Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Multiple reactive sites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mesoporous C3N4 photocatalytic material prepared by using molten salt method and application thereof in photocatalysis field

InactiveCN102992282AEase of mass productionEase of large-scale industrial productionPhysical/chemical process catalystsNitrogen and non-metal compoundsMuffle furnaceBlocking layer

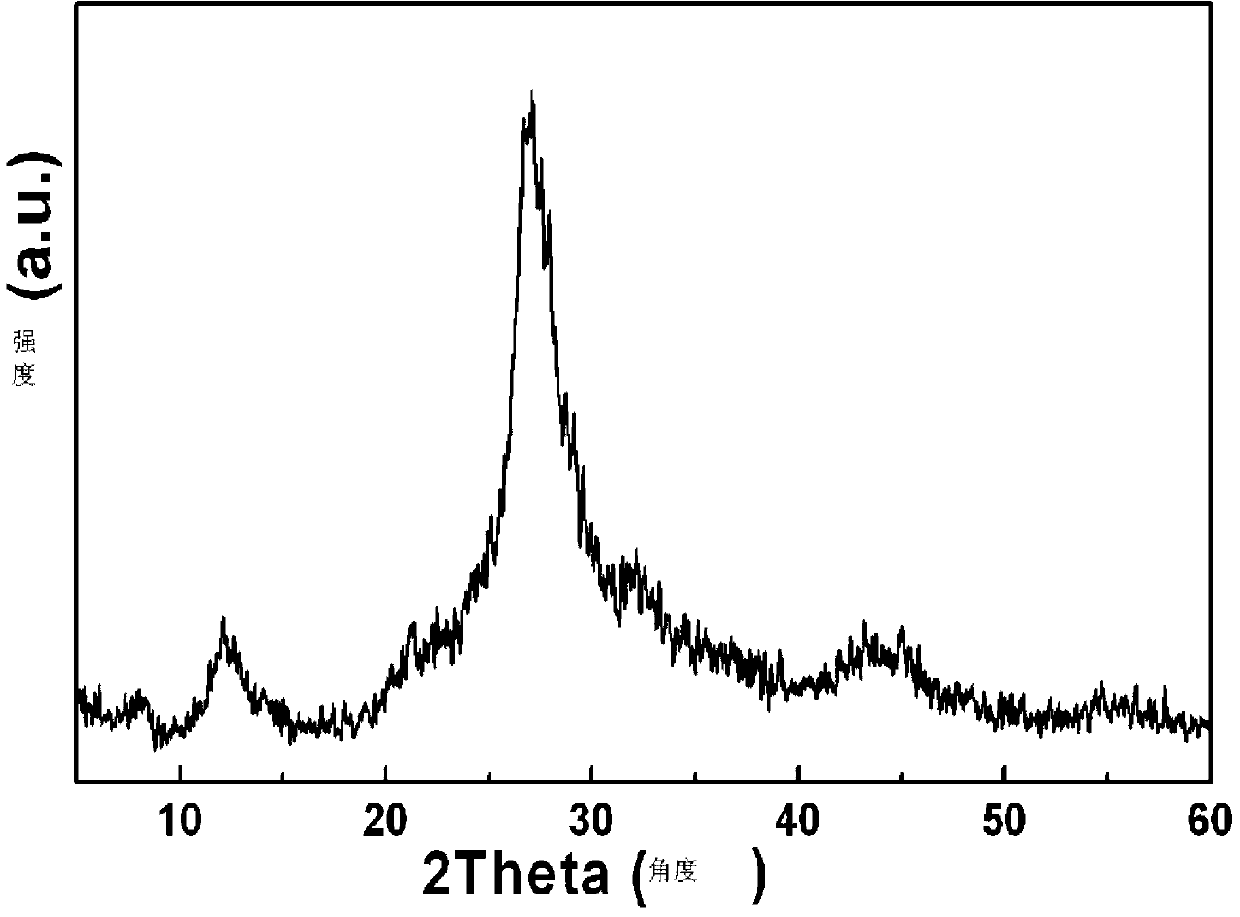

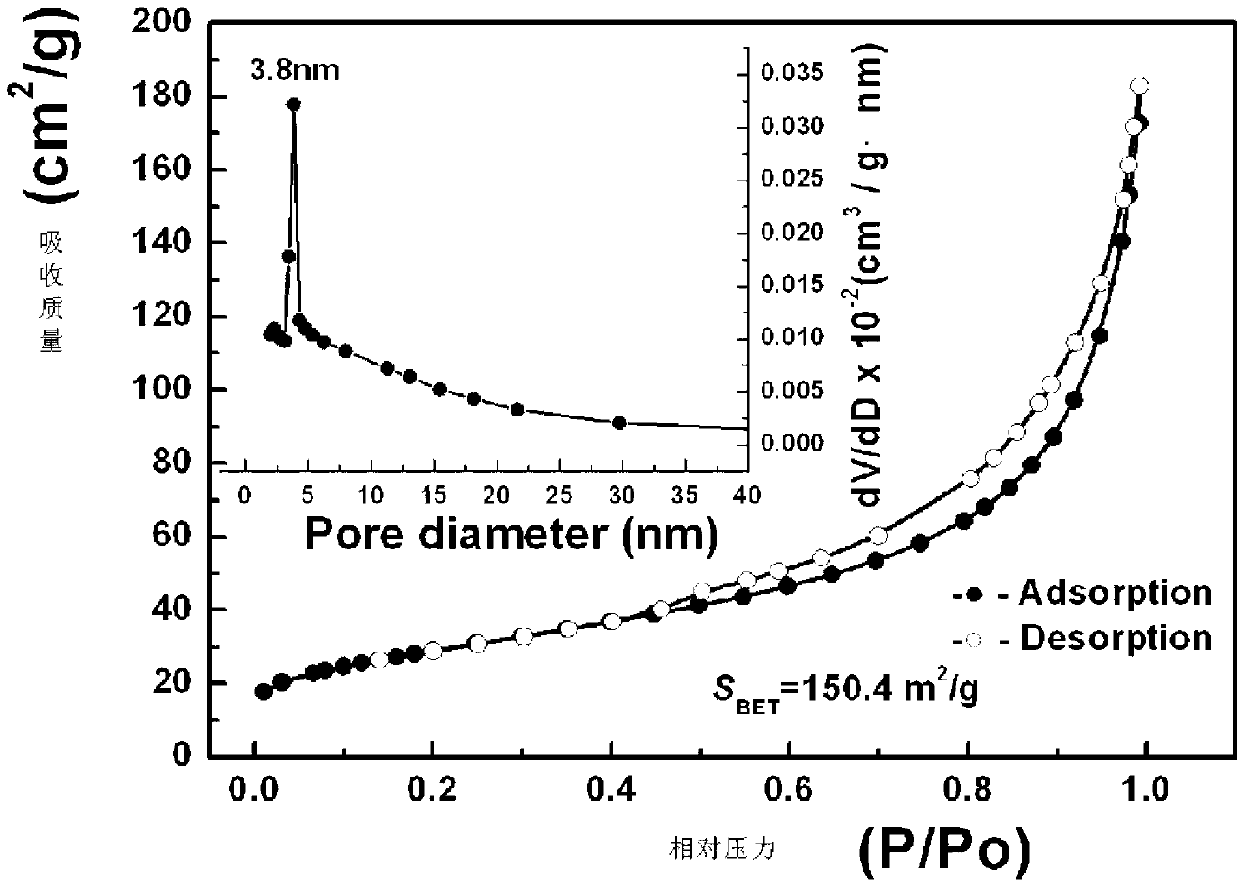

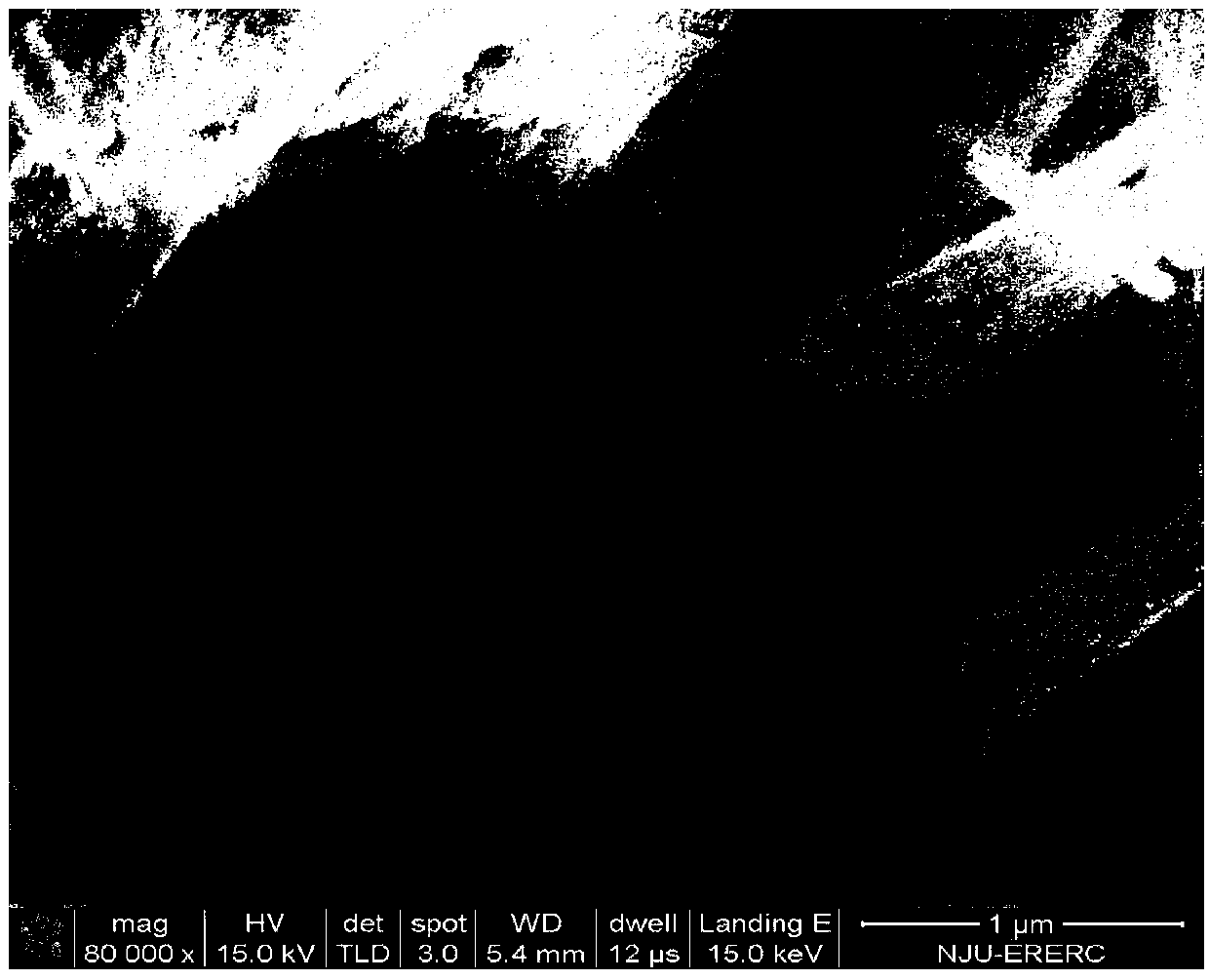

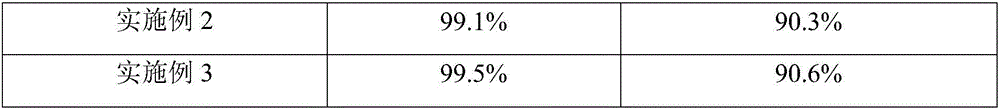

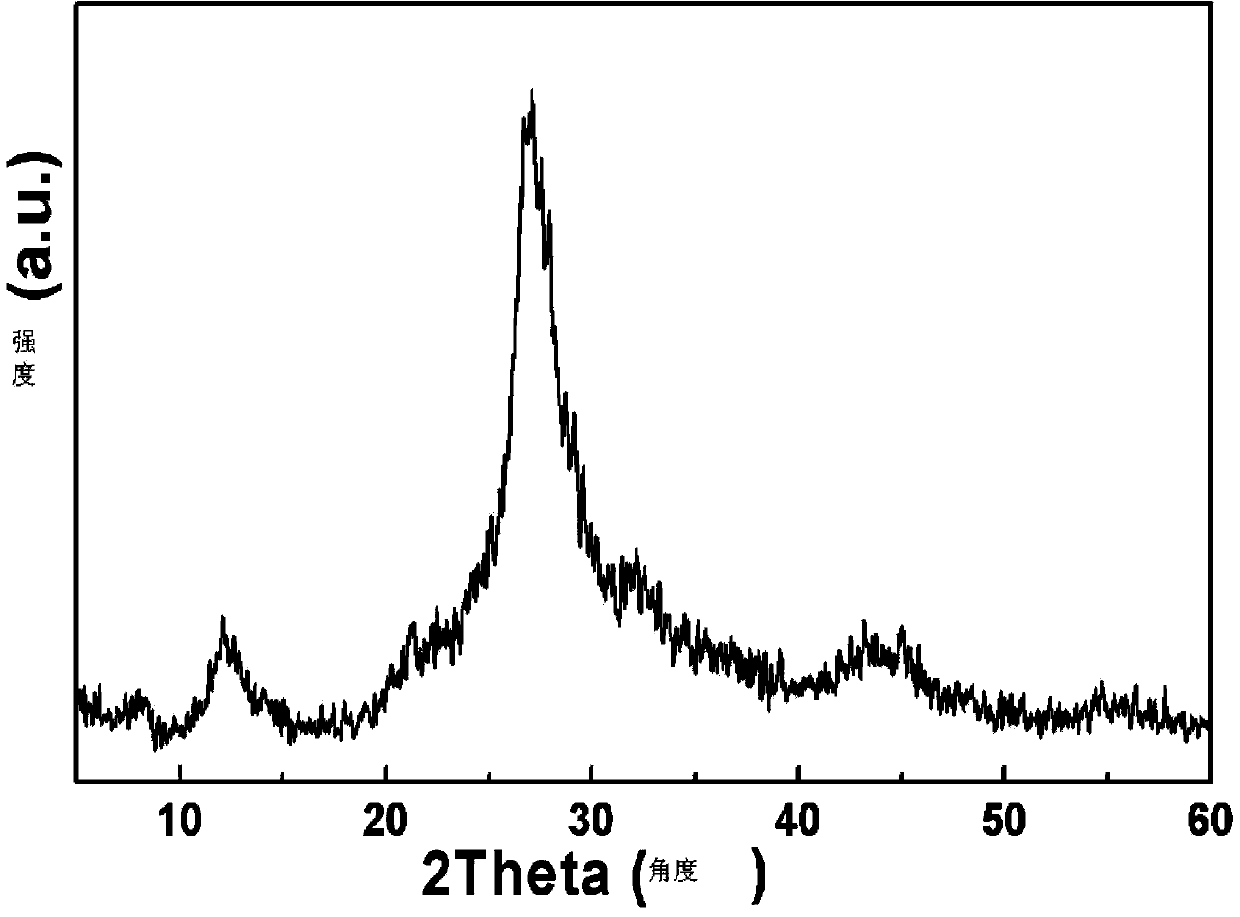

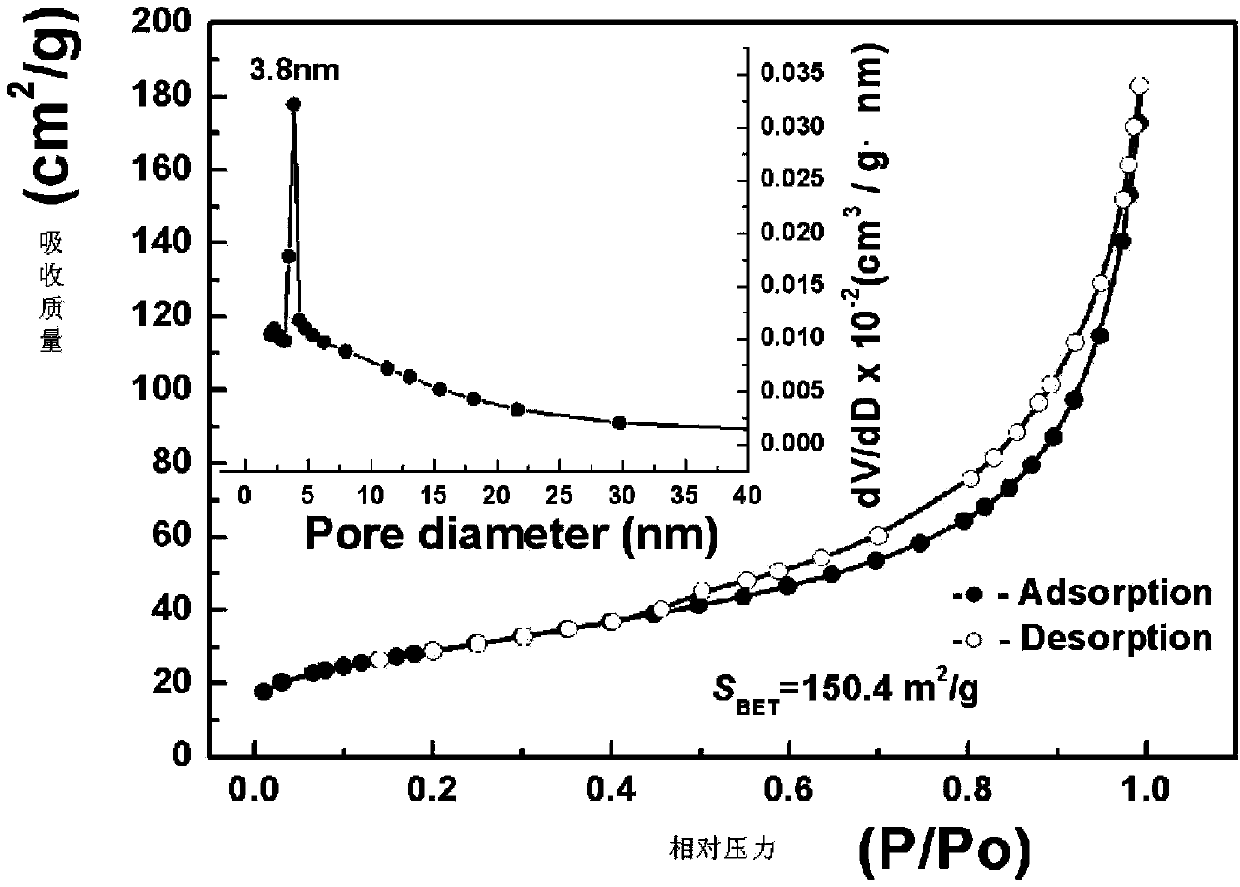

The invention discloses a mesoporous C3N4 photocatalytic material prepared by using a molten salt method and a preparing method thereof. The method comprises the following steps that water-soluble low-melting-point molten salt is fully mixed with melamine, small molten salt drops are used as a blocked layer under the melting temperature of the molten salt, C3N4 grows in a way of being coated with the small drops, and the molten salt is recycled by water washing after reaction, so as to obtain the C3N4 photocatalytic material. The C3N4 photocatalytic material is in a wormlike mesoporous structure, the mesoporous size is within 3.8+ / -1nm, and the forming mechanism of the mesoporous C3N4 photocatalytic material is that the small molten salt drops are used as the growth blocked layer. When the material is prepared, water-soluble low-melting-point chloride salt is used as the molten salt and is fully mixed with melamine to obtain a mixture, the mixture is subjected to the heat treatment in a muffle furnace for 1-5h under the temperature being 400-680 DEG C to obtain samples, and the samples after the heat treatment are washed by water to recycle the molten salt, so as to obtain the mesoporous C3N4 photocatalytic material. In the whole process, a template is not introduced, and the operation is easy and feasible, so that the large-scale industrial production can be realized easily.

