Method for calculating ammonia leakage amount of SCR post-processing system

A calculation method, ammonia leakage technology, applied in the direction of exhaust treatment, electronic control of exhaust treatment device, diagnostic device of exhaust treatment device, etc., can solve the problem of low accuracy of SCR closed-loop control, and achieve accurate SCR closed-loop control , Improve the accuracy and reduce the effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

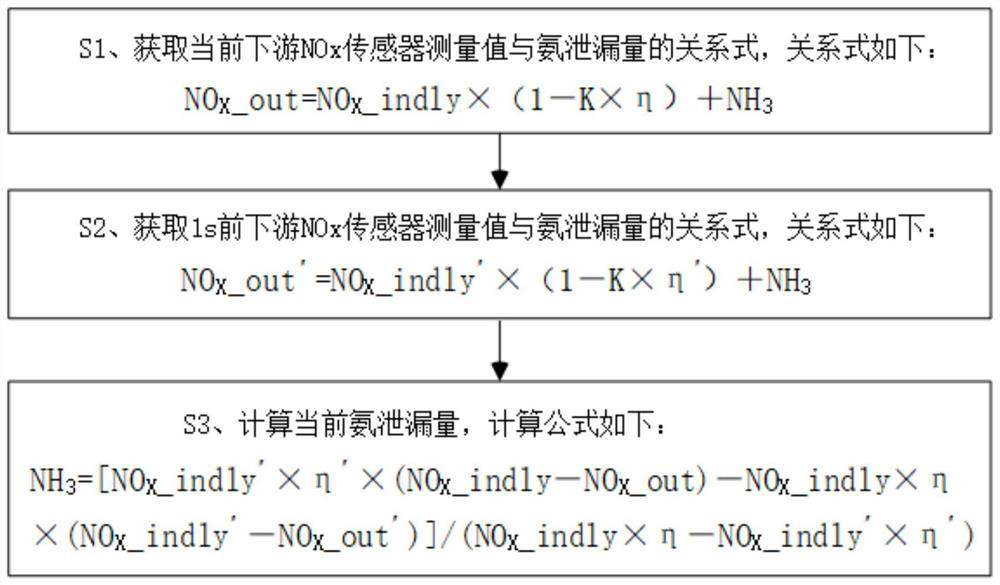

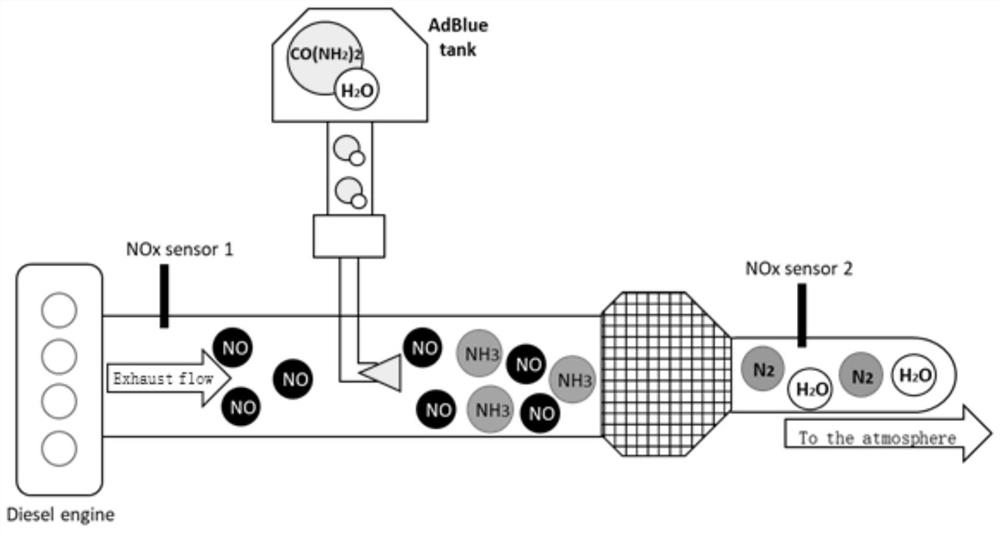

[0061] see figure 1 , a method for calculating ammonia leakage in an SCR aftertreatment system, the method comprising the following steps:

[0062] S1. Obtain the relational expression between the measured value of the current downstream NOx sensor and the amount of ammonia leakage;

[0063] The downstream NOx sensor measurement consists of nitrogen oxides and ammonia slip as shown in the following formula:

[0064] NO X _out=NO X +NH 3

[0065] The amount of nitrogen oxides is obtained by the following formula:

[0066] NO X = NO X _indly×(1-K×η)

[0067] In the above formula, NO X is the amount of nitrogen oxides;

[0068] From the above two formulas, the relationship can be obtained as:

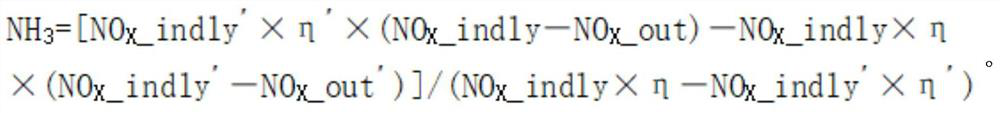

[0069] NO X _out=NO X _indly×(1-K×η)+NH 3

[0070] In the above formula, NO X _out is the measured value of the current downstream NOx sensor, NO X _indly is the measured value of the upstream NOx sensor before t time (t is the time required for gas to flow from the upstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com