Method for processing crude oil with high acid value

A high acid value, crude oil technology, applied in the petroleum industry, cracking, catalytic cracking, etc., can solve the problems of high operating cost, difficult industrial implementation, and unreported process methods, so as to avoid corrosion, inhibit harmful effects, and deacidify good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

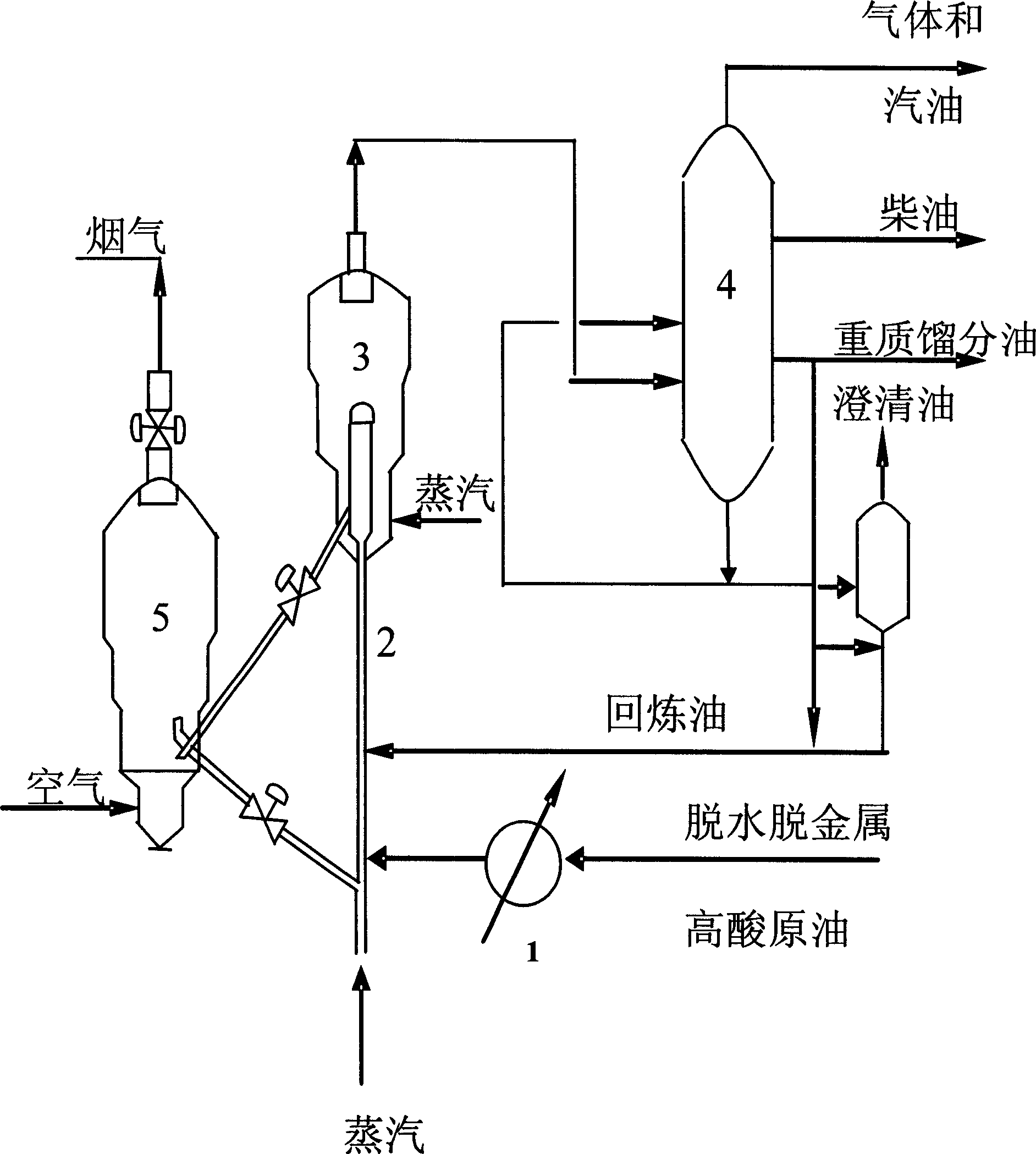

Image

Examples

Embodiment 1

[0025] This example illustrates: the deacidification effect of the method provided by the present invention.

[0026] On a small fixed fluidized bed device, experiments were carried out using Sudan high-acid crude oil A (see Table 1 for physical and chemical properties) and MLC-500 catalyst (commercial brand, industrially produced by Qilu Petrochemical Company Catalyst Factory). MLC-500 catalyst is a balancer taken from an industrial device, its microreaction activity is 62, and its Ni content is 15000μg.g -1 , V content is 6500μg.g -1 , and other physical and chemical properties are shown in Table 2. The deacidification effect under the conditions of different temperature, agent-oil ratio and space velocity was investigated through experiments, and the experimental results are shown in Table 3-5.

[0027] The calculation method of deacidification rate is as follows: deacidification rate=(total acid value of high-acid crude raw material-total acid value of obtained liquid ph...

Embodiment 2

[0034] This embodiment illustrates: the deacidification effect and product distribution of the method provided by the present invention.

[0035] On a small fixed fluidized bed device, the same high-acid crude oil and catalyst as in Example 1 were used for the experiment. The deacidification effect and product distribution were investigated through experiments, and the experimental results are shown in Table 5.

[0036] Process conditions

Embodiment 3

[0038] On the multi-functional catalytic cracking medium-sized unit (the treatment capacity of this unit is 4kg / hr), high-acid crude oil B (see Table 7 for physical and chemical property parameters) and DVR-2 catalyst (trade name, industrial production of catalyst factory of Qilu Petrochemical Company, physical and chemical The properties are shown in Table 8) for experiments. The deacidification effect, product distribution and main properties of high-acid crude oil were investigated through experiments. The experimental results are shown in Table 9.

[0039] Density(20℃) / g·cm -3

[0040] Chemical composition, wt%

[0041] operating conditions

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com