Graphene-based porous macroscopic carbon material and preparation method thereof

A macroscopic and carbon material technology, applied in the field of porous macroscopic carbon materials, can solve the problems of difficult to achieve the theoretical specific surface area of graphene, difficult to obtain specific surface area, etc., to achieve controllable product shape and structure, wide range of raw material sources, reduce Aggregate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

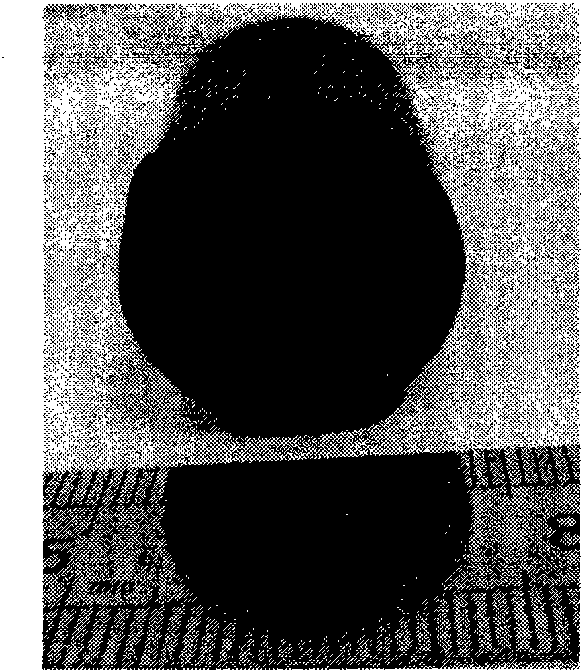

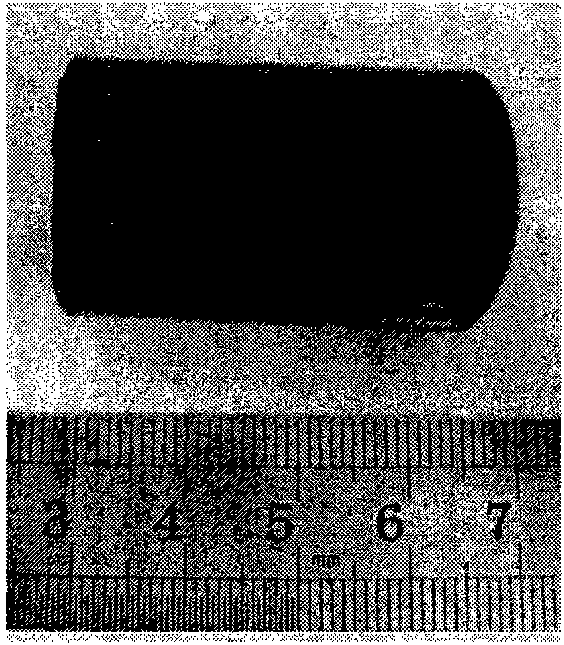

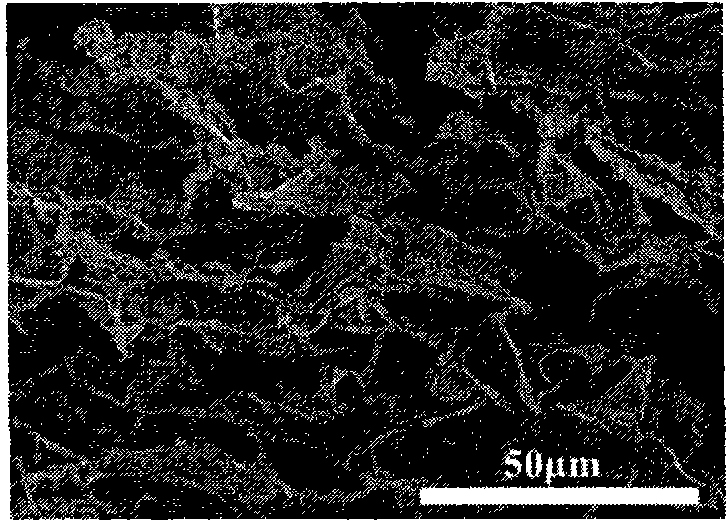

Embodiment 1

[0015] Weigh 160 mg of graphite oxide powder material prepared by the Hummer method, add 80 mL of deionized water, and ultrasonically disperse for 2 h at a power of 200 W to obtain a graphene oxide hydrosol; take 84.718 mL of the uniformly dispersed graphene oxide hydrosol and add 100 mL Add 282μL of 20mg / mL PVA solution into the kettle, stir and then ultrasonically disperse for 20min; put the hydrothermal reaction kettle in a muffle furnace with a temperature of 150℃ for 20h; wait for the hydrothermal reaction kettle After cooling, open the inner tank, pour out the water phase to obtain a smooth cylindrical material, and freeze-dry it at -57°C for 24 hours to obtain a graphene oxide block material; under the protection of argon, the temperature is raised at 5°C / min to The temperature is 300°C, the temperature is kept constant for 2 hours, and then the temperature is raised to 800°C at 5°C / min, and the temperature is kept constant for 3 hours to obtain a graphene-based porous m...

Embodiment 2

[0017] Weigh 160 mg of graphite oxide powder material prepared by the Hummer method, add 80 mL of deionized water, and ultrasonically disperse for 2 h at a power of 200 W to obtain a graphene oxide hydrosol; take 84.158 mL of the uniformly dispersed graphene oxide solution and add 100 mL of Add 842μL of 20mg / mL PVA solution to the hydrothermal reaction kettle, stir and then ultrasonically disperse for 20min; put the hydrothermal reaction kettle in a muffle furnace at 150°C for 20h; wait for the hydrothermal reaction kettle to cool down Open the liner, pour out the water phase, and freeze-dry at -57°C for 24 hours to obtain the graphene oxide block material; raise the temperature to 300°C at 5°C / min under the condition of argon, and keep the temperature at 300°C for 2 hours. Then the temperature was raised to 1000°C at 5°C / min, and the graphene-based porous macroscopic carbon material was obtained after constant temperature for 3 hours. The specific surface area of the materia...

Embodiment 3

[0019] Weigh 160 mg of graphite oxide powder material prepared by the Hummer method, add 80 mL of deionized water, and ultrasonically disperse for 2 h at a power of 200 W to obtain a graphene oxide hydrosol; take 84.83 mL of the uniformly dispersed graphene oxide solution and add 100 mL of Add 170μL of 20mg / mL PVA solution to the hydrothermal reaction kettle, stir and then ultrasonically disperse for 20min; put the hydrothermal reaction kettle in a muffle furnace at 120°C for 20h; wait for the hydrothermal reaction kettle to cool down Open the liner, pour out the water phase, and freeze-dry at -57°C for 24 hours to obtain the graphene oxide block material; raise the temperature to 300°C at 5°C / min under the condition of argon, and keep the temperature at 300°C for 2 hours. Then the temperature was raised to 800°C at 5°C / min, and the graphene-based porous macroscopic carbon material was obtained after constant temperature for 3 hours. The specific surface area of the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com