Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

271results about "Food membrane process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

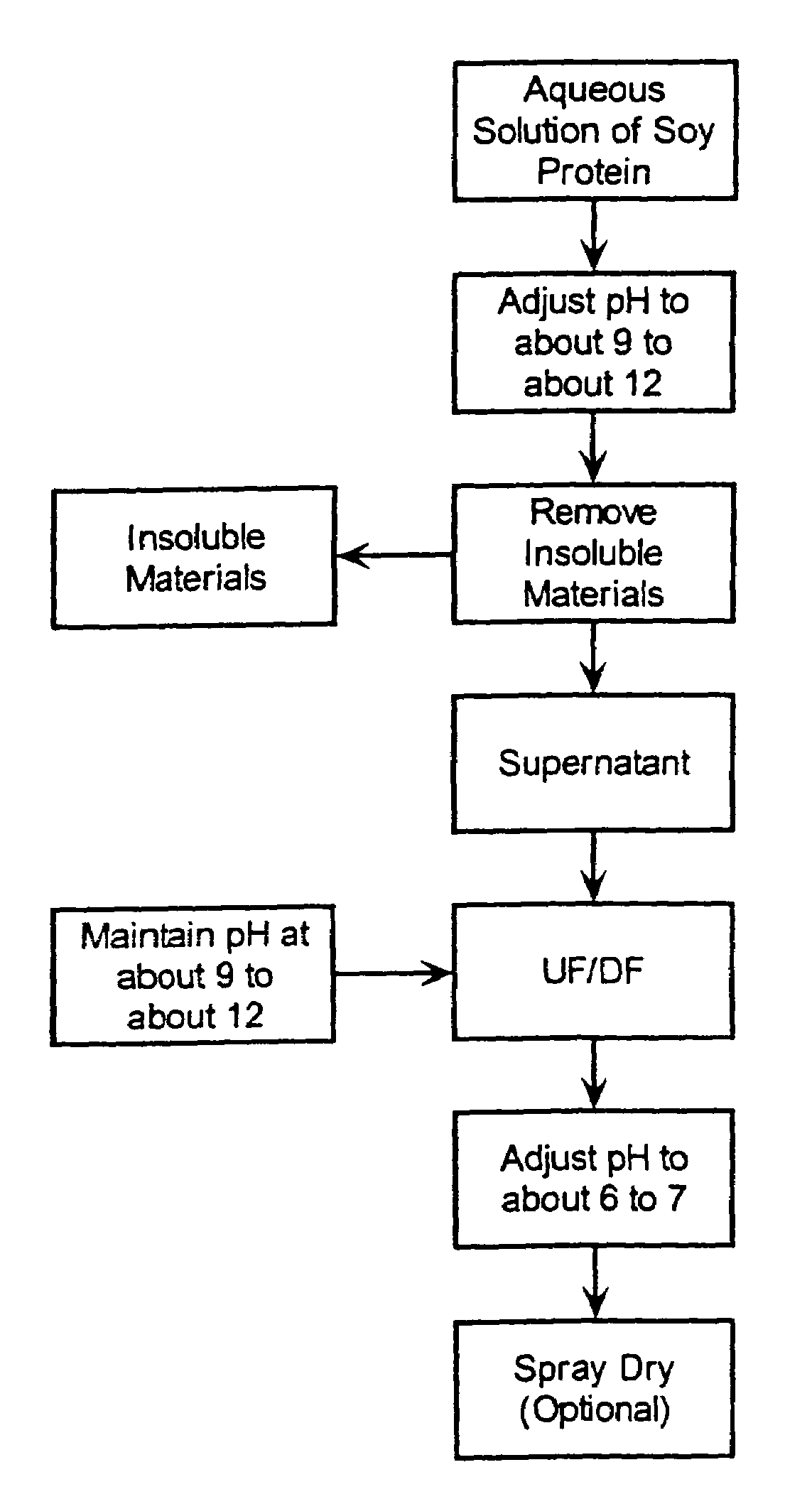

Production of Soluble Protein Solutions from Soy ("S701")

ActiveUS20100098818A1Prevent oxidationMilk preparationProtein composition from vegetable seedsProtein solutionSports drink

A soy protein product, which may be an isolate, produces transparent heat-stable solutions at low pH values and is useful for the fortification of soft drinks and sports drinks without precipitation of protein. The soy protein product is obtained by extracting a soy protein source material with an aqueous calcium salt solution to form an aqueous soy protein solution, separating the aqueous soy protein solution from residual soy protein source, adjusting the pH of the aqueous soy protein solution to a pH of about 1.5 to about 4.4 to produce an acidified clear soy protein solution, which may be dried, following optional concentration and diafiltration, to provide the soy protein product.

Owner:BURCON NUTRASCI MB

Whey protein product and a method for its preparation

InactiveUS20110097442A1Improve sensory propertiesImprove stabilityMilk preparationMetabolism disorderWhey proteinTotal protein

The invention relates to a whey protein product having a ratio of whey protein to casein in the range from about 90:10 to about 50:50 and the total protein content of at least 20% on dry matter basis, and a method for its preparation. The product has a favourable amino acid composition and is especially suitable for athletes.

Owner:VALIO OY

Protein isolation procedures for reducing phytic acid

ActiveUS20050255226A1Reduced phytic acid contentHigh nutritional valueBiocideProtein composition from vegetable seedsIsolation proceduresProtein isolate

Owner:BURCON NUTRASCI MB

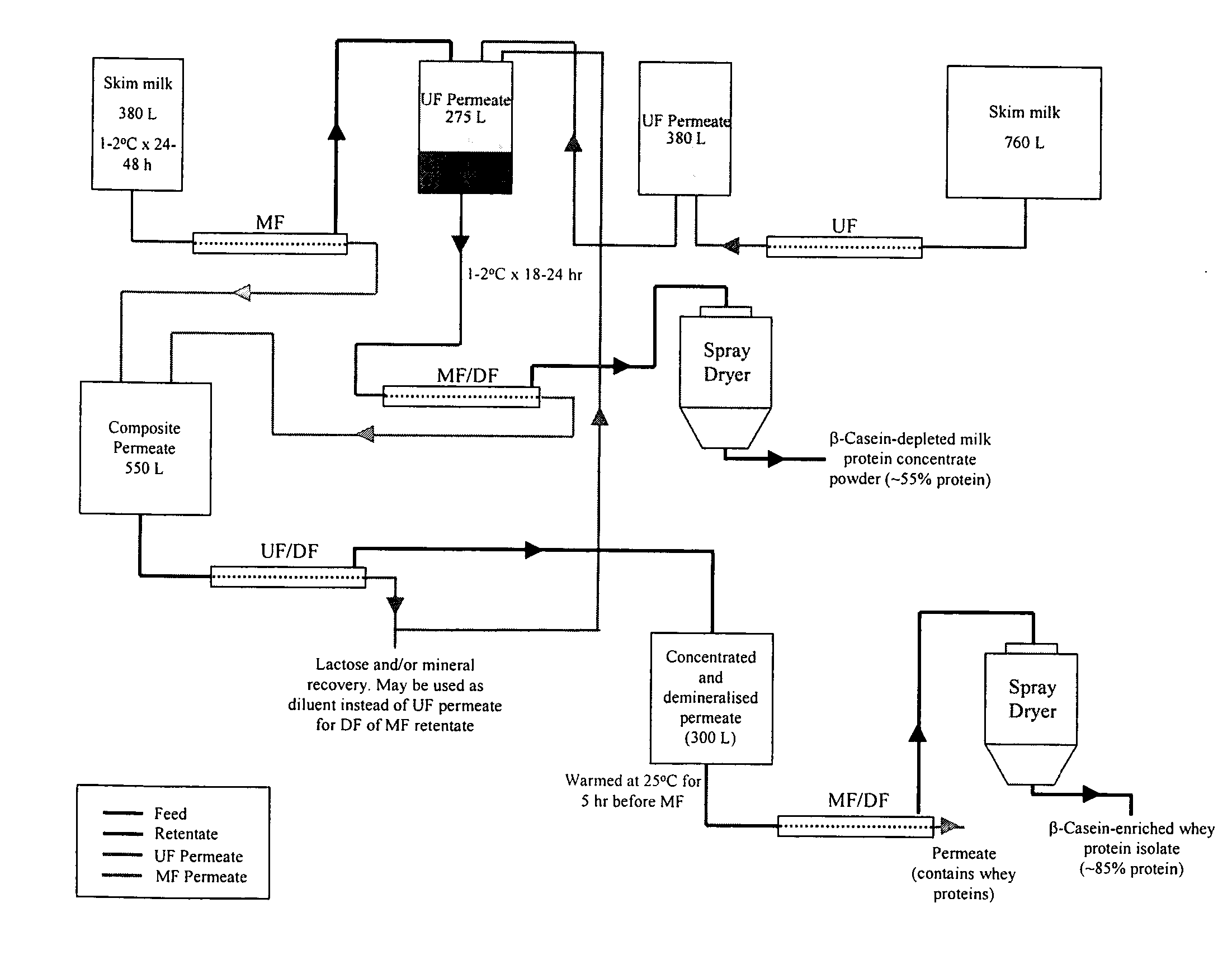

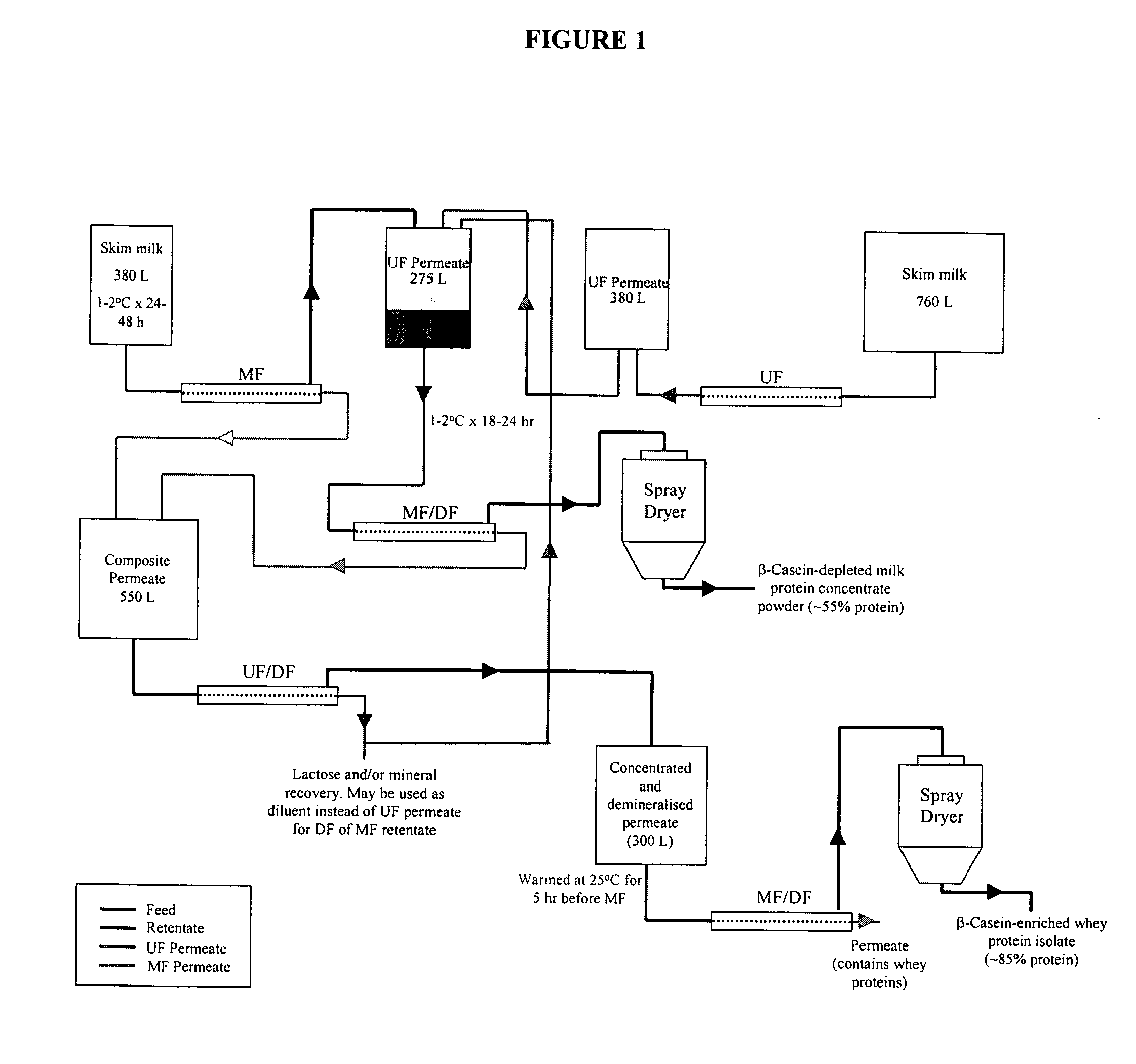

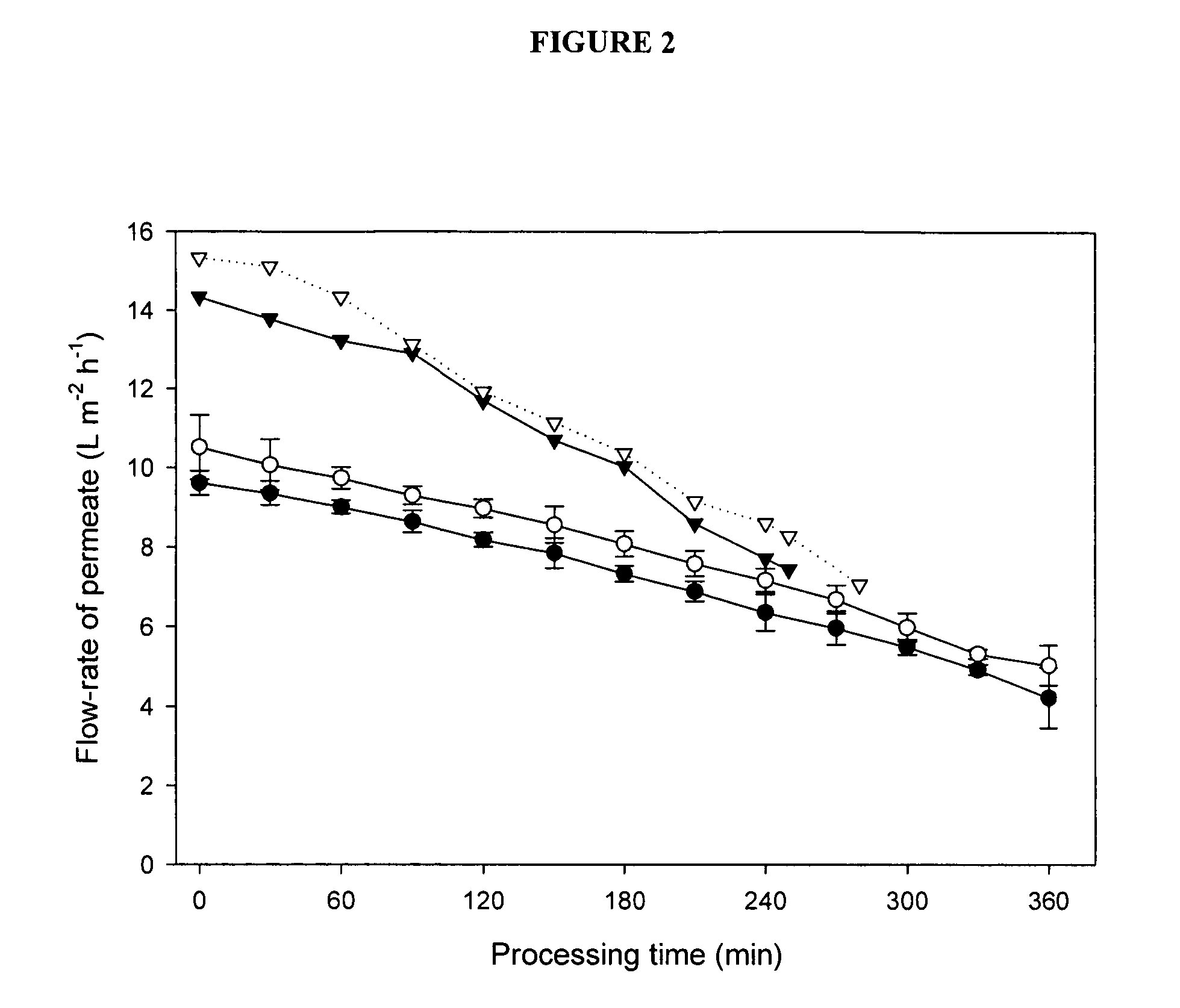

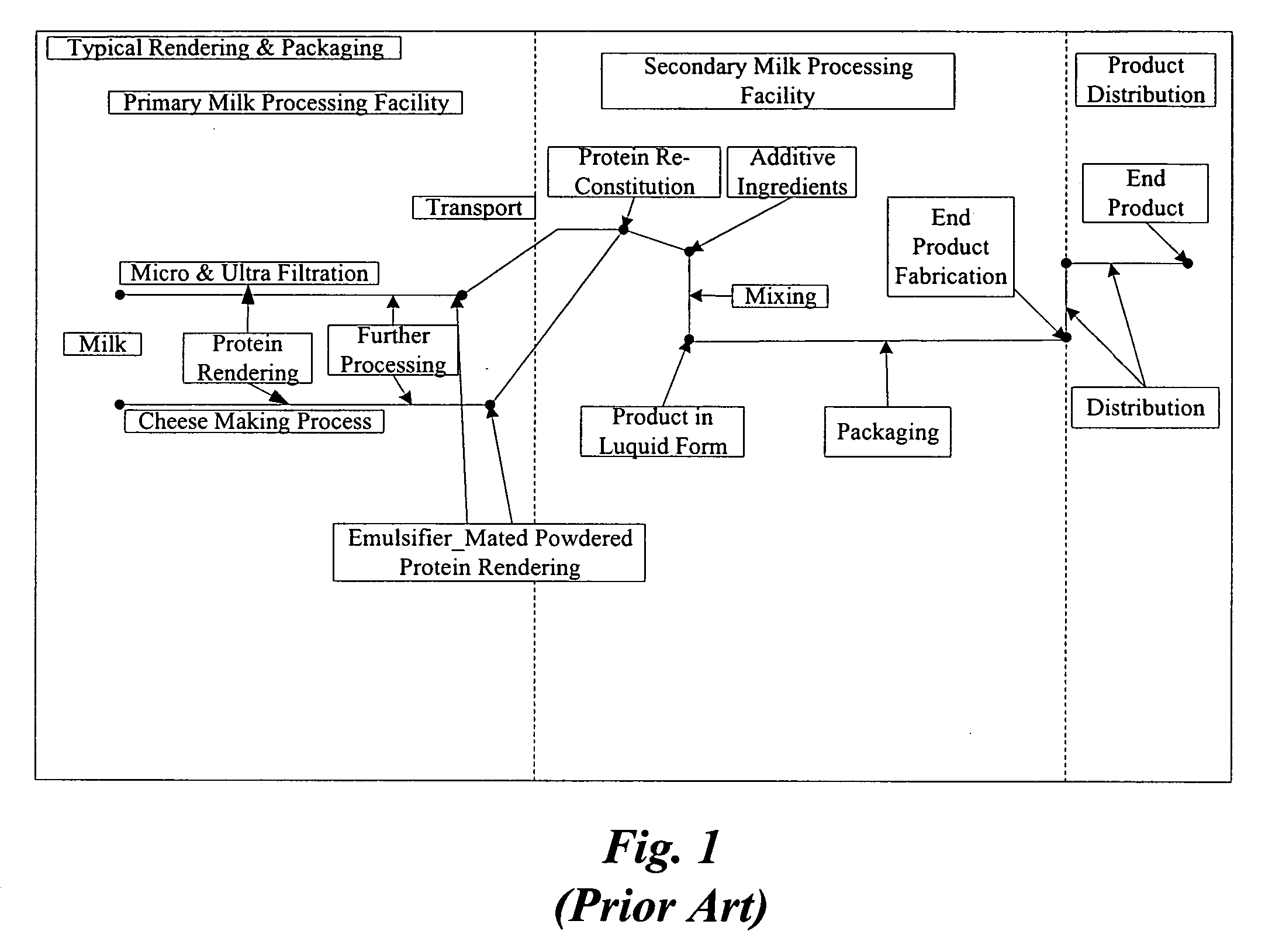

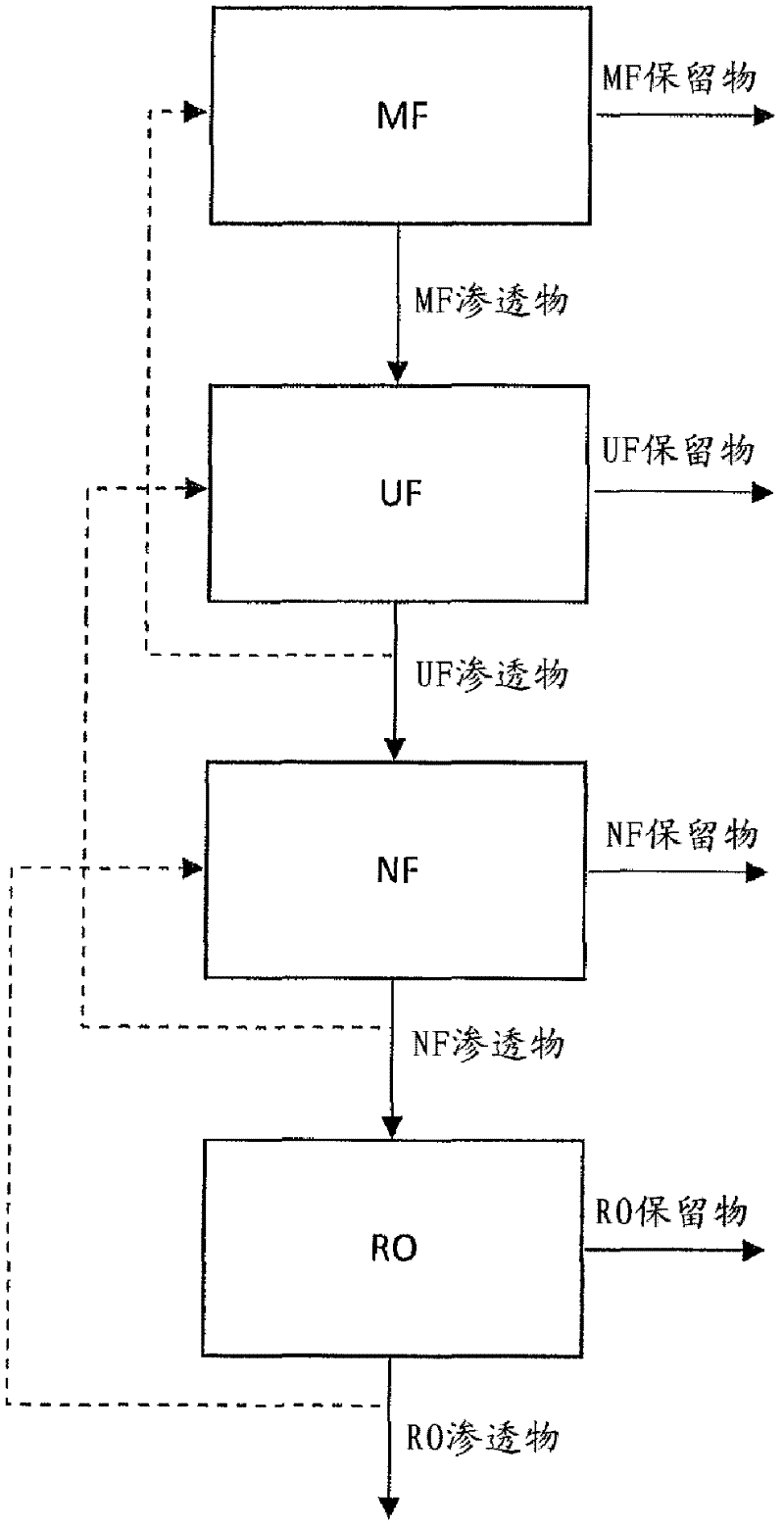

Purification of beta casein from milk

ActiveUS20070104847A1Without negatively impactingFunctionalMilk preparationFood membrane processMilk SerumMicrofiltration membrane

A method is provided for obtaining β-casein from skim milk. Purification of β-casein from milk is achieved through a process of microfiltration using cross-flow polymeric microfiltration membranes. Cooling of the milk prior to microfiltration results in improved separation of β-casein from the other milk serum proteins. Further filtration and demineralization of the microfiltered permeate results in enrichment of the fraction containing soluble β-casein. An integrated scheme that allows a dairy plant to continuously separate and purify β-casein is provided. Also provided is a method for obtaining cheese with improved meltability and reduced bitterness.