Owner:NANJING UNIV

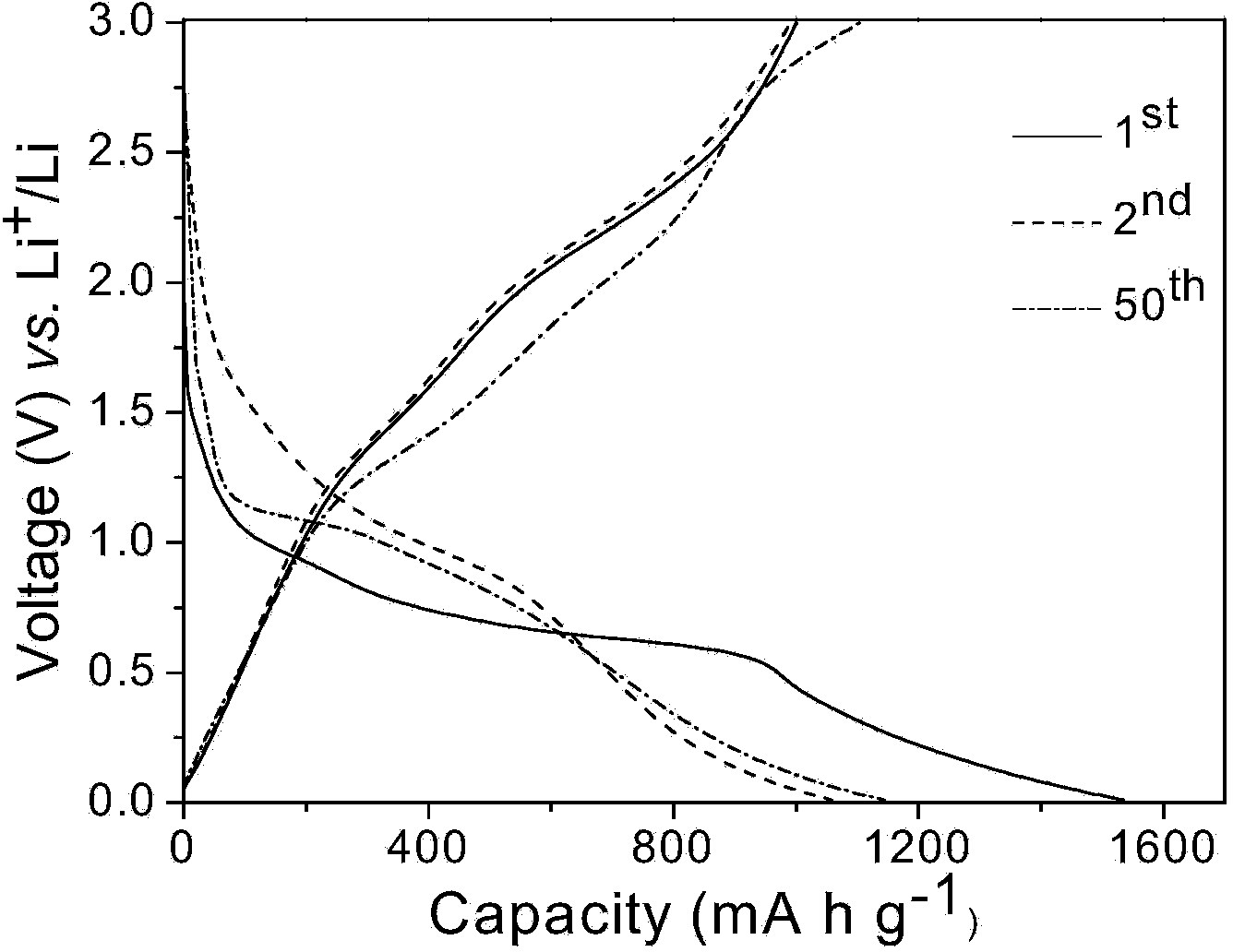

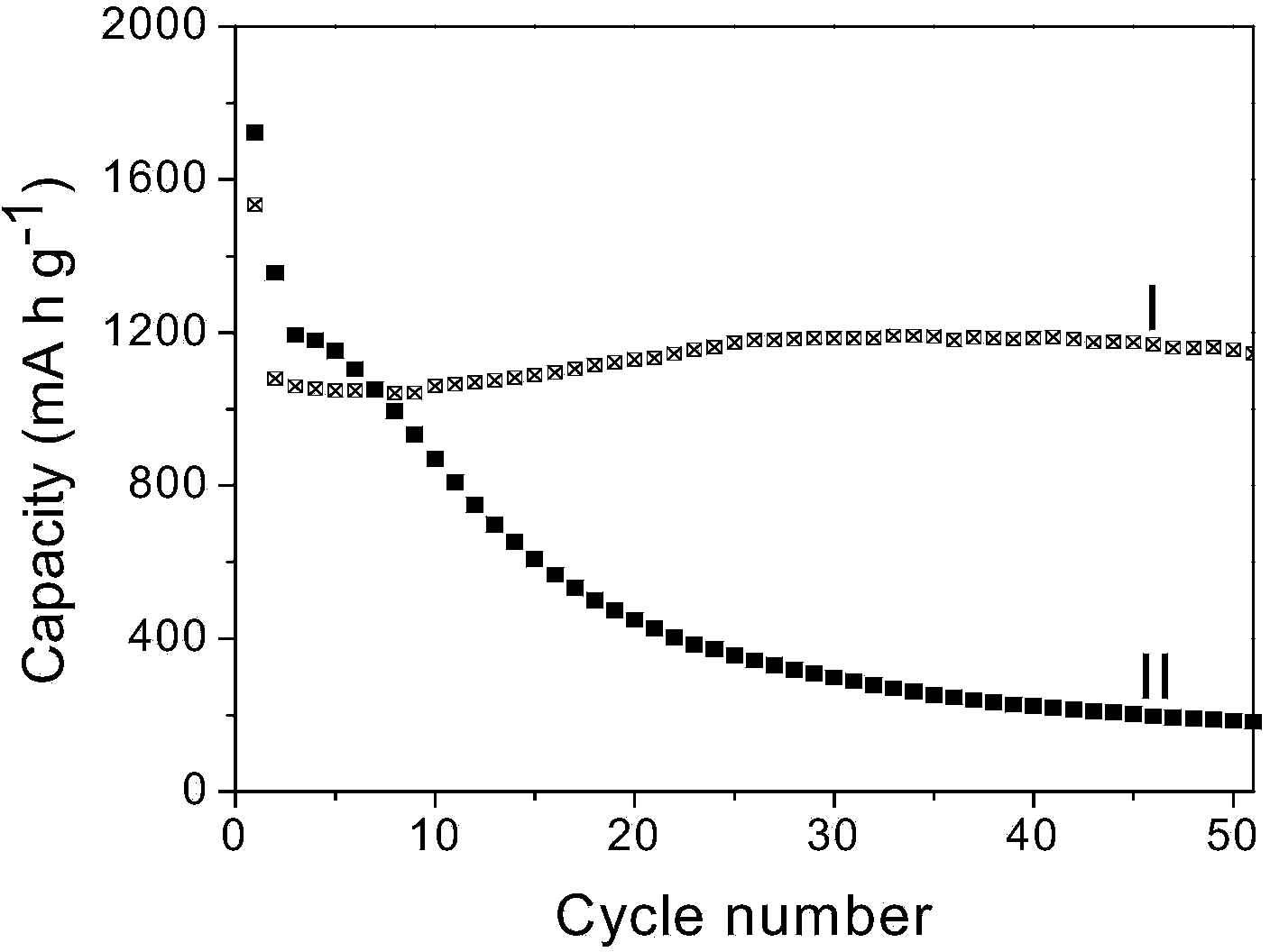

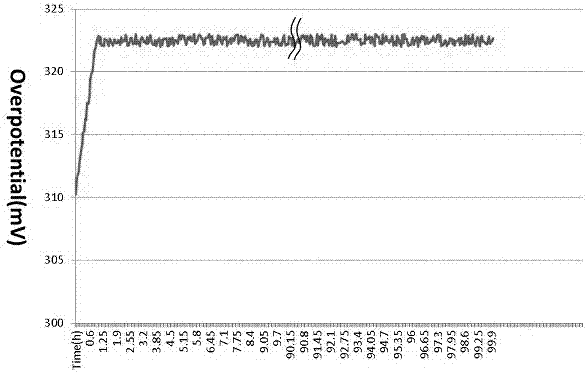

Vanadium phosphate sodium composite nano porous cathode material and method for preparing material by using freeze drying method

InactiveCN106025275ALarge specific surface areaHigh specific capacityMaterial nanotechnologyCell electrodesElectrochemical responseFreeze-drying

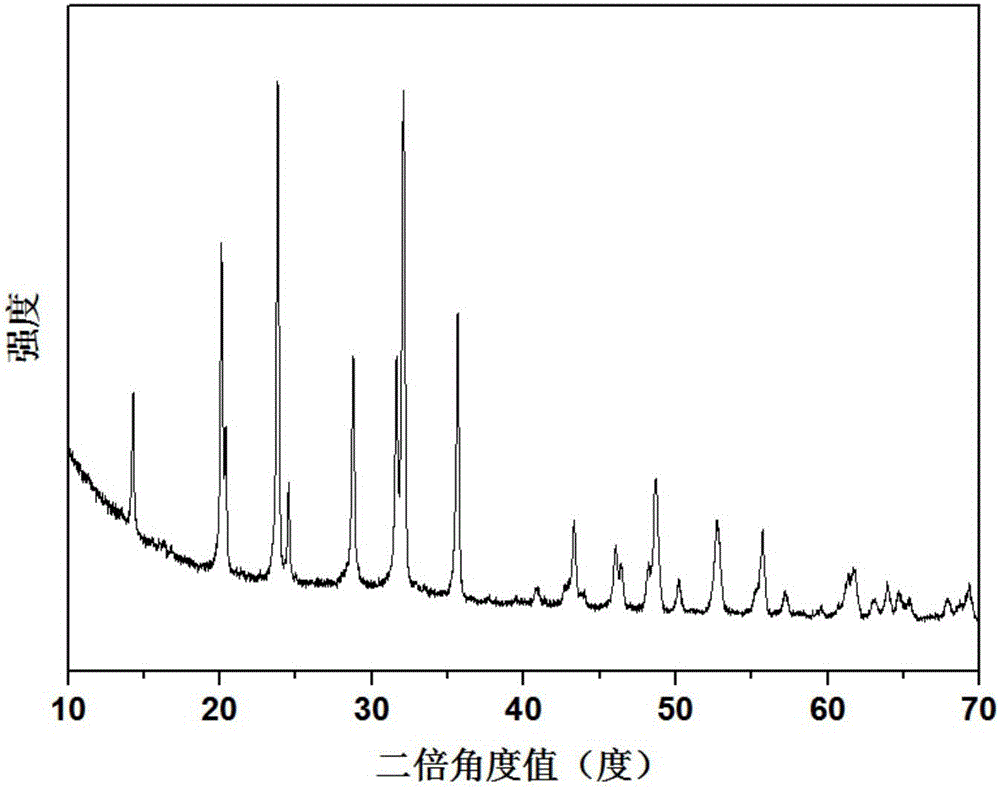

The invention discloses a vanadium phosphate sodium composite nano porous cathode material and a method for preparing the material by using a freeze drying method, which belong to the technical fields of a cell material and its preparation method. The method comprises the following steps: adding a certain amount of a vanadium source in a mixed solvent of deionized water and hydrogen peroxide, after stirring the materials and dissolving the materials, adding a sodium source, a phosphorus source and a carbon source with a stoichiometric ratio to form a mixing solution; then refrigerating the prepared mixing solution in liquid nitrogen to a solid, then performing vacuum drying on the material in a vacuum freeze drier; and finally putting a precursor obtained after freeze drying in mixing gas of argon and hydrogen for calcining to obtain the vanadium phosphate sodium composite nano porous cathode material. The prepared vanadium phosphate sodium composite nano porous cathode material has a three-dimensional porous structure and large specific surface area, and thereby is in favor of infiltration and transmission of an electrolyte, active sites of an electrochemical reaction are multiple, and high specific capacity and good multiplying power performance can be displayed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

