Bacteria cellulose membrane containing silver chloride nano particle and preparation and application thereof

A technology of bacterial cellulose film and bacterial cellulose, which is applied in the field of bacterial cellulose film containing silver chloride nanoparticles and its preparation, can solve the problem of poor air permeability, bacterial cellulose having no antibacterial activity, and affecting wound healing and post-healing Quality and other issues, to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

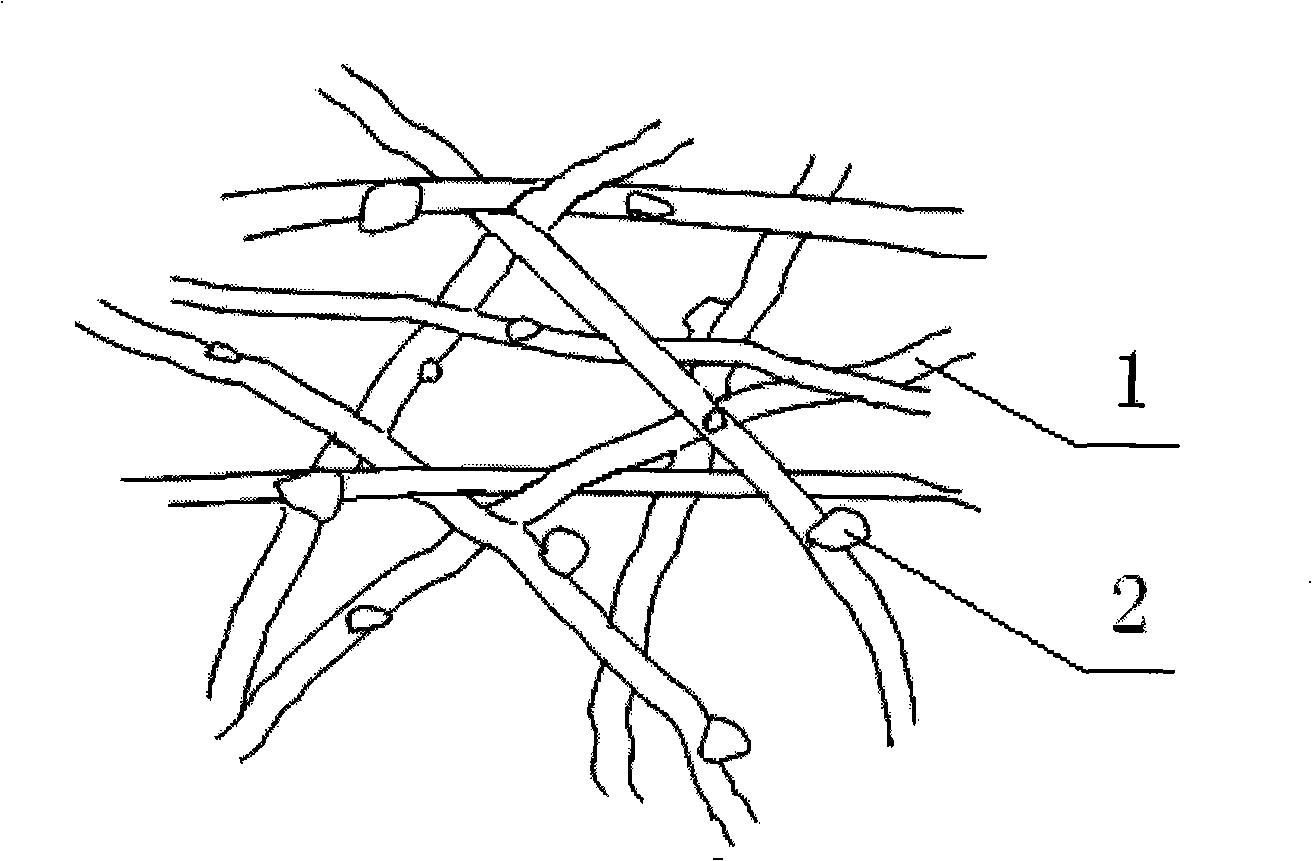

Image

Examples

Embodiment 1

[0024] The commercially available bacterial cellulose wet film prepared by Acetobacter xylinum was obtained by a conventional separation and purification method to obtain the bacterial cellulose wet film. Intercept the bacterial cellulose wet film 1cm with scissors 2 .

[0025] Step 1. Immerse the bacterial cellulose membrane in 10mL at room temperature with a concentration of 0.001mol L -1 In the silver nitrate solution, take it out after 1 minute;

[0026] Step 2, washing the bacterial cellulose membrane obtained by step 1 three times with double distilled water, each one minute;

[0027] Step 3, immerse the bacterial cellulose membrane obtained in step 2 into 10mL, the pH value is 9, and the concentration is 0.001mol L -1 Sodium chloride solution, take it out after 1 minute;

[0028] Step 4, washing the bacterial cellulose membrane obtained by step 3 three times with double distilled water, each one minute;

[0029] Step 5, repeat the above steps 9 times, that is, imme...

Embodiment 2

[0034] The commercially available bacterial cellulose wet film prepared by Acetobacter acetogenes was obtained by a conventional separation and purification method to obtain the bacterial cellulose wet film. Intercept the bacterial cellulose wet film 1cm with scissors 2 .

[0035] Step 1. Immerse the bacterial cellulose membrane in 10 mL at room temperature with a concentration of 0.0001 mol L -1 in the silver citrate solution, take it out after 5 minutes;

[0036] Step 2, washing the bacterial cellulose membrane obtained by step 1 three times with double distilled water, each one minute;

[0037] Step 3. Immerse the bacterial cellulose membrane obtained in step 2 into 10 mL, the pH value is 8, and the concentration is 0.0001 mol L -1 Potassium chloride solution, take out after 5 minutes;

[0038] Step 4, washing the bacterial cellulose membrane obtained by step 3 three times with double distilled water, each one minute;

[0039] Step 5, repeat the above steps 5 times, th...

Embodiment 3

[0043] Commercially available bacterial cellulose wet membranes prepared by Agrobacterium were obtained by conventional separation and purification methods to obtain bacterial cellulose wet membranes. Intercept the bacterial cellulose wet film 1cm with scissors 2 .

[0044] Step 1. Immerse the bacterial cellulose membrane in 10 mL at room temperature with a concentration of 0.0001 mol L -1 in silver nitrate solution for 2 minutes;

[0045] Step 2, washing the bacterial cellulose membrane obtained by step 1 three times with double distilled water, each one minute;

[0046] Step 3. Immerse the bacterial cellulose membrane obtained in step 2 into 10 mL, the pH value is 8, and the concentration is 0.0001 mol L -1 2 minutes in sodium chloride solution;

[0047] Step 4, washing the bacterial cellulose membrane obtained by step 3 three times with double distilled water, each one minute;

[0048]Step 5, repeat the above steps once, that is, immerse the membrane twice in silver ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com