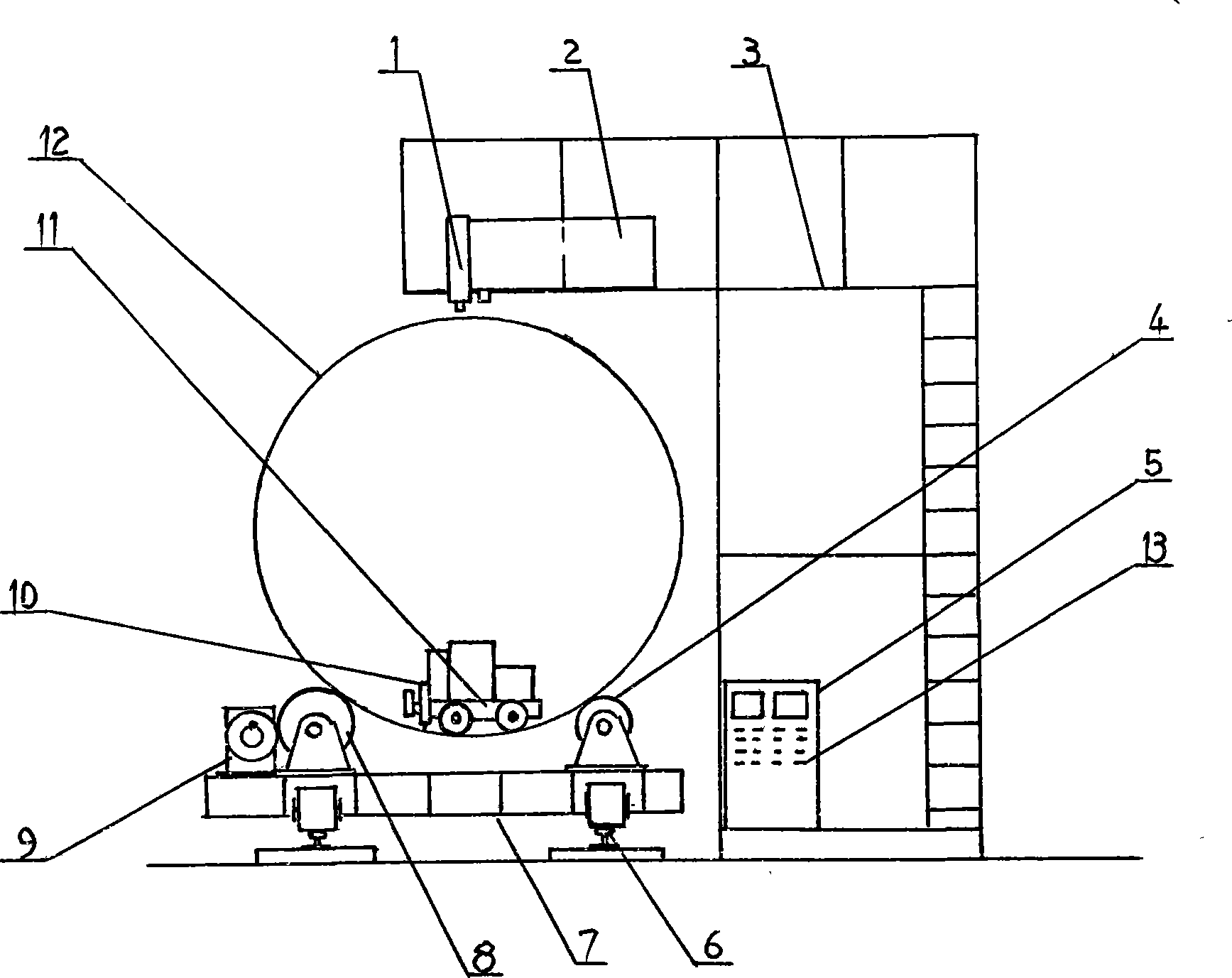

Assembly welding method for producing large diameter extremely thick steel pipes through rotary walking rail and device thereof

A technology for welding steel pipes and large diameters, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of difficult construction quality of large-diameter and extra-thick steel pipes, difficulty in ensuring the verticality of steel pipe installation, and uniform vertical weld gaps. , to achieve the effect of feasible and safe construction methods, avoiding rework losses and reducing personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