Owner:WISCONSIN ALUMNI RES FOUND

Production of soluble protein solutions from soy ("S701" CIP)

ActiveUS20110038993A1Prevent oxidationProtein composition from vegetable seedsFood ingredient as solubility improving agentProtein solutionSports drink

A soy protein product, which may be an isolate, produces transparent heat-stable solutions at low pH values and is useful for the fortification of soft drinks and sports drinks without precipitation of protein. The soy protein product is obtained by extracting a soy protein source material with an aqueous calcium salt solution to form an aqueous soy protein solution, separating the aqueous soy protein solution from residual soy protein source, adjusting the pH of the aqueous soy protein solution to a pH of about 1.5 to about 4.4 to produce an acidified clear soy protein solution, which may be dried, following optional concentration and diafiltration, to provide the soy protein product.

Owner:BURCON NUTRASCI MB

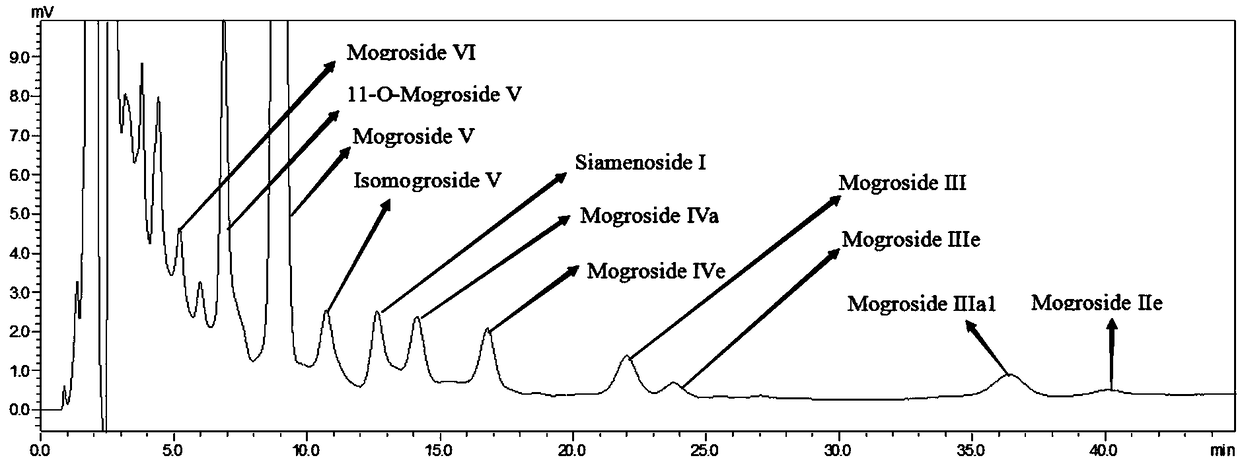

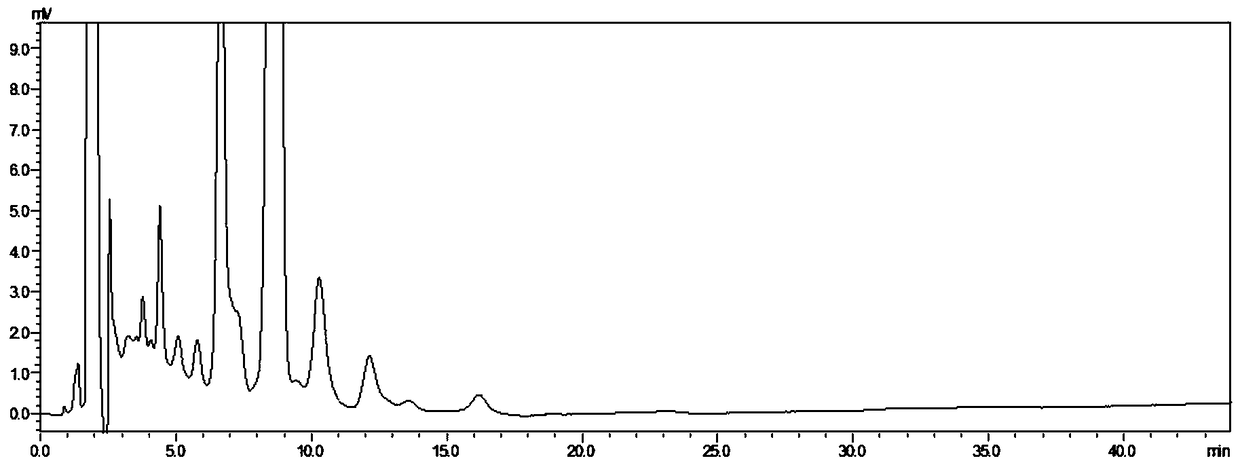

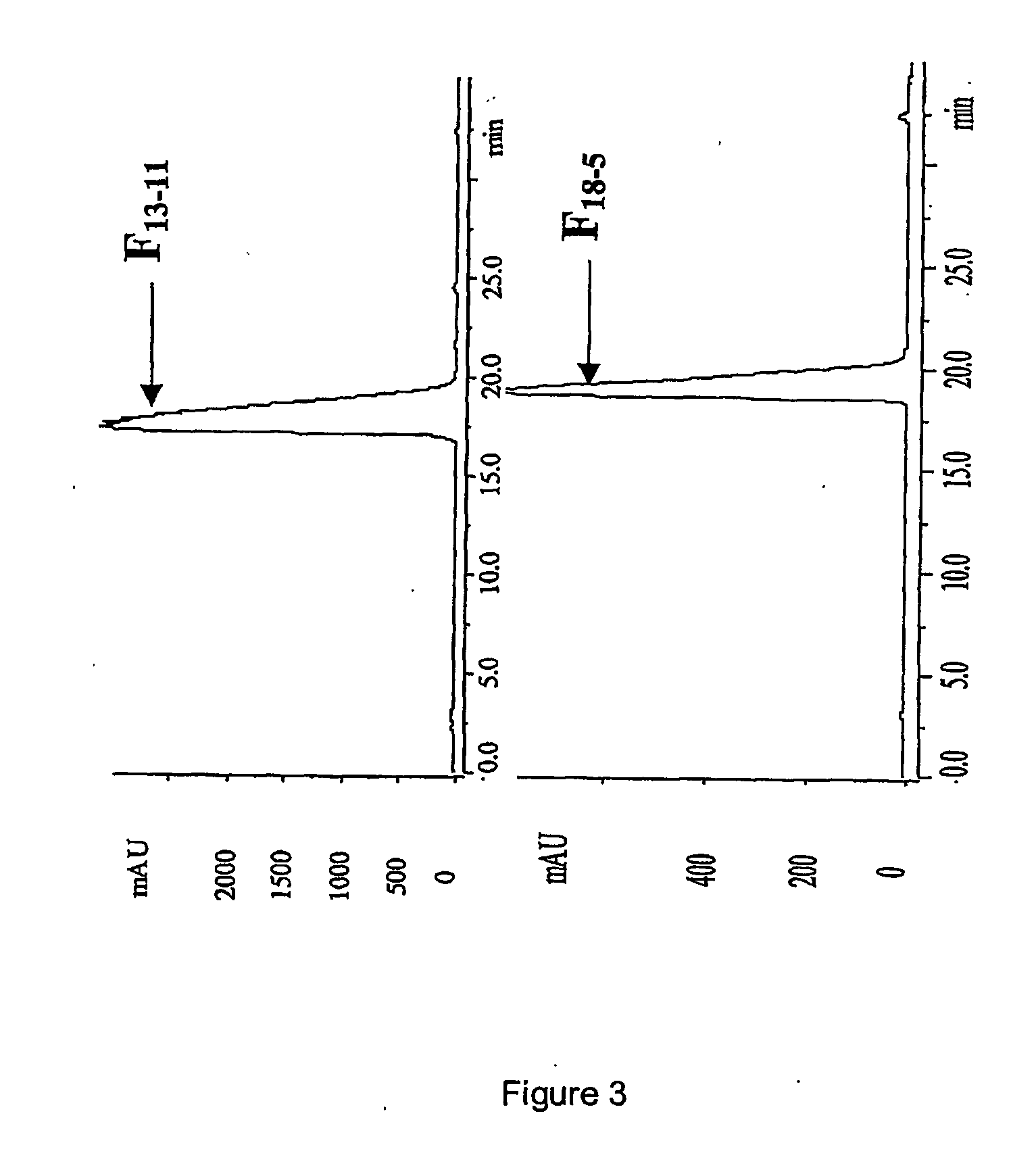

High-Purity Mogrosides And Process For Their Purification

The present invention provides a process for preparation of highly purified mogrosides mixture from low purity mogrosides mixture. The process comprises providing a mixture of low purity mogrosides, dissolving the low purity mogrosides mixture in water or an aqueous alcohol solution to form an initial solution of mogrosides, passing the initial solution through a column system, wherein the column system comprises a plurality of columns, and each column is packed with a sorbent having different affinities to impurities and mogrosides so that one or more columns retains more mogrosides than other columns, washing the columns to remove impurities with an acidic aqueous solution, a basic aqueous solution, and an aqueous alcoholic solution successively, eluting the columns with an aqueous alcohol solution that contains higher alcohol content than the aqueous alcohol solution used in the washing step, wherein the eluate from the columns with high content of mogrosides are combined, and drying the combined eluate to obtain high purity mogrosides with the content of the total mogrosides are more than 70% (w / w). The present invention also provides a sweetener mixture and product comprising high purity mogrosides.

Owner:PURECIRCLE SDN BHD

Production of high-quality protein isolates from defatted meals of Brassica seeds

The present invention provides a method for processing defatted oil seeds, comprising the steps of: (a) solubilizing at least a portion of the protein contained in the oil seeds to produce suspended residual solids and a first solution comprising protein, phenolic-protein complexes, and free phenolic compounds; (b) separating at least a portion of the free phenolic compounds from the first solution and recovering a free phenolic reduced solution; and (c) treating the free phenolic reduced solution to precipitate at least a portion of the protein as a precipitated protein isolate and recovering a treated solution containing a soluble protein isolate. Novel protein products are also disclosed. Food and drink products containing the novel protein products are also disclosed.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

