Method for processing highly acidic crude oil

A high-acid crude oil and process technology, applied in the petroleum industry, cracking, catalytic cracking and other directions, can solve the problems of high residual carbon and heavy metal content, insufficient vaporization of raw materials, blockage of the riser inlet, etc., and achieves low cracking reaction depth and cost. Low, avoid corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

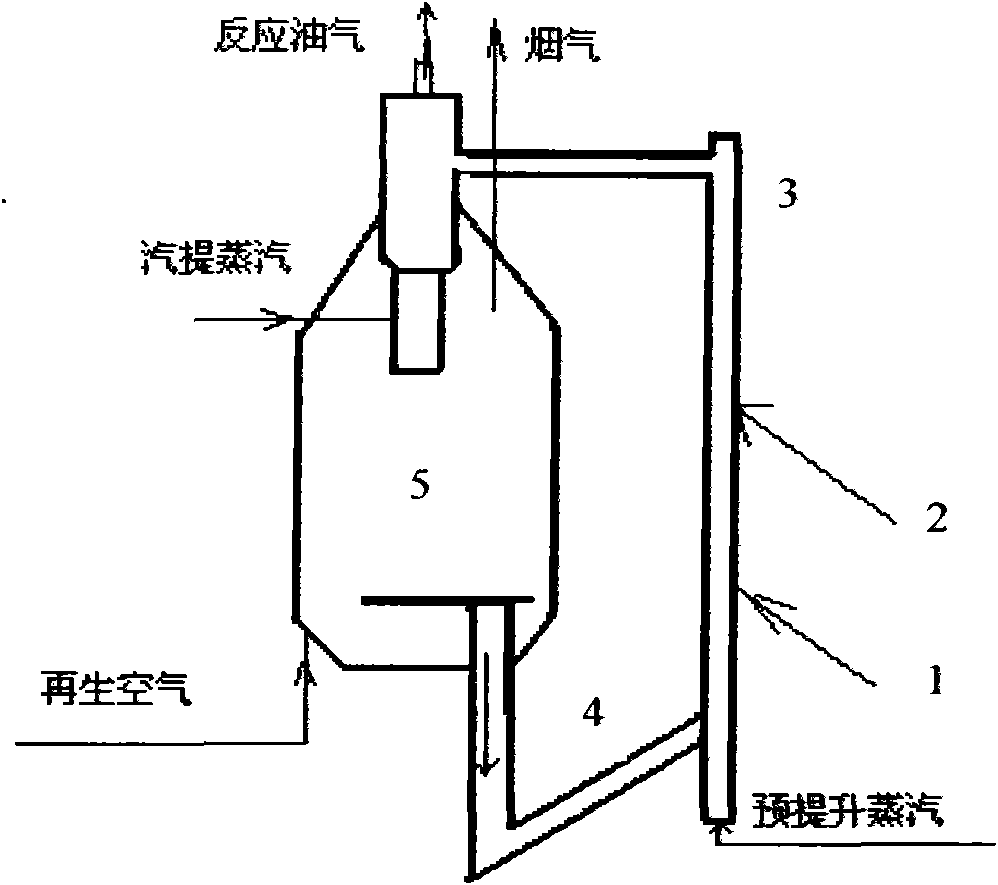

Image

Examples

Embodiment 1-5

[0030] Example description: the deacidification effect and product distribution of the method provided by the present invention.

[0031] Examples 1-5 were all carried out on a small-scale riser fluidized catalytic cracking unit. The primary feed of the riser is Iranian VGO, the secondary feed of the riser is Qinhuangdao high-acid crude oil, and the catalyst is LBO-16 (an industrial balancer produced by Lanzhou Catalyst Factory). The aim is to investigate the deacidification effect under different operating conditions. The properties of Iranian VGO and Qinhuangdao high-acid crude oil are shown in Table 1, the catalyst properties are shown in Table 2, and the main process conditions, product distribution and main product properties of the experiment are shown in Table 3.

[0032] The calculation method of deacidification rate is as follows: deacidification rate=(total acid value of high-acid crude raw material-total acid value of obtained liquid phase product) / total acid value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com