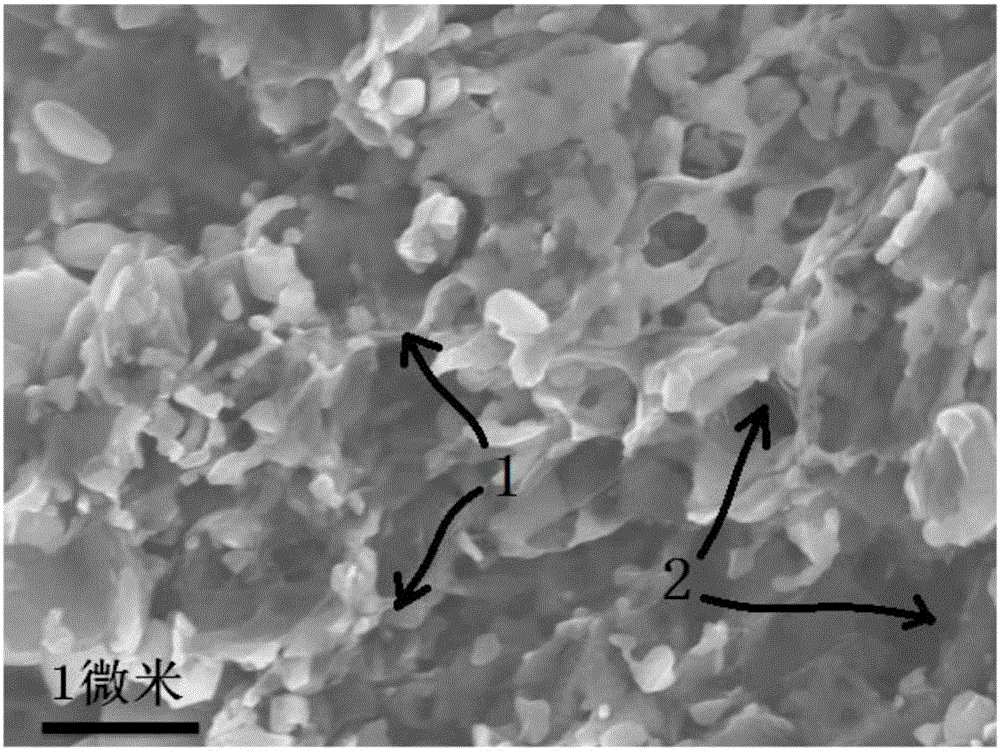

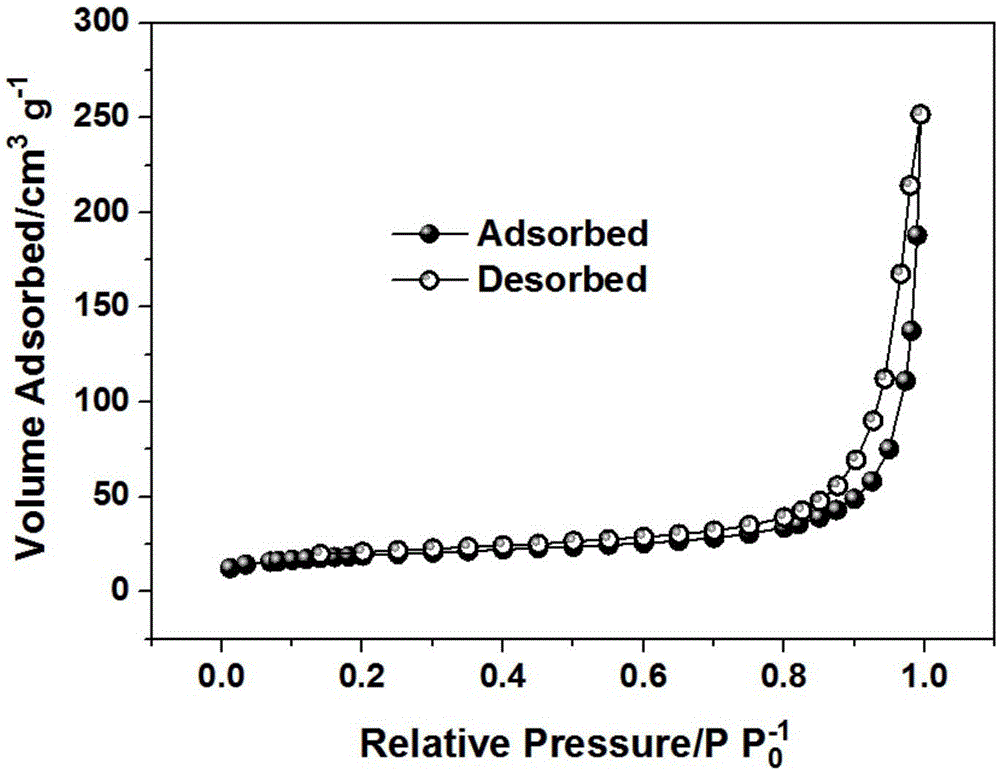

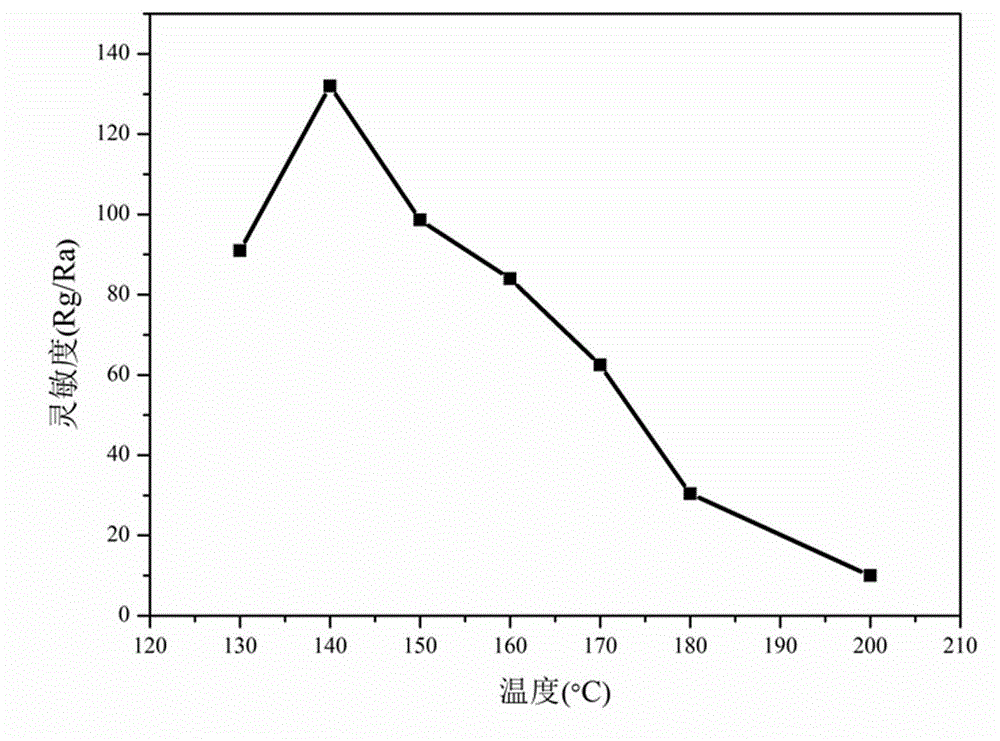

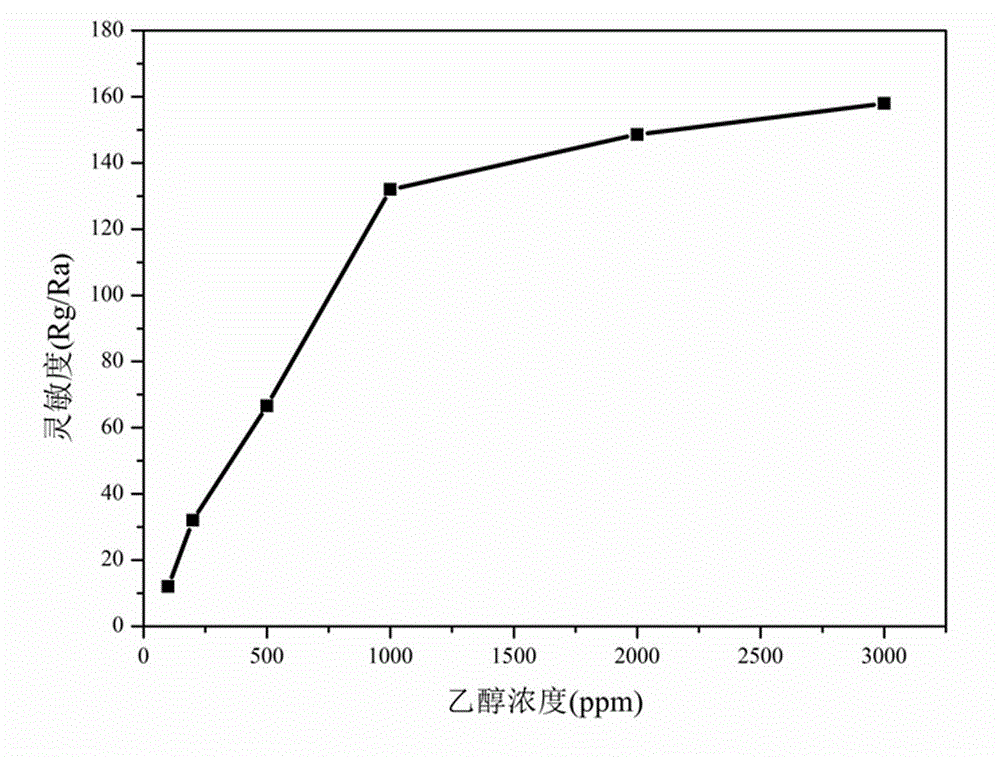

Preparation method of ethanol gas sensor component having ultrafast response recovery property

InactiveCN104819999AHigh sensitivityLower resistanceMaterial nanotechnologyMaterial resistanceNanoparticleGlycerol

The invention discloses a preparation method of an ethanol gas sensor component having an ultrafast response recovery property. In the preparation method, LaFexO3 nano particles in non-stoichiometric ratio prepared through a sol-gel method are employed as a working substance to prepare a beside-heating-type ceramic tube gas sensor component. By means of reduction of a relative element ratio of iron to lanthanum in a precursor, the carrier concentration is increased and the resistance of the component is reduced. By means of selection of a proper La / Fe element ratio, size of crystal grains is reduced and oxygen adsorption capacity is improved, so that the gas sensor is improved in sensitivity on ethanol, is reduced in working temperature and is reduced in response recovery time. A LaFe0.8O3 beside-heating-type ethanol gas sensor prepared in the invention can reach 138 in the sensitivity on ethanol in 1000 ppm at the working temperature of 140 DEG C, wherein the response and recovery times are respectively 1 s and 1.5 s. The gas sensor is less than 22 in all sensitivities on methane, acetone, carbon dioxide and glycerol in 1000 ppm. The gas sensor is high in sensitivity, is low in the working temperature, is ultrafast in response recovery property and is high in selectivity at the same time on ethanol, and is low in cost and is environmental-friendly.

Owner:TAIYUAN UNIV OF TECH

Method for growing vertical transition metal oxide nanosheets on surface of graphene

ActiveCN103950992AIncrease profitLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesChemical synthesisNitrogen gas

The invention relates to a method for growing vertical transition metal oxide nanosheets on a surface of graphene. The method comprises the steps of firstly, ultrasonic separating oxidized graphene; then growing the vertical transition metal oxide nanosheets on the surface of the oxidized graphene through an oil bath manner; finally calcining in nitrogen so as to obtain the material-the graphene with vertical transition metal oxide nanosheets growing on the surface. The method has the characteristic of preparing an electrochemical material which is easy to separate, has high specific surface area and is superior to common nano materials in performances of lithium batteries and supercapacitors by a simple chemical synthesis method.