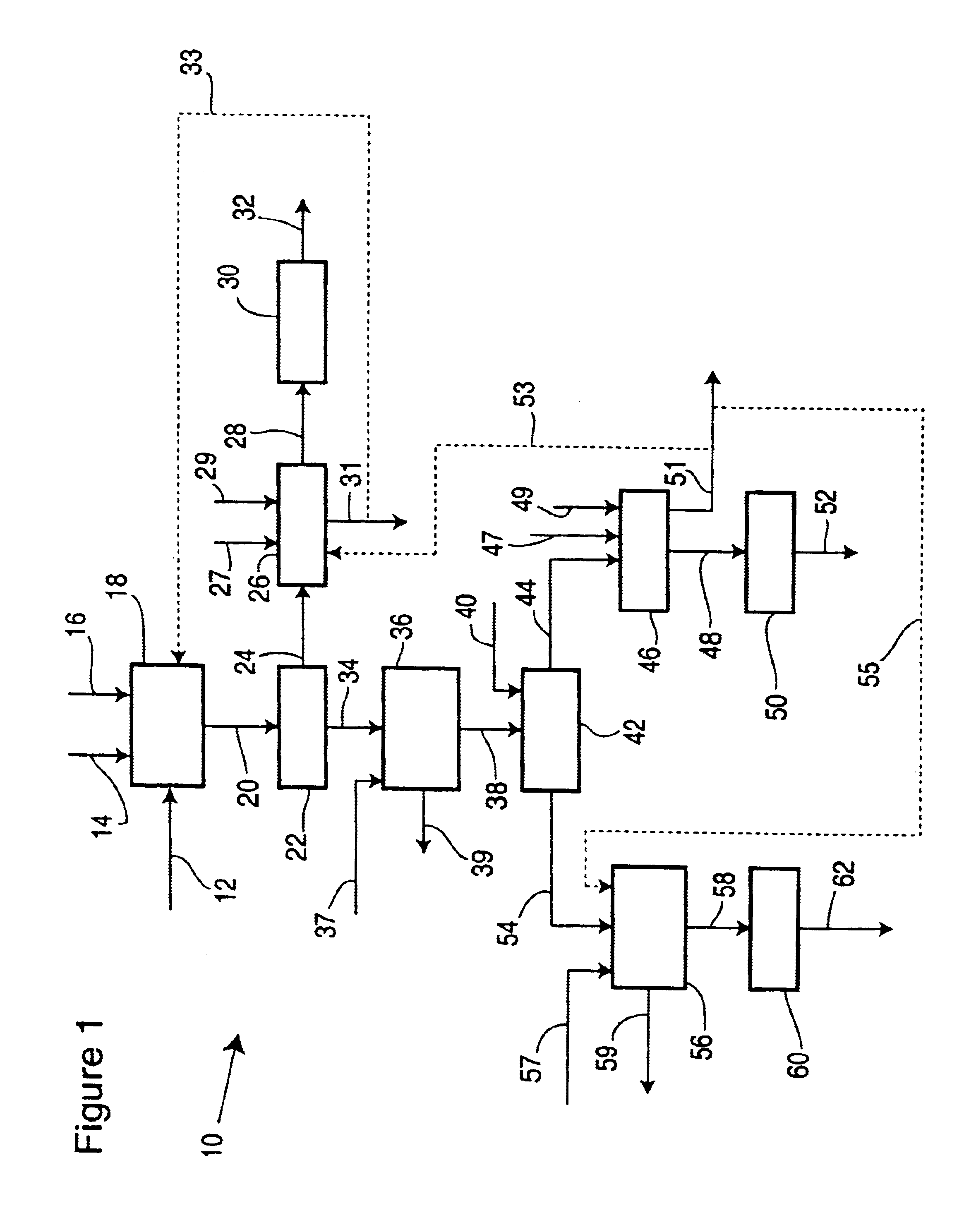

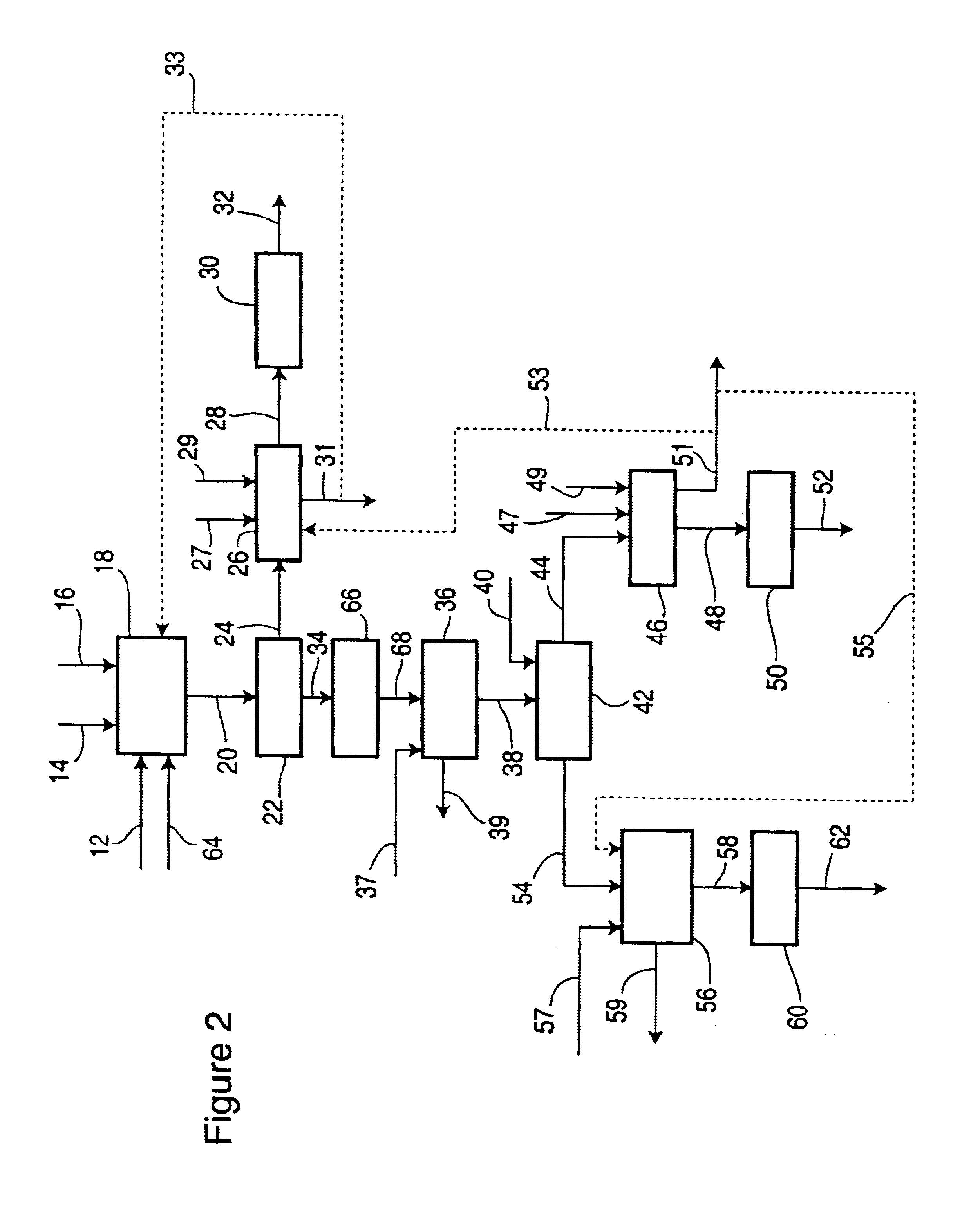

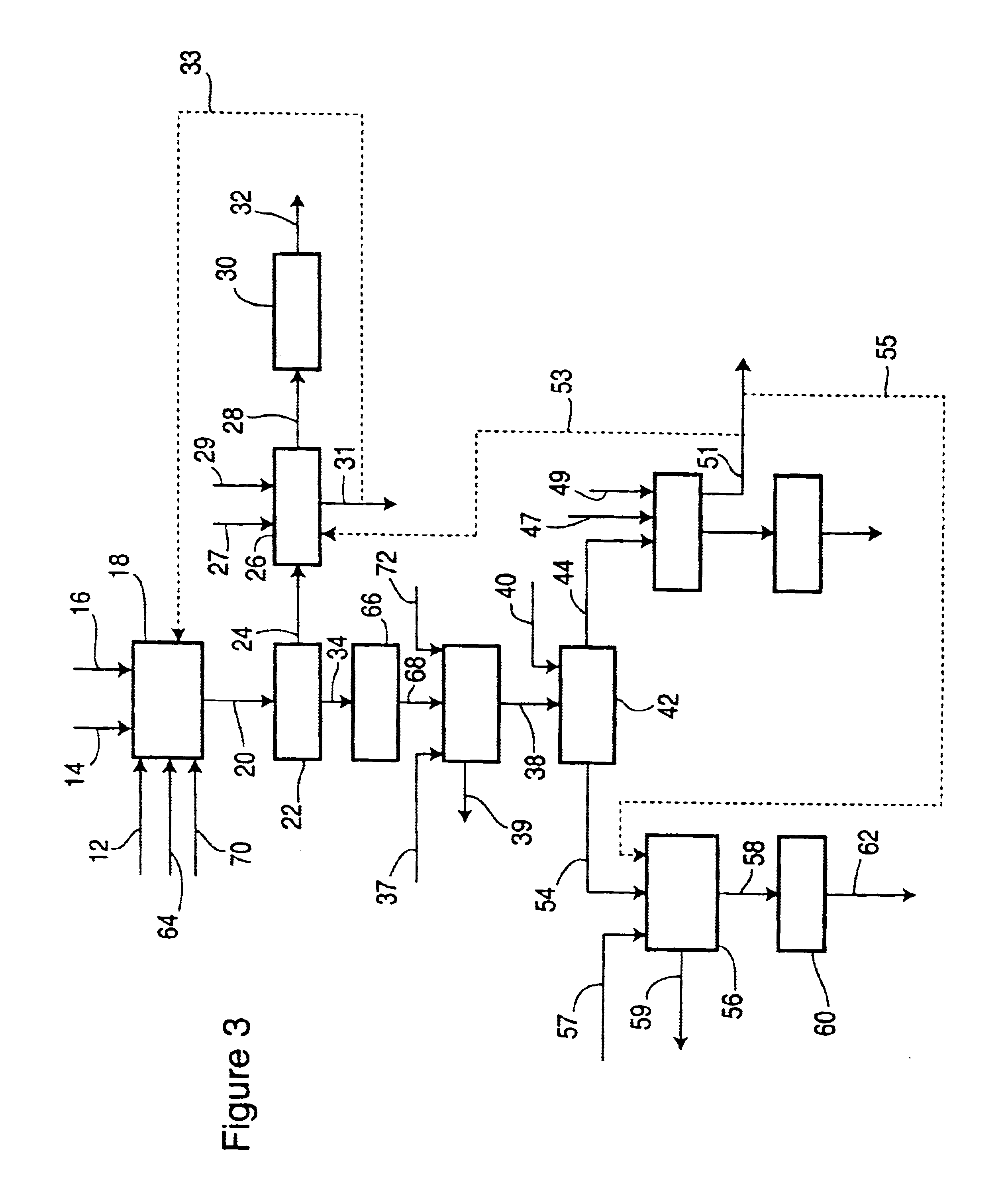

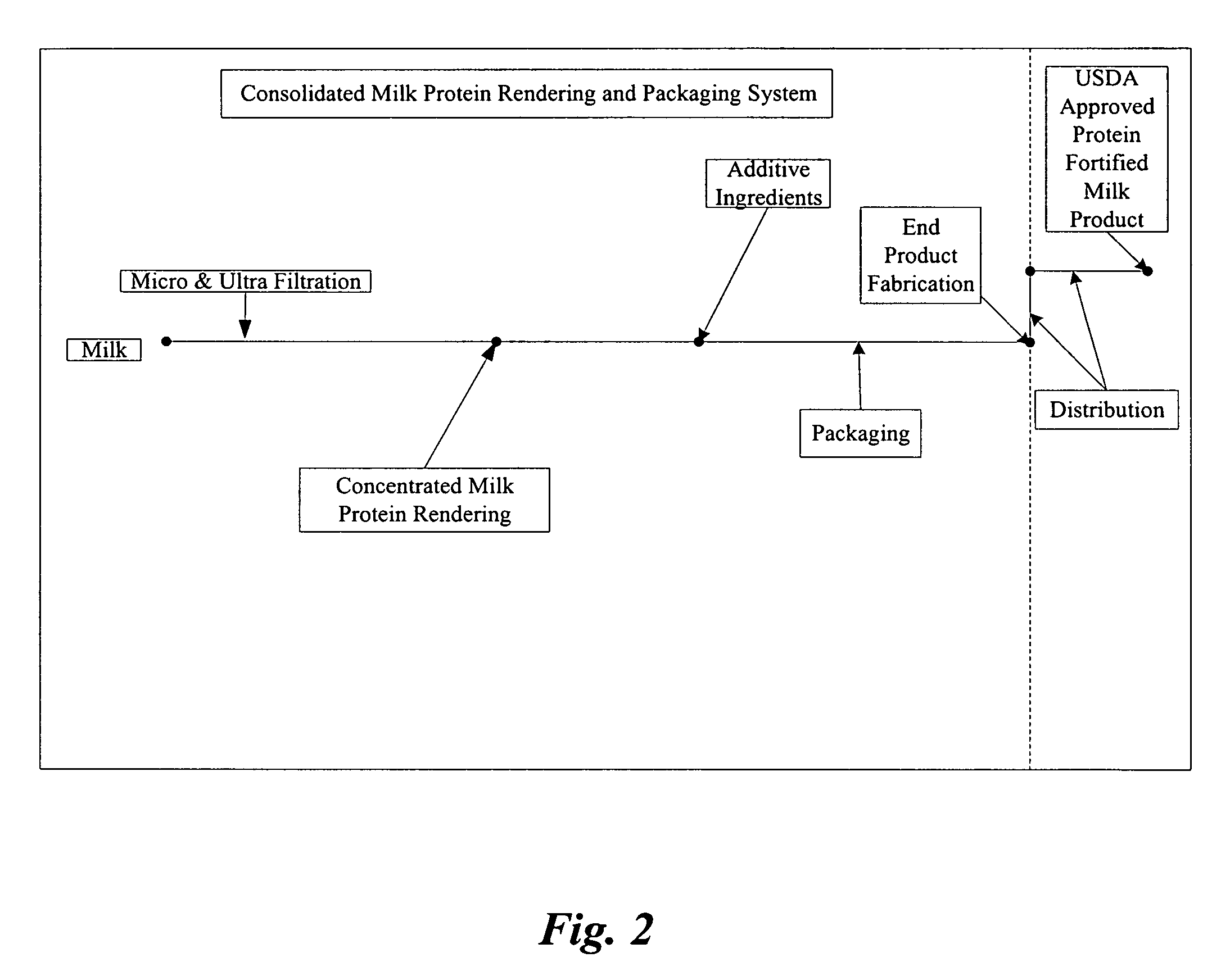

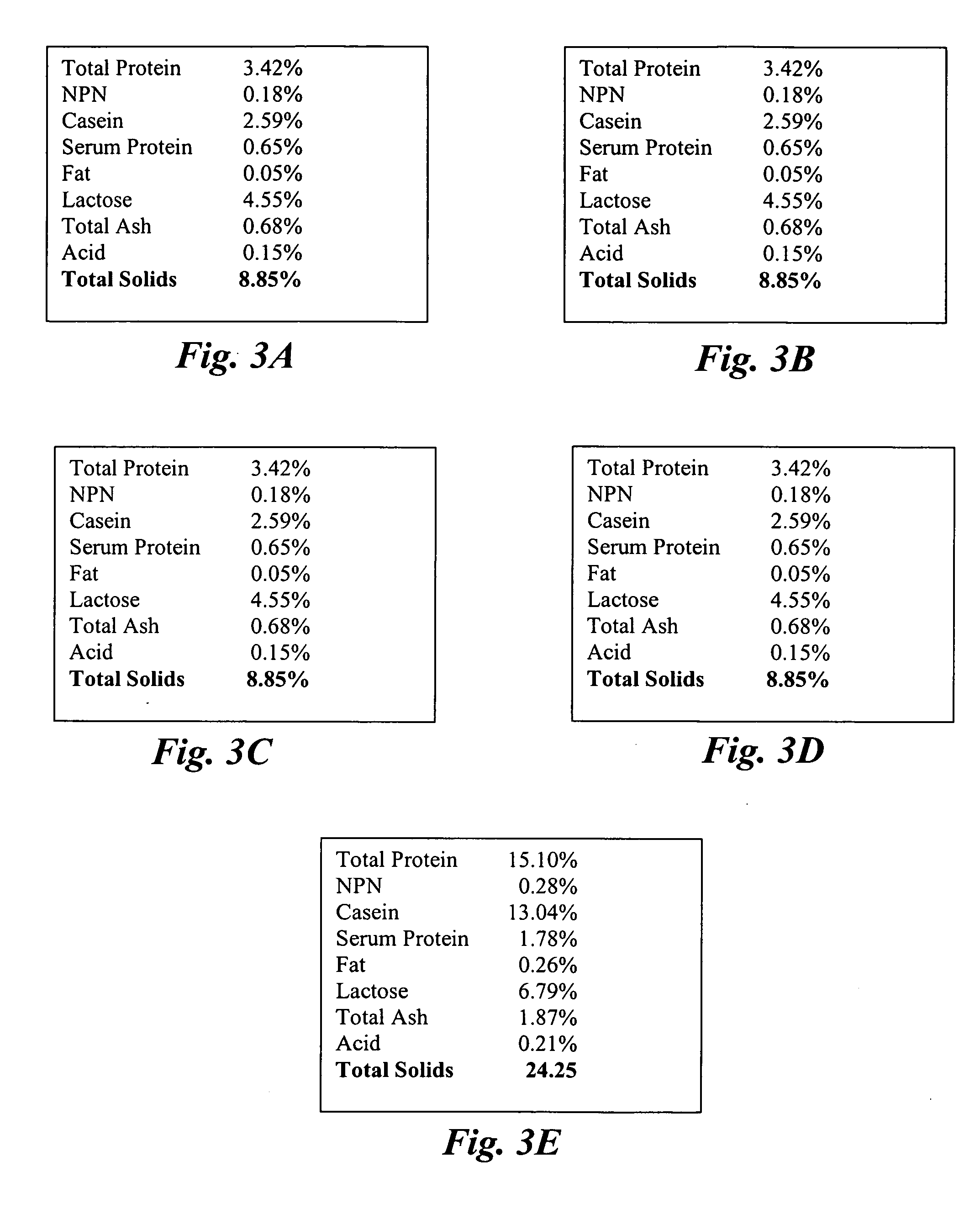

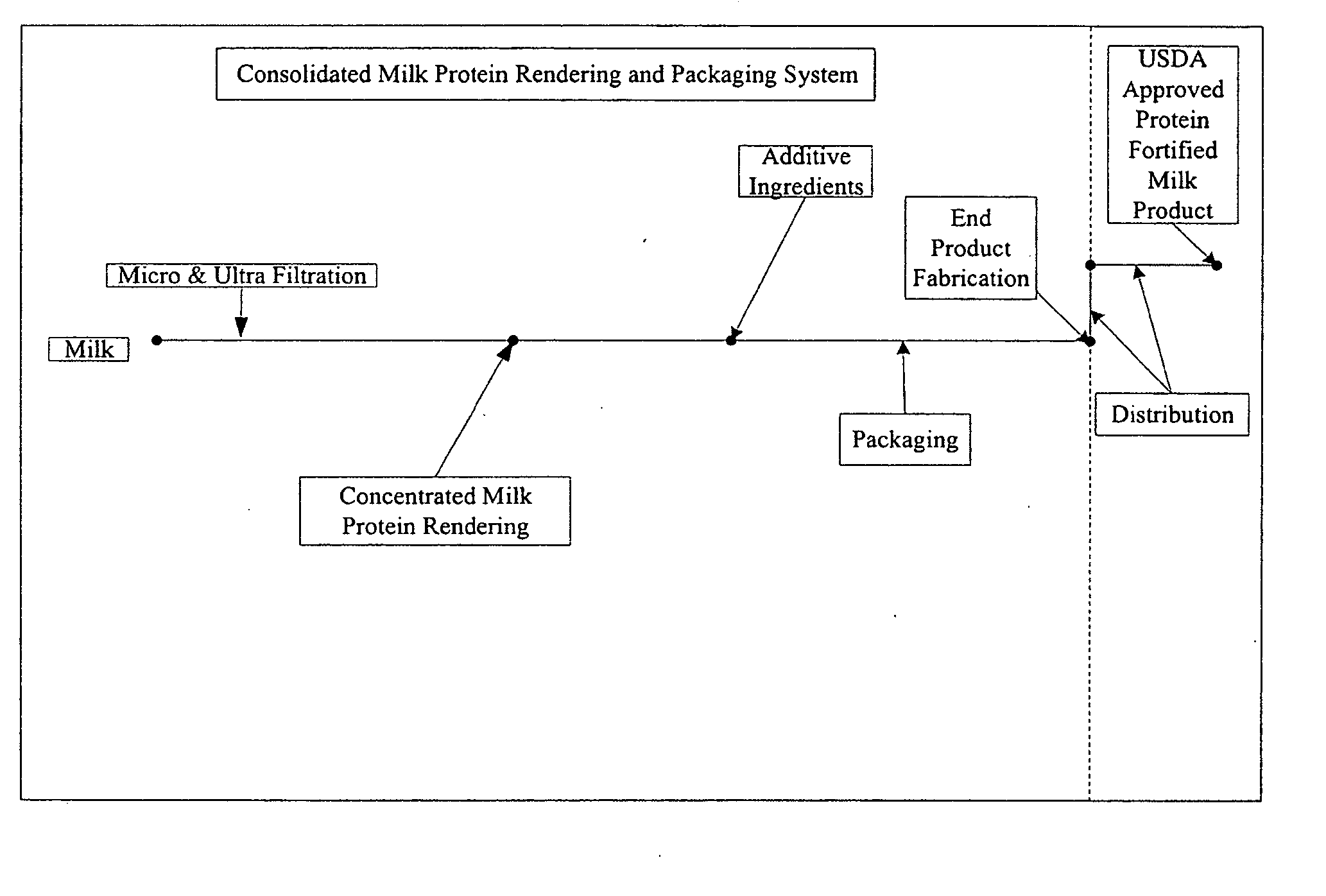

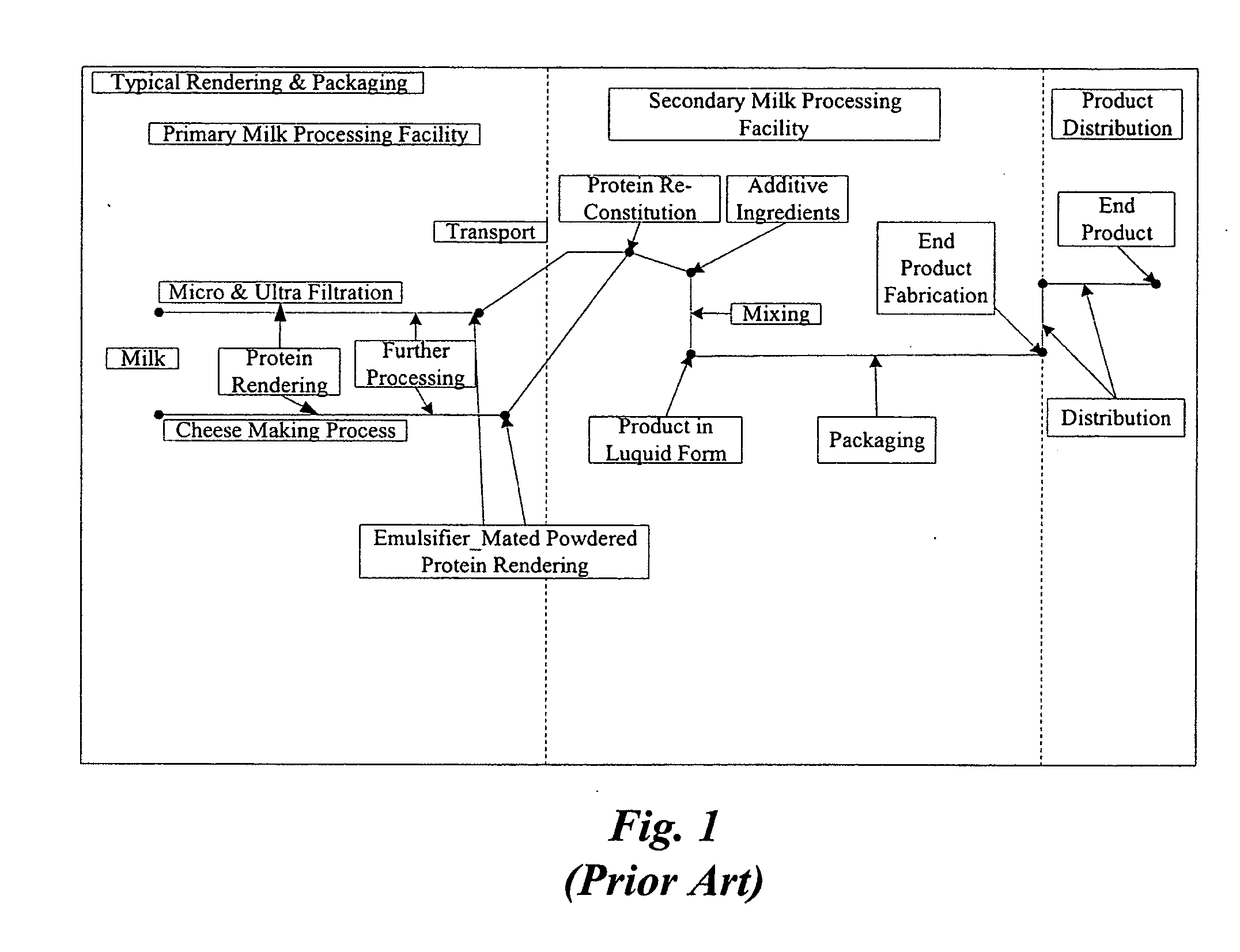

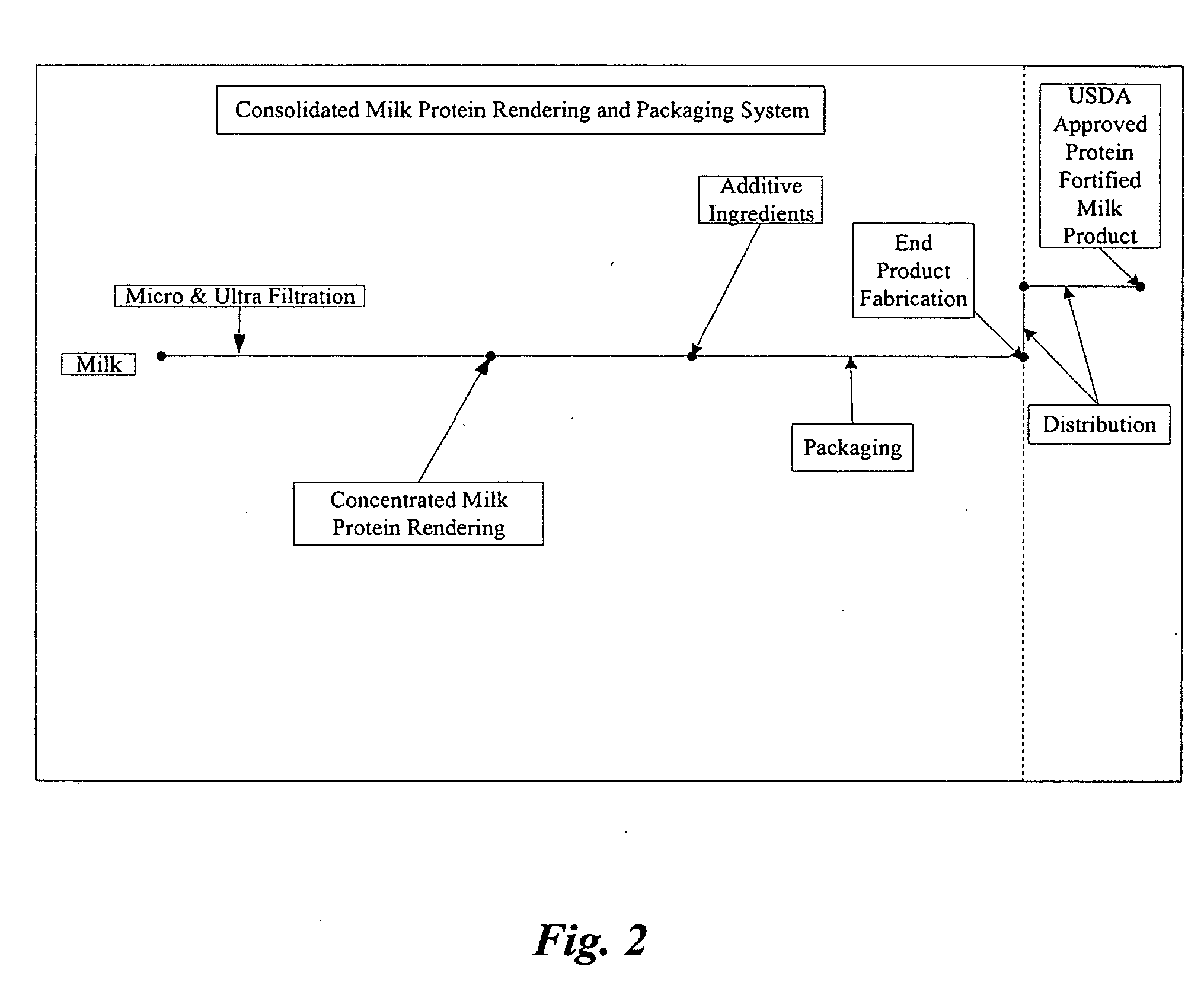

Concentrated-protein food product and process

InactiveUS20050181095A1Ultra-low fatHigh in proteinMilk preparationProtein composition from milkConcentration proteinMicrofiltration

A system, processes, and milk-based food products made from the system and processes, in which cream is separated from milk to produce an ultra-low fat milk product. The milk product is microfiltered to produce a retentate that is ready to drink and is high in protein and has no or substantially no fat. The permeate from the microfiltration process is ultrafiltered to produce a retentate that is high in protein with few other solids. The permeate may be used to provide protein fortification to other food and beverage products, and is especially useful in its liquid form for such fortification.

Owner:DOMINION NUTRITION

Method for extracting high-purity mogroside V from siraitia grosvenorii

ActiveCN106008645AReduce water consumptionReduce extraction timeMembranesSemi-permeable membranesOrganic solventMicrowave

The invention discloses a method for extracting high-purity mogroside V from siraitia grosvenorii, and relates to the extraction method of the mogroside V. The method includes the specific steps: raw material pretreatment, extraction, centrifugation, enzymolysis, ultrafiltration, nanofiltration, decolorization, concentration, microwave drying, and crushing. The membrane technique is adopted for separation and purification, only pure water is used as a solvent, an organic solvent is discarded, and the method has the advantages of simple operation, safe and environmental-protection products, simple process, high quality and low price, and can realize the continuous large-scale industrial production.

