Catalytic cracking sulfur-reducing material and preparation method thereof

A catalytic cracking and sulfur reduction technology, applied in catalytic cracking, chemical instruments and methods, cracking, etc., can solve problems such as limiting catalytic reaction, diffusion limitation, and small pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

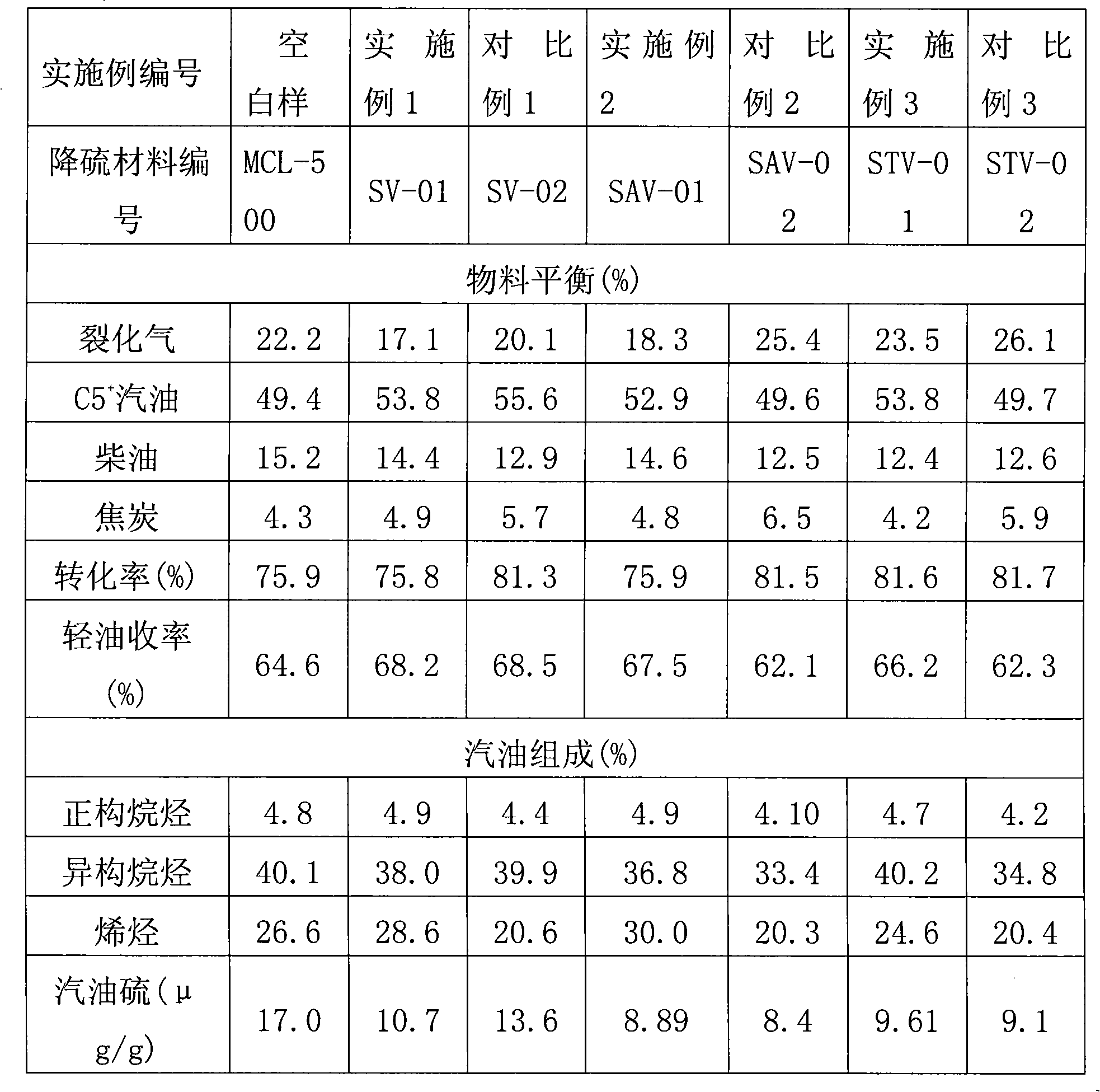

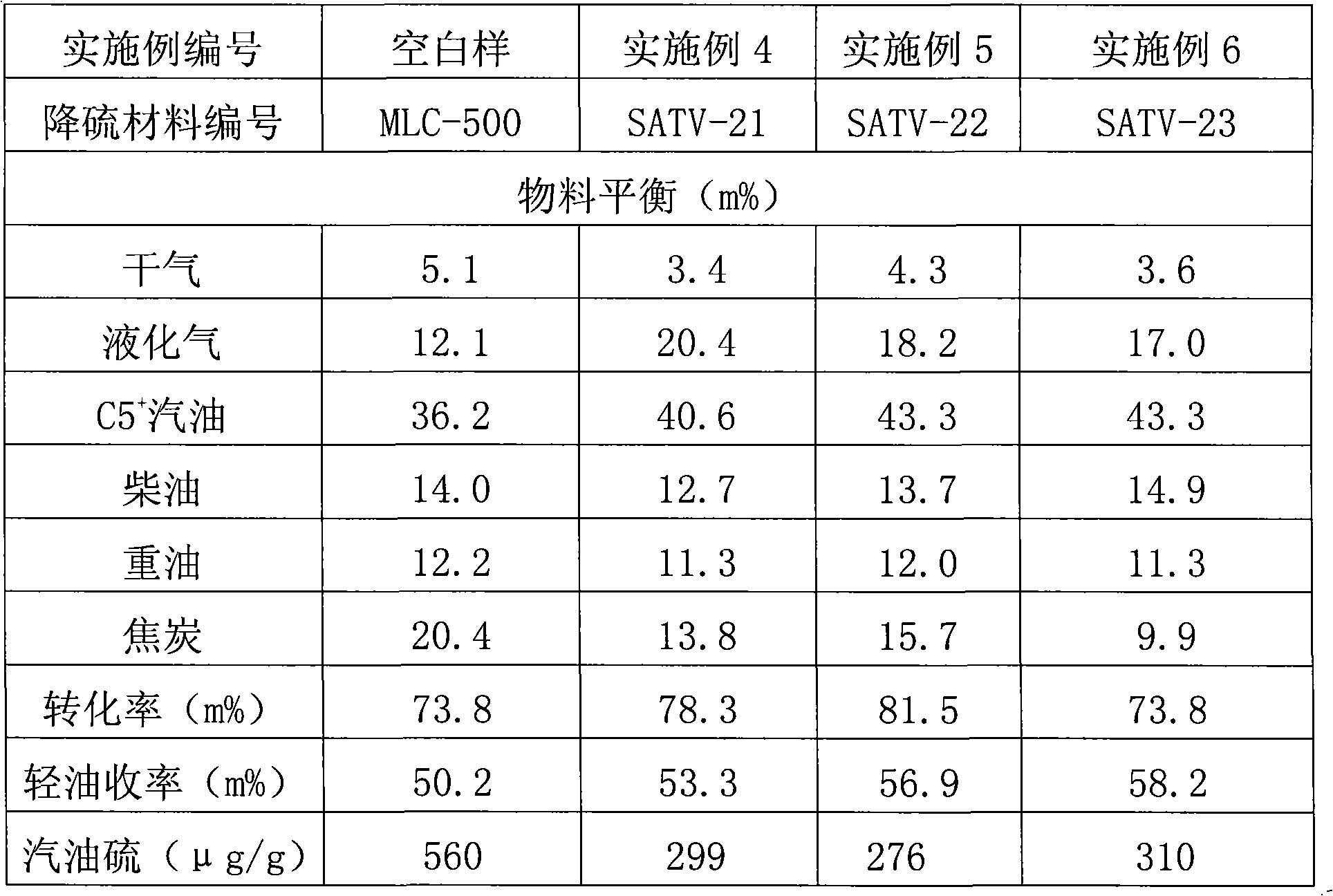

Embodiment 1

[0026] This example illustrates the sulfur reducing material provided by the present invention and its preparation method.

[0027] 12g surfactant fatty alcohol polyoxyethylene ether (C 16 EO 10 ) into 90 g of acidic aqueous solution containing 1 mol / L nitric acid, stirred at 60°C for 2 hours to fully dissolve the surfactant; dissolved quantitative vanadium oxalate in the above surfactant solution, and stirred for 20 minutes; Add lipid to the above solution and stir vigorously for 10 minutes to obtain a clear sol; put the sol in a sealed box and place it in a water bath at 50°C until it gels; the wet gel continues to age in a water bath at 50°C for 3 days; take out the wet Gel, remove the precipitated mother liquor, oven-dry at 60°C for 6 days, and then bake at 500°C for 5 hours to obtain the vanadium-doped sulfur-reducing material provided by the present invention, which is designated as SV-01. The amount of vanadium oxalate added makes the dry basis of the final sulfur-red...

Embodiment 2

[0032] This example illustrates the sulfur reducing material provided by the present invention and its preparation method.