Owner:XI AN JIAOTONG UNIV

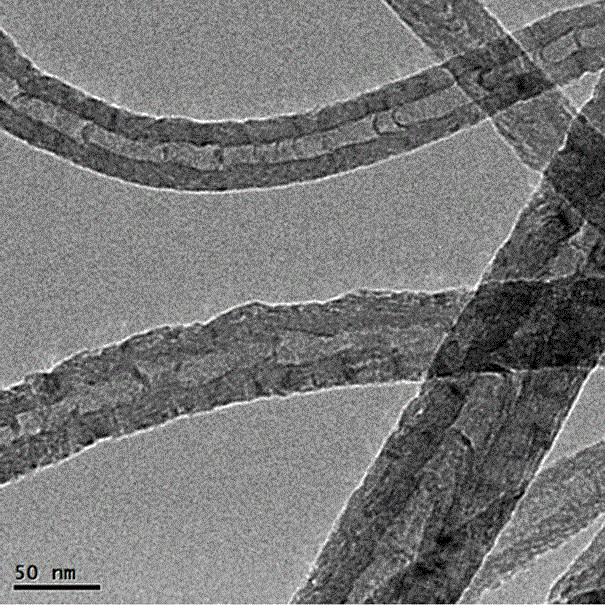

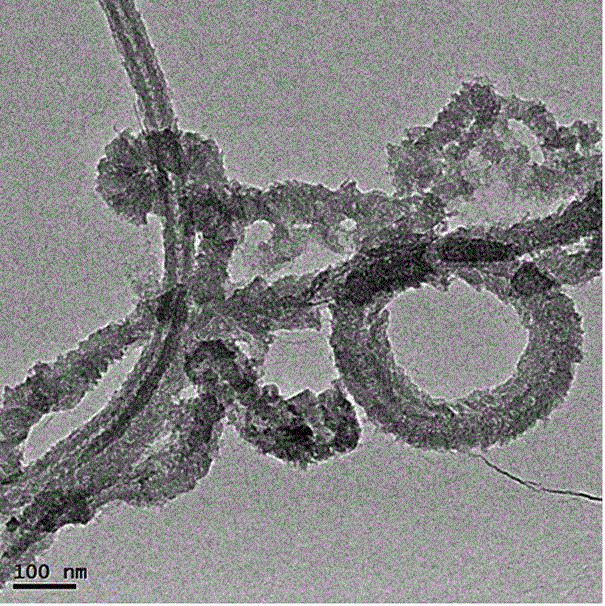

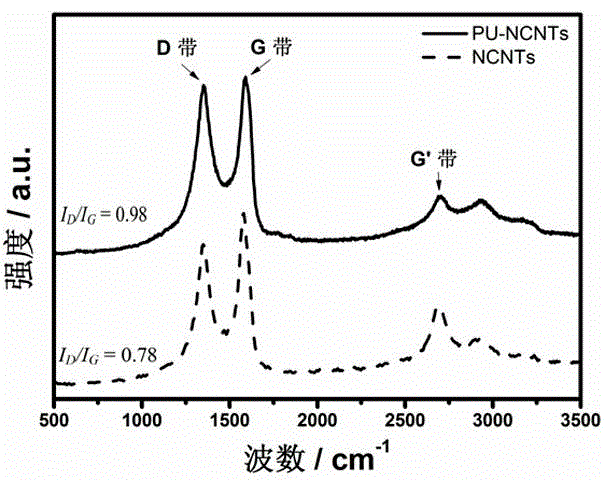

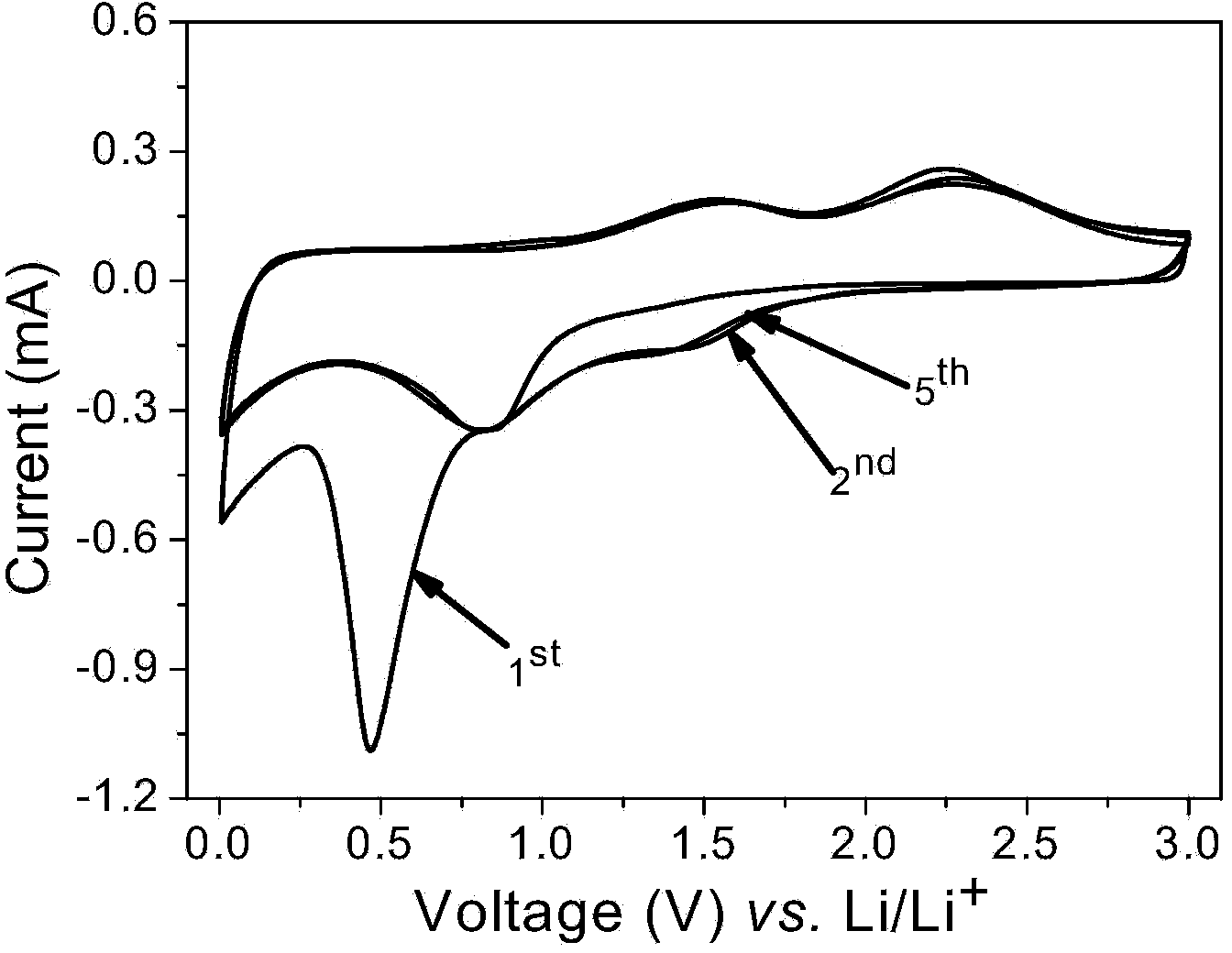

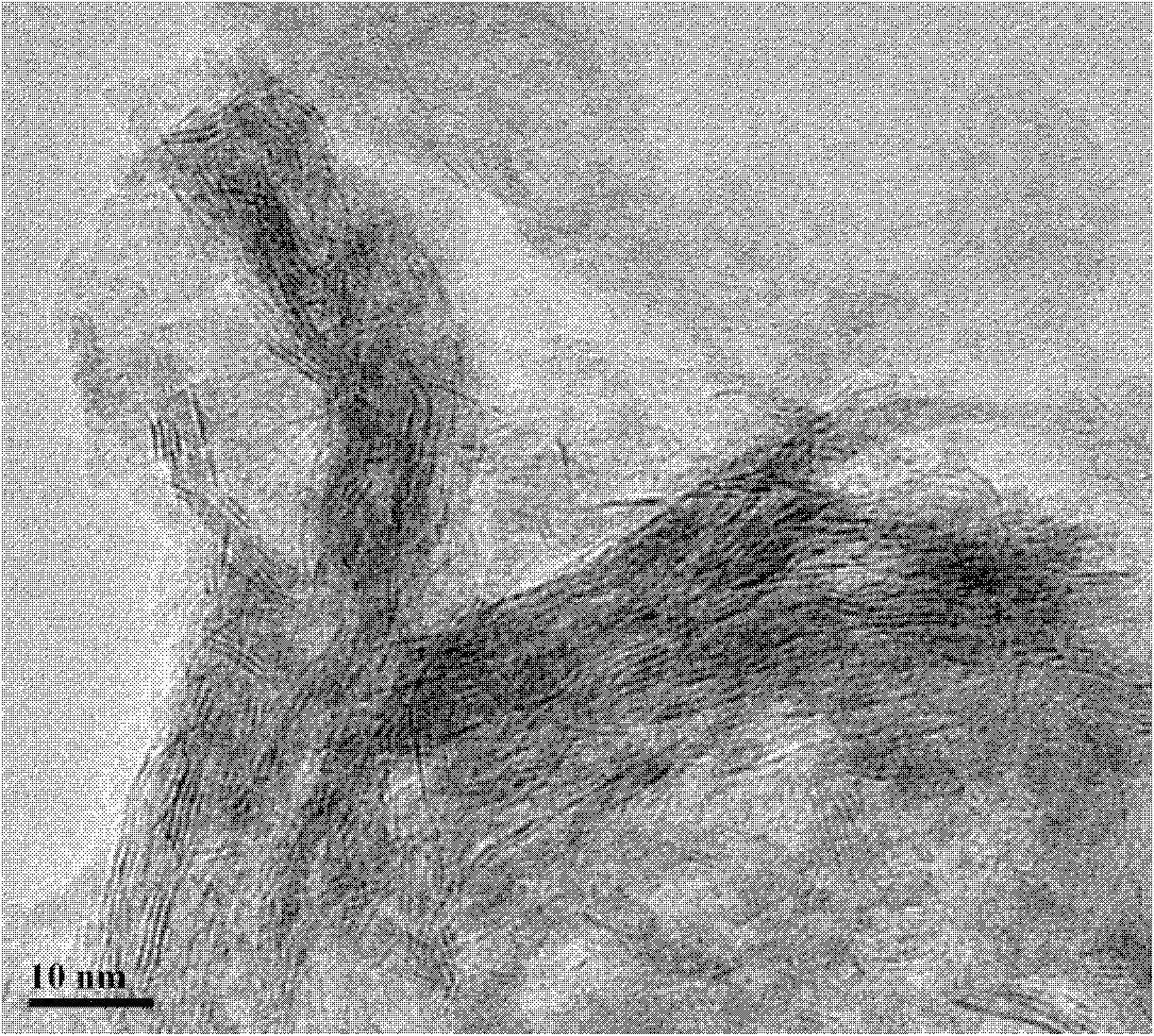

Undone nitrogen doped carbon nanotubes derivative with good electrochemical performance

InactiveCN104529545AImprove conductivityLarge specific surface areaHeterojunctionNitrogen doped graphene

The invention discloses an undone nitrogen doped carbon nanotubes derivative with good electrochemical performance and a preparation method thereof. Undoing bamboo-like nitrogen doped multi-walled carbon nanotubes along the longitudinal direction is conducted through a solution chemical oxidation method, and the nitrogen doped carbon nanotubes derivative is obtained; through controlling the degree of undoing, caterpillar-shaped nitrogen doped graphene / carbon tube composite materials with heterojunction structures are obtained when undoing is conducted half and nitrogen doped graphene nanobelts are obtained when undoing is completed. The undone carbon nano tube is used for modifying a glassy carbon electrode. It is indicated by the test of electrochemical performance that the materials obtained from the undone nitrogen doped carbon nanotubes derivative with good electrochemical performance have the advantages that the specific surface area is high, more reaction active sites are achieved, and the electron transfer rate is higher, so that the wide application prospects in the field of electrochemistry, such as capacitors, lithium batteries, electro-catalysis, and electrochemical sensors are achieved.

Owner:FUZHOU UNIV

Preparation method of metal oxide nanosheet and carbon nanotube composite energy-storage material

ActiveCN103943838ARich varietyLarge specific surface areaCell electrodesSecondary cellsChemical synthesisModified carbon

The invention discloses a preparation method of a metal oxide nanosheet and carbon nanotube composite energy-storage material. The preparation method comprises the following steps: firstly, modifying a carbon nanotube by sulfonated polystyrene; secondly, growing a metal hydroxide precursor on the modified carbon nanotube by adopting an oil bath process; and finally, calcining the precursor in the atmosphere of nitrogen gas, thereby obtaining the metal oxide nanosheet and carbon nanotube composite energy-storage material. The preparation method is characterized in that the composite energy-storage material is prepared by adopting a simple chemical synthesis means and has a high specific surface area and the good conductivity, and both the capacity and the stability of the energy-storage material are superior to those of a traditional metal oxide nanosheet and carbon nanotube composite energy-storage material.

Owner:XI AN JIAOTONG UNIV

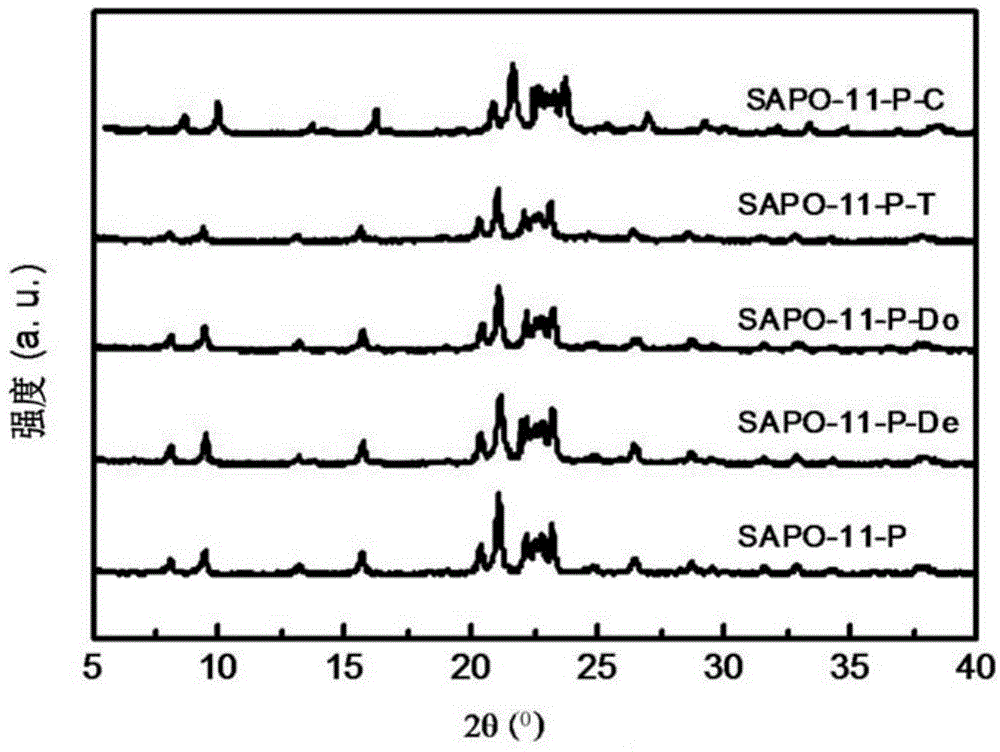

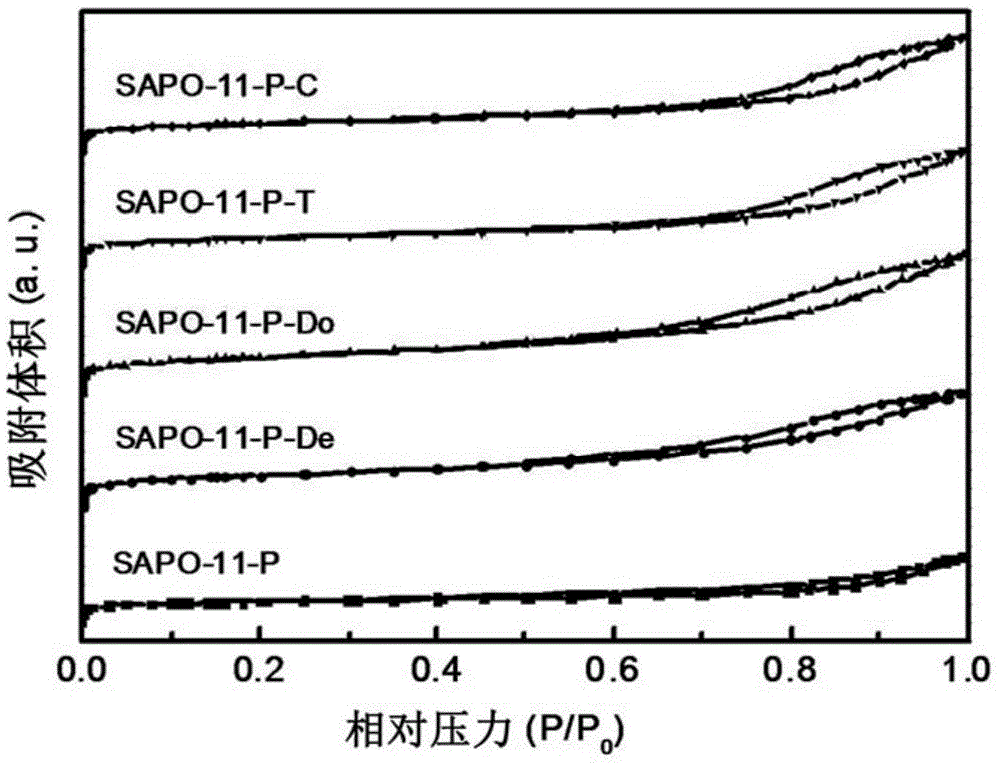

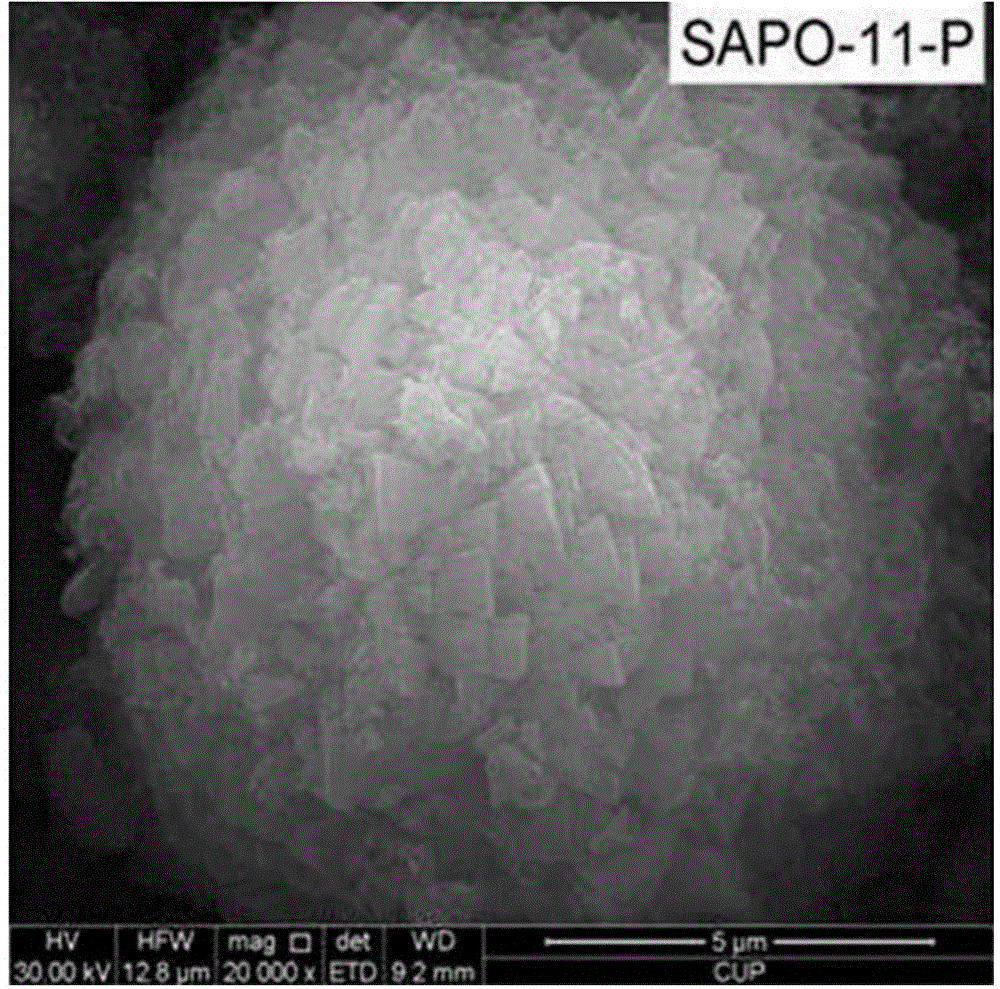

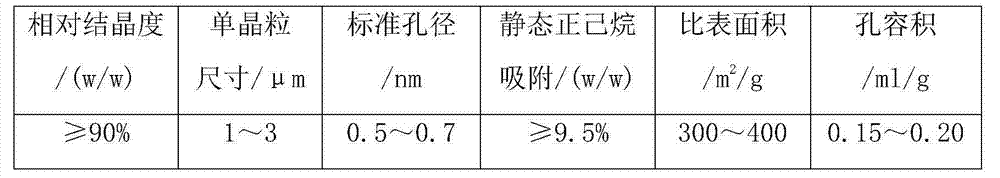

Small crystal grain stepwise pore SAPO-11 molecular sieve and hydrocarbon isomerization catalyst and their preparation methods

ActiveCN105800632APolyacid active siteExposed acid sitesHydrocarbon by isomerisationMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides a small crystal grain stepwise pore SAPO-11 molecular sieve and a hydrocarbon isomerization catalyst and their preparation methods. The preparation method of the molecular sieve comprises dissolving a phosphorus source in water, carrying out stirring, orderly adding at least one aluminum source, at least one silicon source, at least one template, at least one cationic surfactant and at least one cosolvent into the solution, carrying out dissolution and crystallization to obtain crystals, cooling the crystals, carrying out centrifugation, washing and drying to obtain small crystal grain stepwise pore SAPO-11 molecular sieve raw powder, and roasting the small crystal grain stepwise pore SAPO-11 molecular sieve raw powder in air to obtain the small crystal grain stepwise pore SAPO-11 molecular sieve. The invention also provides the small crystal grain stepwise pore SAPO-11 molecular sieve obtained by the preparation method. The invention also provides the hydrocarbon isomerization catalyst with the small crystal grain stepwise pore SAPO-11 molecular sieve as a carrier and a preparation method thereof.