Owner:JIANGXI HAIFU BIOENG

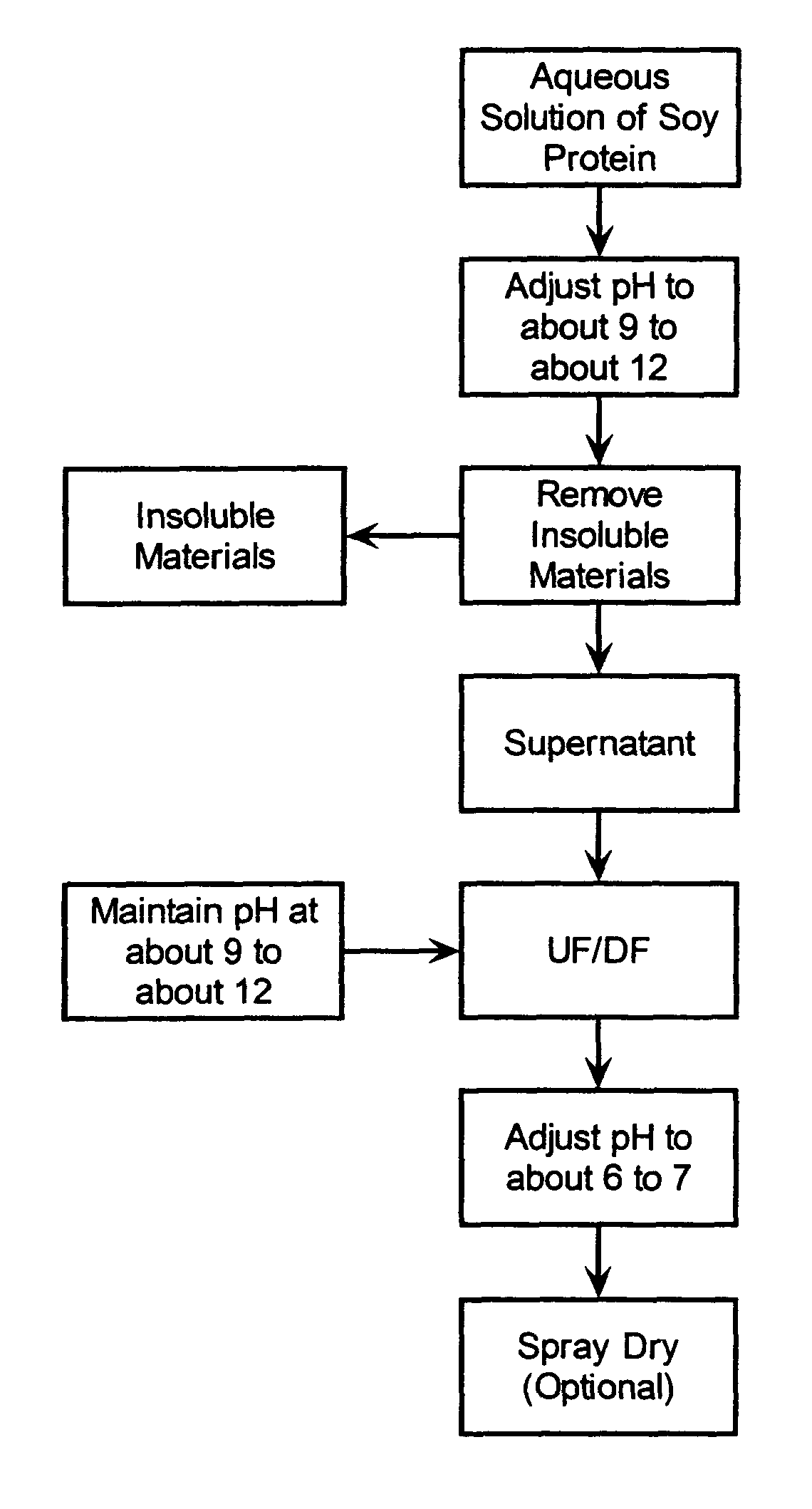

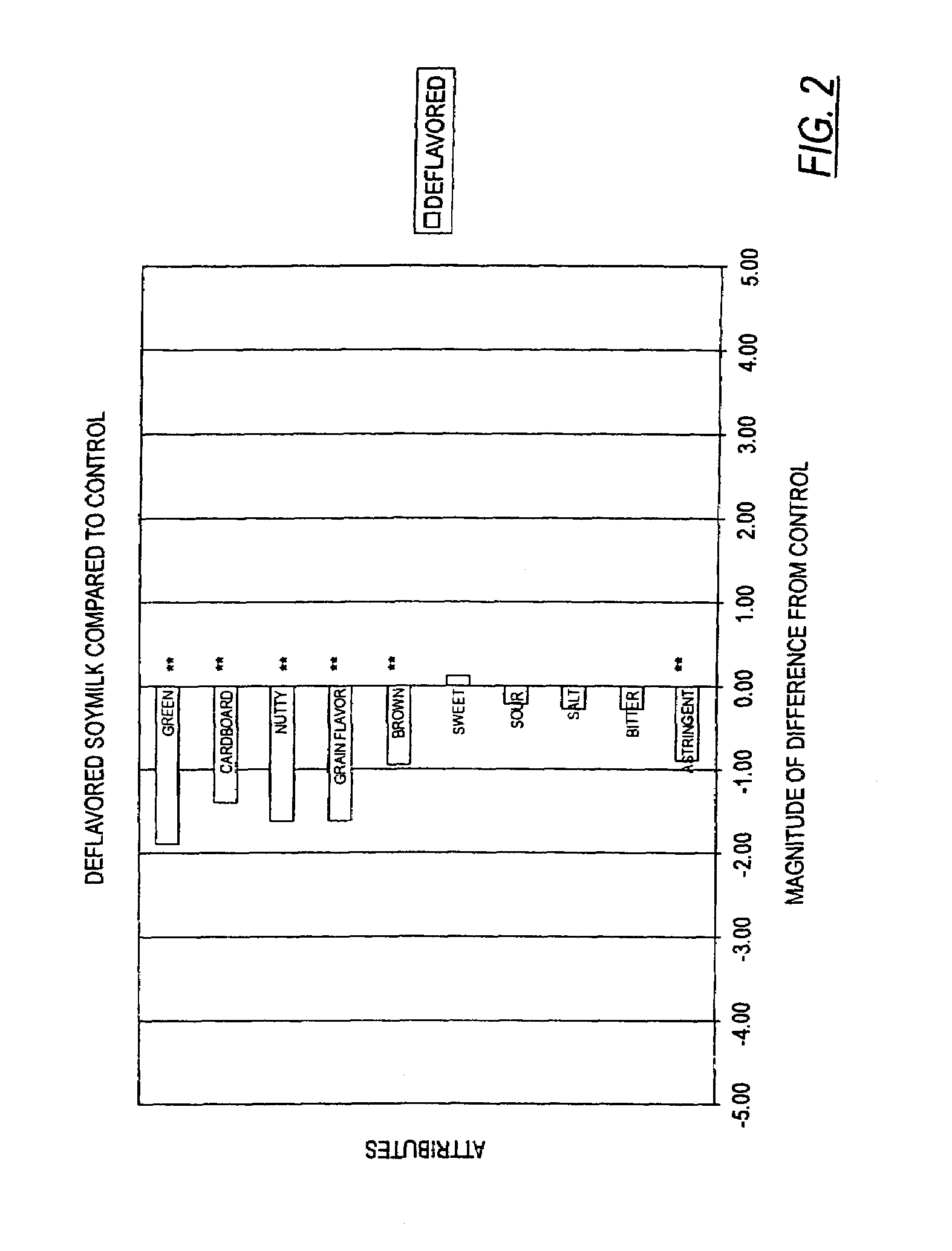

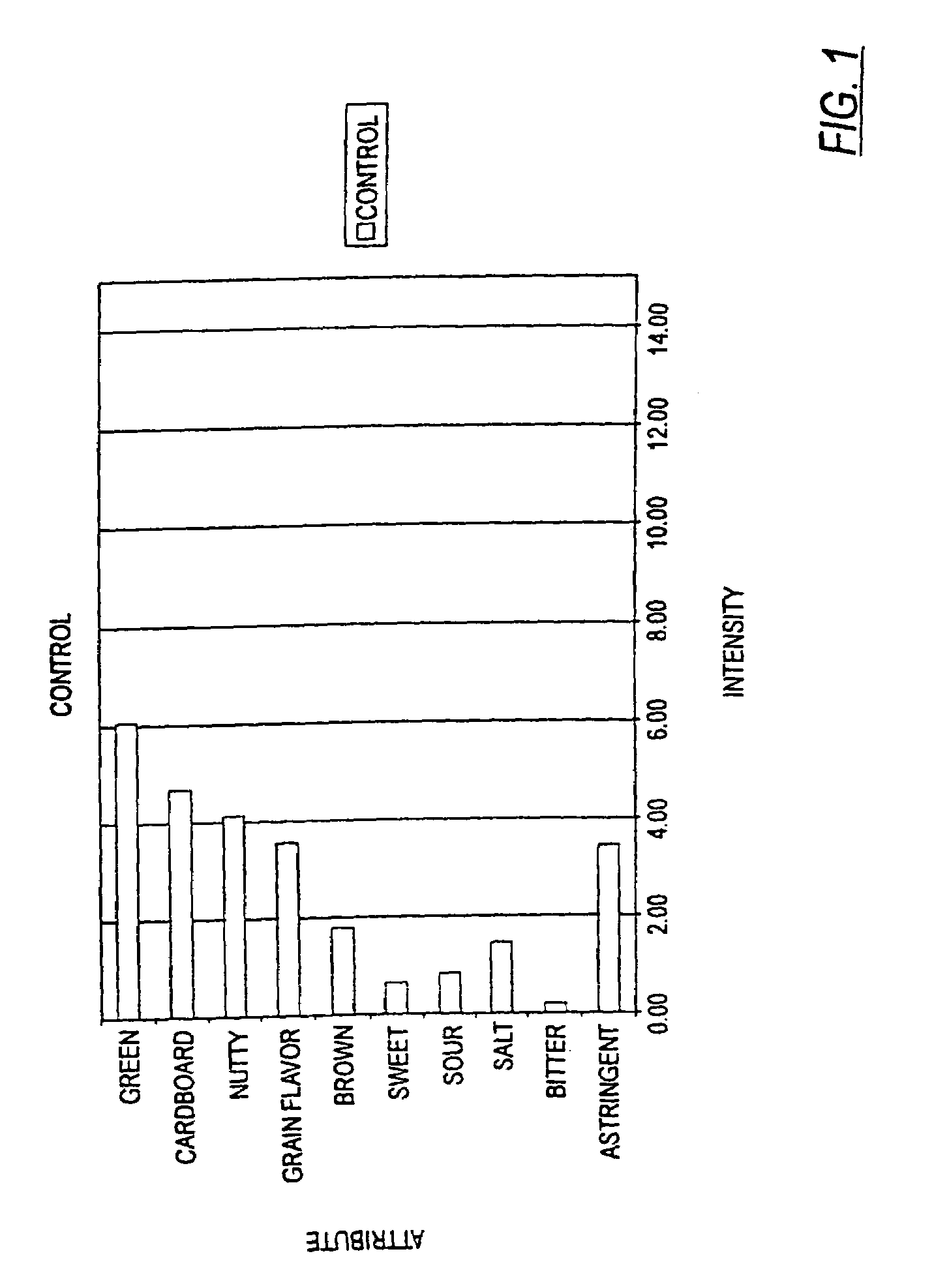

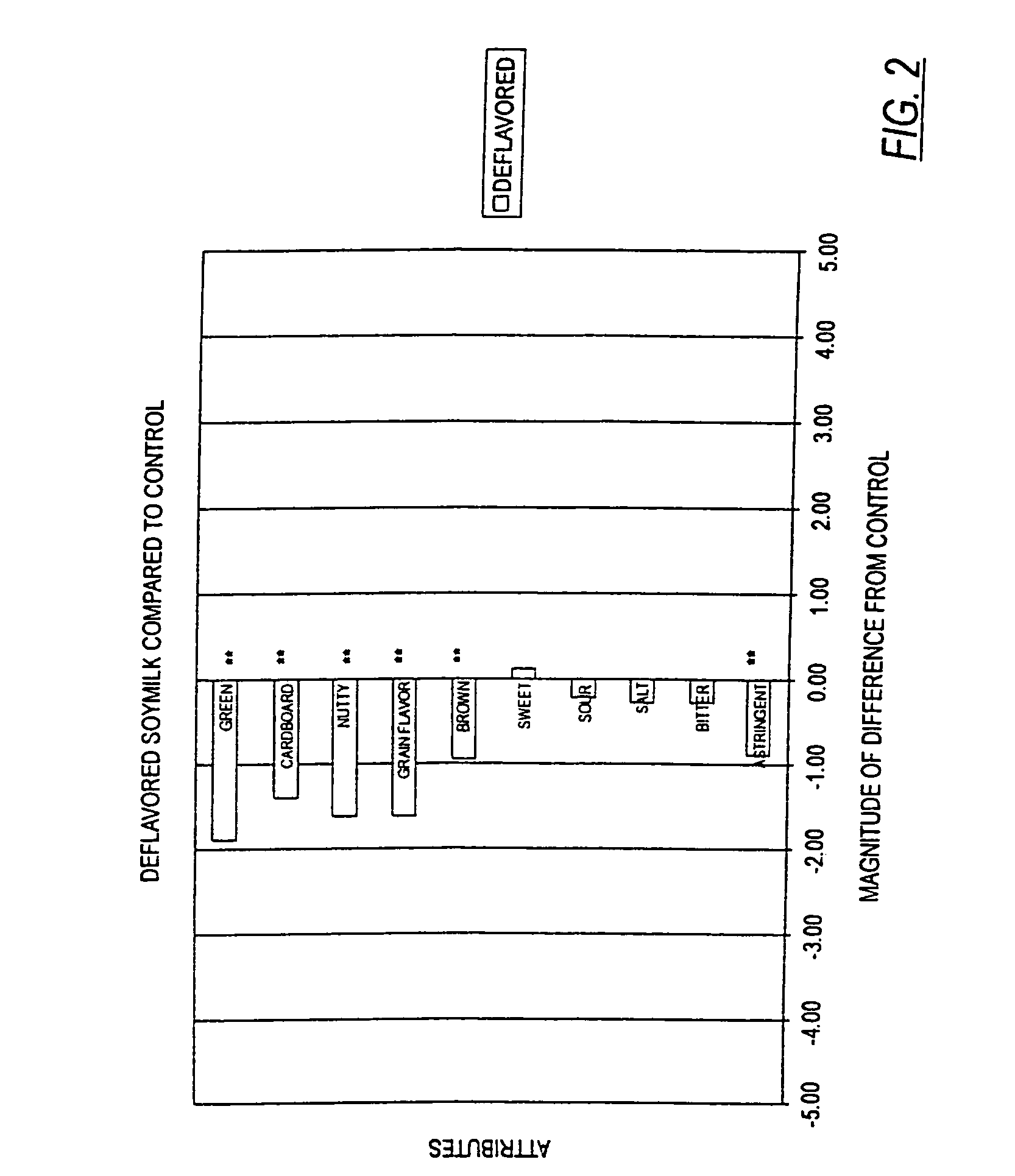

Method of deflavoring soy-derived materials for use in beverages

Soy-containing beverage comprising an aqueous liquid containing deflavored soy protein material are provided. Especially preferred beverage include flavored soymilk beverage and soymilk smoothies.

Owner:KRAFT FOODS INC

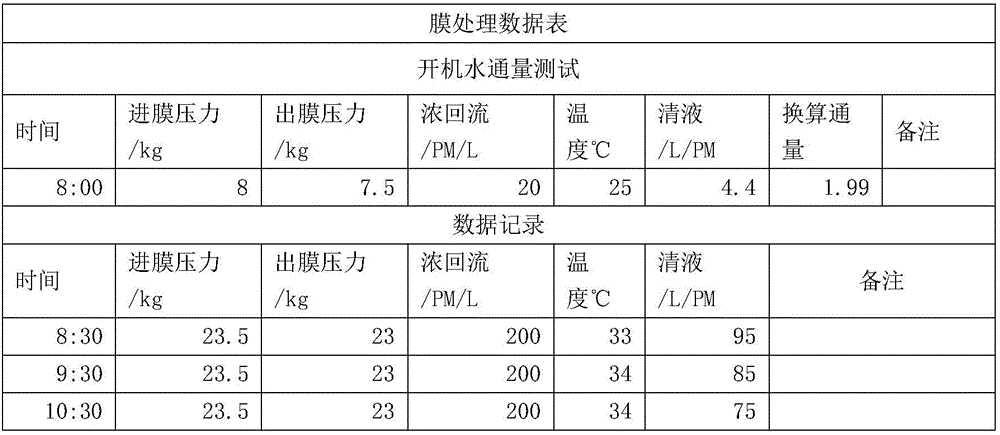

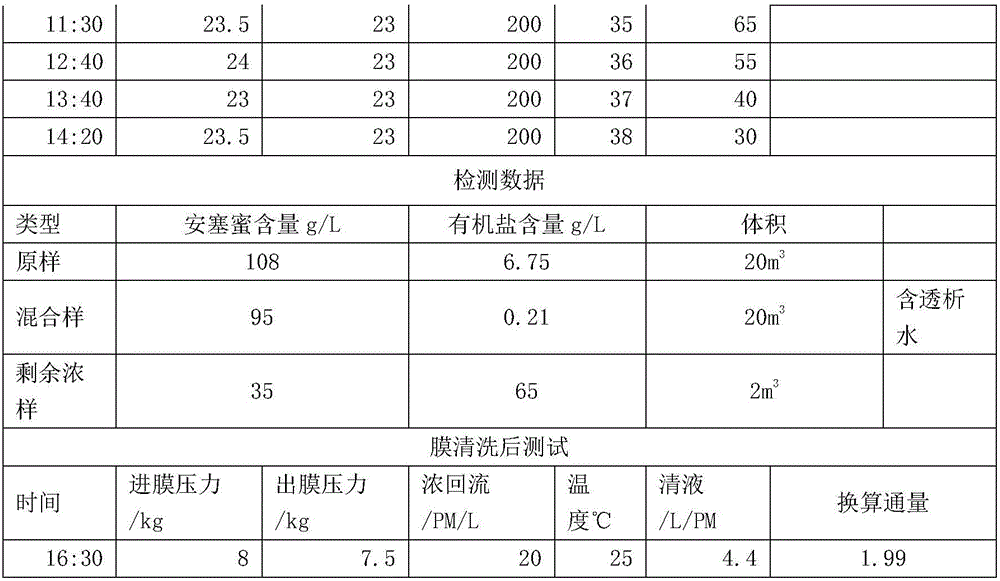

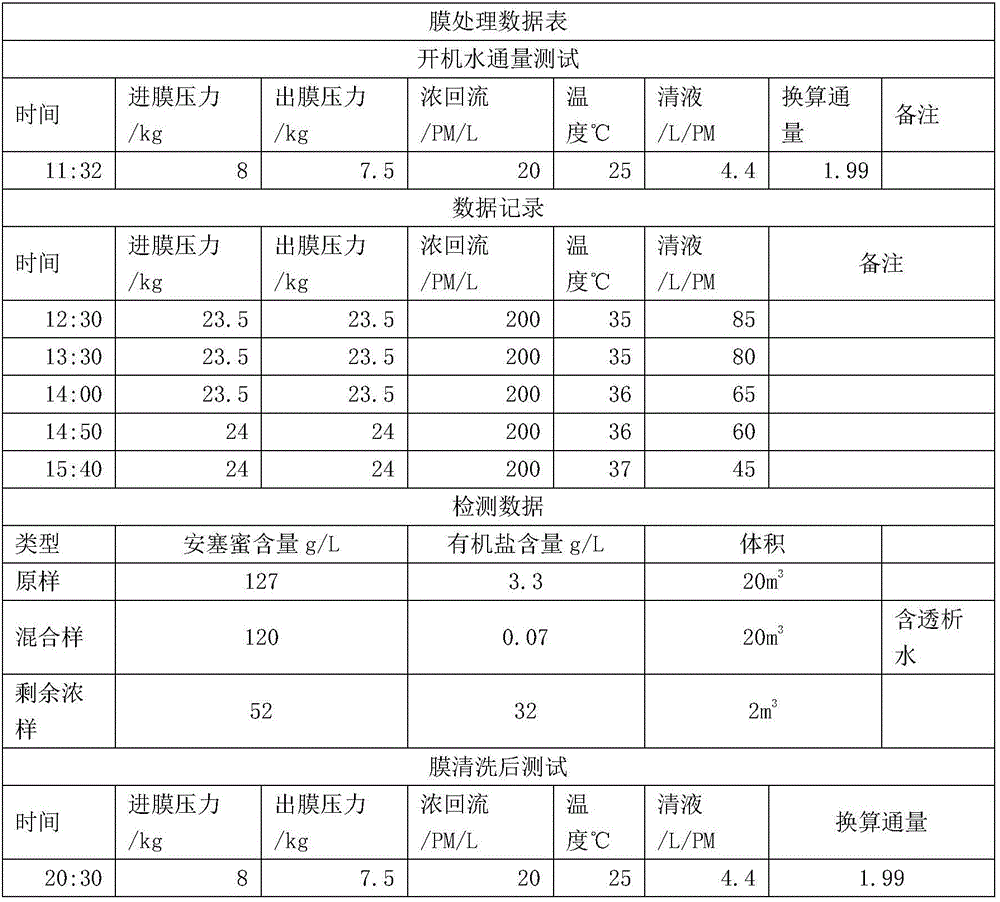

Method for equivalent dialysis through directly adopting membrane treatment

InactiveCN106262665AReduce energy consumptionReduce removal rateSemi-permeable membranesFood membrane processLiquid wasteLiquid storage tank

The invention discloses a method for equivalent dialysis through directly adopting membrane treatment. The method comprises the following steps: S1: storing the filtrate of Acesulfame in a filtrate storage tank, which is taken as a stock solution; S2: adopting a hot water circulation system to increase the temperature of the stock solution in the filtrate storage tank, setting membrane ingress pressure and membrane egress pressure simultaneously, and through transmission and concentration of an organic membrane, allowing a clear membrane liquid to flow to a clear membrane liquid storage tank for recycle; S3: when the clear membrane liquid flux in the clear membrane liquid storage tank drops to 20-60L / PM, using the same amount of water to dialyze, and dialyzing the Acesulfame out and recycling; S4: discharging the residual liquid in a circulation tank to a liquid waste disposing center directly so as to have liquid waste disposal; and S5: washing and detecting membrane equipment. The method disclosed by the invention adopts the hot water circulation system for heating and omits the concentration treating and recycling process, so that the energy consumption is saved, the concentration temperature is low, the material is difficult to break down, the purposes of liquid decoloration and organic salt treatment are realized, the product obtained can be recycled directly, and the equipment has a simple structure and a low treatment cost.

Owner:ANHUI WEIDUO FOOD INGREDIENTS CO LTD

Concentrated-protein food product and process

InactiveUS20060172058A1Protein composition from fishMilk preparationConcentration proteinMicrofiltration

A system, processes, and milk-based food products made from the system and processes, in which cream is separated from milk to produce an ultra-low fat milk product. The milk product is microfiltered to produce a retentate that is ready to drink and is high in protein and has no or substantially no fat. The permeate from the microfiltration process is ultrafiltered to produce a retentate that is high in protein with few other solids. The permeate of the ultrafiltration step, or other milk salt containing fluid may be used to perform diafiltration on the retentate of the microfiltration process. The permeate may also be used to provide protein fortification to other food and beverage products, and is especially useful in its liquid form for such fortification.

Owner:DOMINION NUTRITION

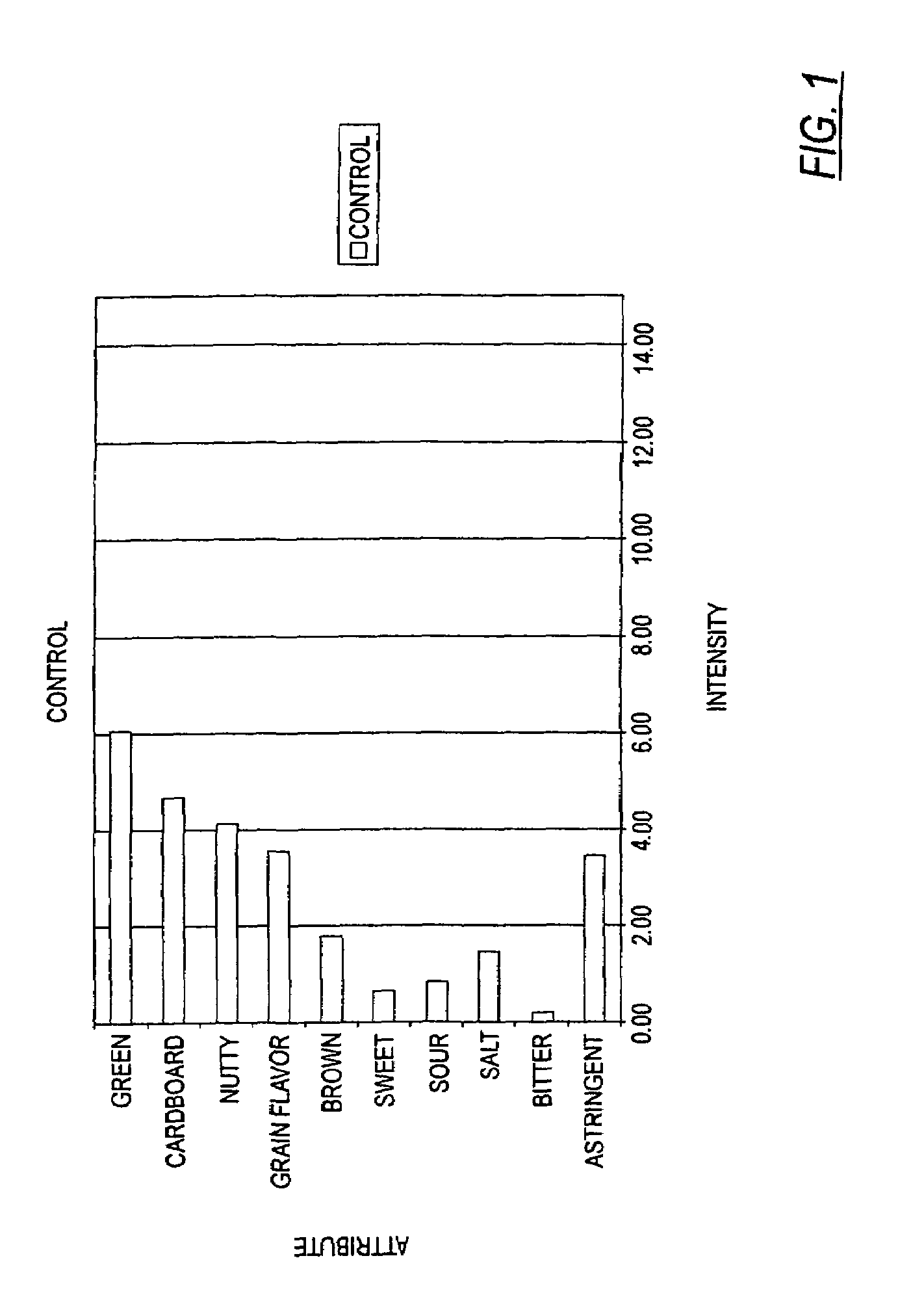

Production of pulse protein products with reduced astringency

ActiveUS20140356510A1Reduce material volumeLow viscosityProtein composition from vegetable seedsFood membrane processBiochemistryAqueous medium

Pulse proteins of reduced astringency are obtained by fractionating pulse protein products which are completely soluble and heat stable in aqueous media at acid pH value of less than about 4.4 into lower molecular weight, less astringent proteins and higher molecular weight, more astringent proteins.

