Sludge curing treatment agent and method for treating sludge by use of curing treatment agent

A technology for sludge solidification and solidification treatment, which is used in dewatering/drying/concentrating sludge treatment, etc. It can solve the problems of long solidification time and high moisture content of sludge, and achieve the effect of short solidification time and low water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

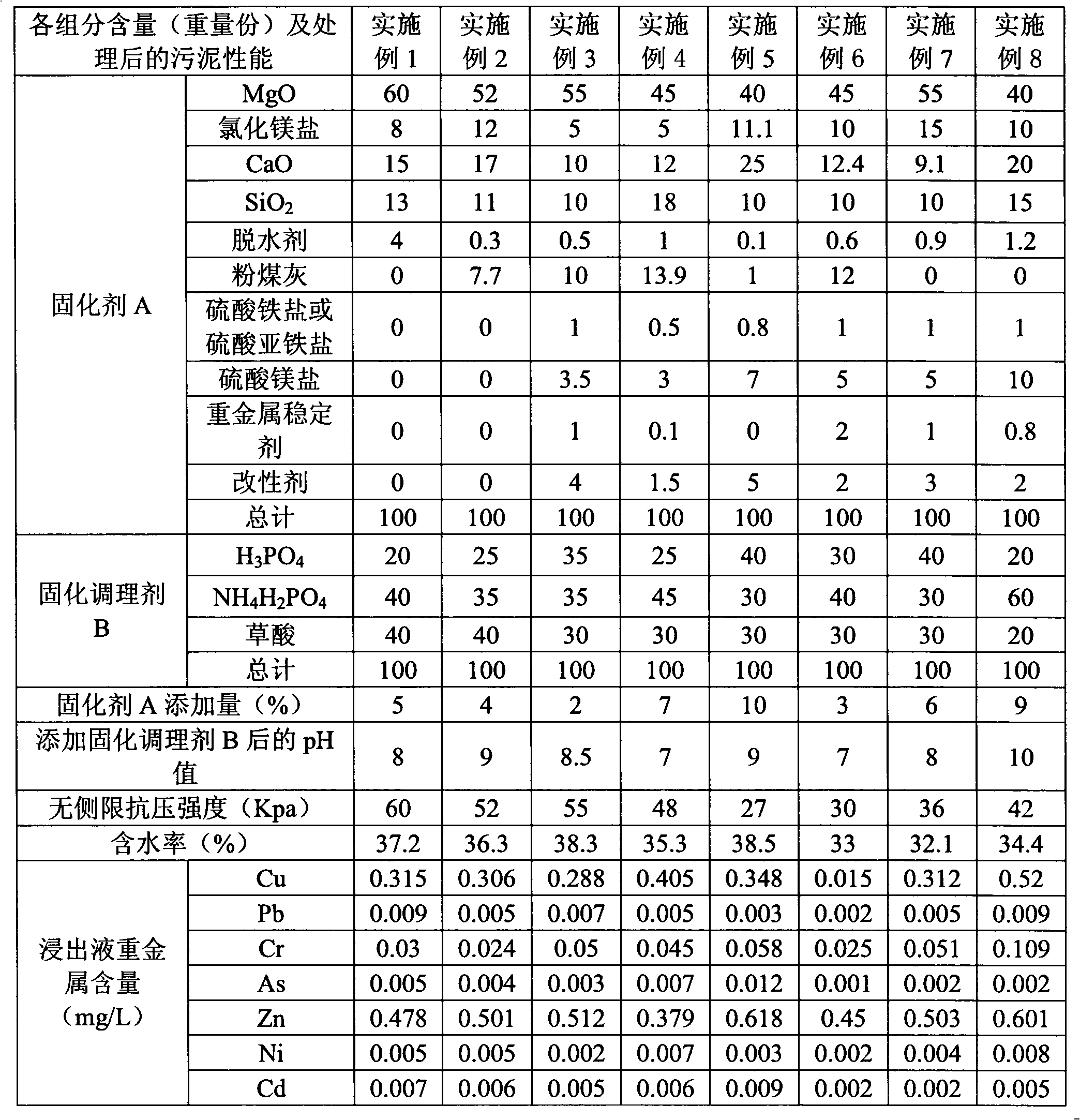

[0038] In the powder mixer, according to the formulations of curing agent A and curing conditioner B in Table 1, various raw materials were added in sequence, and mixed and stirred for 5 to 6 minutes to prepare the finished products of curing agent A and curing conditioner B respectively.

[0039] In the agitator, add curing agent A with 5% of sludge weight to the sludge with a moisture content of 90%, mix and stir for 5-6 minutes, then add solidifying conditioner B and mix and stir for 10-15 minutes, Adjust the pH of the sludge to 8, stir it evenly and then maintain it at room temperature. After 2 days, the unconfined compressive strength of the sludge was tested, and the moisture content of the sludge was tested after 7 days. After 7 days, the heavy metal content of the leaching solution was measured with an atomic absorption spectrophotometer according to the Toxic Leaching of Solid Waste (TCLP) method of the US Environmental Protection Agency. , the test results are listed...

Embodiment 2

[0041] Example 1 was repeated according to the formulations of curing agent A and curing conditioner B in Table 1, wherein the pH of the adjusted sludge was 8.5, and the test results are listed in Table 1.

Embodiment 3

[0043] Example 1 was repeated according to the formulations of curing agent A and curing conditioner B in Table 1, wherein the pH of the adjusted sludge was 7, and the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com