Owner:PETROCHINA CO LTD +1

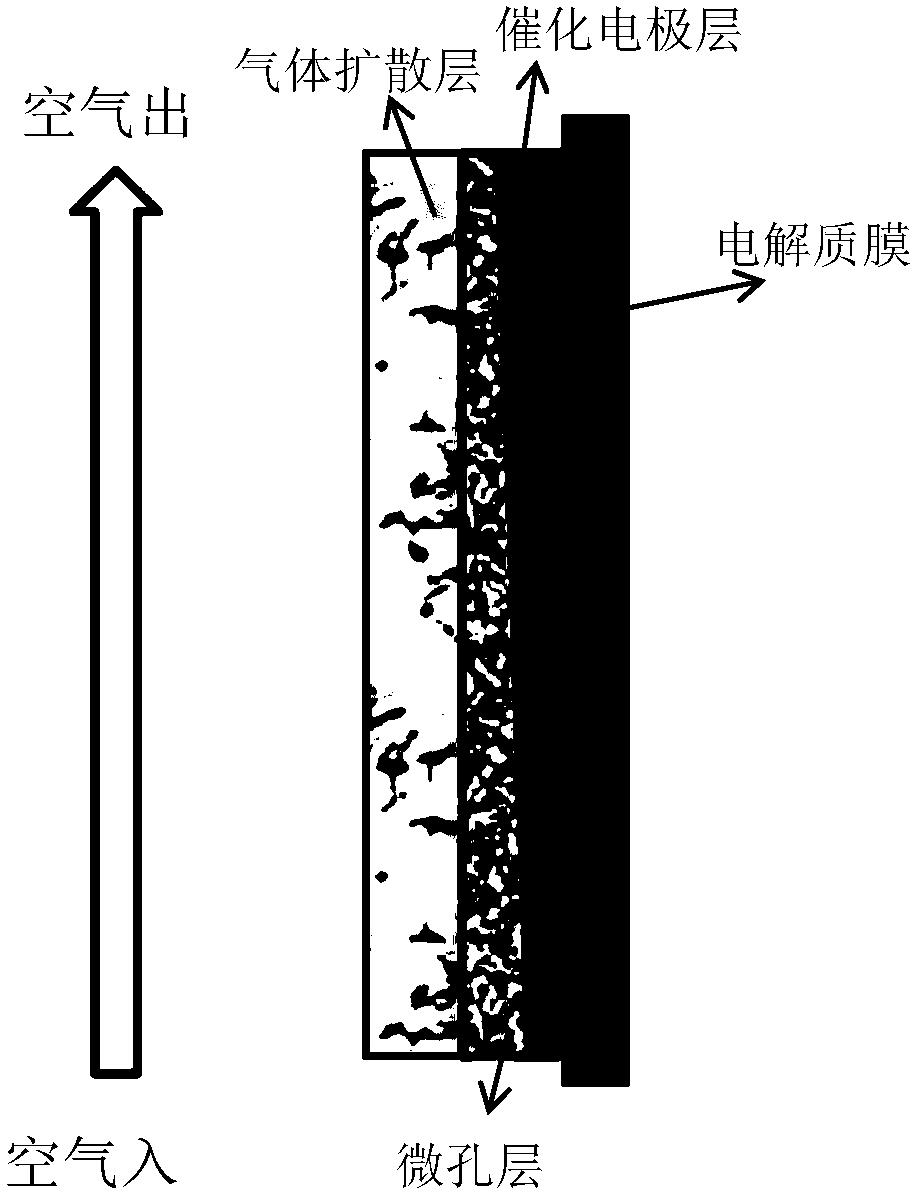

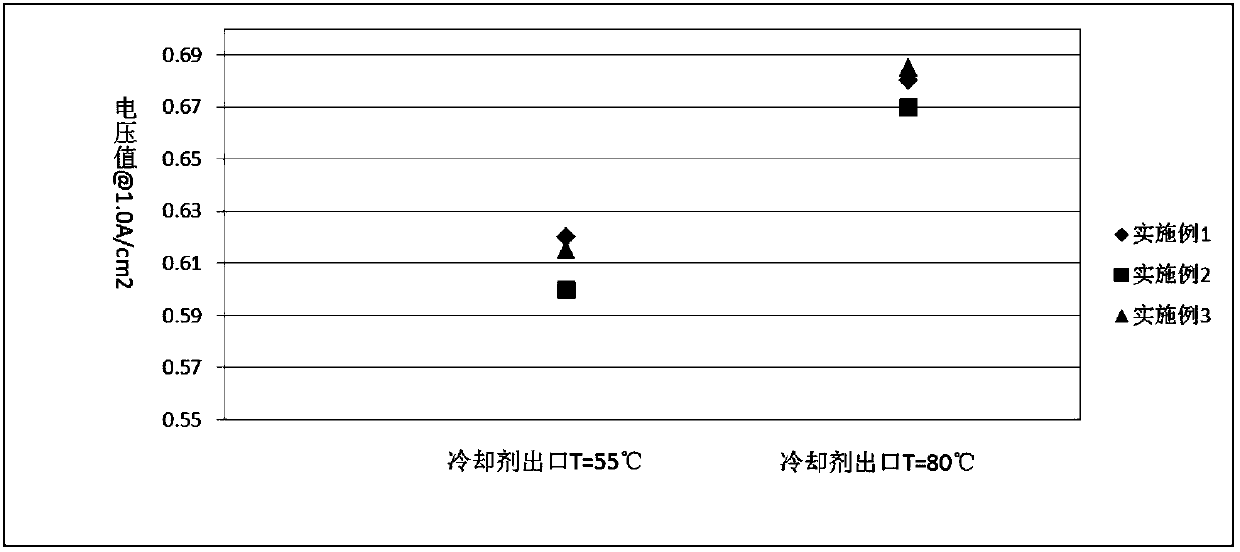

Membrane electrode assembly of fuel cell and production method of membrane electrode assembly

InactiveCN107834088AGood water contentImprove stabilityFinal product manufactureFuel cellsFuel cellsPtru catalyst

The invention provides a membrane electrode assembly of a fuel cell. The membrane electrode assembly comprises a gas diffusion layer, a micro-porous layer, a catalysis layer and an electrolyte membrane which are successively overlapped; in a direction of an air flow path, the thickness of the micro-porous layer is gradually reduced, the thickness of the catalysis layer is gradually increased, andthe total thickness of the micro-porous layer is consistent with the total thickness of the catalysis layer. The invention also provides a production method of the membrane electrode assembly of the fuel cell. The membrane electrode assembly of the fuel cell has the functions of balancing the content of water in areas of a gas inlet and a gas outlet of the fuel cell, finally improving the stability of the fuel cell under various temperatures and humidities, improving durability, reducing the catalyst loading capacity, and the like.

Owner:CRRC QINGDAO SIFANG CO LTD

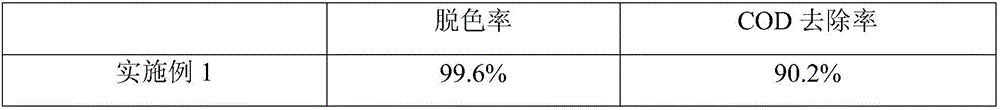

Method for preparing textile fiber/graphene/Bi2WO6 composite environmental catalytic material

InactiveCN106076430ALarge specific surface areaIncrease the areaWater/sewage treatment by irradiationWater treatment compoundsTextile fiberGraphene

The invention relates to a method for preparing a textile fiber / graphene / Bi2WO6 composite environmental catalytic material. The method comprises the steps: dipping textile fibers into a saturated dispersion solution of graphene oxide, then, carrying out baking, carrying out washing, then, putting the textile fibers into a reducer solution, carrying out a reaction for 0.5 to 1 hour at the temperature of 50 DEG C to 80 DEG C, carrying out washing, and carrying out baking, so as to obtain textile fiber / graphene; and adding the textile fiber / graphene into a solution of Bi(NO3)3 and Na3PO4, carrying out stirring, then, adding Na2WO4 and urea into the solution, carrying out a hydrothermal reaction for 3 to 8 hours at the temperature of 120 DEG C to 180 DEG C, carrying out cooling, then, carrying out washing, and carrying out baking, thereby obtaining the textile fiber / graphene / Bi2WO6 composite environmental catalytic material. The method disclosed by the invention is simple and is adaptable to industrial production; and the obtained composite material has a relatively good environment purification effect.

Owner:DONGHUA UNIV +1

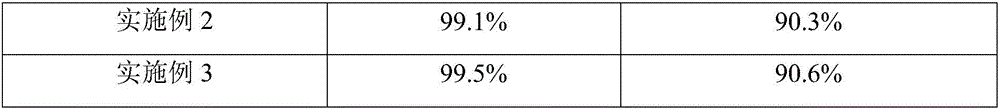

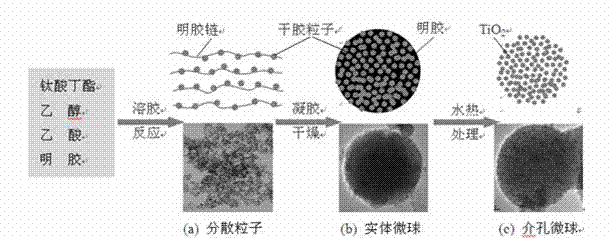

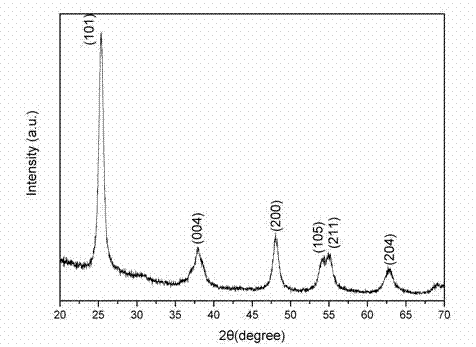

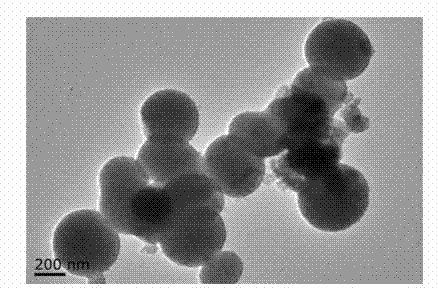

Preparation method for anatase titanium dioxide nanocrystalline mesoporous microsphere

InactiveCN103663548ASimple processReduce energy consumptionMaterial nanotechnologyPhysical/chemical process catalystsAcetic acidAlcohol

The invention discloses a preparation method for an anatase titanium dioxide nanocrystalline mesoporous microsphere. A butyl titanate alcoholic solution is prepared from butyl titanate and alcohol; a gelatin solution is prepared by gelatin and acetic acid; the gelatin solution is slowly dropped into the butyl titanate alcoholic solution to obtain a sol solution; then the sol solution is aged and dried to obtain dry gel; the dry gel is put into distilled water for boiling; after filtration cleaning is executed, the product is cleaned through the alcohol and then is dried to obtain the anatase TiO2 nanocrystalline mesoporous microsphere. The preparation technology disclosed by the invention is simple and favorable for large-scale popularization and application, and a used solvent is safe and environment-friendly.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Fiber/CNT(carbon nano tube)/TiO2 three-dimensional recyclable efficient catalytic material, as well as preparation and application thereof

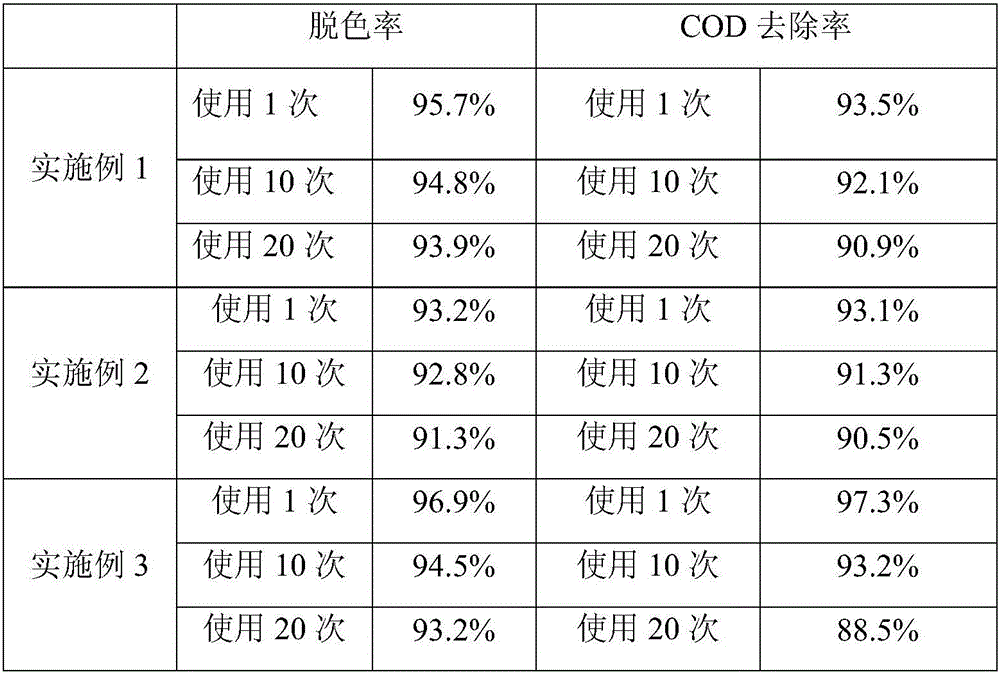

InactiveCN106732815ASpecial Interlayer PropertiesGood dispersionWater/sewage treatment by irradiationWater treatment compoundsHigh concentrationTextile fiber

The invention relates to a fiber / CNT(carbon nano tube) / TiO2 three-dimensional recyclable efficient catalytic material, as well as preparation and application thereof. A three-dimensional continuous structure is constructed on the surface of textile fiber by CNTs, and surfaces of the CNTs are loaded with nano TiO2. Preparation comprises: soaking fiber in a dispersion liquid containing CNT compound TiO2 and polyethylene glycol 2000, lasting reaction for 2-4 h at 60-80 DEG C, drying, washing with water, repeating processes of soaking, drying and washing with water for 3-5 times, and obtaining the material. The fiber / CNT / TiO2 three-dimensional recyclable efficient catalytic material is low in cost, the preparation method is simple, requirements on equipment is are low, and the operability is good; a water treatment agent provided by the invention can remove high-concentration organic pollutants in water, is suitable for advanced treatment of various wastewater, protects the environment, avoids secondary pollution, and has the advantages of being antibacterial, removing odor, absorbing other heavy metal ions, and the like.