Owner:BURCON NUTRASCI MB

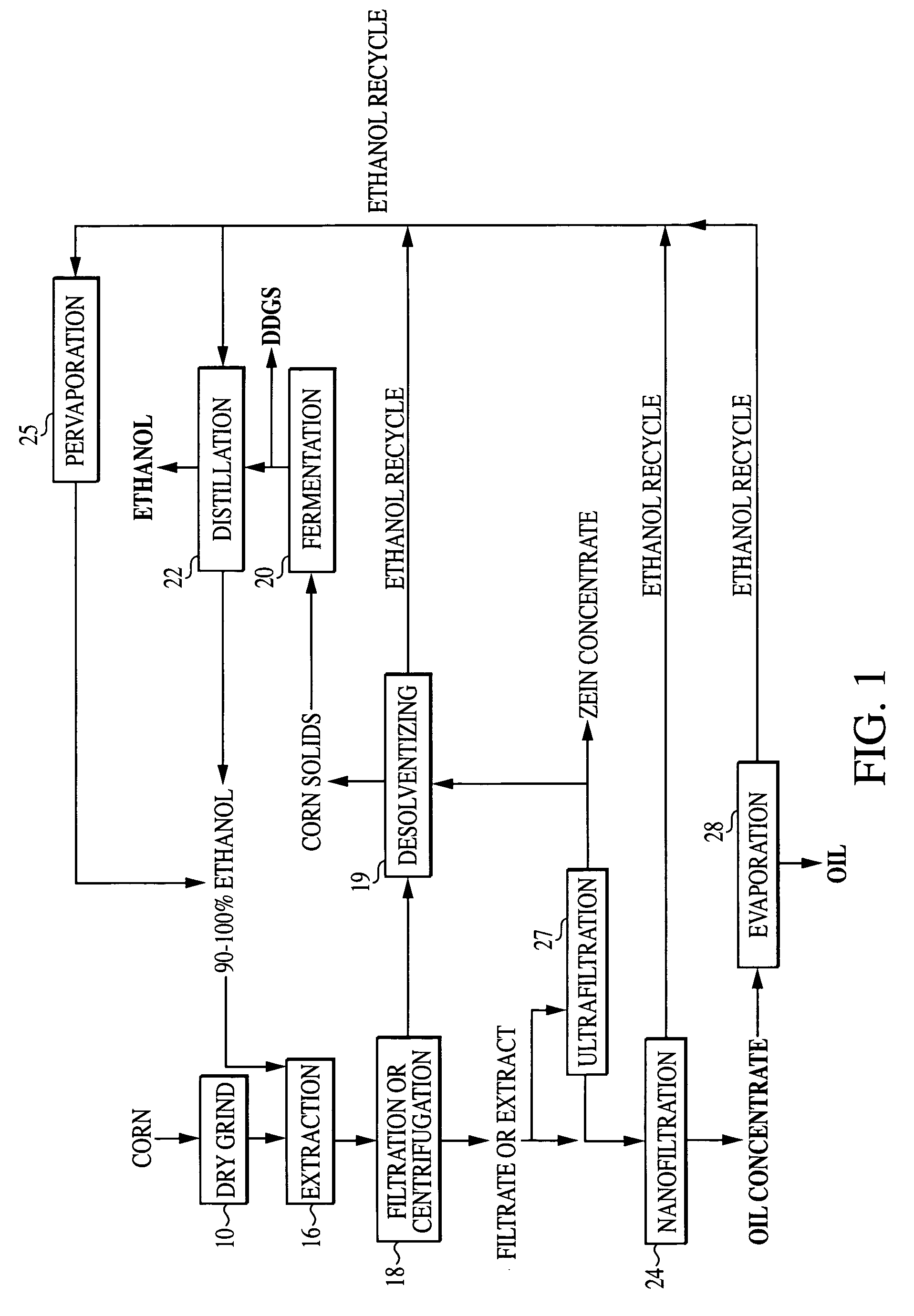

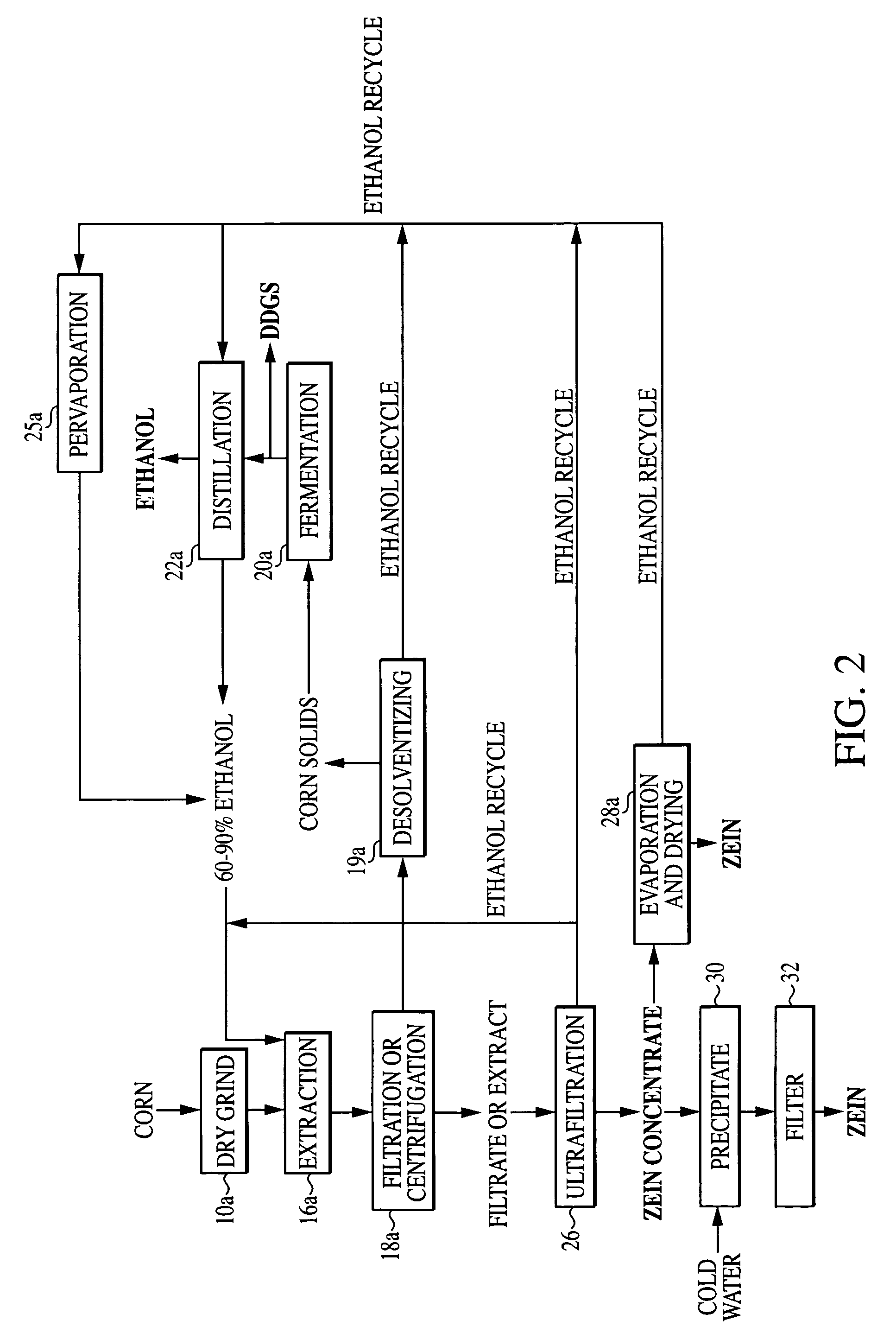

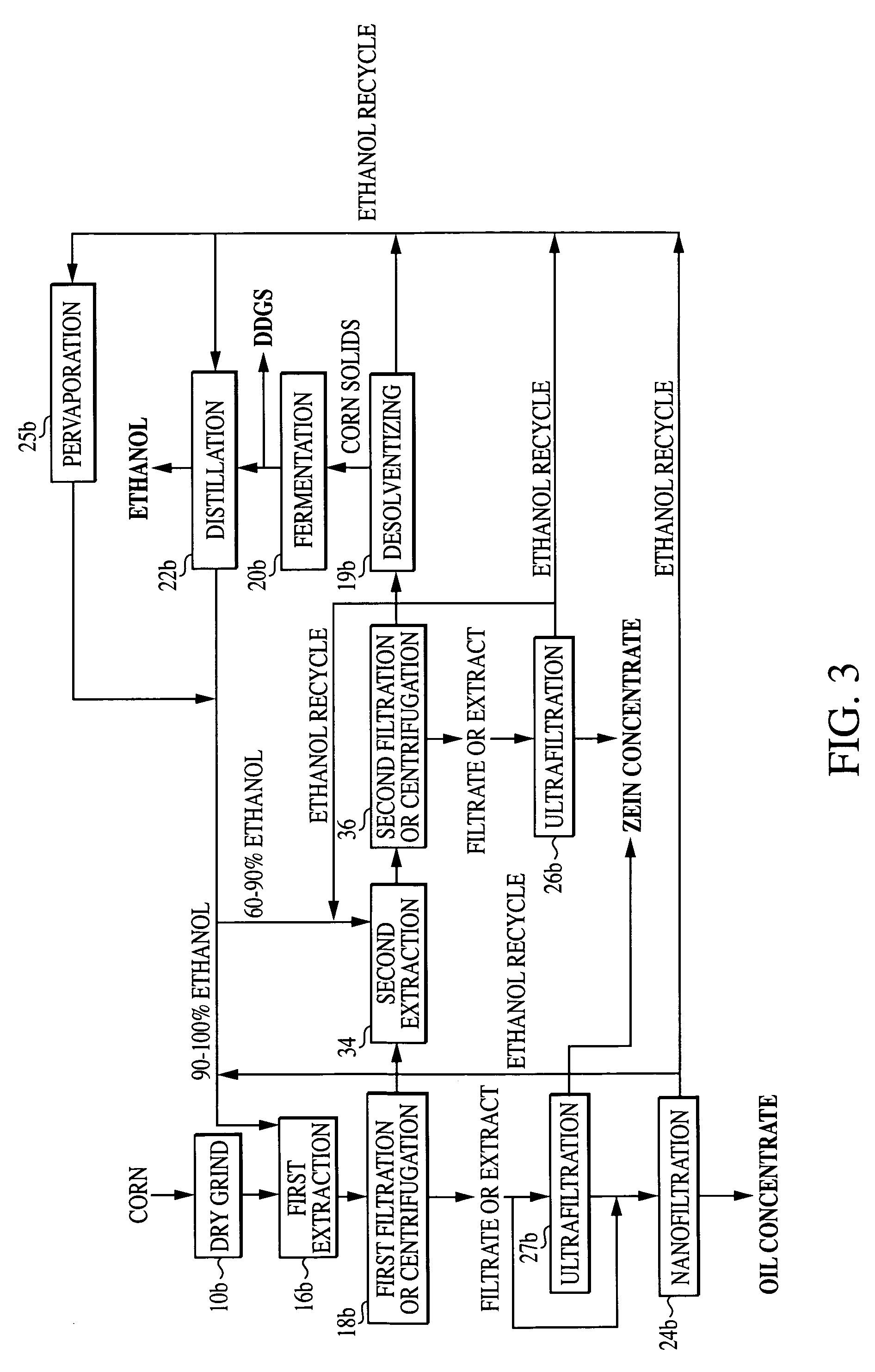

Method and system for extraction of zein and/or oil from corn

InactiveUS20050049400A1Protein composition from vegetable seedsFatty-oils/fats refiningGliadinEthanol

A corn product removal process for removing zein and / or oil from dry-milled corn. Oils and / or zein are extracted from corn using ethanol. Corn solids are separated from the ethanol, oil and zein mixture produced by extracting. Thereafter, the ethanol, oil and zein mixture is membrane filtered to restrain zein from the mixture and pass an oil and ethanol mixture. The zein and / or oil may be concentrated and purified.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Method used for preparing grosvenor momordica fruit sweet taste composition from grosvenor momordica fruit, and applications thereof

PendingCN109247561AControl contentGreat tasteCosmetic preparationsJuice extractionBiotechnologyOrganosolv

The invention provides a method used for preparing a grosvenor momordica fruit sweet taste composition from grosvenor momordica fruit, and applications thereof. The method comprises following steps: immature grosvenor momordica fruits are subjected to ripening, juicing, pure water extraction, impurity removing, and concentration and purifying so as to obtain the grosvenor momordica fruit sweet taste composition. The invention also discloses a composite sweetener containing the grosvenor momordica fruit sweet taste composition, and the composite sweetener can be widely used in food, beverage, health care product, and daily chemical product. According to the method, the contents of components such as mogroside III and mogroside IIe are controlled, so that the taste of the grosvenor momordicafruit sweet taste composition is better. In the preparation process, only pure water is adopted, no organic solvent such as ethanol is adopted, the production process is green, and is better for health.

Owner:HUNAN NUSTREETCARAX

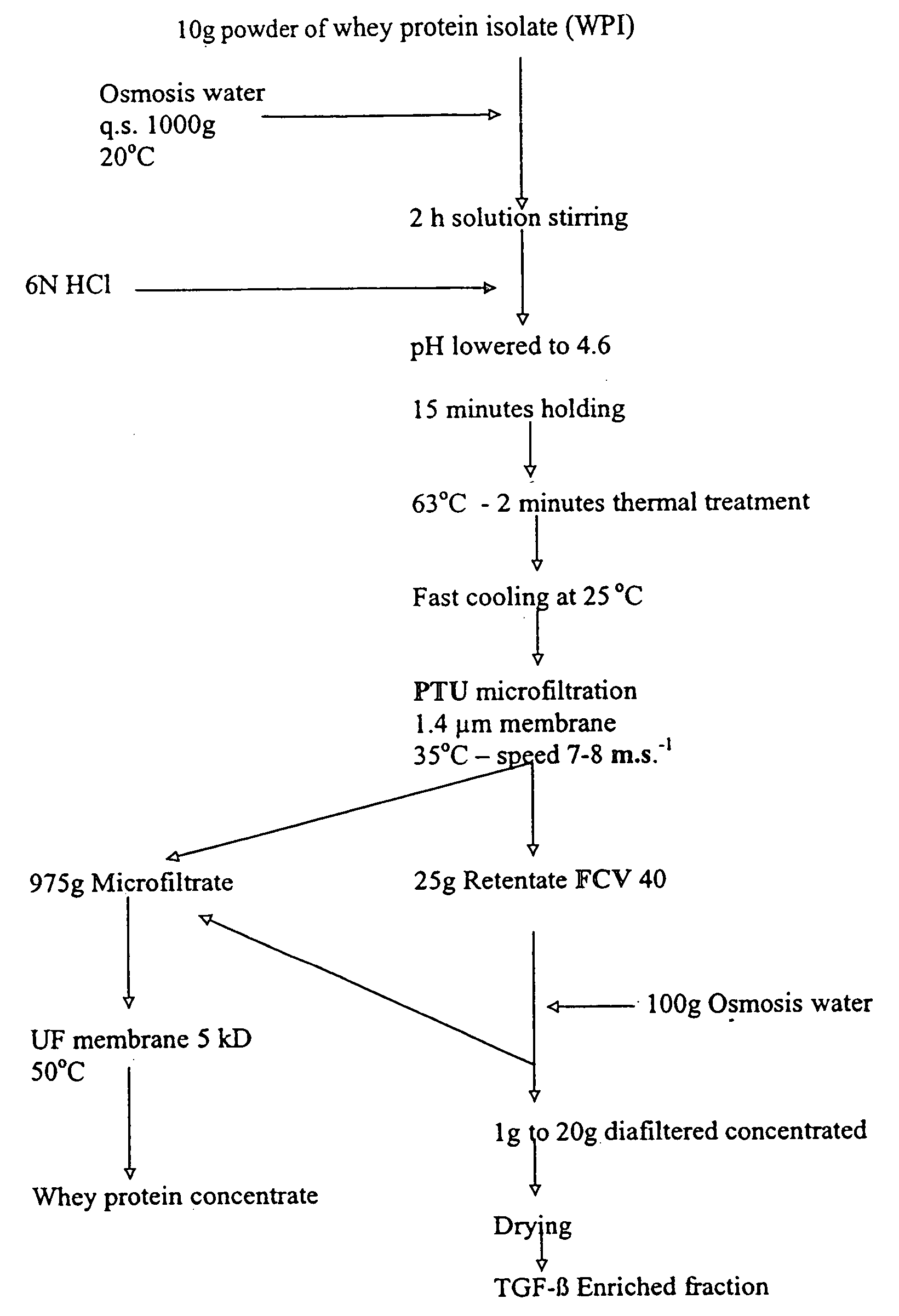

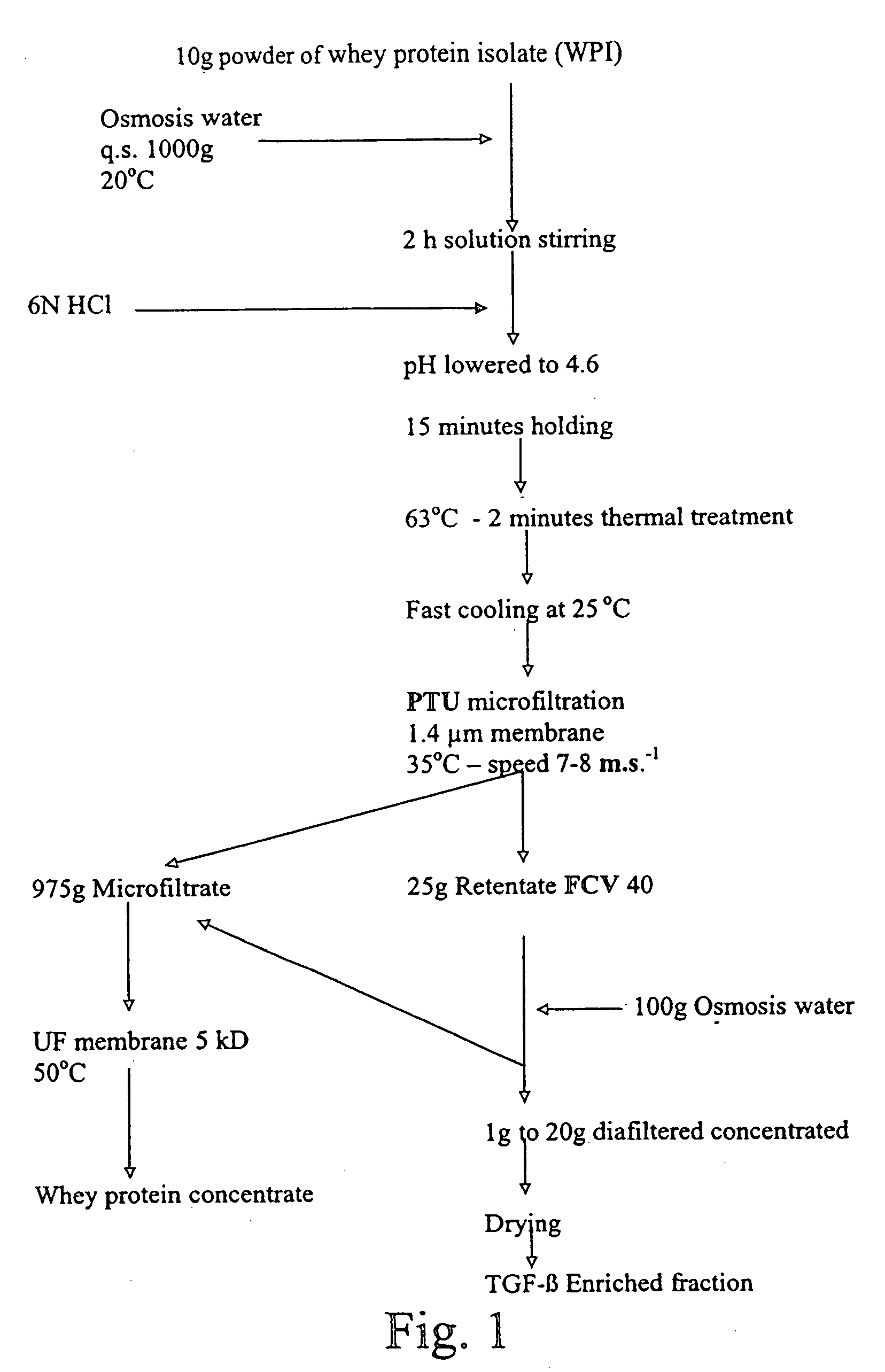

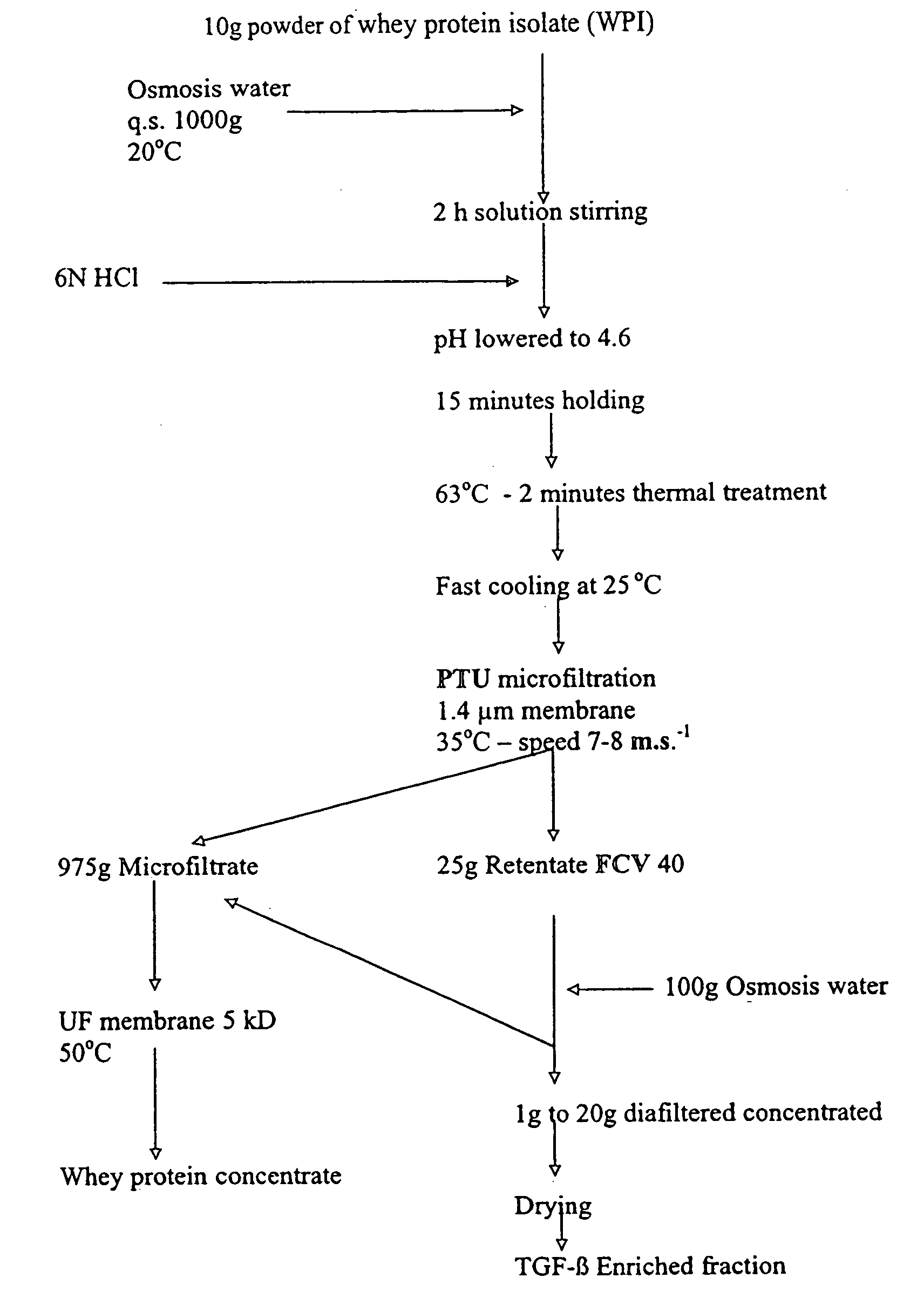

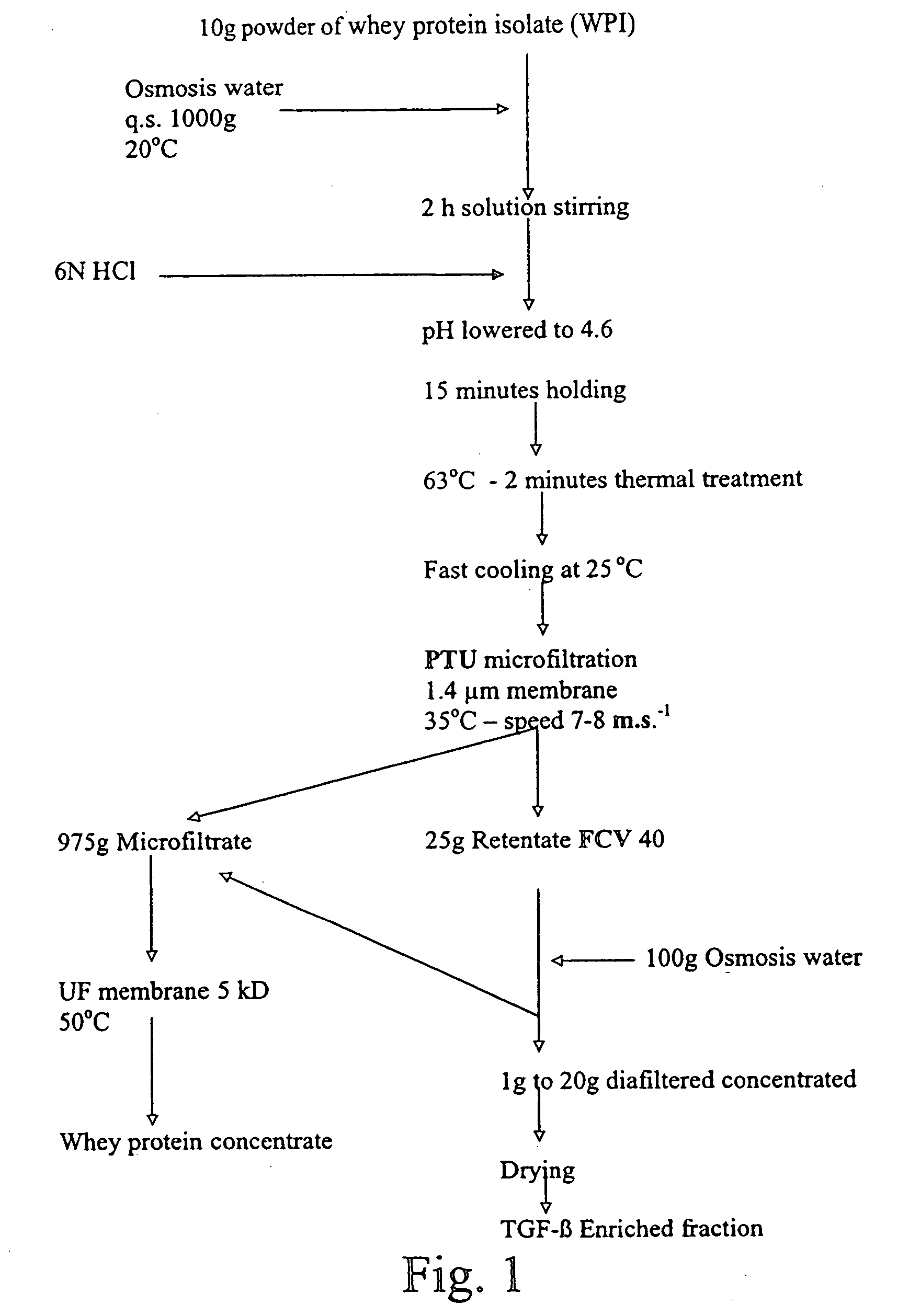

Method for obtaining a TGF-beta enriched protein fraction in activated form, protein fraction and therapeutic applications

