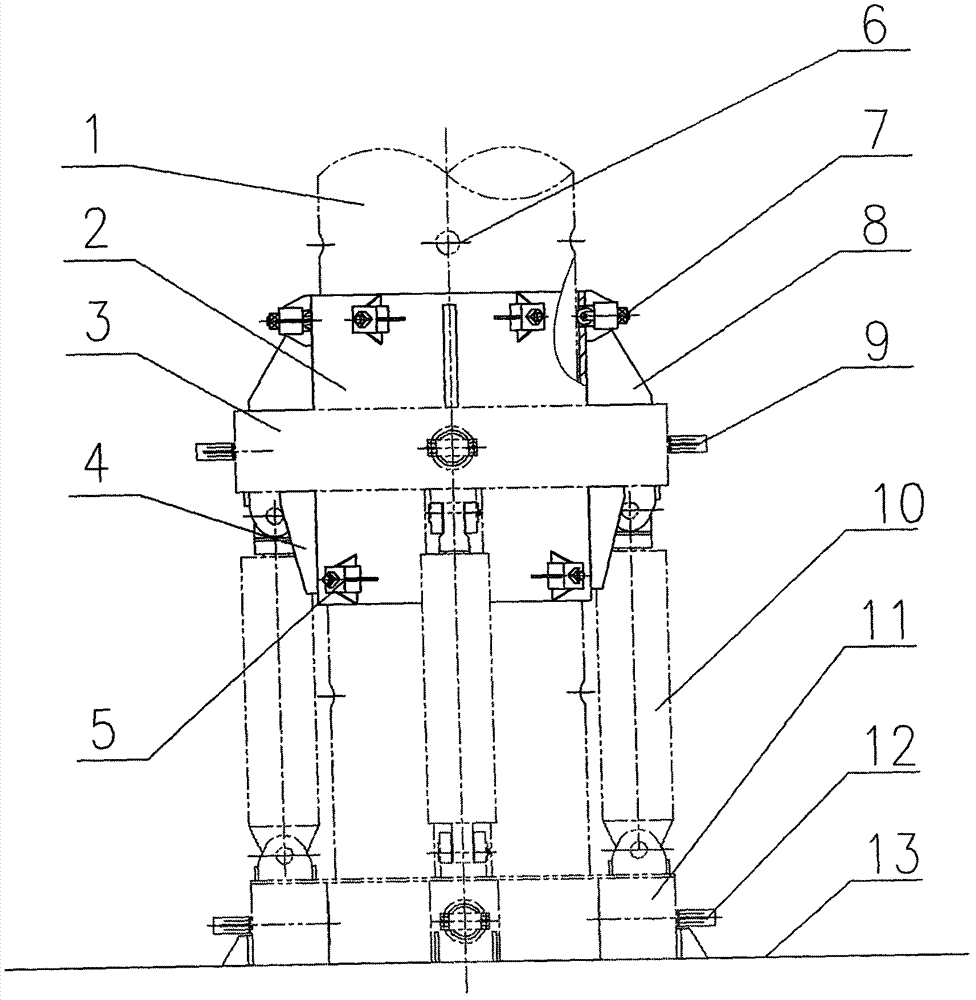

Hydraulic lifting pile righting guide device for offshore jack-up platform

A self-elevating platform, hydraulic lifting technology, applied in the field of marine engineering, to achieve the effect of compact structure, strong practicability, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

