Mesoporous C3N4 photocatalytic material prepared by using molten salt method and application thereof in photocatalysis field

A photocatalytic material, C3N4 technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as not easy to promote industrialization, not environmentally friendly, cumbersome process, etc., to achieve easy large-scale The effect of industrialized production and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

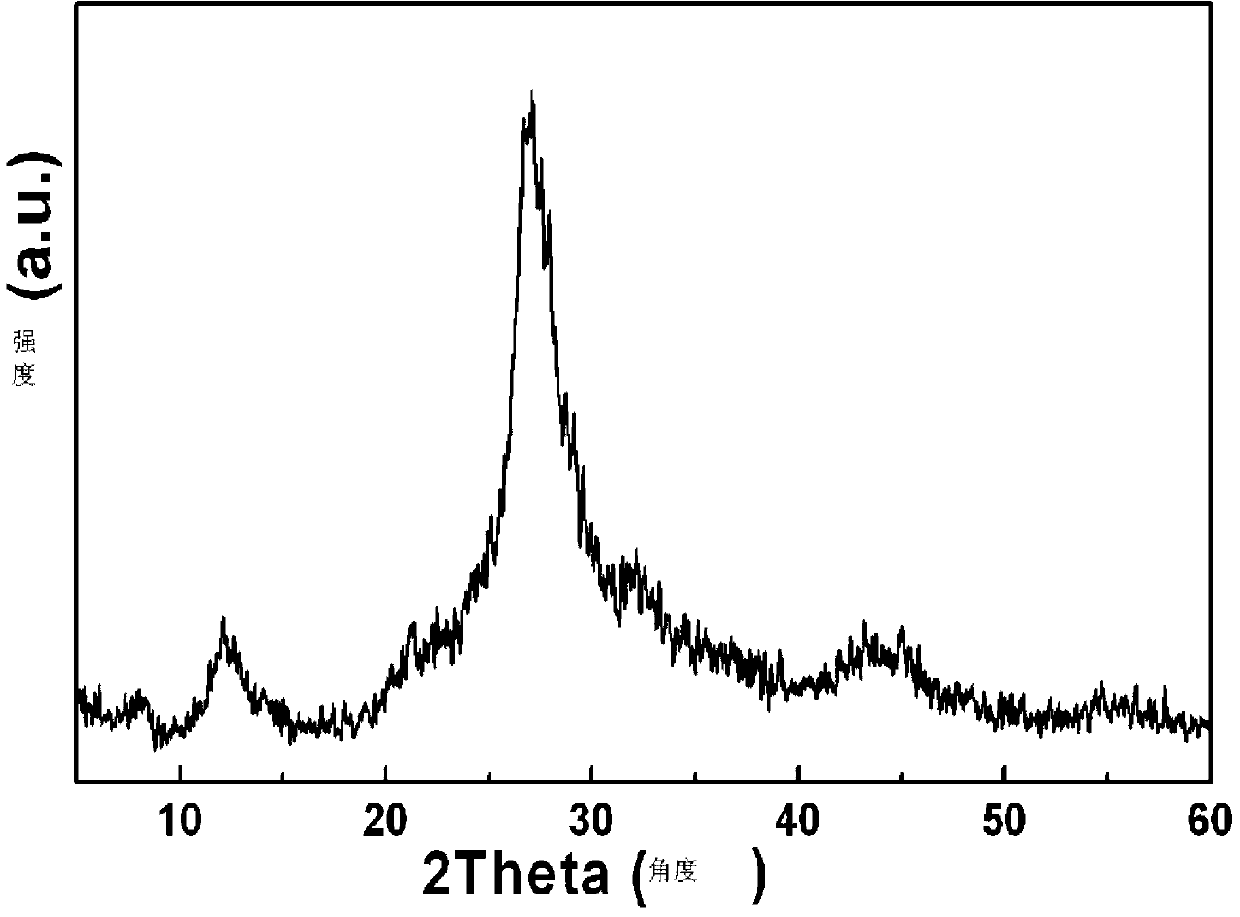

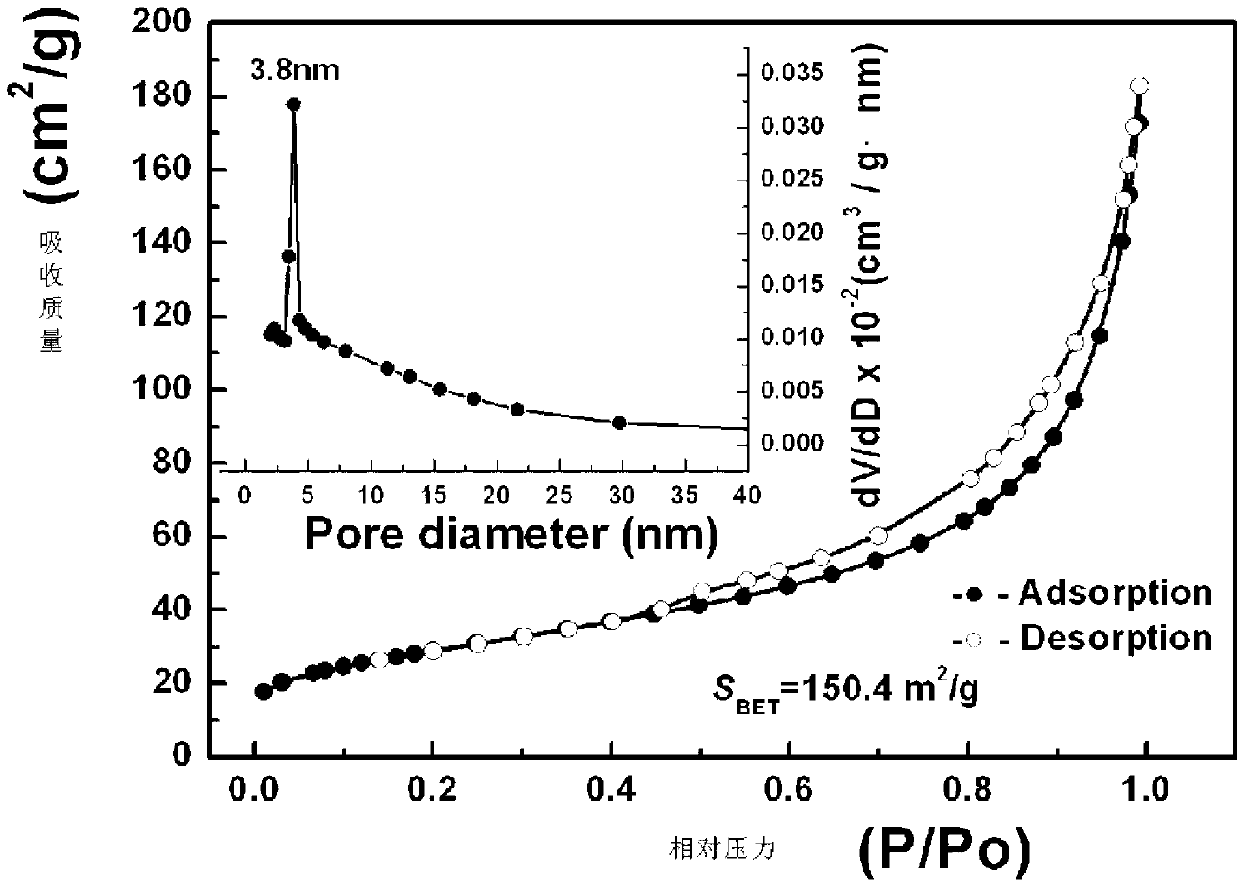

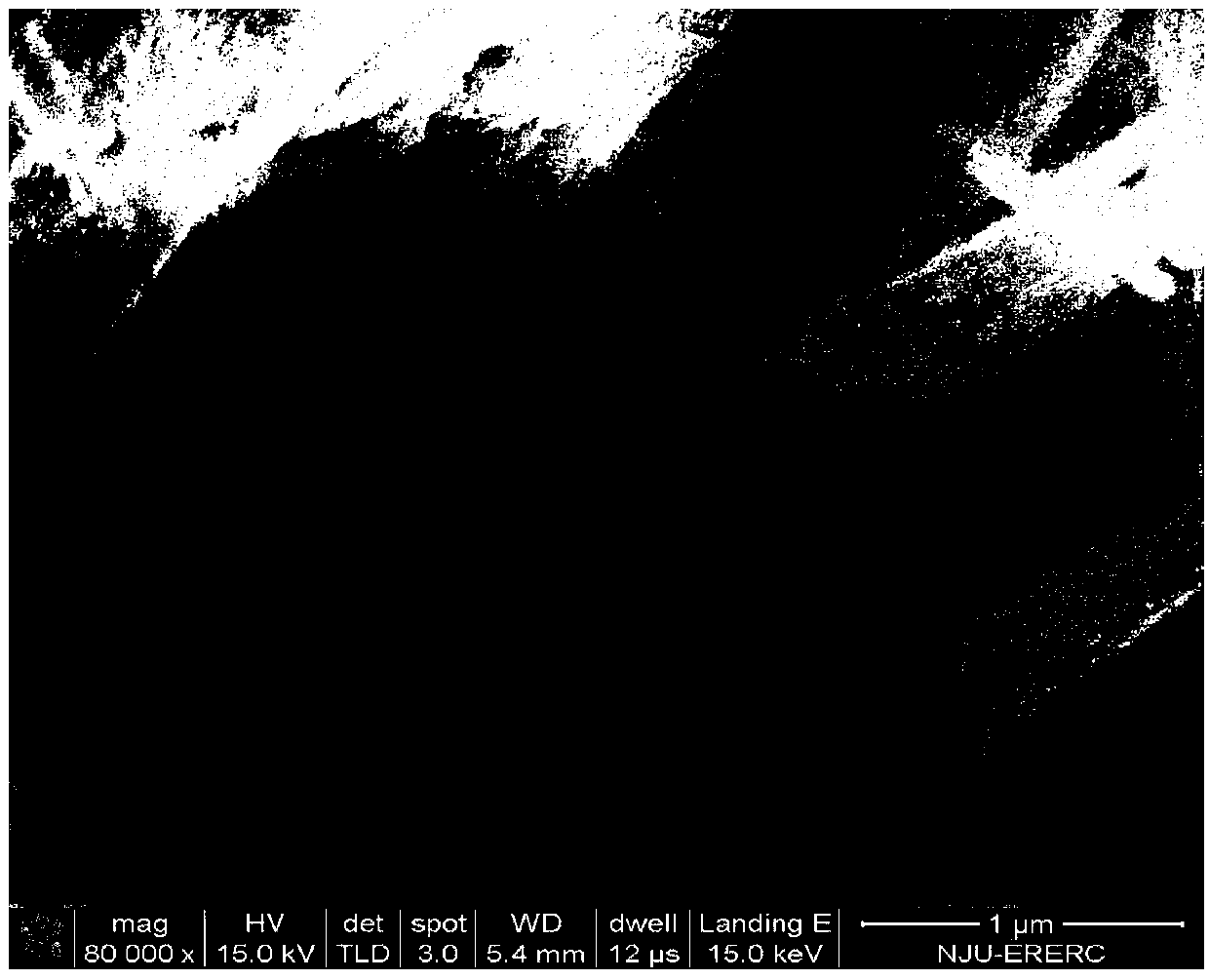

[0026] mesoporous C 3 N 4 Preparation: Weigh 1.0g of sodium chloride powder, 1.0g of potassium chloride, 1.0g of lithium chloride and mix with 0.6g of melamine. After the mixed powder is fully ground and mixed evenly, it is placed in a crucible and heat-treated in a muffle