Owner:DONGHUA UNIV

Preparation method of electrode used for CO2 electrochemical reduction reaction

The invention relates to a preparation method of an electrode used for CO2 electrochemical reduction reaction. The electrode is prepared with foam copper, a copper wire mesh, a copper foil, a copper plate, a titanium wire mesh or a titanium plate as a substrate. The preparation method includes the steps of uniformly mixing a copper precursor solution being 0.01-2.0 M in concentrate and a template agent being 0.01-1.5 M in concentrate according to the molar ratio of 5:1-1:20 and magnetically stirring the solution for more than 30 min; moving the solution into a reaction kettle, immersing the substrate into the solution and performing a sealing reaction for 4-12 h; moving the substrate out from the reaction kettle, washing and drying the substrate, and performing thermal treatment to the substrate at 300-800 DEG C for 1-5 h under protection of an inert gas or an oxidizing atmosphere to obtain the substrate to which metal oxides are attached; and performing electrochemical reduction to the substrate to which metal oxides are attached in an acidic electrolyte to obtain the electrode. The preparation method is simple in preparation method and is suitable for large-scale production. The electrode is large in specific surface area and is high in CO2 oxygen reduction catalytic performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

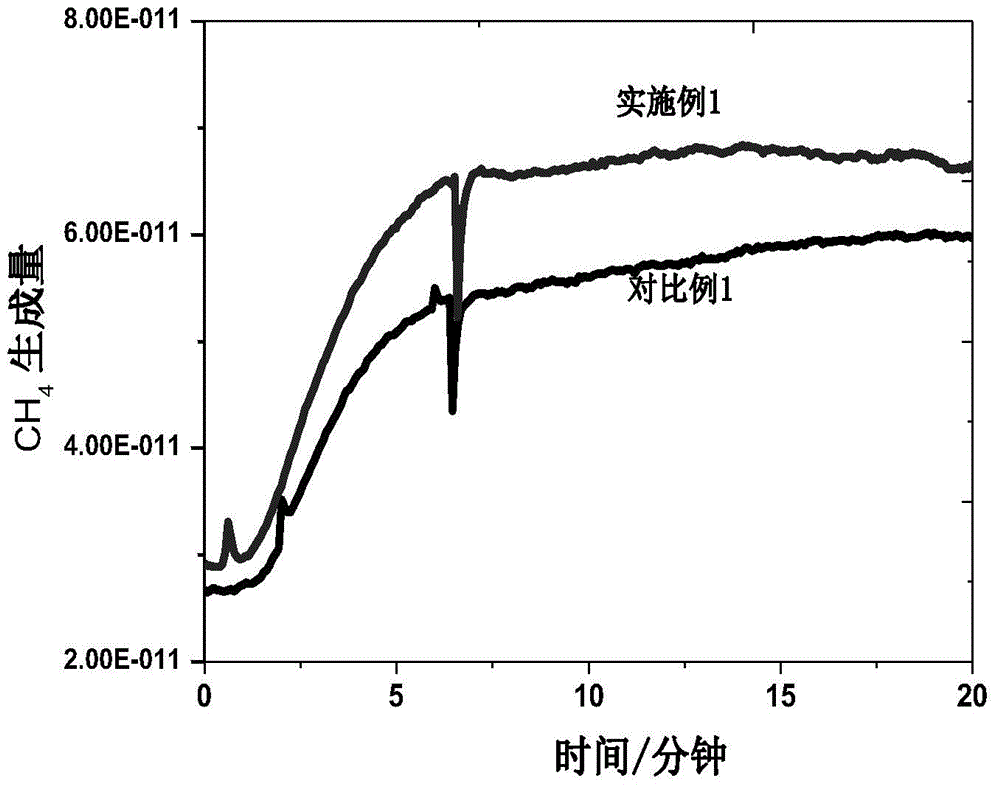

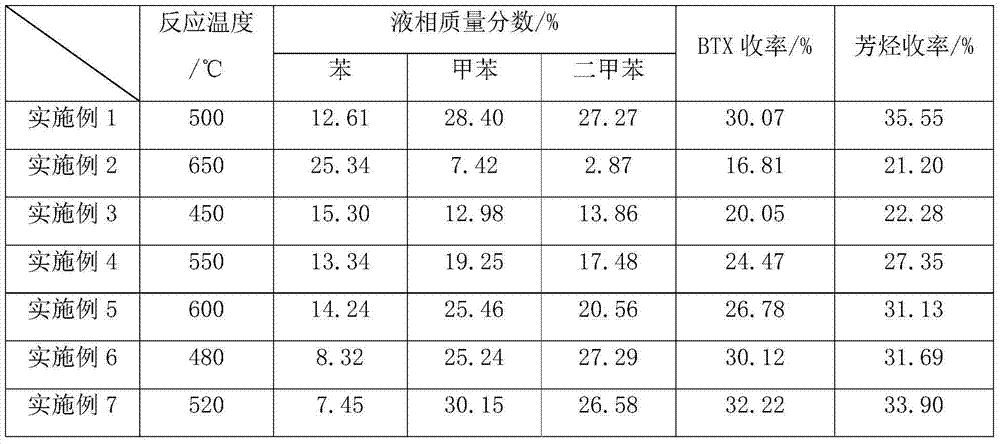

Catalyst for aromatization of low-carbon mixed hydrocarbons in Fischer-Tropsch synthesis tail gas and its preparation method and use

ActiveCN103752346AOmit the dehydrogenation stepMultiple reactive sitesOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrocarbon condensationAlkanePtru catalyst

The invention discloses a catalyst for aromatization of low-carbon mixed hydrocarbons in Fischer-Tropsch synthesis tail gas and its preparation method and use. The catalyst comprises a Pt-loading inorganic refractory oxide and a transition metal- and heteropoly acid-modified ZSM-5 molecular sieve according to a weight ratio of 0.3-3.0: 1. The Pt-loading inorganic refractory oxide comprises 0.2-5wt% of Pt2O and the balance an inorganic refractory oxide. The transition metal- and heteropoly acid-modified ZSM-5 molecular sieve comprises 0.5-10wt% of a transition metal oxide, 1.0-15wt% of heteropoly acid and the balance a ZSM-5 molecular sieve. The catalyst can be directly used for an aromatization reaction of mixed low-carbon alkanes and mixed low-carbon olefins separated from Fischer-Tropsch synthesis tail gas, can avoid a raw material dehydrogenation step, and has the advantages of high activity, good selectivity, carbon formation difficulty and good stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Nickel cobalt oxyhydroxide-doped graphene oxide used as oxygen evolution catalysis material

InactiveCN107961793AImprove electrocatalytic performanceReduce the possibilityEnergy inputMetal/metal-oxides/metal-hydroxide catalystsDoped grapheneOxide composite

The invention discloses a nickel cobalt oxyhydroxide-doped graphene oxide composite catalyst, and preparation and application thereof. The transition metal oxyhydroxide-doped graphene oxide compositecatalyst comprises graphene oxide and Ni<x>Co<1-x>OOH, wherein x is in a range of 0.5 to 0.9. The Ni-Co transition metal oxyhydroxide-doped graphene oxide shows superior oxidizability, photoelectrochemical properties and electrocatalytic activity due to its special structure, high specific surface area and high activity.

Owner:SHANXI DATONG UNIV

Preparation method of metal oxide/sulfide and ordered mesoporous carbon composite energy-storage material

ActiveCN103943826AHigh specific surface areaImprove electrochemical performanceCell electrodesSecondary cellsRound-bottom flaskChemical synthesis

The invention discloses a preparation method of a metal oxide / sulfide and ordered mesoporous carbon composite energy-storage material. The preparation method comprises the following steps: firstly, synthesizing a metal oxide / sulfide precursor-@CMK-3 composite in a round-bottom flask / reaction kettle by adopting a simple solution / hydrothermal process, and then calcining the composite in nitrogen gas to obtain the metal oxide / sulfide and ordered mesoporous carbon (CMK-3) composite energy-storage material. The preparation method is characterized in that the energy-storage material is prepared by adopting a simple chemical synthesis means, and the energy-storage material is easy to separate and has a mesoporous characteristic, a high specific surface area and electrochemical properties superior to that of common metal oxide / sulfide and carbon materials.

Owner:XI AN JIAOTONG UNIV

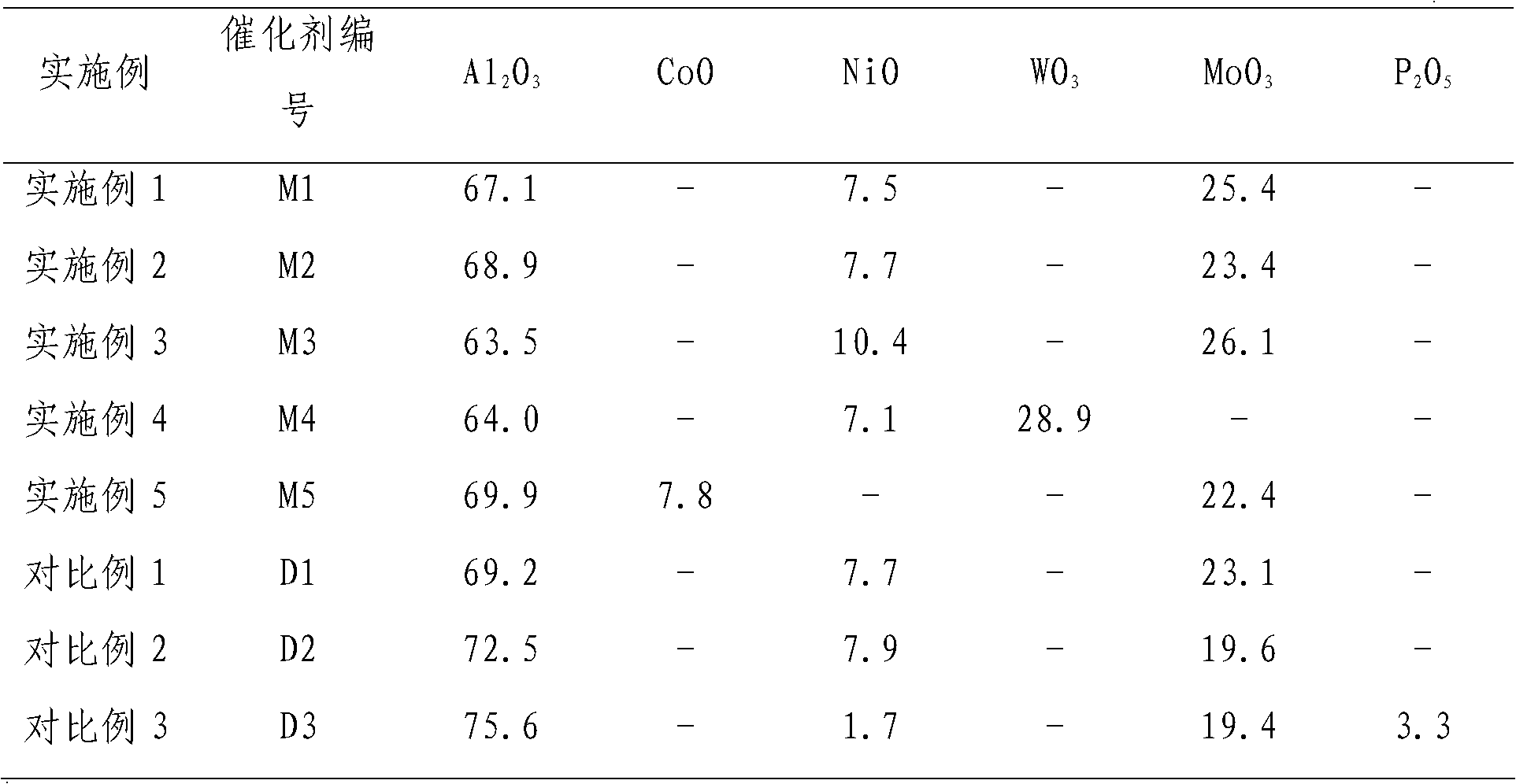

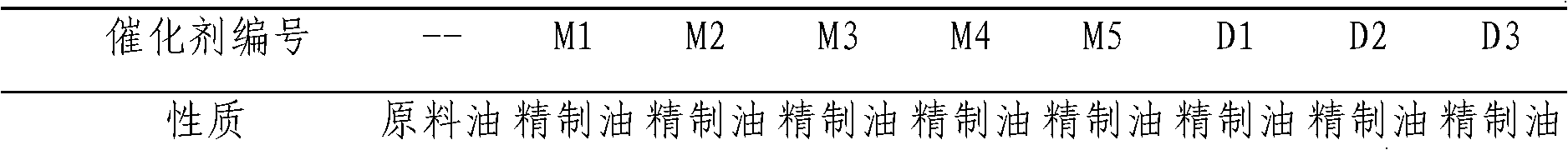

Preparation method for hydrorefining catalyst

ActiveCN102836725AEvenly distributedIncrease surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSulfurSpinel

The present invention relates to a preparation method for a high hydrogenation activity catalyst. The method comprises that: a VIII group metal-containing solid compound and alumina are subjected to kneading, strip extruding and forming to prepare a high specific surface area alumina complex containing the VIII group metal; then the alumina complex containing the VIII group metal, a salt solution of a VIB group metal, urea and a reaction aid are subjected to a hydrothermal reaction in an autoclave; and treatments of drying and calcination are performed to prepare the hydrorefining catalyst. Compared with catalysts prepared by the conventional impregnation method, the catalyst prepared by the preparation method of the present invention has the following characteristics that: the reaction on the carrier surface is performed to generate a novel metal activity phase precursor so as to easily vulcanize into the II type Co(Ni)-Mo(W)-S phase with the higher hydrogenation activity, and formation of spinel with no hydrogenation activity is reduced, such that activities of hydrodesulfurization and hydrodenitrogenation of the catalyst can be substantially improved, and the method is particularly suitable for deep hydrorefining of poor quality high sulfur distillate oil.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of fiber/graphene/copper sulfide flexible electrode material

ActiveCN108597906AFacilitated DiffusionIncrease contact interfaceHybrid capacitor electrodesHybrid/EDL manufactureIonCvd graphene

The invention discloses a preparation method of a fiber / graphene / copper sulfide flexible electrode material. The preparation method is characterized by comprising the following steps: A, soaking pretreated fiber fabric into an oxidized graphene suspension and drying, and repeating the step several times to obtain a fiber / oxidized graphene material, wherein the oxidized graphene suspension is obtained by dispersing oxidized graphene powder into deionized water ultrasonically; B, carrying out in-situ reduction on the fiber / oxidized graphene material to obtain a fiber / graphene material; and C, soaking the fiber / graphene material obtained in the step B into a hydrothermal reactor containing copper salt and a sulfur-containing precursor solution, and carrying out heating reaction synthesis to obtain the fiber / graphene / copper sulfide flexible electrode material. According to the material obtained by the method, a carbon material with high electrical conductivity is compounded with copper sulfide with high specific capacitance and low electrical conductivity, so that the advantages of the carbon material and copper sulfide are fully developed. The material has relatively high area specific capacitance and power characteristic, and is excellent in cycle performance.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Carboxyl terminated dendritic polymer adsorption material and preparation method thereof

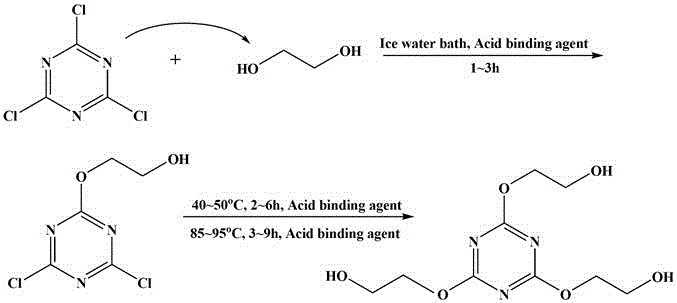

ActiveCN105013455AImprove adsorption capacityActive reaction site is goodOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceBenzenesulfonic acid

The invention relates to a carboxyl terminated dendritic polymer adsorption material and a preparation method thereof. The dendritic polymer has a network spherical three-dimensional structure, and can greatly improve the adsorption efficiency as an adsorption material. The preparation method includes: dissolving cyanuric chloride in acetone or tetrahydrofuran, adding the mixture into an acetone solution of diol to obtain a primary hydroxy terminated dendritic polymer crude product, conducting purification to obtain a primary hydroxy terminated dendritic polymer; taking cyanuric chloride as the core, adopting the primary hydroxy terminated dendritic polymer as the branching unit to prepare a secondary hydroxy terminated dendritic polymer crude product and a tertiary hydroxy terminated dendritic polymer crude product, and carrying out purification; and dispersing the hydroxy terminated dendritic polymer in water, adding maleic anhydride and p-toluenesulfonic acid to prepare a carboxyl terminated dendritic polymer crude product, and conducting purification to obtain the carboxyl terminated dendritic polymer adsorption material. The method provided by the invention has the characteristics of mild conditions, simple process and short production cycle. The product contains a lot of active carboxyl terminal groups, has strong adsorption performance, and is expected to be used in heavy metal ion and organic wastewater treatment and other fields.