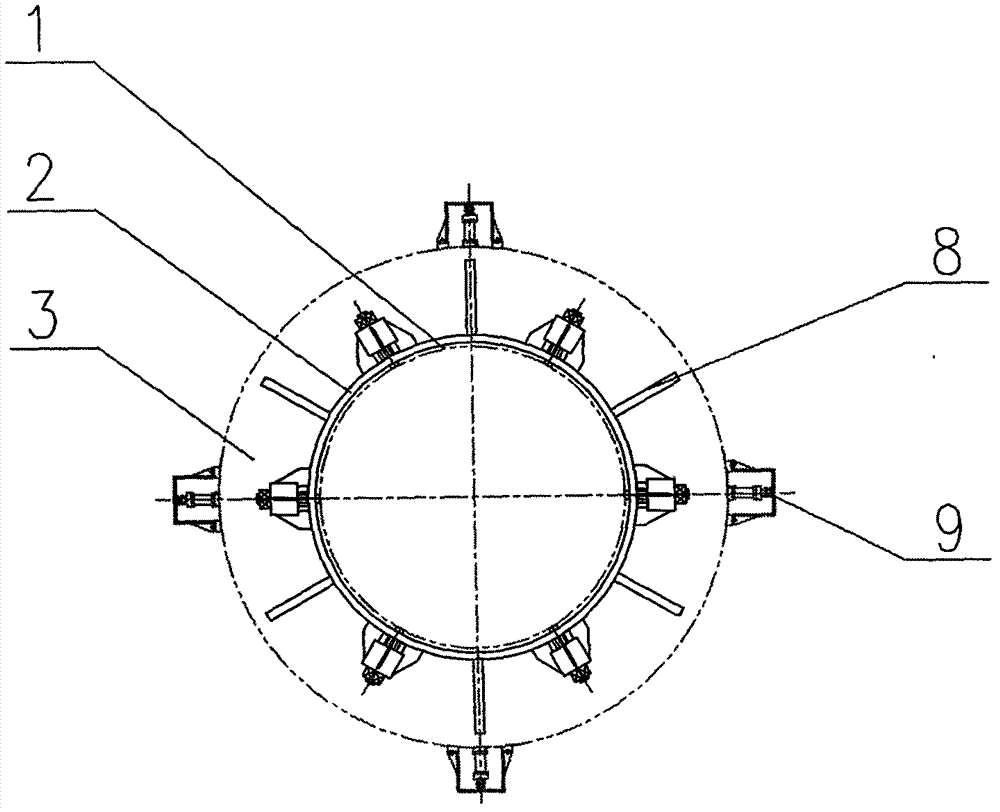

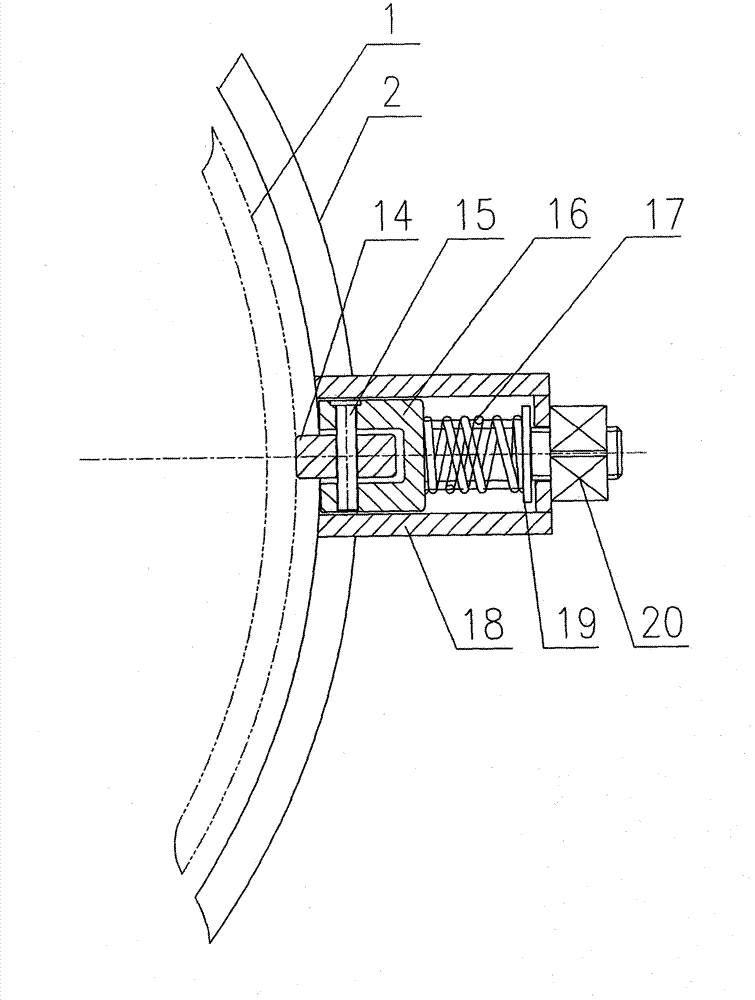

[0019] The specific embodiment of the present invention is as follows: According to a kind of marine self-elevating platform hydraulic lift righting guide device figure 1 , figure 2 , image 3 Shown for further description: firstly, the tugboat lifts the marine self-elevating platform to the predetermined sea area and anchors it in place. This is the platform support pile 1 is fixed with the platform body 13 through the lower hydraulic bolt 12. When the platform is inserted, it is The platform support pile 1 goes down: first, the hydraulic pump of the platform hydraulic station starts to start and put into operation, and the hydraulic operating platform of the hydraulic lifting pile system is operated, and the platform lifting cylinder 10 drives the lifting ring beam 3 and the righting guide sleeve 2 to go up; when it goes up to a When the pin hole pitch is reached, the platform lifting cylinder 10 stops; the upper hydraulic pin 9 is inserted into the pin hole 6 on the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com