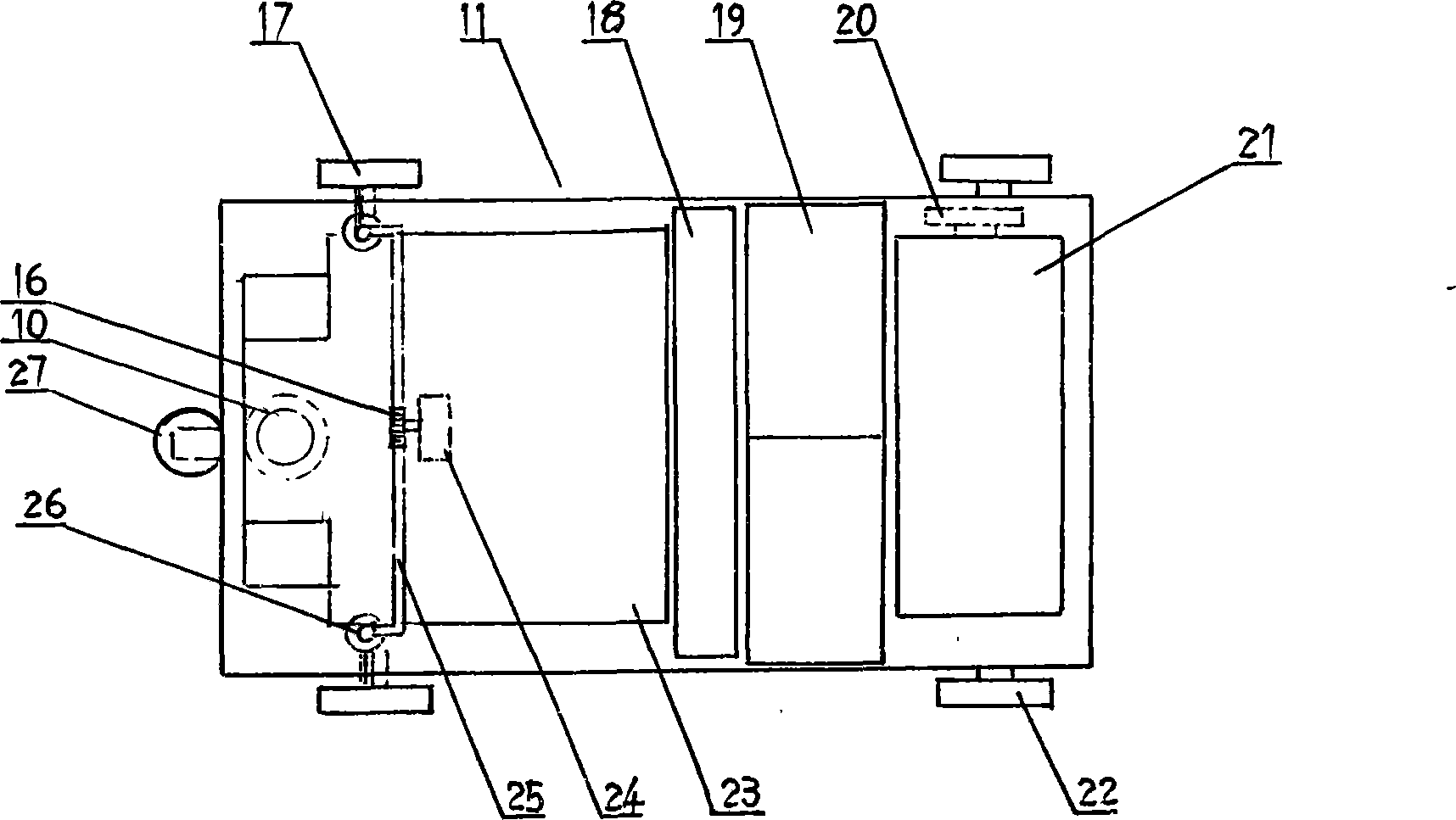

[0027] A method for manufacturing large-diameter and extra-thick steel pipes by assembling and welding rotating tracks, comprising the following steps:

