Diamond-like material field electron emission cathode and manufacture method

A field electron emission and diamond technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of limited increase in emission current and low space density of emitters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

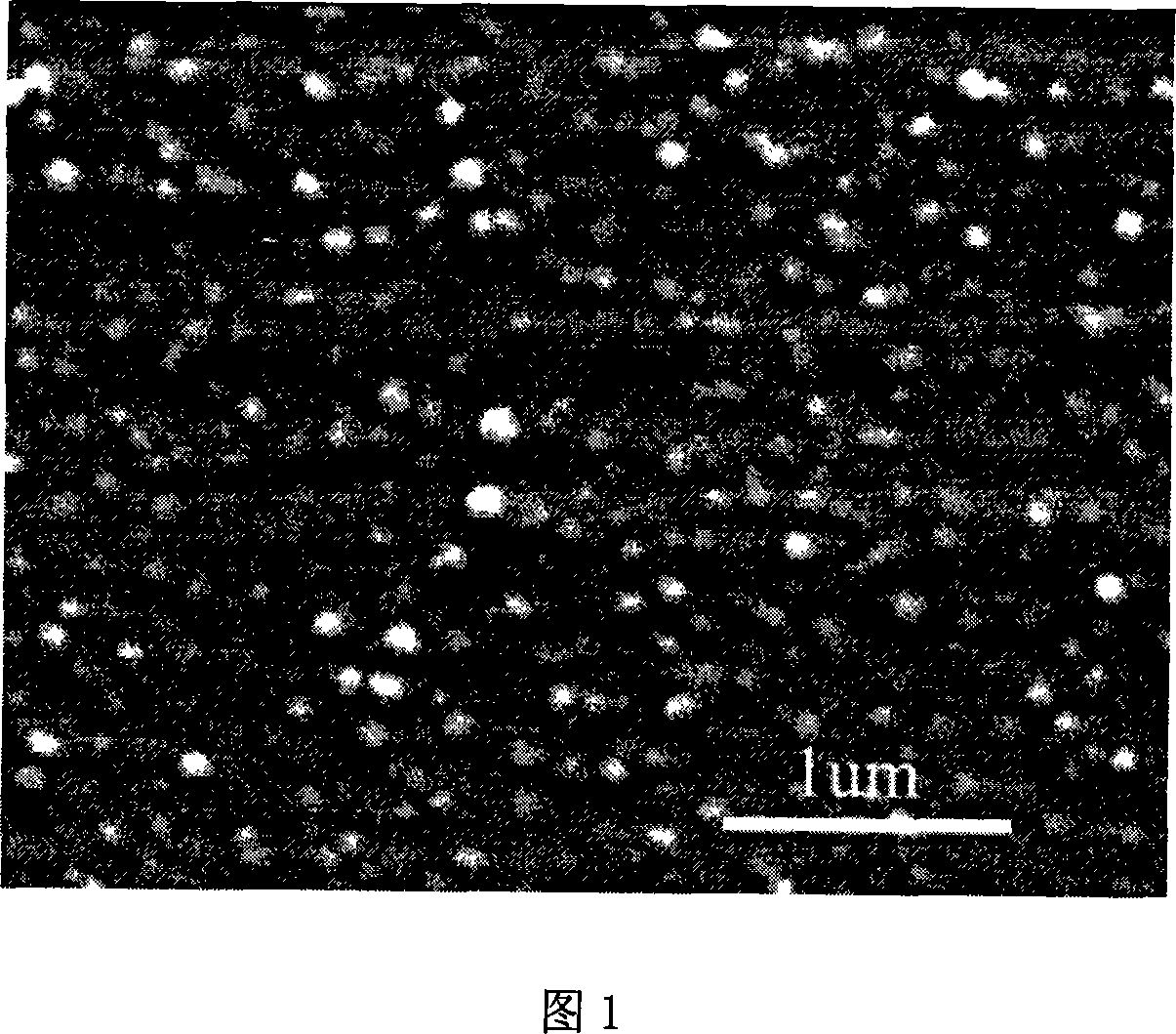

[0013] Embodiment: Fig. 1 has provided the SEM photo of an actual BN working material / Si substrate cathode structure, we have confirmed that these sharp points are exactly the working emitter of this structure field emission from the measurement, after measuring the emitter areal density at 10 10 piece / cm 2 . The preparation conditions are as follows: Ar is fixed at 50 sccm to maintain a pressure of 150 Pa, He is adjusted between 10 sccm and 300 sccm to realize beam adjustment; the distance range of sputtering vapor drift from generation to extraction is adjusted to 10-12 cm. Adjust the size of the extracted beam to 5A / min~6A / min, and the deposition time is 100min.