The invention concerns a method for obtaining a highly enriched TGF-beta protein fraction in activated form, from a liquid solution rich in proteins said to be soluble in the aqueous phase of milk and / or of whey, said method comprising the following steps; a) adjusting soluble proteins purified at a concentration between 5 and 30 g / liter of solution; b) precipitating part of the whey proteins by acidic treatment of the solution thus obtained to a pH ranging between 4 and 5.5 and at a temperature ranging between 55° C. and 68° C.; c) carrying out a microfiltration of the treated solution by diafiltration, so as to obtain respectively a microfiltration retentate and a microfiltrate; d) recuperating the microfiltration retentate containing the protein fraction highly enriched in TGF-beta; e) drying the microfiltration retentate which has been subjected to diafiltration to obtain a powder highly enriched in TGF-beta.

Owner:PIERRE JOUAN BIOTECH

Whey protein product and a method for its preparation

InactiveCN102595915ASimple structureImprove stabilityMilk preparationMetabolism disorderWhey proteinTotal protein

The invention relates to a whey protein product having a ratio of whey protein to casein in the range from about 90:10 to about 50:50 and the total protein content of at least 20% on dry matter basis, and a method for its preparation. The product has a favourable amino acid composition and is especially suitable for athletes.

Owner:VALIO LTD

Milk protein concentrates

InactiveUS20130011515A1Reduce the amount requiredMilk preparationProtein composition from milkFiltrationWhey protein

A method for making a milk protein concentrate can comprise heating a liquid milk composition at near its natural pH to a temperature that causes the whey protein in the milk to bind to the casein in the milk to form protein aggregates. After cooling, the liquid milk composition can be subjected to membrane filtration using a membrane filter having a large pore size. The protein aggregates are retained to yield a milk protein concentrate. The concentrate can be further treated to provide a concentrate having a lowered lactose content.

Owner:HORMEL FOODS

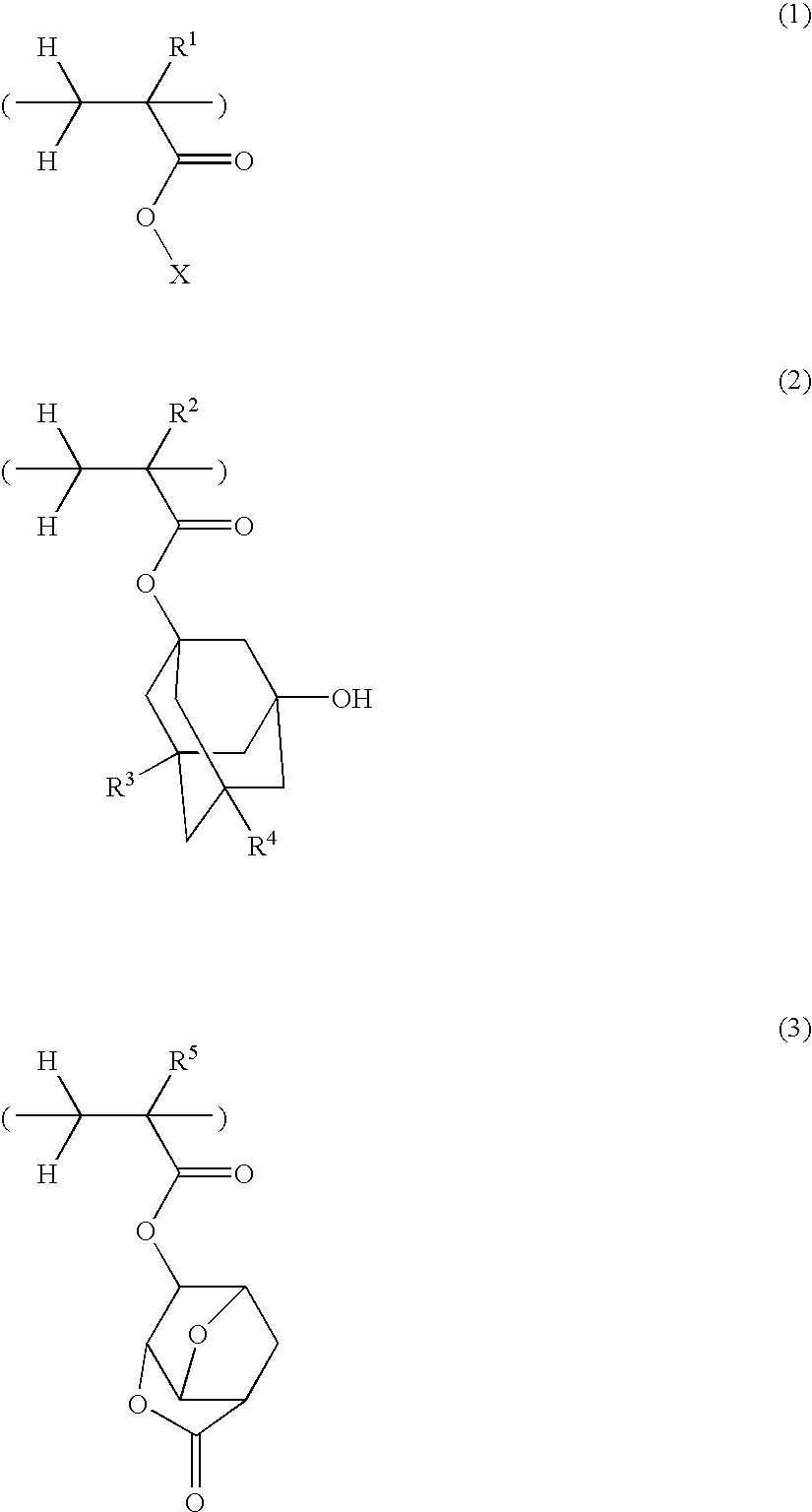

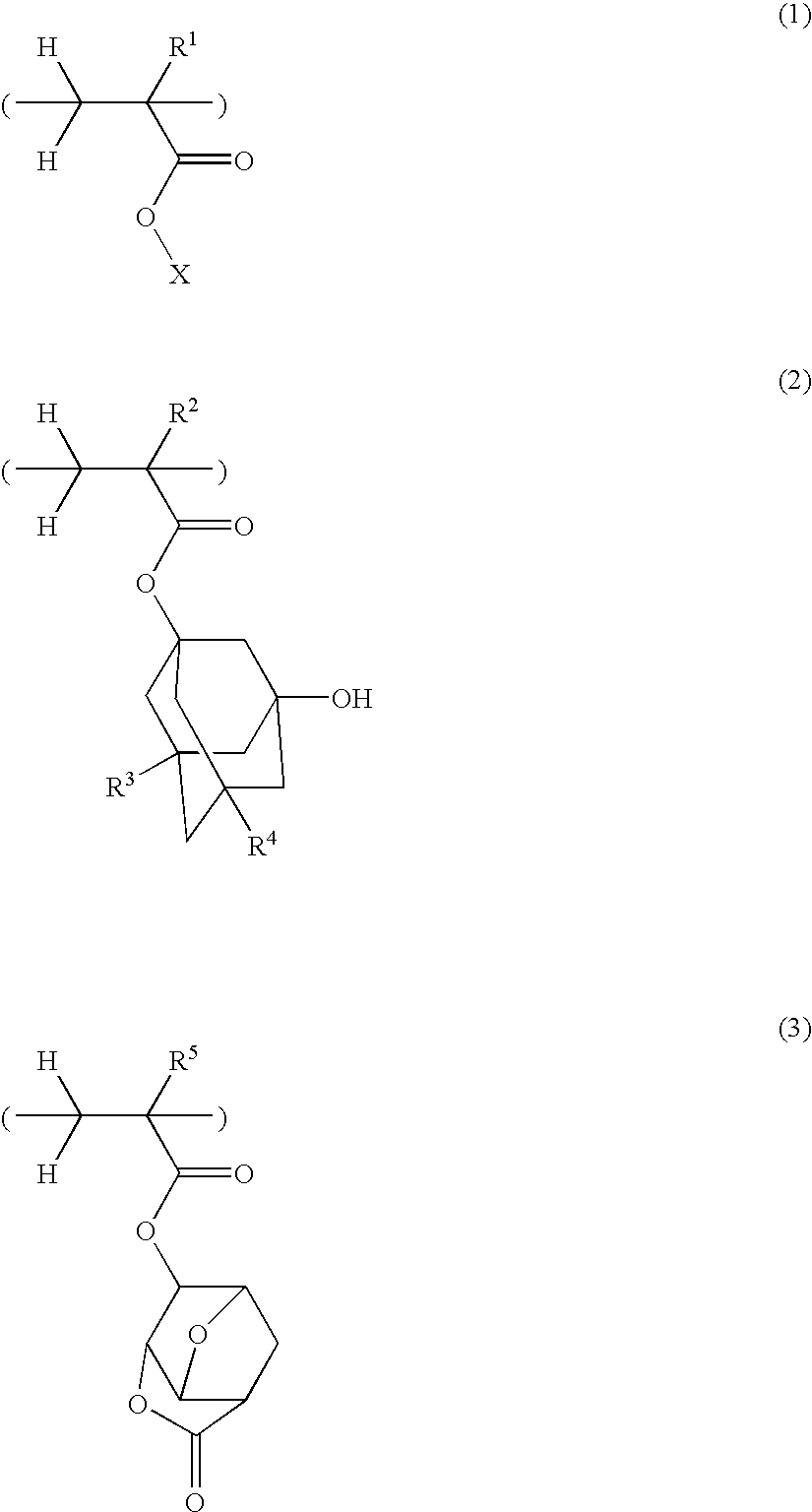

Polymer, resist composition and patterning process

InactiveUS20050208424A1Improve resolutionImproved in proximity biasPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistHigh energy

A polymer comprising repeat units of formulae (1) to (3) increases a dissolution rate in an alkali developer under the action of an acid. R1, R2 and R5 are H or CH3, R3 and R4 are H or OH, and X is a tertiary alkyl group having an adamantane structure. A resist composition comprising the inventive polymer has a sensitivity to high-energy radiation, improved resolution and minimized proximity bias and lends itself to micropatterning with electron beams or deep UV for VLSI fabrication.

Owner:SHIN ETSU CHEM IND CO LTD

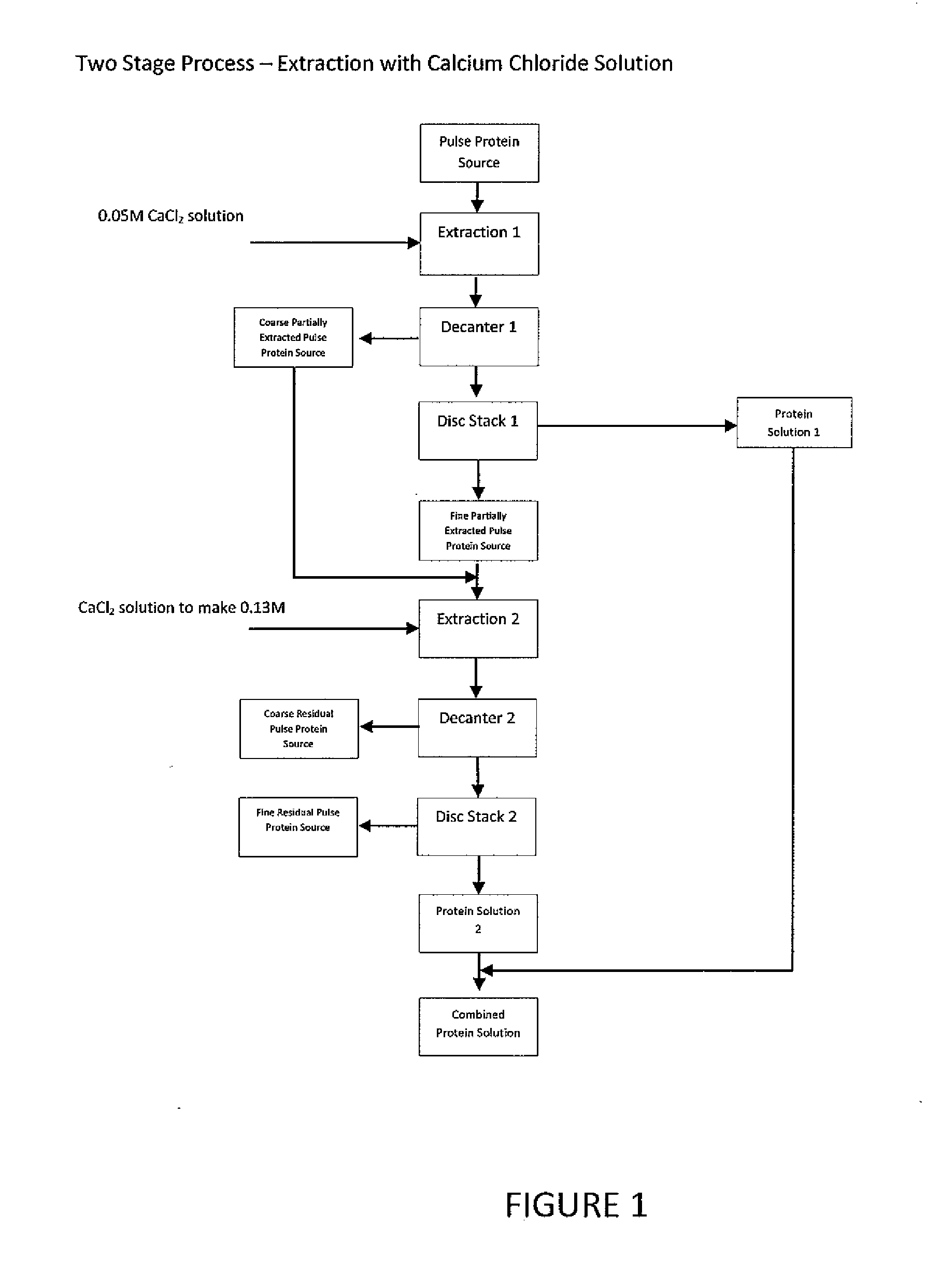

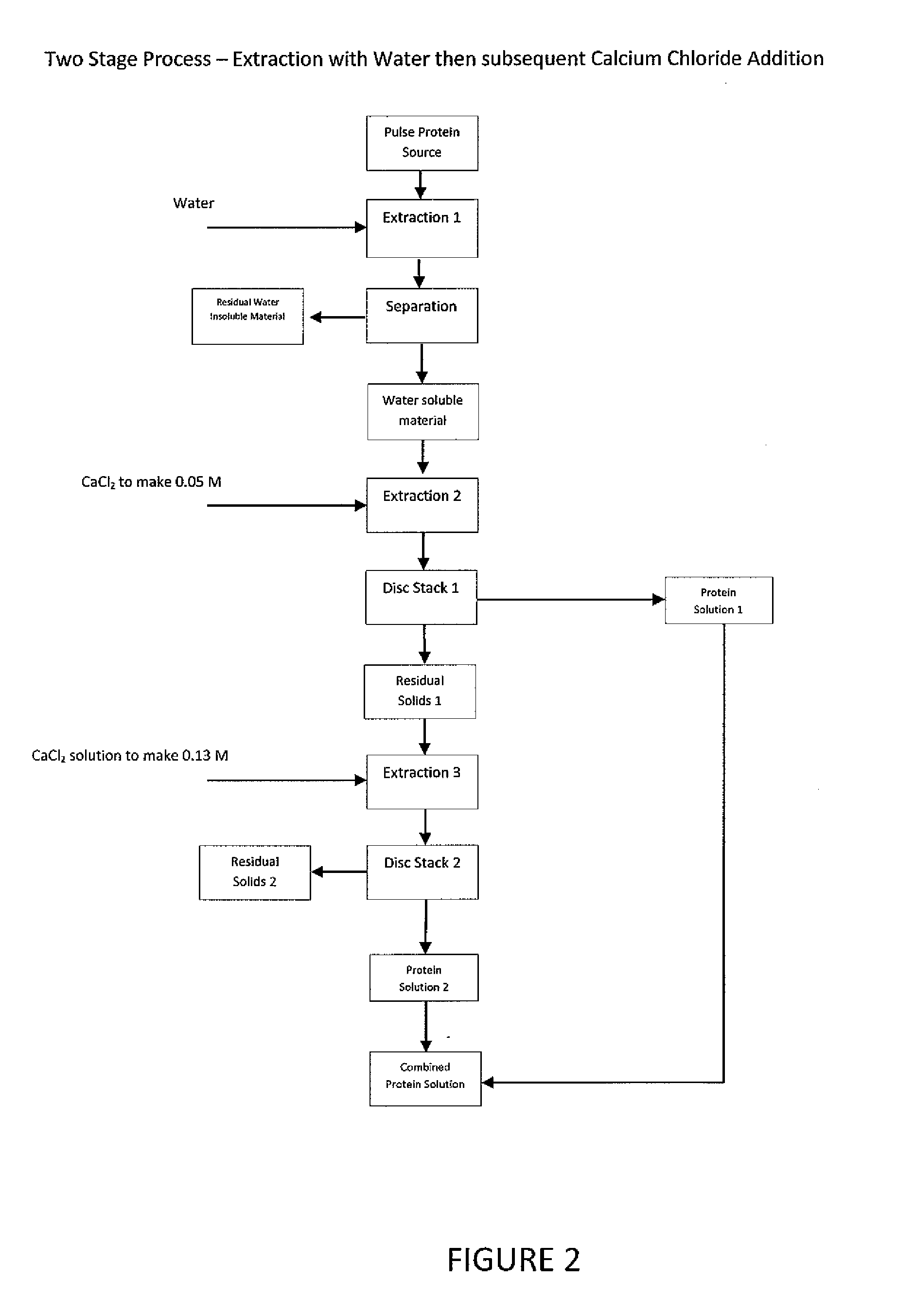

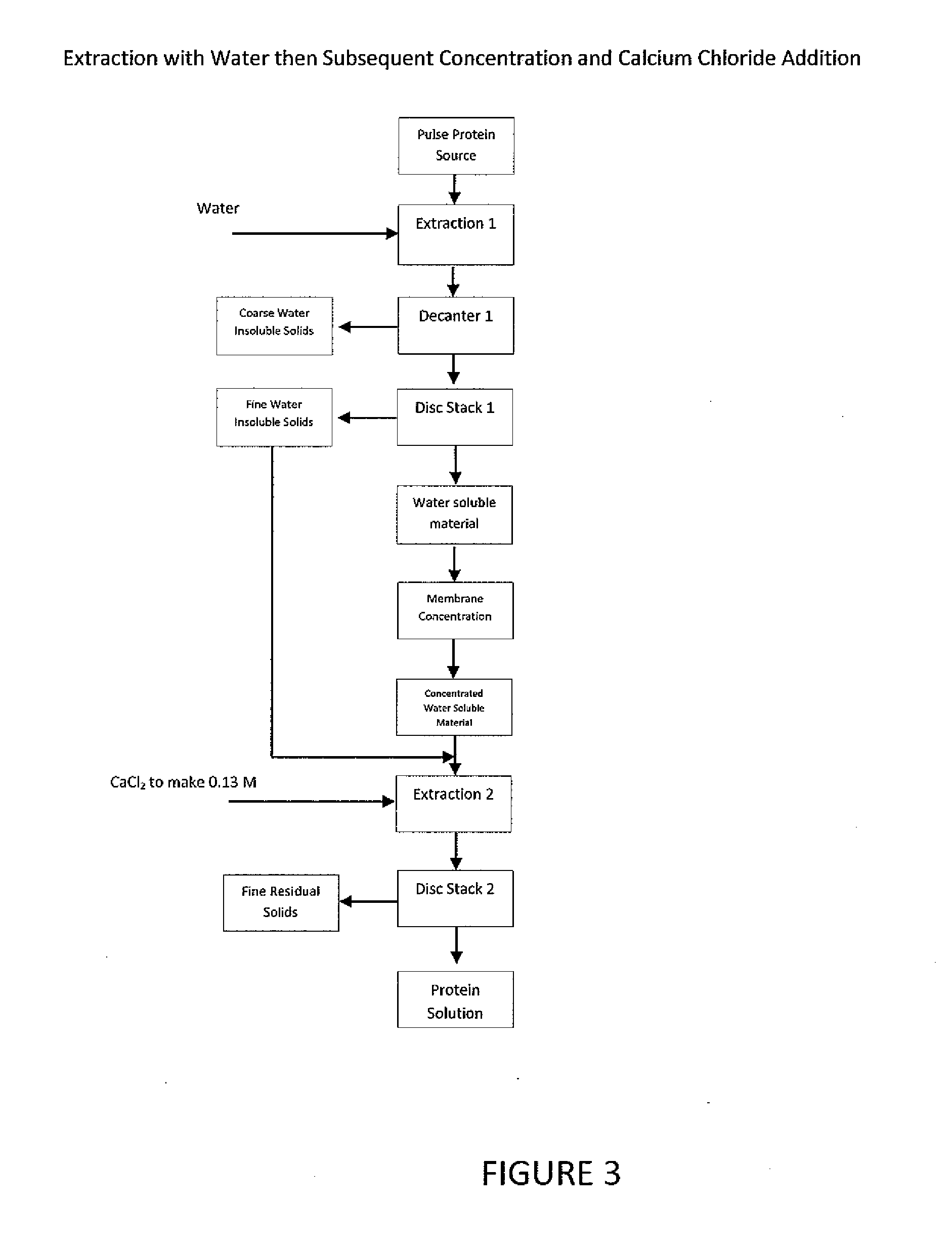

Production of soluble protein products from pulses

InactiveUS20130287928A1Protein composition from vegetable seedsFood membrane processSource materialChloride

Protein products from pulses are obtained using procedures in which calcium chloride is used in multiple extractions of pulse protein source material.