[0033] 12g surfactant fatty alcohol polyoxyethylene ether (C 16 EO 10 ) into 70g of acidic aqueous solution containing 1mol / L nitric acid, stirred at 60°C for 2 hours to fully dissolve the surfactant; dissolved quantitative aluminum nitrate and vanadium oxalate in the above surfactant solution, and stirred for 20 minutes; Add methyl silicate to the above solution and stir vigorously for 10 minutes to obtain a clear sol; put the sol in a sealed box and place it in a water bath at 50°C until it gels; the wet gel continues to age in a water bath at 50°C for 3 days Take out the wet gel, remove the precipitated mother liquor, dry in an oven at 60°C for 6 days, and then bake at 500°C for 5 hours to obtain the vanadium and aluminum doped sulfur reducing material provided by the present invention, which is designated as SAV-01. The amount of vanadium oxalate a...

Embodiment 3

[0038] This example illustrates the sulfur reducing material provided by the present invention and its preparation method.

[0039] 12g surfactant fatty alcohol polyoxyethylene ether (C 16 EO 10 ) into 120 g of acidic aqueous solution containing 1 mol / L nitric acid, stirred at 70°C for 2 hours to fully dissolve the surfactant; dissolved quantitative vanadium oxalate in the above surfactant solution, and stirred for 20 minutes; Add 38g of methyl orthosilicate and stir for 20 minutes; then add the mixed solution of butyl titanate and methyl orthosilicate to the above surfactant and vanadium oxalate solution, stir vigorously for 10 minutes to obtain a clear sol; put the sol into In a sealed box, put it in a water bath at 40°C until it gels; the wet gel continues to age in a water bath at 40°C for 3 days; take out the wet gel, remove the precipitated mother liquor, dry it in an oven at 60°C for 6 days, and then dry it at 500°C The vanadium and titanium doped sulfur-reducing mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com