Production method for direct growth of one-dimensional nano cuprous oxide array on metallic copper substrate

A technology of copper substrate and metal copper, which is applied in nanostructure manufacturing, chemical instruments and methods, copper oxide/copper hydroxide, etc., to achieve excellent field emission performance, good visible light catalytic performance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

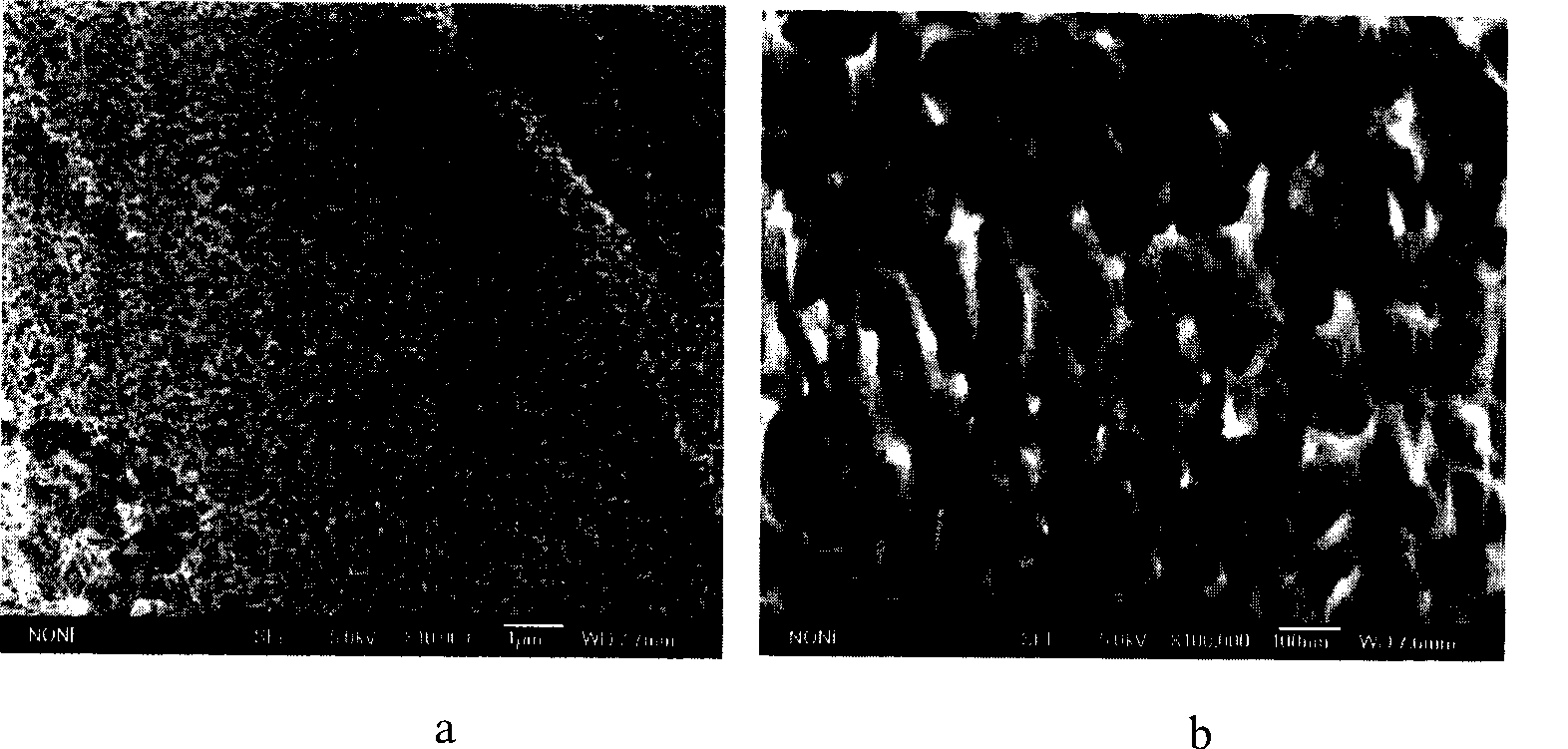

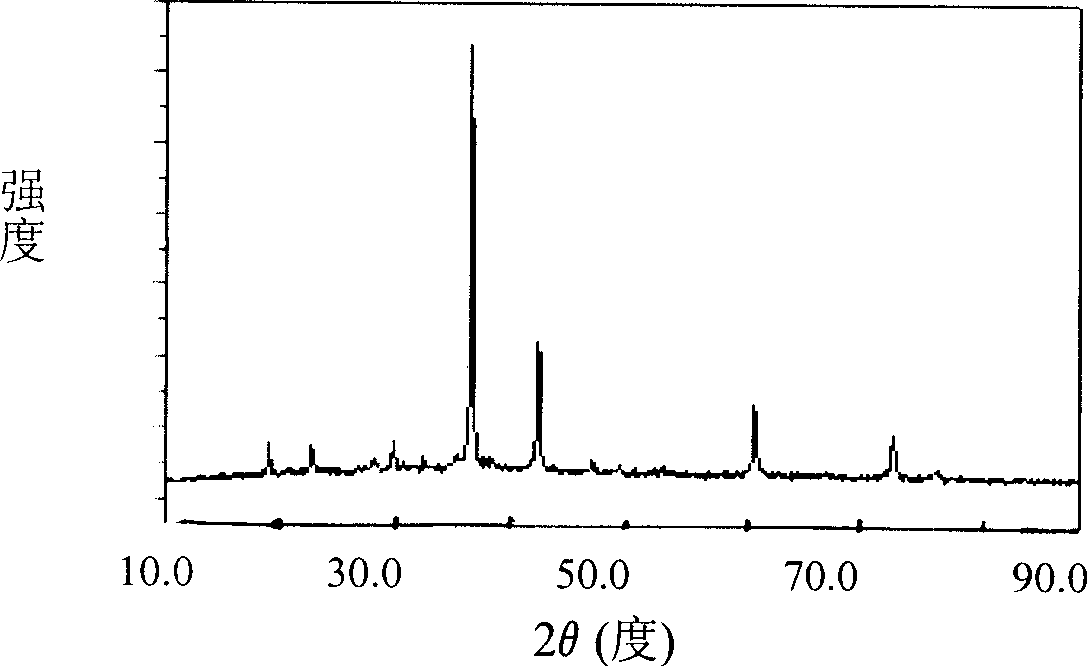

Embodiment 1

[0035] Polish the surface of 8cm×8cm copper foil with sandpaper and soak it in 20% (weight) concentrated hydrochloric acid for 10 seconds to remove the oxide on the surface, wash the surface with distilled water for 3 times, and then ultrasonically wash the copper foil in ethanol Remove the organic matter on the surface and dry it for later use; the copper foil is used as the anode, the titanium is the cathode, and there is a diaphragm (heterogeneous quaternary ammonium anion exchange membrane, the same below) between the cathode and the anode to prevent the hydrogen bubbles generated by the cathode from contacting the anode ; 3.5M sodium chloride (NaCl) and 0.01M cetyltrimethylammonium bromide (CTAB) are ultrasonically mixed and poured into the anode chamber in the electrolytic cell, and 0.1M sodium hydroxide (NaOH) is used as the cathode Electrolyte, after the temperature of the electrolytic cell rises to 80°C, adjust the electrolytic current density to 0.06A / cm 2 ; After 10...

