System and method for detecting key parameters of large-power vibration valve

A technology of key parameters and detection system, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as difficulty in guaranteeing qualified products of valve bodies, large space required for testing work, and high labor intensity, etc. Achieve the effect of saving labor auxiliary manpower and producing raw materials, reducing testing costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

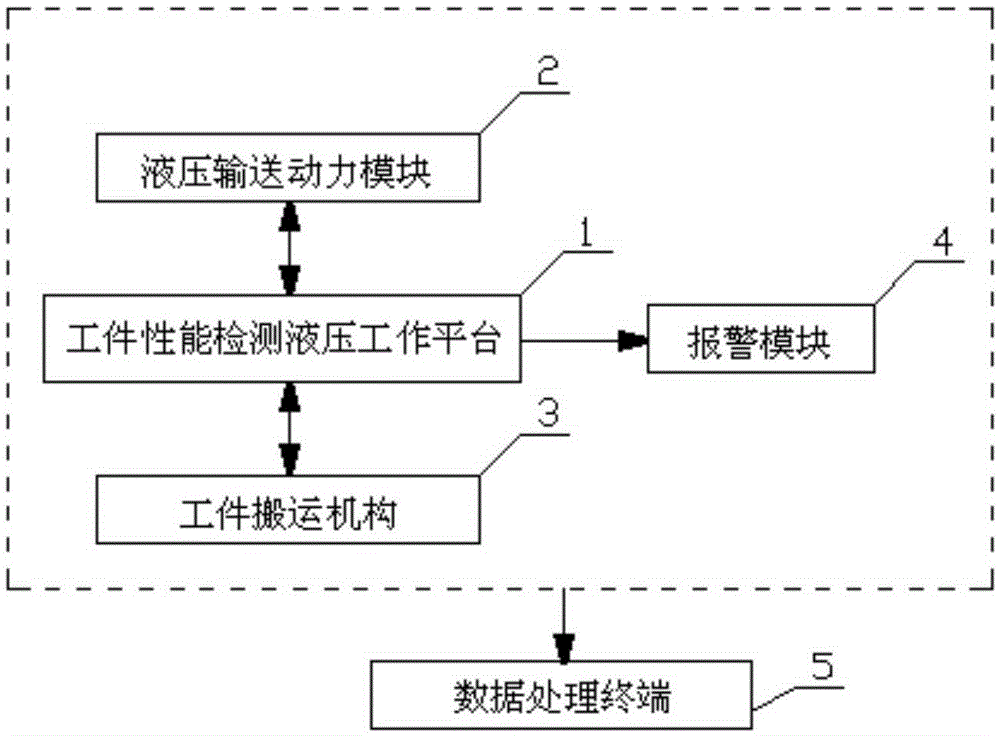

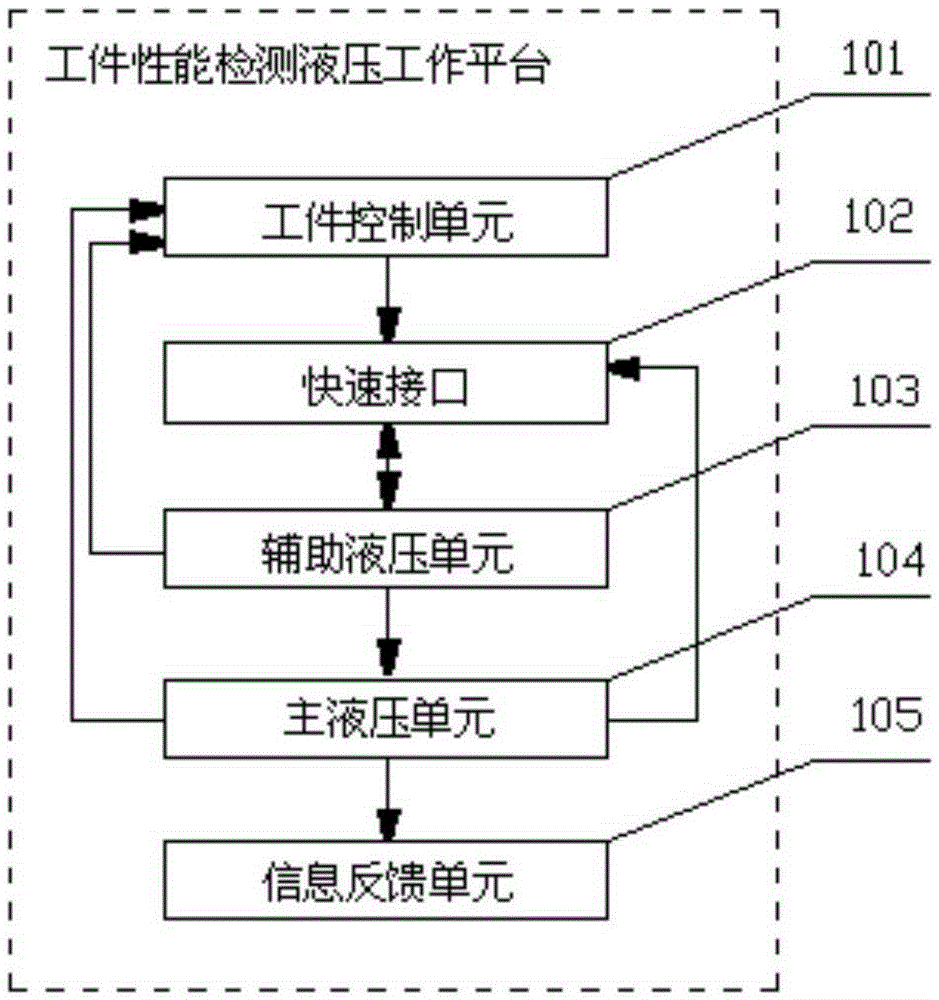

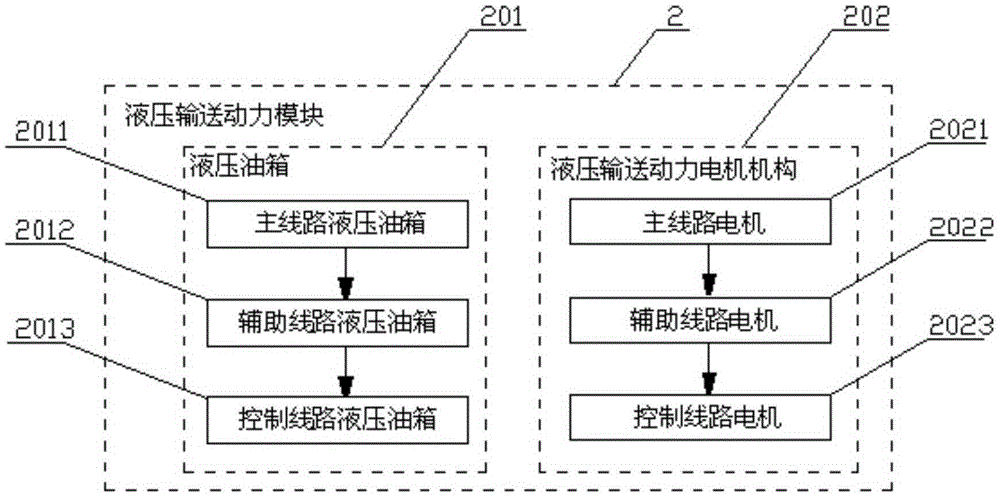

[0080] Figure 7 It is a layout diagram of each equipment of the detection device, and the workpiece performance detection hydraulic work platform 1 also includes a frame 6, a hydraulic pipeline, a solenoid valve integrated control device 106, and an electrical control system. The operation process of this detection device includes feeding and hydraulic positioning, hydraulic clamping and liquid circuit docking, leakage (sealing performance) detection, reversing (running performance) detection, and the steps of discharging:

[0081] 1) Feeding and hydraulic positioning: such as Figure 8 As shown, the workpiece handling mechanism will load the detected workpiece to the detection table, press the detected workpiece, start the feed control button, push the feed hydraulic cylinder, and the proximity switch controls the stroke of the hydraulic cylinder, and the workpiece enters the correct detection position;

[0082] 2) Hydraulic clamping and liquid circuit docking: After the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com