Total mixed pellet feed for meat sheep and manufacturing method and application of feed

A pellet feed and fully mixed technology, which is applied in application, animal feed, animal feed, etc., can solve problems such as the utilization rate of roughage, achieve the effects of increasing daily weight gain, improving feed palatability, and ensuring rumen health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

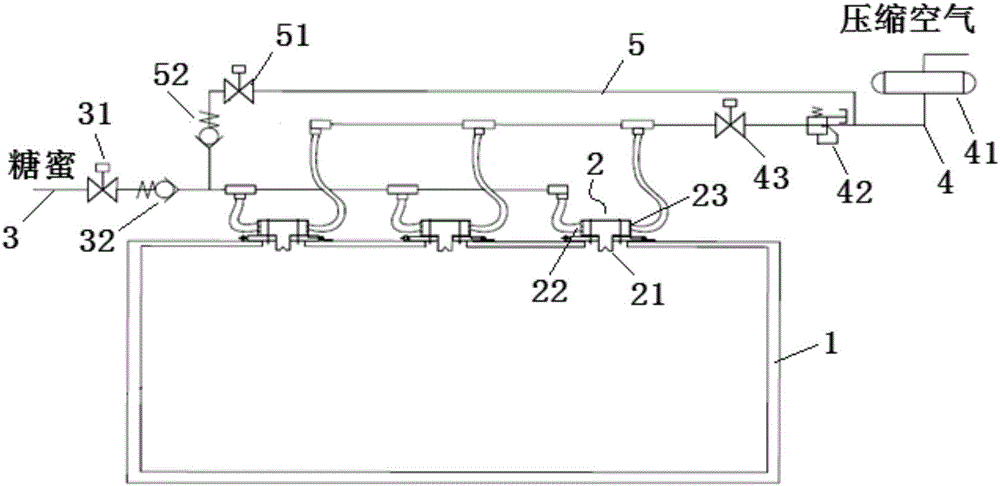

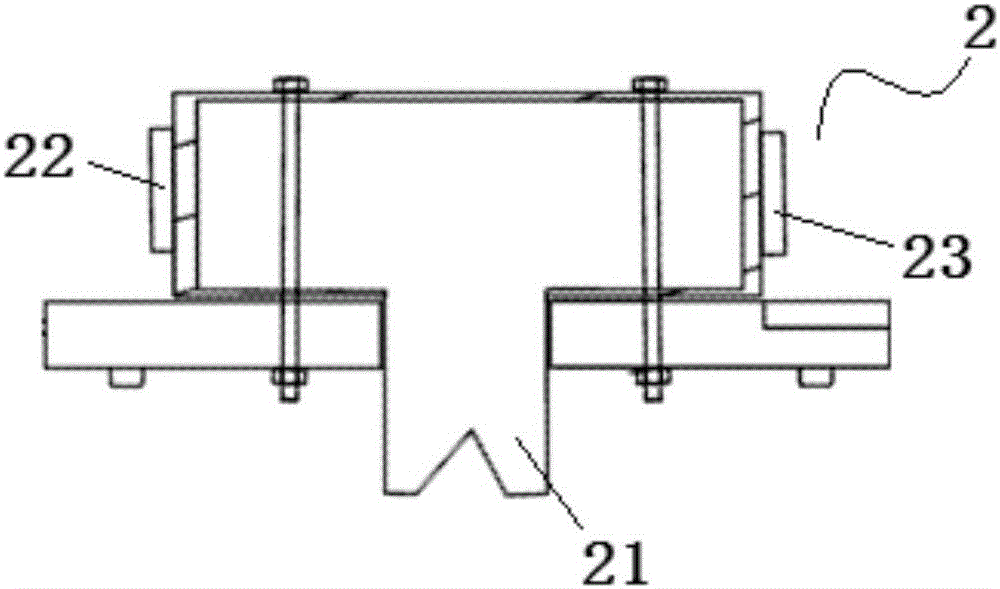

Method used

Image

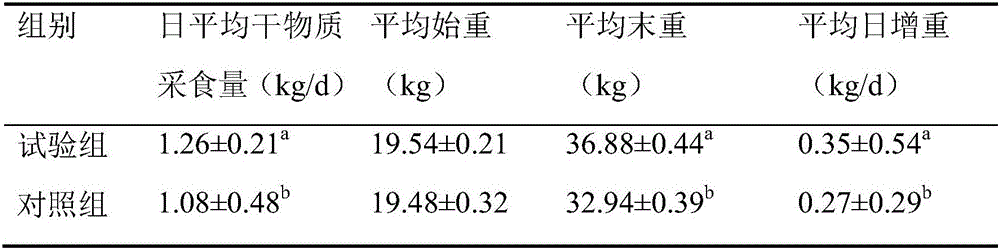

Examples

Embodiment 1

[0103] Embodiment 1. Preparing full mixed granular feed for mutton sheep in the early stage of fattening

[0104] 1. Formula

[0105] Straw 25.00%, Caragana 10.00%, Sunflower Hull 10.00%, Leymus chinensis 10.00%, Corn 20.00%, Molasses 9.00%, Soybean Meal 5.00%, Sesame Meal 2.00%, Corn Dried Distillers Grains (DDGS) 3.30%, Salt 0.80% , calcium hydrogen phosphate 0.36%, stone powder 0.60%, slow-release protein 0.50%, sodium bicarbonate 1.00%, antifungal agent 0.04%, ammonium chloride 0.40%, Chinese herbal medicine premix 1.00%, fattening mutton sheep premix 1.00%.

[0106] The composition of fattening mutton sheep premix is as follows: per kilogram of fattening mutton sheep premix contains vitamin A700000.00IU, vitamin D240000.00IU, vitamin E3500.00mg, copper1470.00mg, iron8860.00mg, zinc8820.00mg, manganese4280.00mg, iodine 135.00mg, selenium 55.00mg, cobalt 72.00mg, monensin 0.25kg, antioxidant 0.05kg, the balance is rice husk powder.

[0107] In parts by weight, the compo...

Embodiment 2

[0131] Embodiment 2, the whole mixed granular feed of mutton sheep is prepared in the fattening period

[0132] 1. Formula

[0133] Straw 20.00%, Caragana 5.00%, Sunflower husk 10.00%, Leymus chinensis 10.00%, Corn 25.00%, Molasses 10.00%, Soybean meal 5.00%, Cotton meal 2.00%, Corn germ meal 3.00%, Corn dry distillers grains (DDGS) 3.70%, salt 0.60%, calcium hydrogen phosphate 0.46%, stone powder 0.70%, slow-release protein 0.80%, sodium bicarbonate 1.00%, antifungal agent (0.04%, ammonium chloride 0.50%, Chinese herbal medicine premix 1.00%, fattening Meat sheep premix 1.20%.

[0134] The composition of fattening mutton sheep premix is as follows: per kilogram of fattening mutton sheep premix contains vitamin A 580000.00IU, vitamin D 200000.00IU, vitamin E 2900.00mg, copper 1225.00mg, iron 7383.00mg, zinc 7350.00mg, manganese 3566.00mg, iodine 112.50 mg, selenium 46.00mg, cobalt 60.00mg, monensin 0.21kg, antioxidant 0.05kg, and the balance is rice husk powder.

[0135] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com