Temperature control system of in-cylinder direct injection gasoline injector

A gasoline injector and temperature control system technology, applied in the charging system, machine/engine, fuel injection device, etc., can solve the problems of high particulate matter emission, inability to accurately control the fuel temperature, and difficulty in starting the exhaust gas. The effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific examples and with reference to the accompanying drawings.

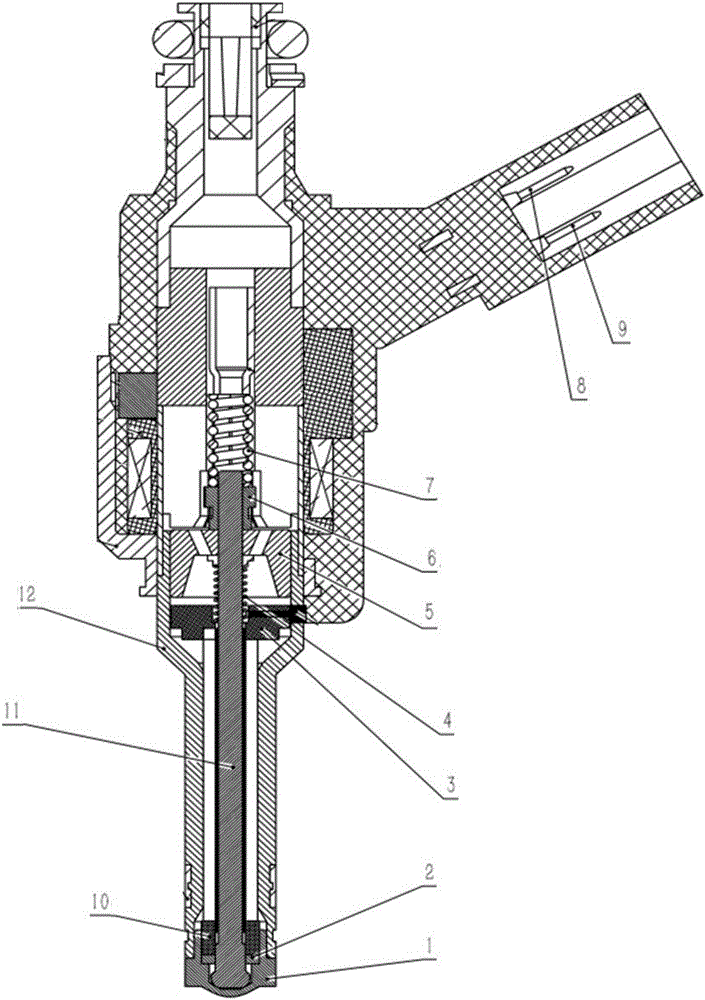

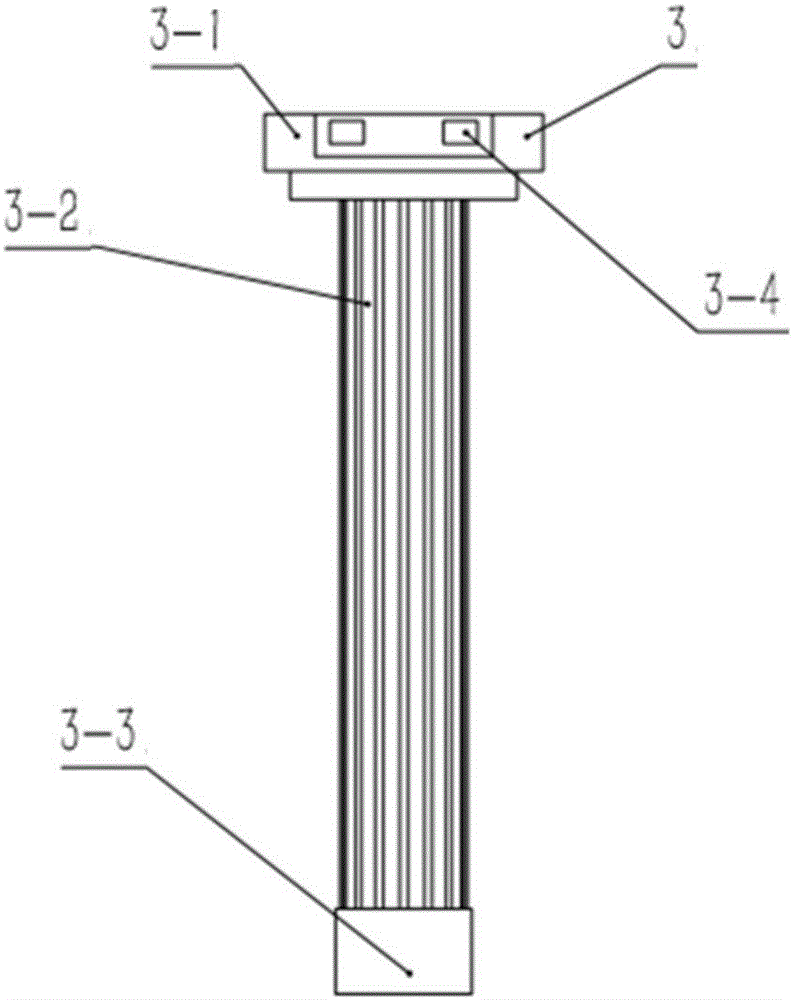

[0019] see first figure 1 , figure 1 It is a sectional view of the overall structure of the fuel injector involved in the present invention. As can be seen from the figure, the temperature control system of the direct injection gasoline injector in the cylinder of the present invention includes a fuel temperature control assembly 3 arranged on the injector and an engine control unit (not shown) arranged on the engine compartment, the described The needle valve 11 of the in-cylinder direct injection gasoline injector is bound in the guide tube 12 along the inner edge of the guide pipe 12 through the bottom-up valve seat 1, the needle valve guide seat 2, the heating cylinder insulation pad 10, the fuel temperature control ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com