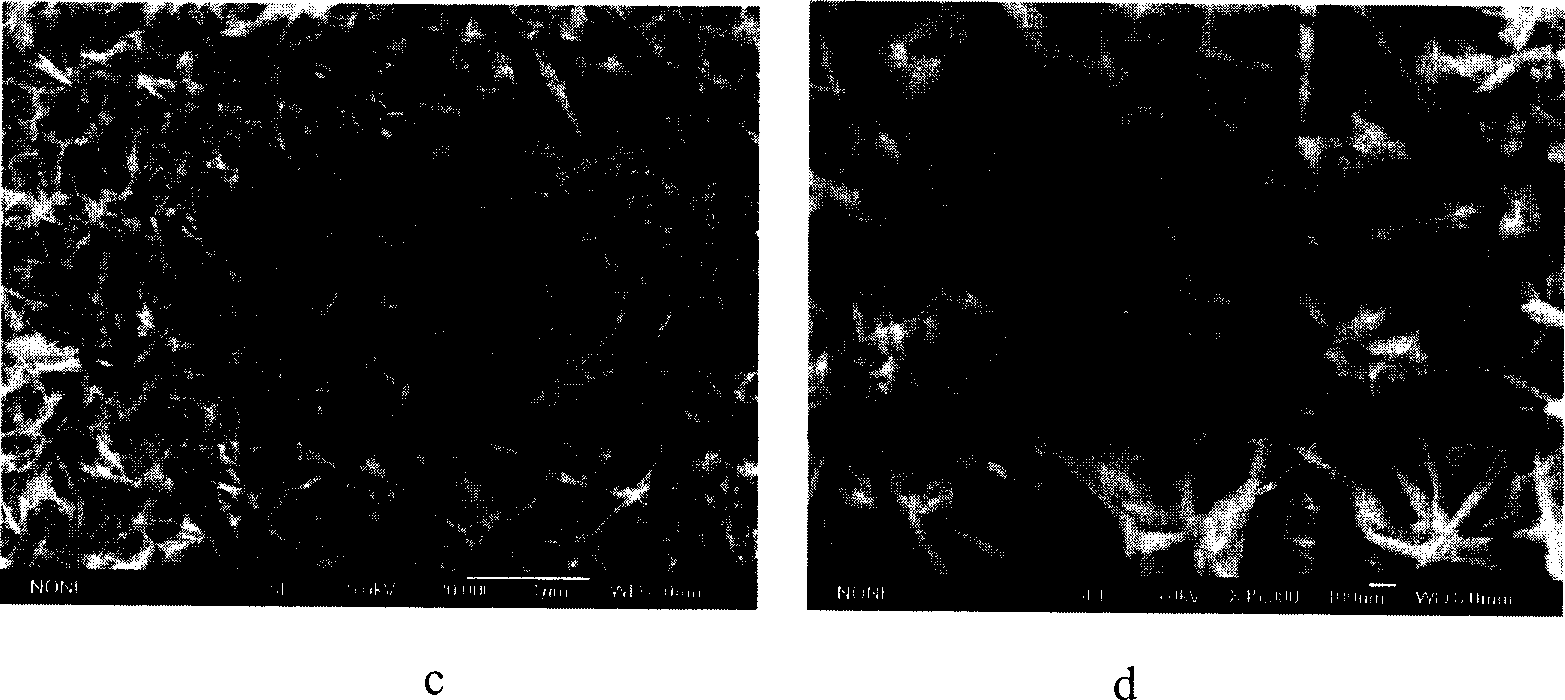

Embodiment 2

[0039] Put the copper net of 15cm * 15cm into 10% (weight) concentrated hydrochloric acid and soak for 1 minute to remove the oxide on the surface, wash the surface with distilled water for 3 times, then ultrasonically wash the copper net in ethanol to remove the organic matter on the surface, bake Standby after drying; the copper mesh is used as the anode, the nickel alloy is the cathode, and there is a diaphragm between the cathode and the anode; 1M potassium chloride (KCl) and 0.001M glucose are ultrasonically mixed and then poured into the anode chamber in the electrolytic cell, and 0.1 M Potassium hydroxide (KOH) is used as the catholyte, and after the temperature of the electrolytic cell rises to 50°C, adjust the electrolytic current density to 0.05A / cm 2 After 20 minutes of electrolysis, take out the copper foil, put it into distilled water for cleaning, and soak it in the alcohol solution containing 1‰ (weight) benzotriazole for 3 hours; wash it with ethanol after takin...

Embodiment 3

[0042] After polishing the surface of the 10cm×10cm copper sheet, put it into 30% (weight) concentrated hydrochloric acid and soak for 10 seconds to remove the oxide on the surface, wash the surface 3 times with distilled water, and then remove the copper sheet by ultrasonic cleaning in ethanol The organic matter on the surface is standby after drying; the copper sheet is used as the anode, the nickel alloy is the cathode, and there is a diaphragm between the cathode and the anode; 0.005M ammonium chloride (NH 4 Cl) and 0.1M polyvinyl alcohol are ultrasonically mixed and poured into the anode chamber in the electrolytic cell, 10M potassium hydroxide (KOH) is used as the catholyte, and after the temperature of the electrolytic cell rises to 90°C, the electrolytic current density is adjusted to 0.1 A / cm 2 After 5 minutes of electrolysis, take out the copper sheet, put it into distilled water for cleaning, and soak it in the alcohol solution containing 1‰ (weight) benzotriazole f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com