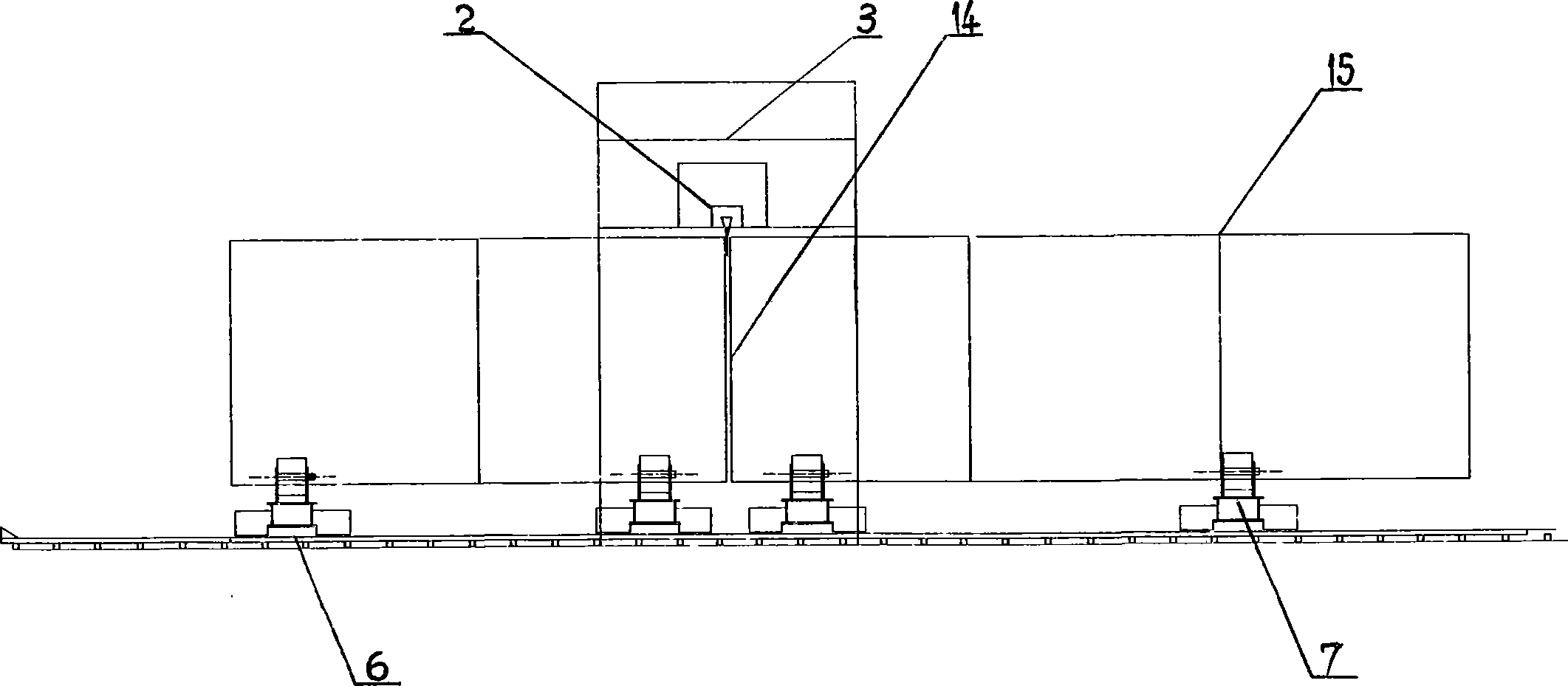

[0028] (1) Carry out site cleaning and leveling at the construction site, and lay tracks on a flat and solid site. Carry out hardening treatment to the on-site assembly site to ensure flatness and foundation bearing capacity to meet the supporting capacity of large-diameter and extra-thick steel pipe assembly and welding, so as to avoid uneven settlement during welding construction from affecting the assembly and welding quality of steel pipes.

[0029] Before the track is installed, measure and stake out the site, measure the elevation of the track installation position, chisel out the super high part, fill and level the low-lying areas, control the smoothness of the track installation and the elevation of the top surface of the track, and adopt the method of supporting pads if necessary Be adjusted to ensure the flatness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com