Method and device for physically deacidifying and deodorizing grease with high acid value and thermal instability

A thermally unstable, physical deacidification technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of difficult to use continuous refining process, small scale and batch size, etc., to control the cost, energy consumption and production. Low cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

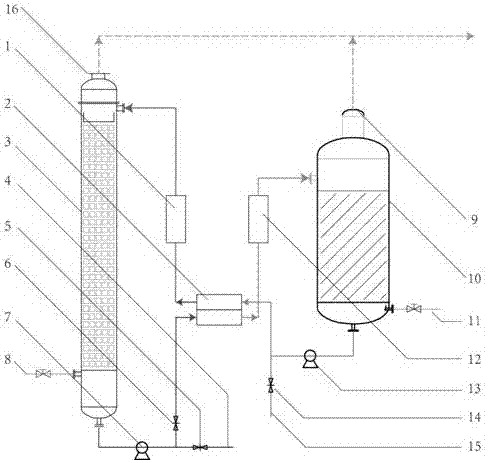

Image

Examples

Embodiment 1

[0039] The oil to be deacidified and deodorized is a batch of 2 tons of rubber tree seed oil with high acid value (acid value 25mgKOH / 100g) and heat instability (linolenic acid content 20%) that has been pretreated (degummed and decolorized). The following methods are used for deacidification and deodorization:

[0040] (1) The above-mentioned small batch, high acid value, thermally unstable oil to be deacidified and deodorized is deacidified by steam for 6 minutes at a temperature of 260°C and an absolute pressure of 100-250Pa;

[0041] (2) The grease obtained in step (1) is cooled to 200°C by heat exchange, and under an absolute pressure of 100-250Pa, deodorization treatment is carried out by passing water vapor for 30 minutes;

[0042] (3) Heat the oil obtained in step (2) to 260°C by heat exchange, carry out deacidification treatment according to step (1), and then carry out deodorization treatment according to step (2), repeat steps (1) and (2) Operate until the acid val...

Embodiment 2

[0049] The oil to be deacidified and deodorized is a batch of 2 tons of rubber tree seed oil with high acid value (acid value 45mgKOH / 100g) and heat instability (linolenic acid content 20%) that has been pretreated (degummed and decolorized).

[0050] The operation is the same as in Example 1, only the temperature of the deacidification tower is controlled at 240°C, and the temperature of the deodorization tank is controlled at 180°C.

[0051] In this operation, the oil circulates twice in the device on average, is heated for 12 minutes in the deacidification tower at 240°C, and has an average residence time of 60 minutes in the deodorization tank at 180°C (including the initial heating process). The oil after deacidification and deodorization is measured: the acid value is 0.7mgKOH / 100g, which meets the acid value requirements of first-grade oil in the enterprise standard (≤1mgKOH / 100g); the content of isomerized fatty acid is 0.22g / 100g, which meets the "GB 28050 Below the "...

Embodiment 3

[0053] The oil to be deacidified and deodorized is a batch of 2 tons of high acid value (acid value 18mgKOH / 100g) and thermally unstable (linolenic acid content 42%) sachaeji fruit oil that has been pretreated (degummed and decolorized).

[0054] The operation is the same as in Example 1, only the temperature of the deacidification tower is controlled at 240°C, and the temperature of the deodorization tank is controlled at 180°C.

[0055] In this operation, the oil circulates twice in the device on average, is heated for 12 minutes in the deacidification tower at 240°C, and has an average residence time of 60 minutes in the deodorization tank at 180°C (including the initial heating process). The oil after deacidification and deodorization is measured: the acid value is 0.8mgKOH / 100g, which meets the acid value requirements in the enterprise standard (≤3mgKOH / 100g); the content of isomerized fatty acid is 0.25g / 100g, which meets the requirements of "GB 28050 Food Safety National...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com