Owner:上海球球云环保科技有限公司

Carbon/graphene composite super-capacitor electrode materials and preparation method thereof

InactiveCN108899213ARich sourcesEasy to passHybrid capacitor electrodesCapacitanceComposite electrode

Owner:BEIJING UNIV OF CHEM TECH

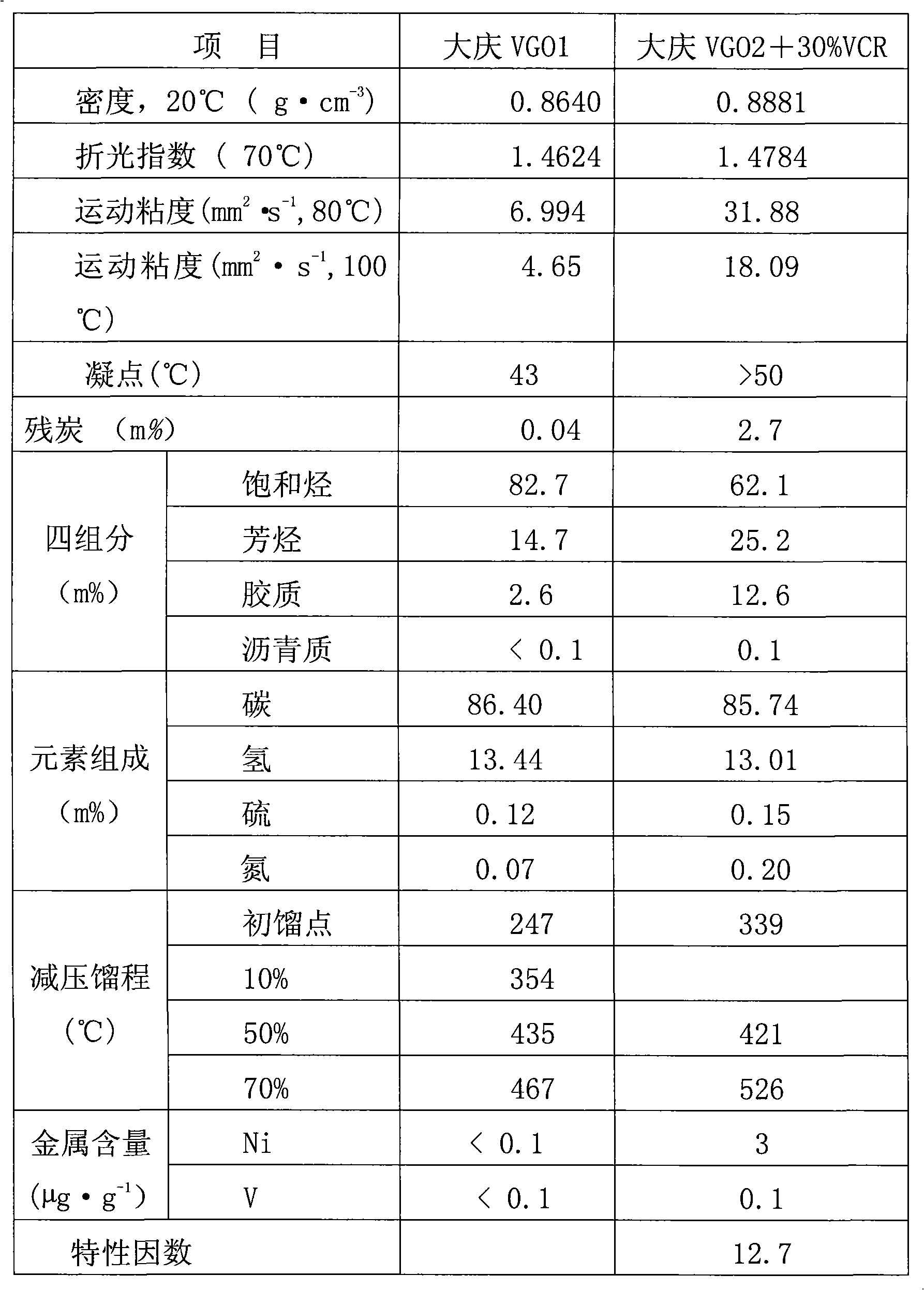

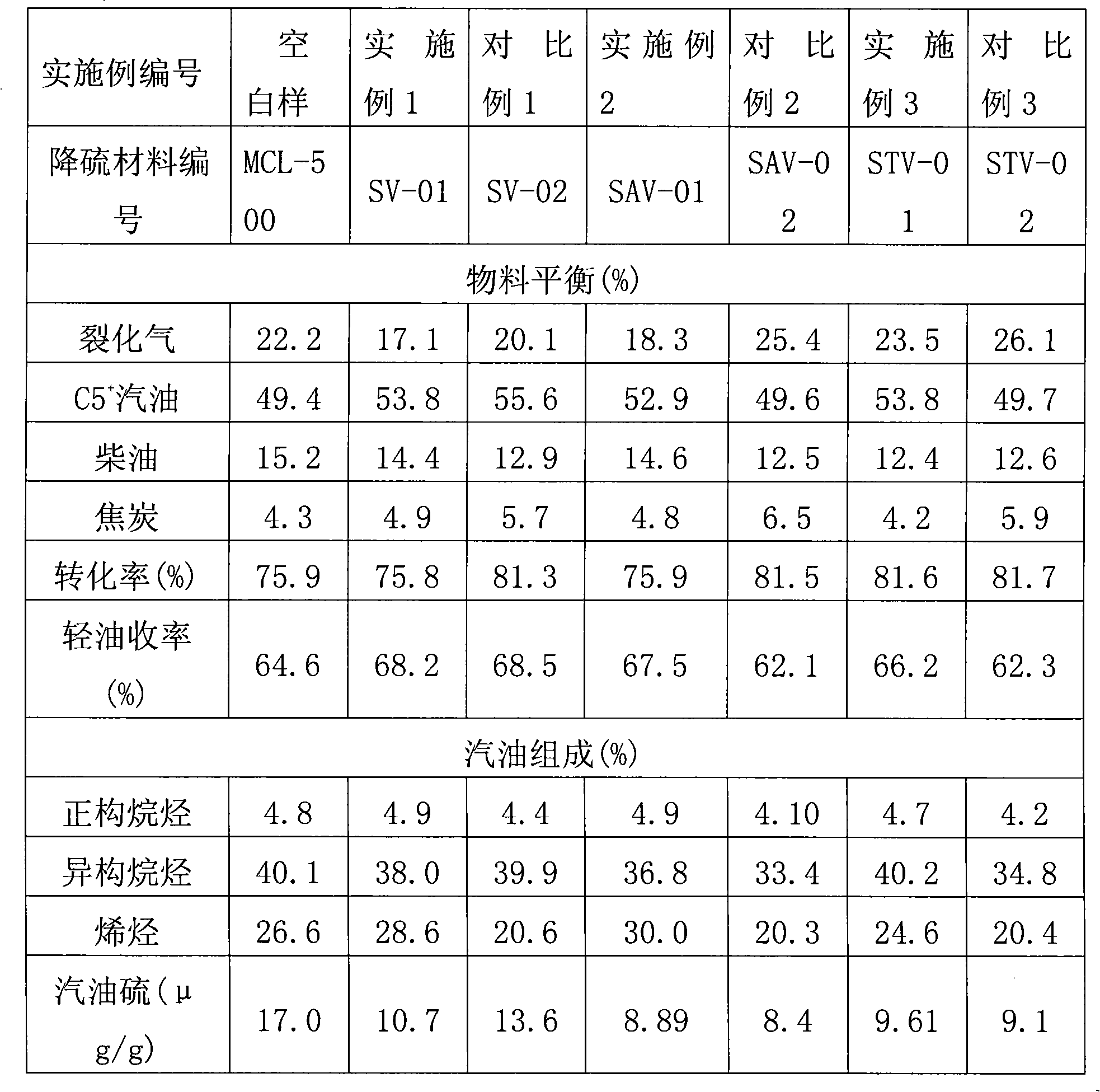

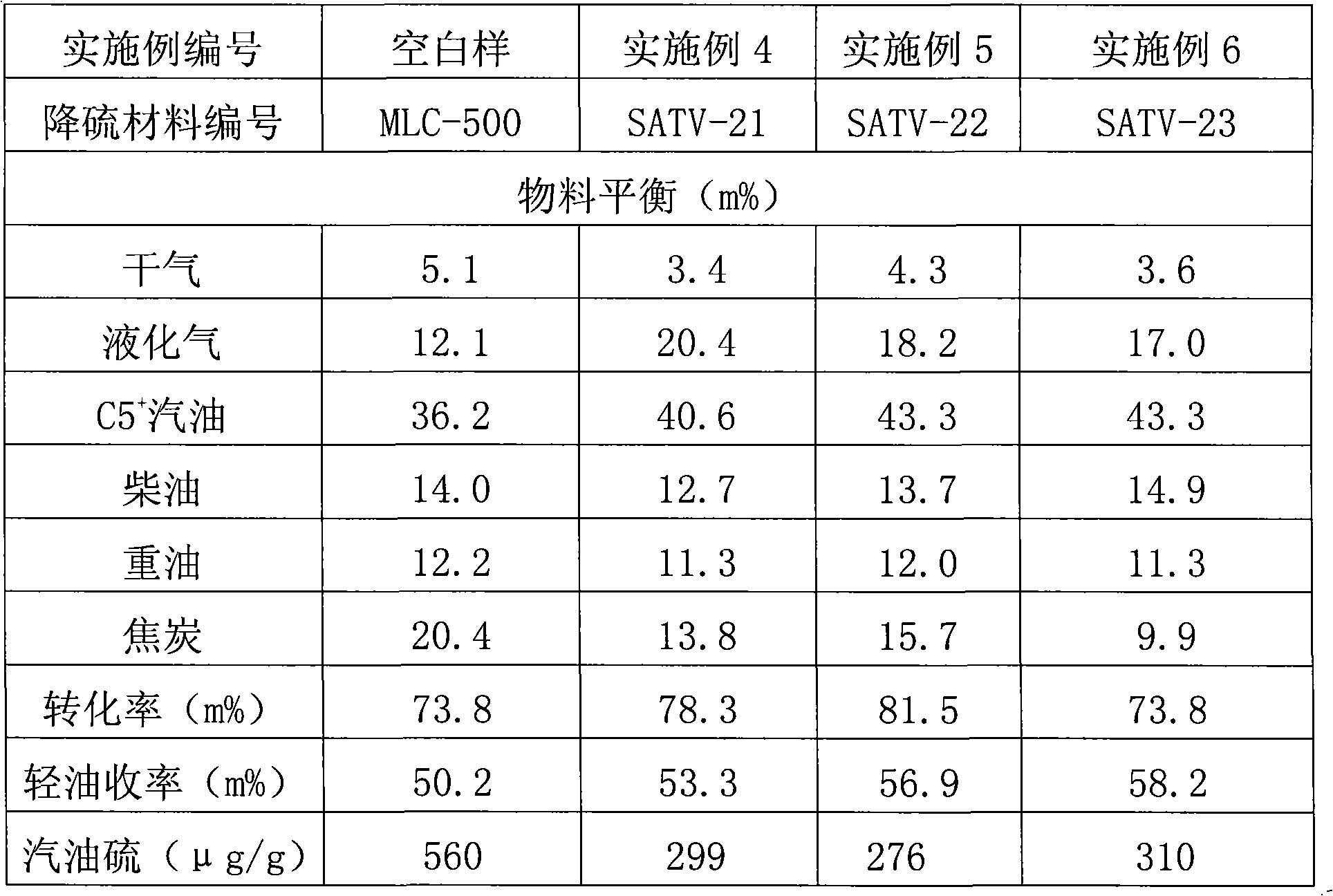

Catalytic cracking sulfur-reducing material and preparation method thereof

ActiveCN101570694AFast transport diffusionMultiple reactive sitesCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsChemistryPetroleum

The invention relates to a catalytic cracking sulfur-reducing material and a preparation method thereof. The catalytic cracking sulfur-reducing material comprises the following compositions by weight percent: 0.5 to 20 percent of vanadium as calculated by V2O5, 0.1 to 30 percent of aluminum as calculated by Al2O3, 0.1 to 30 percent of titanium as calculated by TiO2, and the balance of silicon oxide, and the total weight of various compositions is 100 percent. The preparation method comprises the following steps: firstly, dissolving a surfactant into acid water solution, wherein the solution temperature is between 25 and 95 DEG C; secondly, mixing a silicon source and the acid water solution containing the surfactant for hydrolysis after the surfactant is completely dissolved, and obtaining sol; thirdly, curing the sol at a temperature of between 30 and 80 DEG C to obtain wet gel; fourthly, continuously aging the obtained wet gel for 1 to 10 days at a temperature of between 30 and 200 DEG C; fifthly, drying the aged wet gel for 1 to 7 days at a temperature of between 50 and 120 DEG C; and sixthly, roasting the dried gel for 1 to 20 hours at a temperature of between 300 and 800 DEG C to obtain the mesoporous sulfur-reducing material. The catalytic cracking sulfur-reducing material has high petroleum hydrocarbon cracking activity and obvious desulfurization activity.

Owner:PETROCHINA CO LTD +1

Preparation method of fiber/graphene/zinc sulfide flexible electrode material

InactiveCN108766783AImprove conductivityFacilitated DiffusionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention discloses a preparation method of a fiber / graphene / zinc sulfide flexible electrode material. The preparation method comprises the following steps of A, steeping preprocessed fiber fabricinto graphene oxide suspension liquid and drying, repeating the step for many times to acquire fiber / graphene oxide material, wherein the graphene oxide suspension liquid is prepared by ultrasonically dispersing graphene oxide powder into deionized water; B, performing in-situ reduction on the fiber / graphene oxide material to acquire fiber / graphene material; and C, steeping the fiber / graphene material acquired in the step B to a hydrothermal reaction kettle including zinc salt and sulfur-containing polymeric precursor solution, and synthesizing the fiber / graphene / zinc sulfide flexible electrode material via a heating reaction. The material prepared according to the method provided by the invention, carbon material with good conductivity is compounded with zinc sulfide with high specific capacitance and poor conductivity, and gives full play to advantages of the carbon material and zinc sulfide. The fiber / graphene / zinc sulfide flexible electrode material has relatively high area ratiocapacitance and power characteristic and excellent cycle performance.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Method for preparing textile fiber/graphene/BiVO4/BiPO4 composite environmental catalytic material

InactiveCN106076432ALarge specific surface areaIncrease the areaWater/sewage treatment by irradiationWater treatment compoundsTextile fiberGraphene

The invention relates to a method for preparing a textile fiber / graphene / BiVO4 / BiPO4 composite environmental catalytic material. The method comprises the steps: dipping textile fibers into a saturated dispersion solution of graphene oxide, then, carrying out baking, carrying out washing, then, putting the washed textile fibers into a reducer solution, carrying out a reaction for 0.5 to 1 hour at the temperature of 50 DEG C to 80 DEG C, carrying out washing, and carrying out baking, so as to obtain textile fiber / graphene; and adding the textile fiber / graphene into a solution of Bi(NO3)3 and Na3PO4, carrying out stirring, then, adding NaVO3, NaH2PO4 and urea, carrying out a hydrothermal reaction for 3 to 8 hours at the temperature of 120 DEG C to 180 DEG C, carrying out cooling, then, carrying out washing, and carrying out baking, thereby obtaining the textile fiber / graphene / BiVO4 / BiPO4 composite environmental catalytic material. The method disclosed by the invention is simple and is adaptable to industrial production; and the obtained composite material has a relatively good environment purification effect.