Owner:SCHWEIZ MARTIN +1

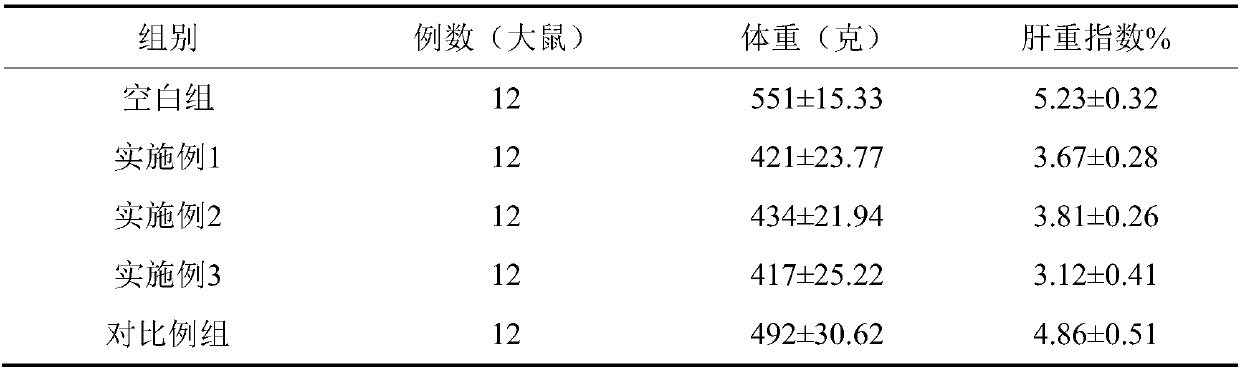

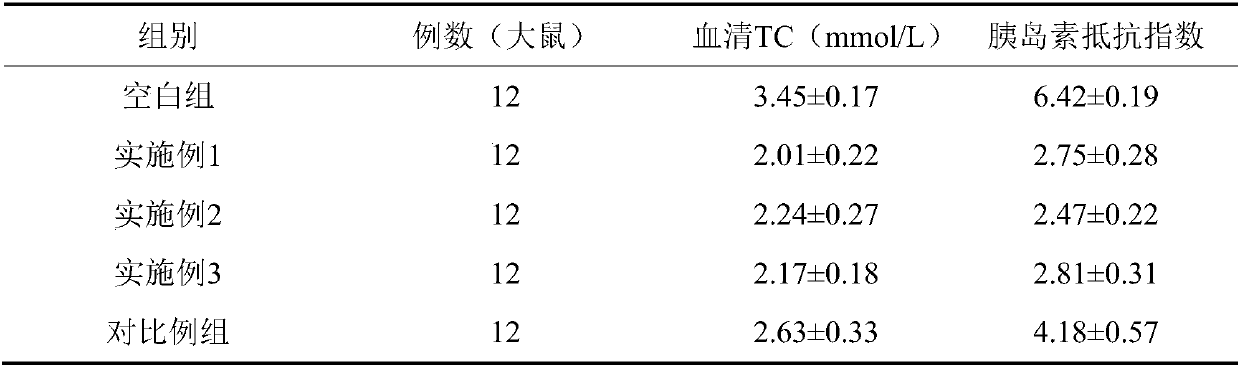

Weight-reducing meal replacement composition and preparation method thereof

PendingCN109601916AFood ingredient as antioxidantFood ingredient as thickening agentIsomaltooligosaccharideVitamin C

The invention relates to the technical field of weight-reducing products, and specially discloses a weight-reducing meal replacement composition and a preparation method thereof. The weight-reducing meal replacement composition is composed of the following ingredients: soybean protein isolate, casein, medium-chain triglyceride, psyllium husk powder, resistant dextrin, konjac powder, chia seeds, tender barley leaf powder, isomalto-oligosaccharide, inulin, fructo-oligosaccharides, compound minerals, compound vitamins, comprehensive fruit and vegetable powder, vitamin C, curcumin, white grape powder, matcha powder and a saussurea involucrate flower culture. The weight-reducing meal replacement composition is capable of regulating glucose and lipid metabolism as well as correcting disturbanceof glucose and lipid metabolism in obese people under the premise of providing adequate proteins, minerals and trace elements for the body; moreover, the weight-reducing meal replacement composition is also capable of achieving the effects of inhibiting sugar and fat absorption, reducing cholesterol and ensuring long-lasting satiety while relatively low calorie is provided.

Owner:孙语彤

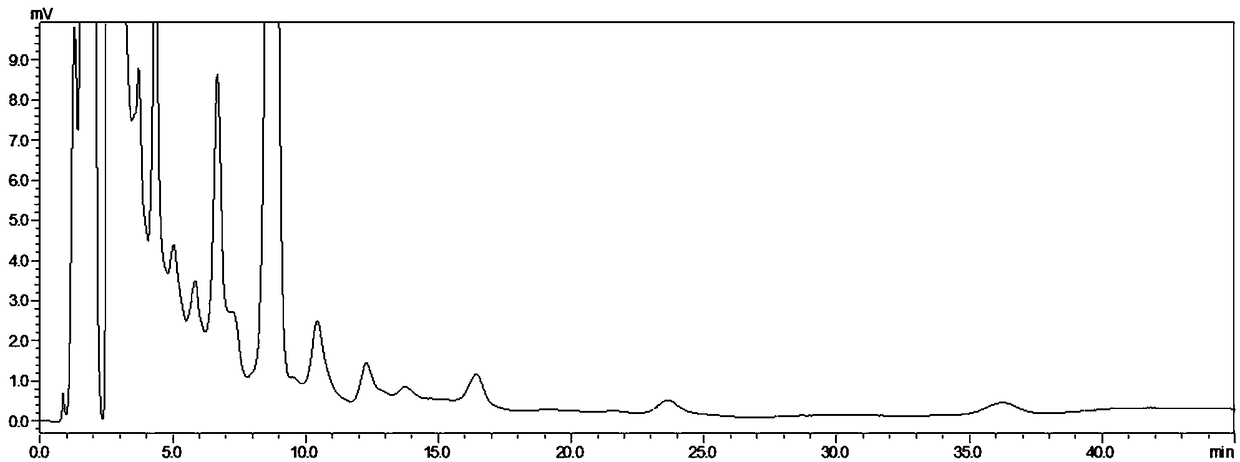

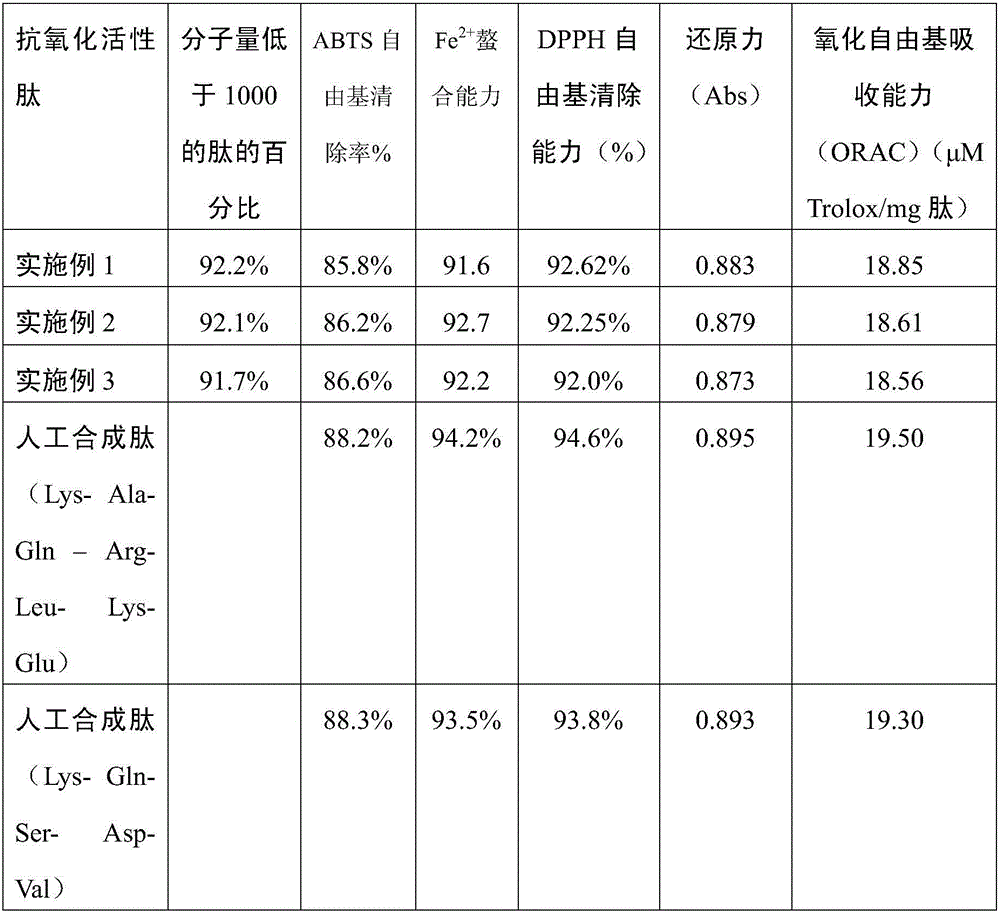

Protein peptide with antioxidant activity and preparation method thereof

ActiveCN106434804AImprove functional propertiesEase of industrial productionFood ingredient as antioxidantCosmetic preparationsUltrafiltrationProtein C

The invention provides protein peptide with antioxidant activity and a preparation method thereof, and belongs to the technical field of processing of aquatic-product foods. The preparation method of the protein peptide comprises the following steps of: (1) carrying out ultrasonic treatment on degreased fish serum; (2) adding compound protease to carry out enzymolysis without the need of adding acid or alkaline to regulate the pH value in the process of enzymolysis; (3) carrying out centrifugal treatment on enzymatic solution and taking supernatant for ultrafiltration; and (4) carrying out column separation on the filtrate, collecting elution peaks, and separating eluent by reversed phase high-performance liquid chromatography, thereby obtaining the protein peptide. The preparation method is simple in operation and is suitable for industrial production; acid or alkaline is not needed for regulating the pH value in the preparation process, no any additive is added, the functional characteristics of the product can be better remained, the product yield is high, the flavor is good, and the prepared protein peptide has excellent antioxidant function and can be widely applied in manufacture of specially-needed foods and nutritional foods.

Owner:人民国肽集团有限公司

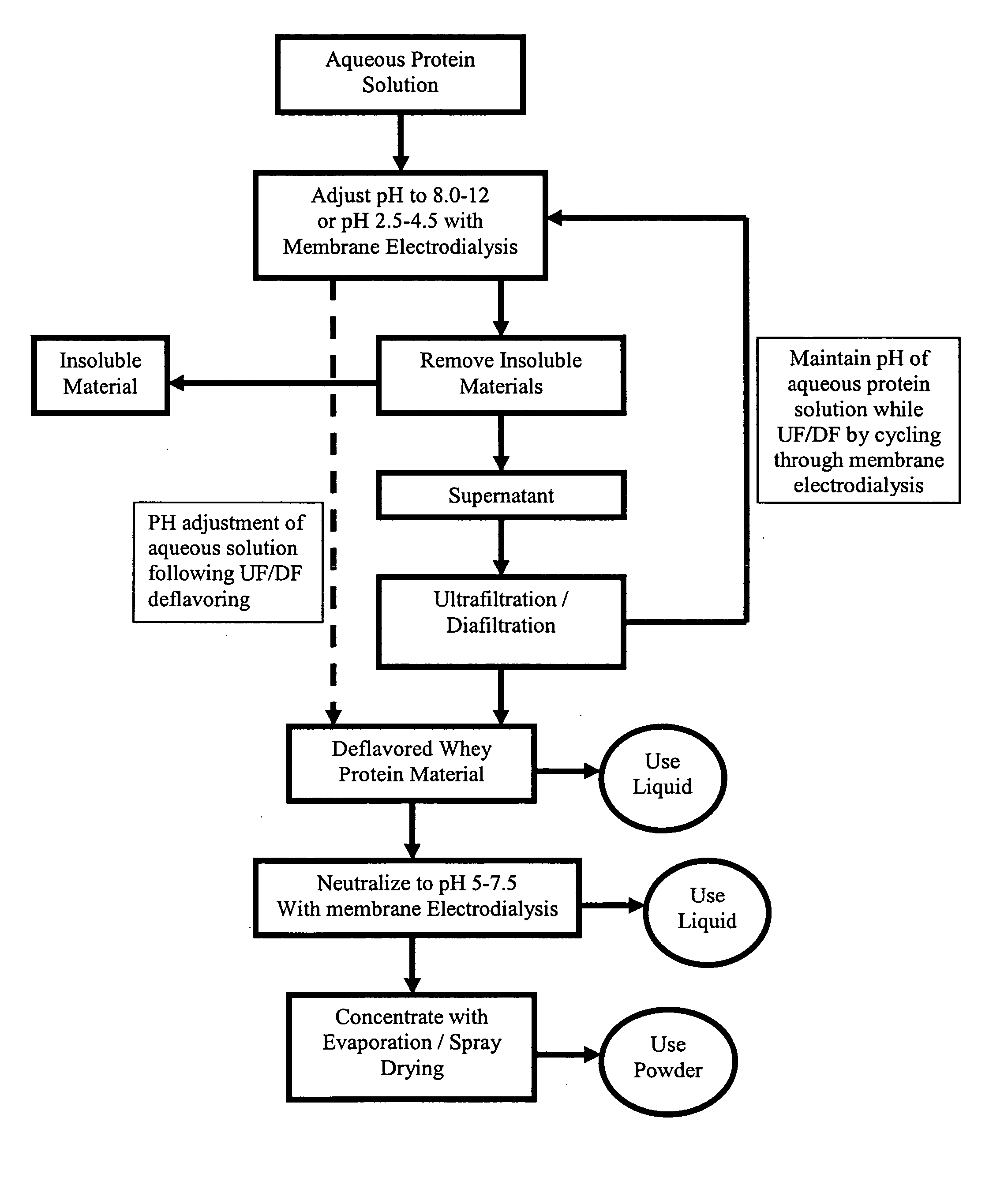

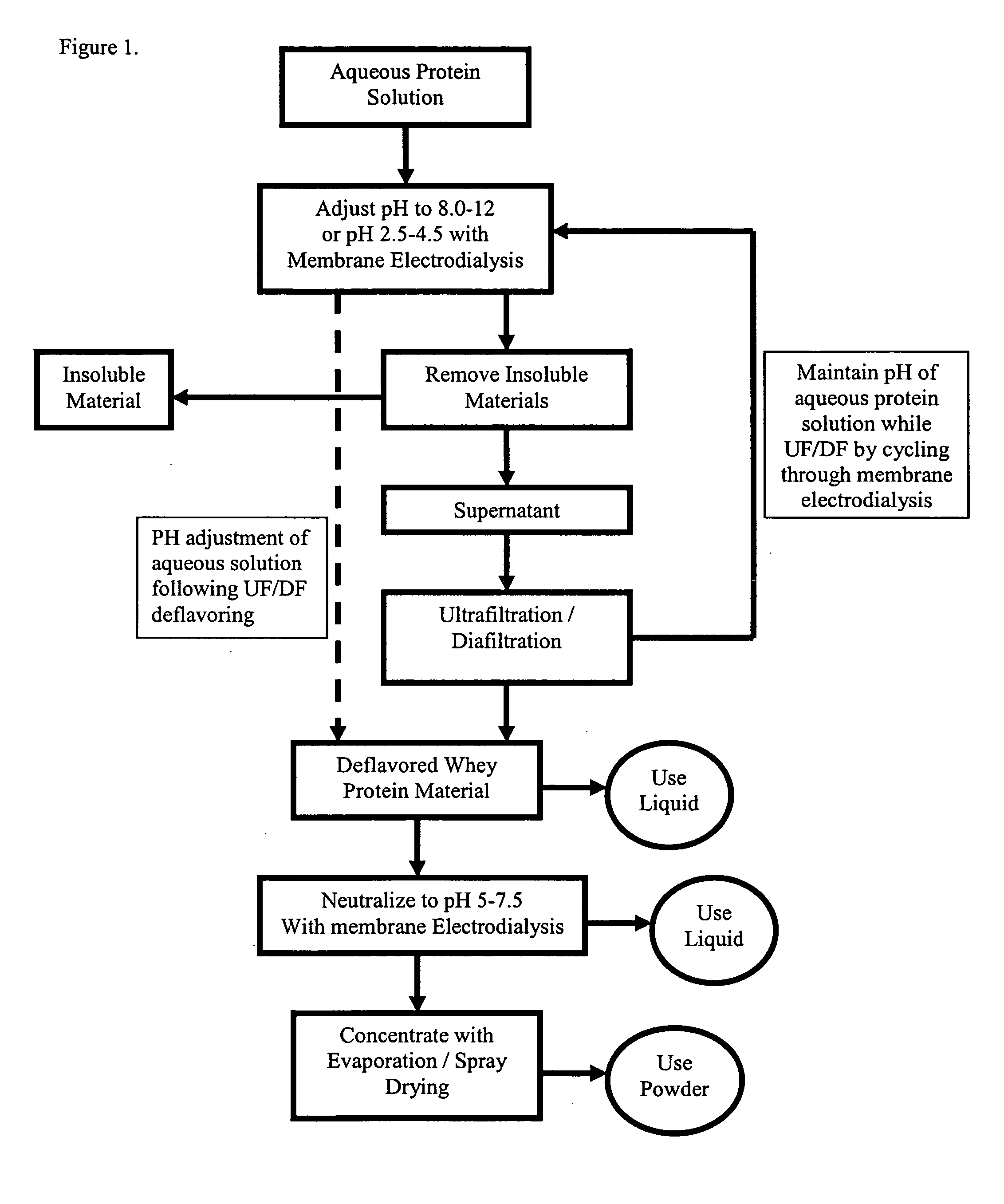

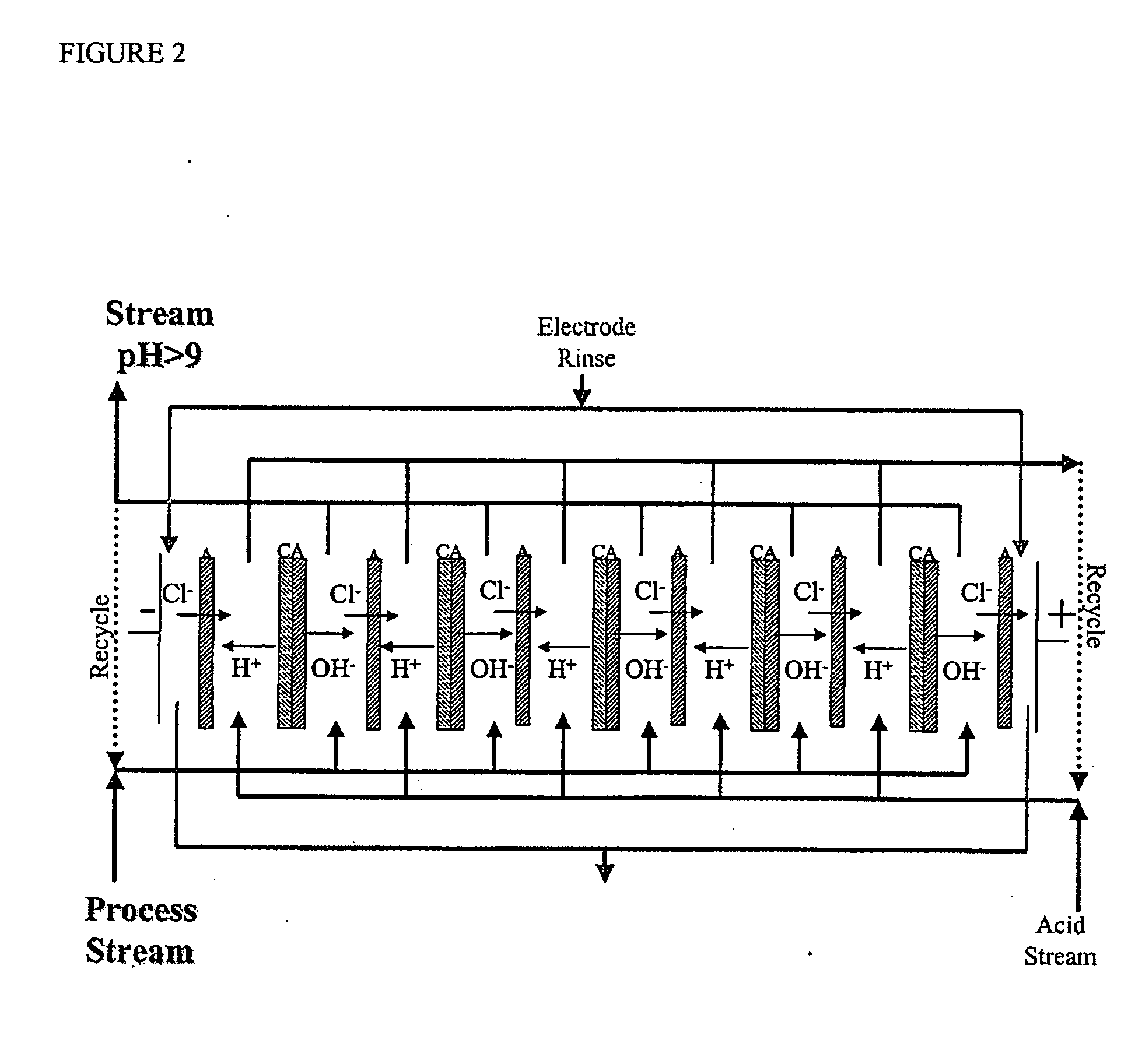

Method of deflavoring whey protein using membrane electrodialysis

InactiveUS20050276904A1Reduce solubilityLarge solubilityFood membrane processWhey manufactureFlavorWhey protein isolate

Whey protein materials such as whey from cheese making processes, whey protein concentrates, and whey protein isolates, are deflavored by adjusting the pH of an aqueous composition of such whey protein materials to about 8.0 to about 12 using membrane electrodialysis to solubilize the whey proteins and to release the flavoring compounds and thereafter passing the pH-adjusted composition to an ultrafiltration membrane having a molecular weight cutoff up to about 50,000 Daltons under conditions at which the flavoring compounds pass through the membrane, leaving the retained whey protein material with improved flavor. the membrane, leaving the retained whey protein material with improved flavor.

Owner:KRAFT FOODS GRP BRANDS LLC

Method for obtaining a TGF-beta enriched protein fraction in activated form, protein fraction and therapeutic applications

The invention concerns a method for obtaining a highly enriched TGF-beta protein fraction in activated form, from a liquid solution rich in proteins said to be soluble in the aqueous phase of milk and / or of whey, said method comprising the following steps; a) adjusting soluble proteins purified at a concentration between 5 and 30 g / liter of solution; b) precipitating part of the whey proteins by acidic treatment of the solution thus obtained to a pH ranging between 4 and 5.5 and at a temperature ranging between 55° C. and 68° C.; c) carrying out a microfiltration of the treated solution by diafiltration, so as to obtain respectively a microfiltration retentate and a microfiltrate; d) recuperating the microfiltration retentate containing the protein fraction highly enriched in TGF-beta; e) drying the microfiltration retentate which has been subjected to diafiltration to obtain a powder highly enriched in TGF-beta.