furnace at 500°C. 2h, the sintered powder was ultrasonically washed three times with deionized water, centrifuged, and dried at 60°C for 4h to obtain mesoporous C 3 N 4 . XRD analysis showed ( figure 1 ), the prepared C 3 N 4 It is a pure phase product. BET analysis shows that ( figure 2 ), the prepared C 3 N 4 Has a high specific surface area, about 150.4m 2 / g (the mass ratio of molten salt to melamine is 15:1), and the average mesopore size is 3.8nm. Scanning electron microscope observation shows ( image 3 ), the prepared C 3 N 4 It is a semi-coiled tube with a length of micron order. UV-Vis spectrophotometer analysis showed that ( Figure 4 ), the resulting mesoporous C 3 N 4 The ligh...

Embodiment 2

[0028] mesoporous C 3 N 4 Preparation: Weigh 0.1g of sodium chloride powder, 0.8g of potassium chloride, 1.0g of lithium chloride and mix with 0.6g of melamine. After the mixed powder is fully ground and mixed evenly, it is placed in a crucible and heat-treated in a muffle furnace at 450°C. 2h, the sintered powder was ultrasonically washed three times with deionized water, centrifuged, and dried at 60°C for 4h to obtain mesoporous C 3 N 4 .

Embodiment 3

[0030] mesoporous C 3 N 4 Preparation: Weigh 1.0g of sodium chloride powder, 0.6g of potassium chloride, 0.1g of lithium chloride and 0.6g of melamine and mix them. After the mixed powders are thoroughly ground and mixed evenly, they are placed in a crucible and heat-treated in a muffle furnace at 650°C. 2h, the sintered powder was ultrasonically washed three times with deionized water, centrifuged, and dried at 60°C for 4h to obtain mesoporous C 3 N 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com