Method for preparing molybdenum disulfide film for field emission device

A field emission device, molybdenum disulfide technology, applied in the manufacture of discharge tubes/lamps, electrical components, cold cathode manufacturing, etc., can solve the problem that the two-dimensional atomic crystal material MoS2 is rarely studied, and achieve rich spatial geometric edges , large specific surface area, and the effect of reducing the applied electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

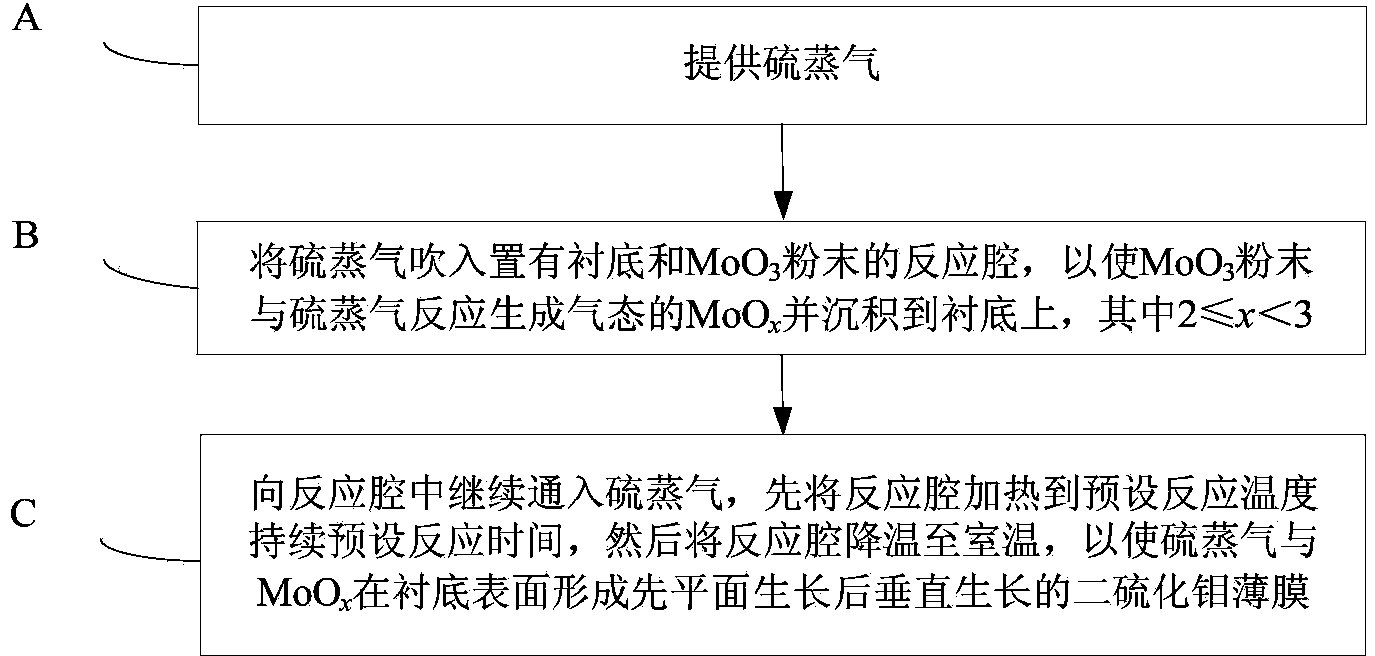

[0025] The present invention proposes a method for preparing a molybdenum disulfide thin film for field emission devices, such as figure 1 shown, including:

[0026] A. Provide sulfur vapor.

[0027] Specifically, the sulfur vapor can be obtained by sublimation of sulfur powder.

[0028] B. Blowing sulfur vapor into the substrate and MoO 3 Powder reaction chamber to make MoO 3 The powder reacts with sulfur vapor to form gaseous MoO x and deposited on the substrate, where 2≤x<3.

[0029] Specifically, sulfur vapor can be blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com