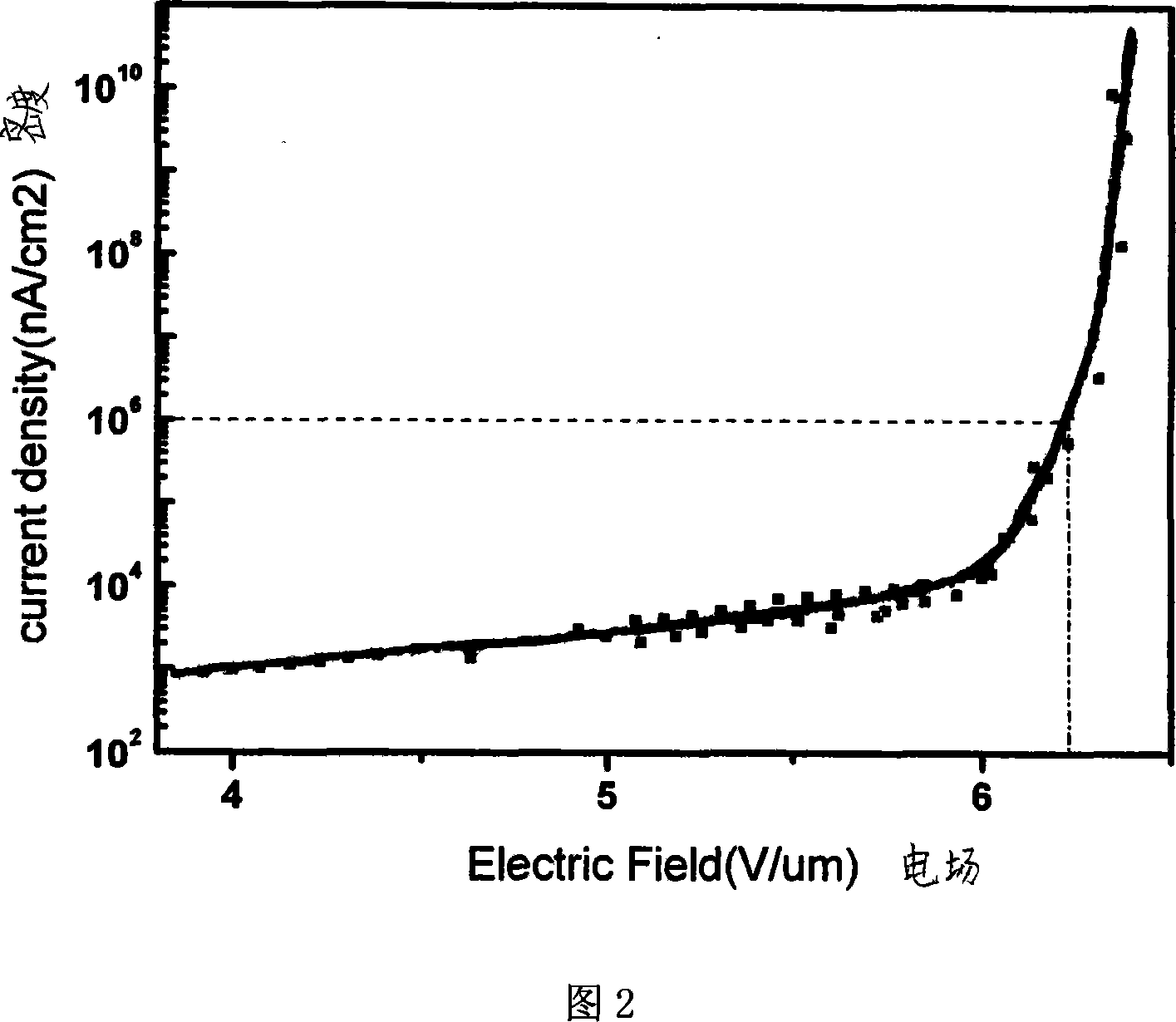

[0014] Fig. 2 presents the results of field emission measurements of the structures described above. From which we can see that at a field strength of 4V / um, the sample starts to emit electrons in the F-N mode, and at an electric field strength of 6.2V / um, the emission current of the sample reaches 1mA / cm 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com