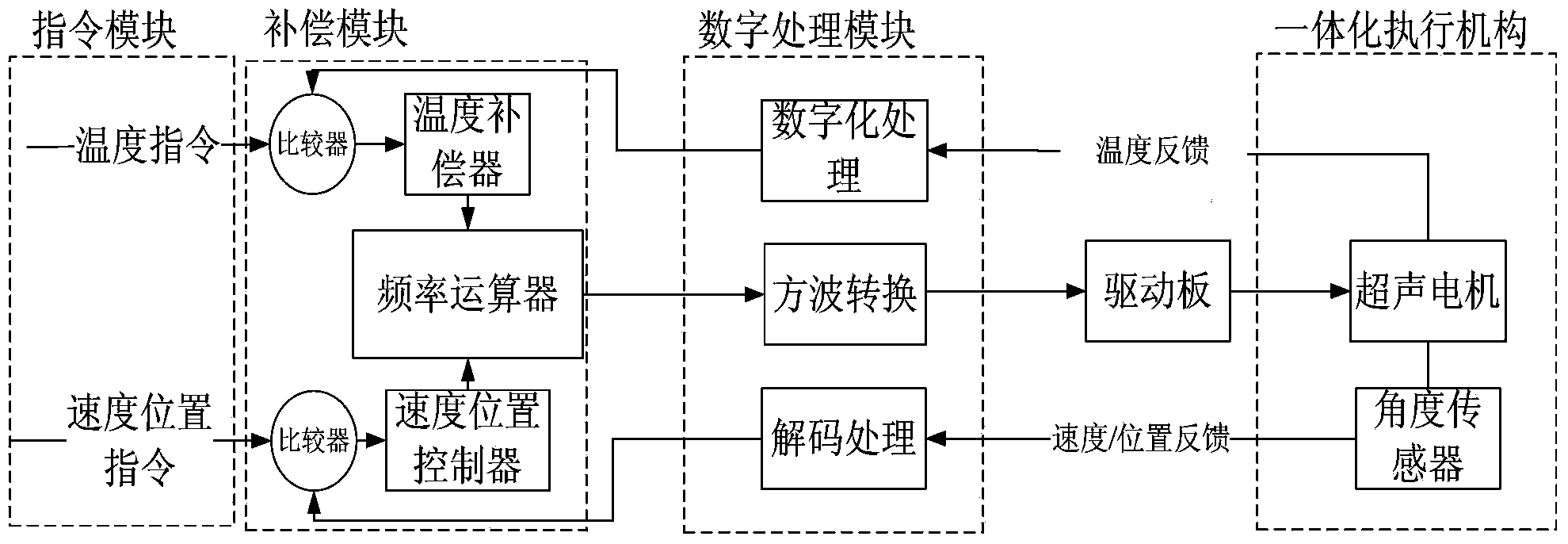

[0035] Such as figure 1 As shown, the present invention includes a command module, a compensation module, a digital processing module, a drive board and an integrated actuator.

[0036] Since the present invention realizes the closed-loop control of the ultrasonic motor, the structure and working principle of the present invention will be described respectively below according to the initial forward control and feedback loop control. The initial positive control refers to the drive control process of the ultrasonic motor completed by the command when there is no feedback signal when the command is issued for the first time. Feedback loop control refers to the process in which the control system controls the feedback information again after the integrated actuator sends feedback information.

[0037] a. Initial positive control

[0038] The command module sends speed and position commands to the compensation module, and the speed and position commands set the angular velocity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com