Owner:DONGHUA UNIV

Preparation method for textile fiber/graphene/Ag3PO4 composite environment catalysis material

InactiveCN106000472AIncrease reaction rateAccelerate photocatalytic degradation reactionWater/sewage treatment by irradiationWater treatment compoundsChemistryUrea

The invention relates to a preparation method for a textile fiber / graphene / Ag3PO4 composite environment catalysis material. The preparation method comprises the following steps: dipping textile fibers in a saturated solution of graphene oxide, then drying the textile fibers, cleaning the textile fibers, placing the textile fibers in a solution of a reducing agent, carrying out a reaction at 50 to 80 DEG C for 0.5 to 1 h and then successively carrying out cleaning and drying so as to obtain textile fiber / graphene; and adding the textile fiber / graphene into a AgNO3 solution, carrying out stirring, then adding Na3PO4 and urea, carrying out a hydrothermal reaction at 120 to 180 DEG C for 3 to 8 h and successively carrying out cooling, cleaning and drying so as to obtain the textile fiber / graphene / Ag3PO4 composite environment catalysis material. The preparation method provided by the invention is simple and is suitable for industrial production; and the obtained textile fiber / graphene / Ag3PO4 composite environment catalysis material has good environment purifying effect.

Owner:DONGHUA UNIV

Method for preparing solid-oxide fuel battery cathode

InactiveCN101281966ALarge specific surface areaHigh catalytic activityCell electrodesFuel cellsHYDROSOL

A preparation method for a solid oxide fuel cell cathode relates to a preparation method for a fuel cell cathode, which resolves problem in prior art that catalytic activity of a solid oxide fuel cell cathode is low under middle and low temperature. The preparation method includes: preparing sol from La1-xSrx(NO3)3M(NO3)2 and citric acid solution, filling the sol into a hole of an anode aluminum oxide template, calcining under high temperature, dipping into NaOH solution, and obtaining the solid oxide fuel cell cathode. Catalytic activity of the solid oxide fuel cell cathode of present invention is high under middle and low temperature.

Owner:HARBIN INST OF TECH

Sterilizing agent for vehicles and preparation method of sterilizing agent

InactiveCN108849874ALarge specific surface areaMultiple reactive sitesBiocideFungicidesTitaniumGraphene

The invention relates to the technical field of automobile spare parts, in particular to a sterilizing agent for vehicles and a preparation method of the sterilizing agent. The preparation method of the sterilizing agent for the vehicles comprises the following steps: enabling organic titanate ester, organic silicate ester and hexadecyl trimethyl ammonium bromide to react to obtain a silicon-titanium photocatalyst; compounding the silicon-titanium photocatalyst and graphene oxide-modified 4-amino-1,2,4-triazole to obtain the sterilizing agent for the vehicles. The sterilizing agent for the vehicles can be used for concentrating and efficiently degrading harmful gas in the vehicles so as to achieve the purposes of purifying air in the vehicles and improving air quality.

Owner:WUHU DEXIN AUTO PARTS

Preparation method of textile fiber/graphene/NaTaO3 composite environmental catalytic material

InactiveCN105903494ALarge specific surface areaIncrease the areaOrganic-compounds/hydrides/coordination-complexes catalystsTextile fiberGraphene

The invention relates to a preparation method of a textile fiber / graphene / NaTaO3 composite environmental catalytic material. The preparation method comprises the steps of dipping textile fibers into saturated dispersing liquid of graphene oxide, then conducting drying and cleaning, then placing the textile fibers into a reducing agent solution, conducting a reaction for 0.5-1 hour at the temperature of 0-80 DEG C, and conducting cleaning and drying, so that textile fiber / graphene is obtained; adding the textile fiber / graphene into a solution containing Ta2O5 and Na3PO4, conducting stirring, then NaOH and urea, conducting a hydrothermal reaction for 3-8 hours at the temperature of 120-180 DEG C, and after the materials are cooled, conducting washing and drying, so that the textile fiber / graphene / NaTaO3 composite environmental catalytic material is obtained. The method is simple and suitable for industrialized production; the obtained composite material has a good environment purification effect.

Owner:DONGHUA UNIV

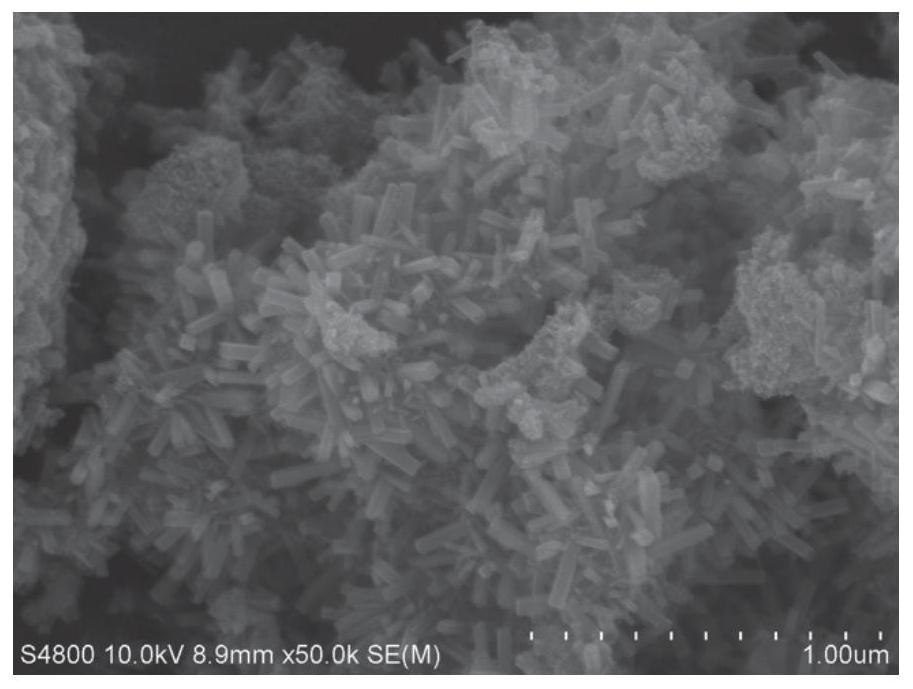

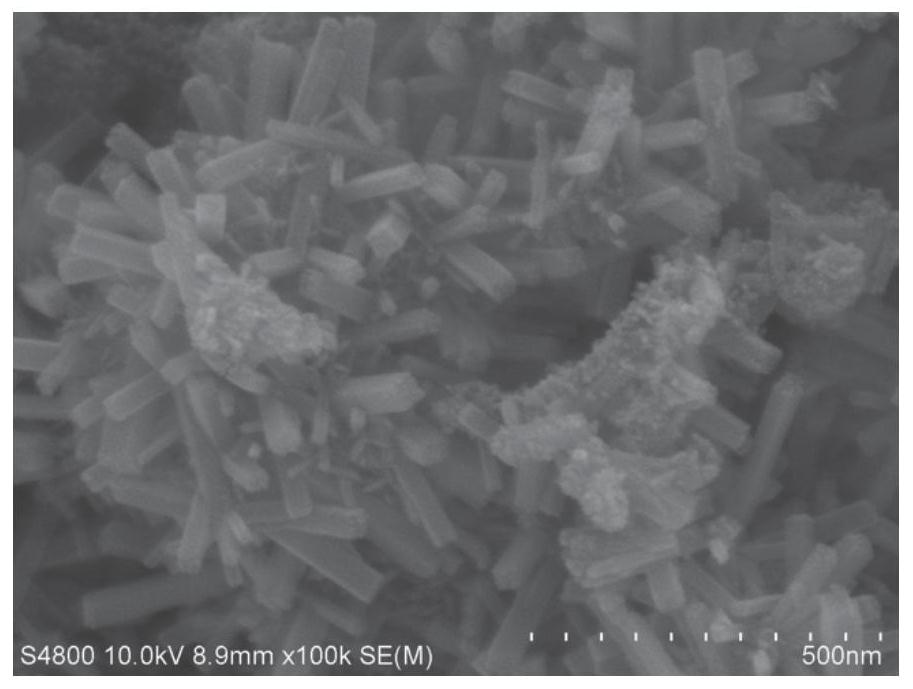

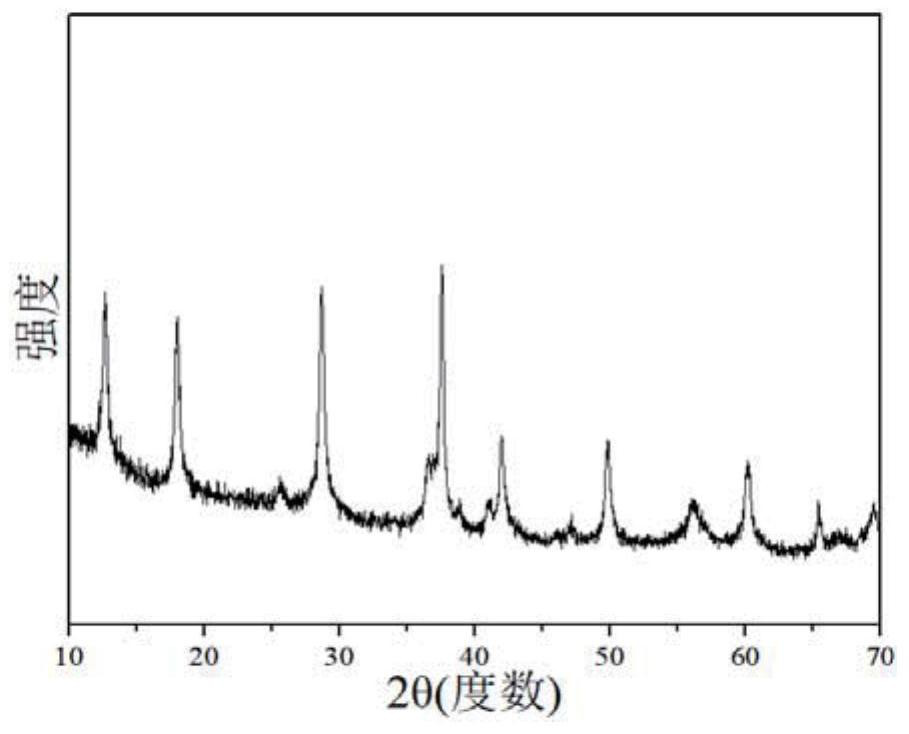

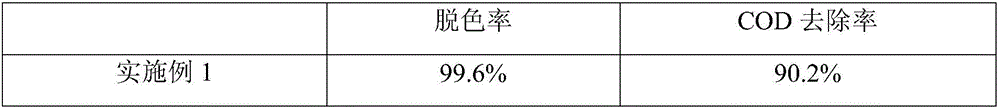

Cryptomelane type manganese dioxide oxidant with three-dimensional structure as well as preparation method and application thereof

PendingCN113117669AThe operation method is simple and safeHigh yieldWater contaminantsHeterogenous catalyst chemical elementsOxidizing agentPotassium permanganate

The invention discloses a cryptomelane type manganese dioxide oxidant with a three-dimensional structure as well as a preparation method and application thereof. The preparation method comprises the following steps that a uniformly mixed reaction system containing potassium permanganate, divalent manganese salt, cerium salt, bismuth salt and acid is subjected to a reaction at 50-100 DEG C for 5-24 h, the cryptomelane type manganese dioxide oxidant with a three-dimensional structure is prepared, and the molar ratio of potassium permanganate to cerium salt to bismuth salt is 1: (0.015-0.075): (0.012-0.55). The preparation method disclosed by the invention is simple, high in yield and good in repeatability, the used raw materials are low in toxicity, and large-scale production is facilitated. The cryptomelane type manganese dioxide oxidant prepared by the method has a unique center aggregation type cuboid structure and a single cryptomelane crystal phase, can greatly improve the specific surface area and the surface adsorption energy, and can be used as a solid oxidant to directly oxidize and degrade organic pollutants in a water body under a neutral condition.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nano composite material simultaneously modified by non-noble metal cocatalyst and defects as well as preparation method and application thereof

PendingCN111185208ASimple stepsMild reaction conditionsPhysical/chemical process catalystsOrganic compound preparationBenzaldehydeBENZYL ALCOHOL/WATER

The invention discloses a nano composite material simultaneously modified by a non-noble metal cocatalyst and defects as well as a preparation method and application thereof. The nano composite material is characterized in that 2D non-noble metal cocatalyst Ni12P5 nanosheets are uniformly loaded on a 3D spherical hierarchical structure assembled by 2D porous ZnIn2S4 nanosheets modified by zinc defects VZn. The photocatalyst prepared by the invention shows excellent activity, selectivity and stability for preparing benzaldehyde and hydrogen by catalyzing benzyl alcohol with visible light, and the preparation method is simple and convenient in steps, mild in reaction conditions and high in yield.

Owner:HUAIBEI NORMAL UNIVERSITY

Method for preparing textile fiber/graphene/BiPO4 composite environmental catalytic material

InactiveCN106076425ALarge specific surface areaIncrease the areaWater/sewage treatment by irradiationWater treatment compoundsTextile fiberReducing agent

The invention relates to a method for preparing a textile fiber / graphene / BiPO4 composite environmental catalytic material. The method comprises the steps: dipping textile fibers into a saturated dispersion solution of graphene oxide, then, carrying out baking, carrying out washing, then, putting the textile fibers into a reducer solution, carrying out a reaction for 0.5 to 1 hour at the temperature of 50 DEG C to 80 DEG C, carrying out washing, and carrying out baking, so as to obtain textile fiber / graphene; and adding the textile fiber / graphene into a solution of Bi(NO3)3 and Na3PO4, carrying out stirring, then, adding NaH2PO4 and urea into the solution, carrying out a hydrothermal reaction for 3 to 8 hours at the temperature of 120 DEG C to 180 DEG C, carrying out cooling, then, carrying out washing, and carrying out baking, thereby obtaining the textile fiber / graphene / BiPO4 composite environmental catalytic material. The method disclosed by the invention is simple and is adaptable to industrial production; and the obtained composite material has a relatively good environment purification effect.

Owner:DONGHUA UNIV +1

Mesoporous C3N4 photocatalytic material prepared by using molten salt method and application thereof in photocatalysis field

InactiveCN102992282BEase of mass productionEase of large-scale industrial productionPhysical/chemical process catalystsNitrogen and non-metal compoundsMuffle furnaceBlocking layer

The invention discloses a molten salt method for preparing C3N4 photocatalytic materials and a preparation method. Water-soluble low melting point molten salt and melamine are fully mixed, and small droplets of molten salt at the melting temperature of the molten salt are used as barrier layers, and C3N4 is wrapped around the small droplets. The droplets grow, and after the reaction, the molten salt is recovered by washing with water to obtain the C3N4 photocatalytic material. The C3N4 material has a worm-like mesoporous structure, and the mesopore size is 3.8±1nm. Its formation mechanism is to use small droplets of molten salt as a growth barrier. During preparation, water-soluble low-melting point chloride salt is used as molten salt, which is fully mixed with melamine. The mixture is heat-treated in a muffle furnace at 400-680°C for 1-5 hours. The heat-treated sample is washed with water to recover the molten salt to obtain mesopores. C3N4 photocatalytic material. No template introduction process is required, it is simple and easy to implement and is easy for large-scale industrial production.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com