Owner:PIERRE JOUAN BIOTECH

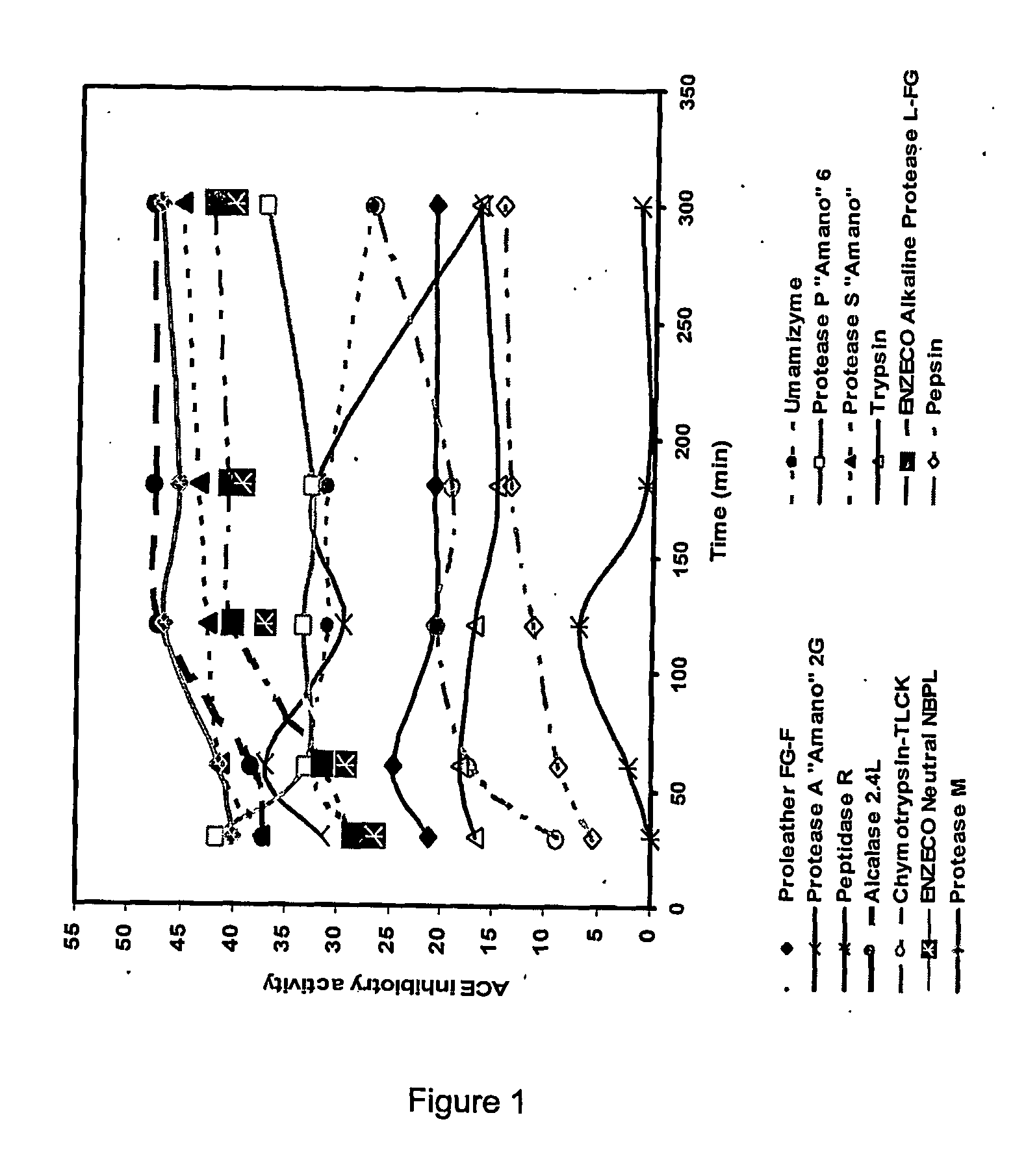

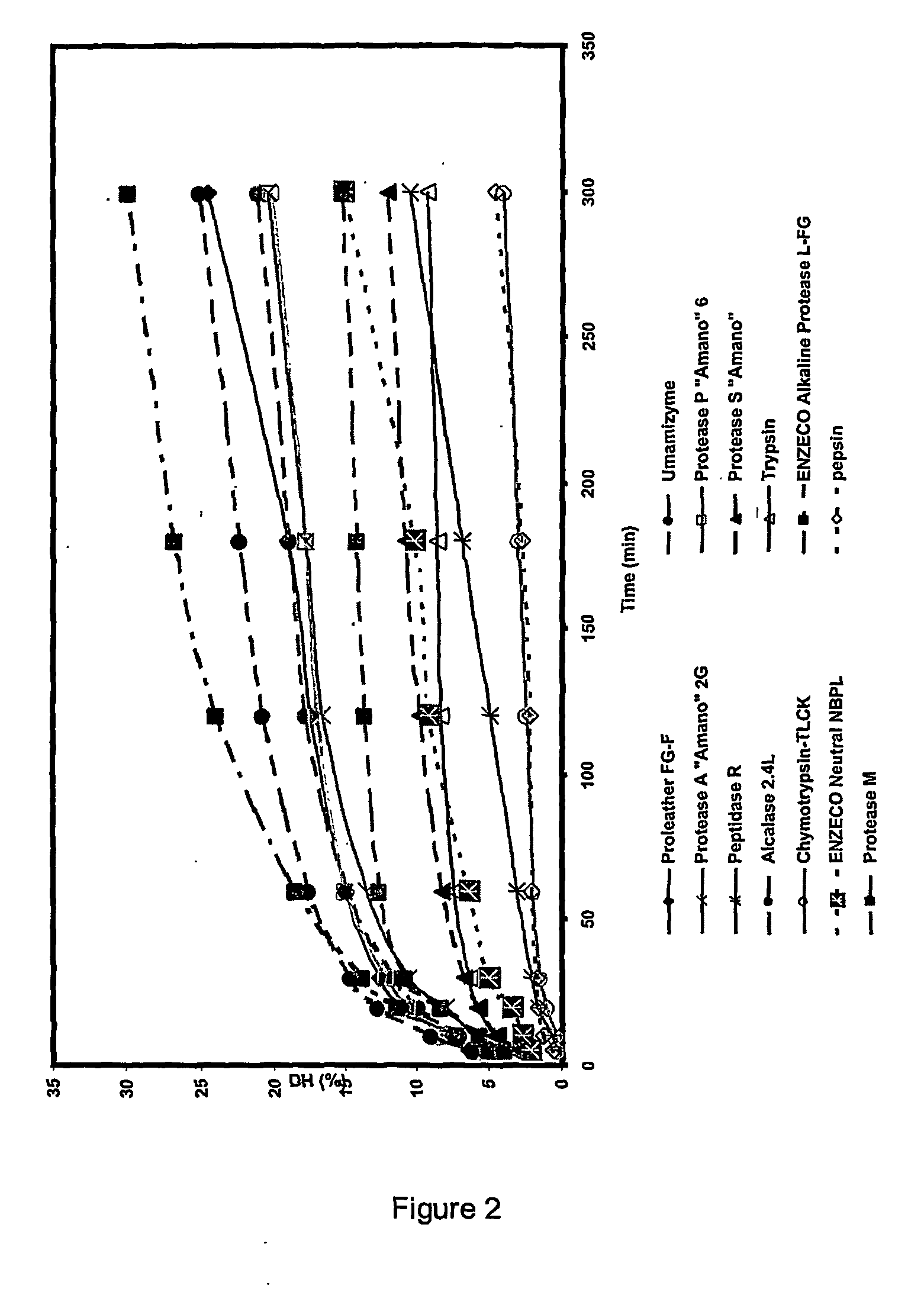

Ace inhibitory peptides from plant materials

InactiveUS20060217318A1Inhibitory activityReduce high blood pressureDipeptide ingredientsTetrapeptide ingredientsOrganic solventDigestion

Improved processes are provided for preparing ACE inhibitory peptide containing hydrolysates from a plant material such as a seed meal or flour. In one embodiment, the seed meal or flour is extracted with an organic solvent prior to digestion. Also provided are ACE inhibitory peptides Val-Ser-Val and Phe-Leu.

Owner:AGRI & AGRI FOOD

Production of soluble protein solutions from soy ("S701" CIP)

ActiveUS8563071B2Protein composition from vegetable seedsFood ingredient as solubility improving agentProtein solutionSports drink

A soy protein product, which may be an isolate, produces transparent heat-stable solutions at low pH values and is useful for the fortification of soft drinks and sports drinks without precipitation of protein. The soy protein product is obtained by extracting a soy protein source material with an aqueous calcium salt solution to form an aqueous soy protein solution, separating the aqueous soy protein solution from residual soy protein source, adjusting the pH of the aqueous soy protein solution to a pH of about 1.5 to about 4.4 to produce an acidified clear soy protein solution, which may be dried, following optional concentration and diafiltration, to provide the soy protein product.

Owner:BURCON NUTRASCI MB

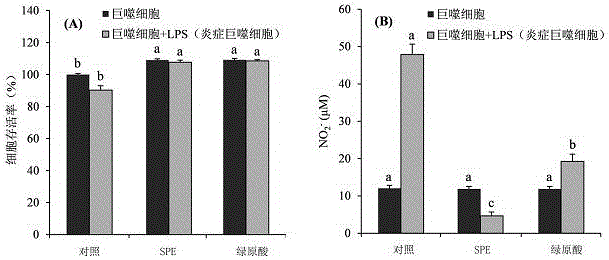

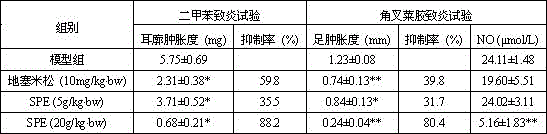

Phenolic extract of stevia rebaudiana and application of phenolic extract in anti-inflammatory products

ActiveCN106236808AReduce NO contentAbundant sources of raw materialsAntipyreticAnalgesicsInflammatory factorsSerum ige

The invention discloses a phenolic extract of stevia rebaudiana and application of the phenolic extract in anti-inflammatory products, and belongs to the technical field of plant extracts. Main components of the phenolic extract of stevia rebaudiana disclosed by the invention are chlorogenic acid and flavonoid compounds. The phenolic extract of stevia rebaudiana can significantly inhibit xylene-induced ear swelling and carrageenin-induced paw swelling, inhibit LPS-induced macrophage NO release, can decrease the content of inflammatory factor NO in serum, and has good anti-inflammatory activity; the phenolic extract of stevia rebaudiana provided by the invention has advantages of rich source of raw materials, easy industrialization, no toxic or side effect and the like, and has broad development and application prospects as anti-inflammatory products.

Owner:CHENGUANG BIOTECH GRP CO LTD

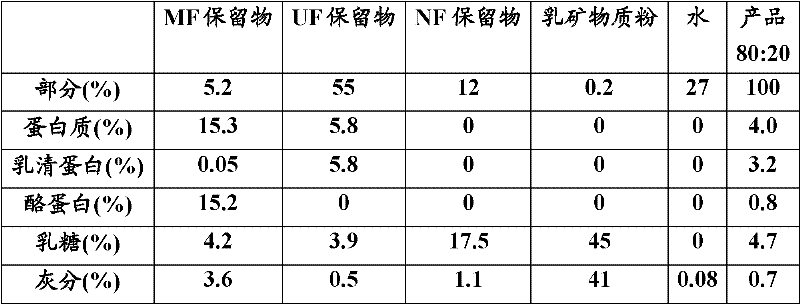

Process for the humanization of animal skim milk and products obtained thereby

ActiveUS20150093490A1Efficient and cheap processMinimum of process stepMilk preparationProtein composition from milkMicrofiltrationFiltration technique

The invention relates to a process for the treatment of animal skim milk and for the production of an infant formula base product from animal skim milk, which process is highly efficient and cost effective, as only membrane filtration techniques, such as microfiltration and ultrafiltration, are required. By carefully controlling the process parameters, a product is obtained in which most of the major components are within the desired range for an infant formula base product. The invention also relates to products obtainable by the process according to the invention.

Owner:NUTRICIA

Method of preparation of high quality soy cultured products

Soy-containing fermented products, especially soy-containing yogurts, beverage, as well as methods for producing such products, are provided. The soy-containing fermented products are prepared using deflavored soy protein material, preferably deflavored soy milk.

Owner:KRAFT FOODS INC

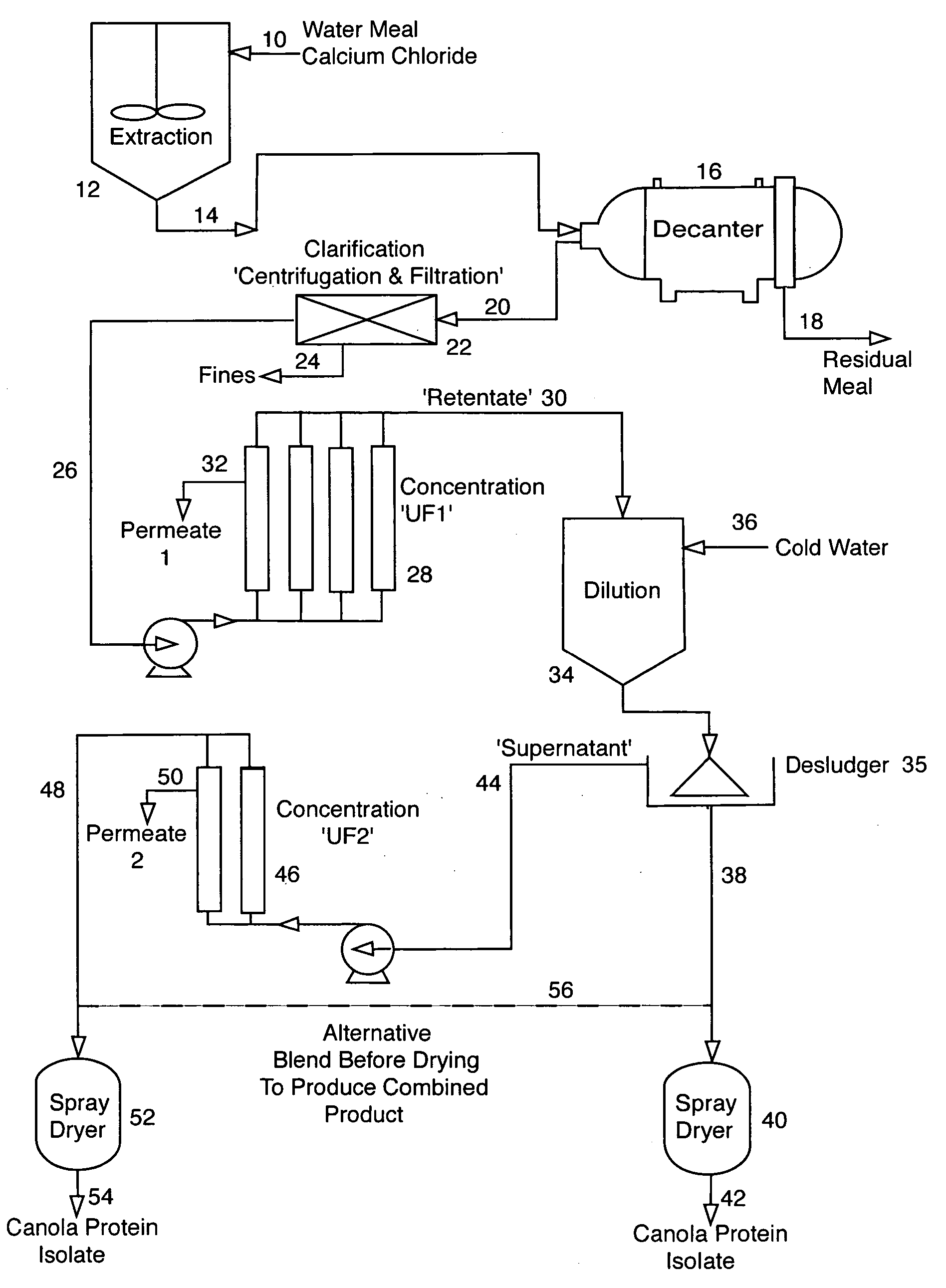

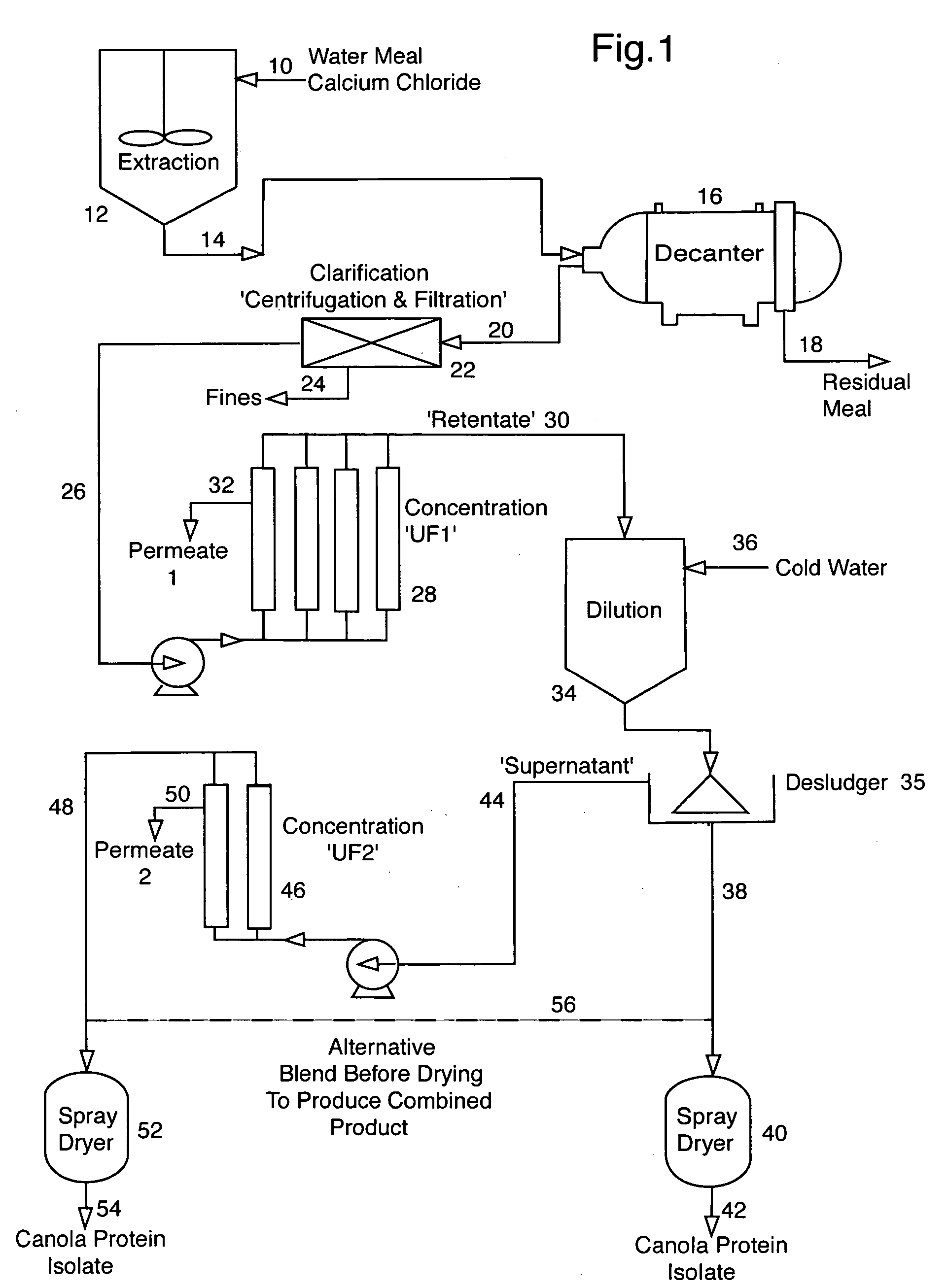

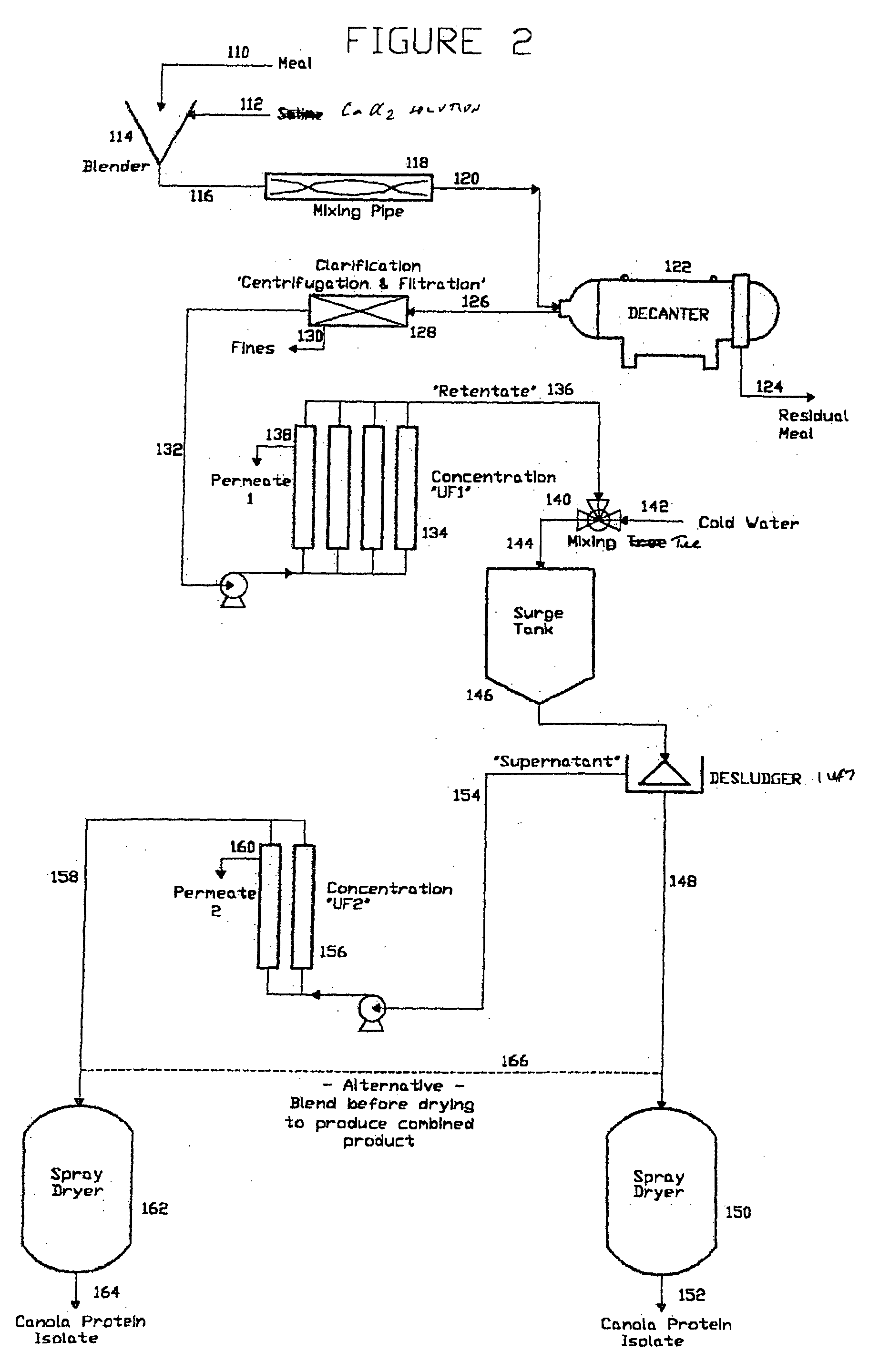

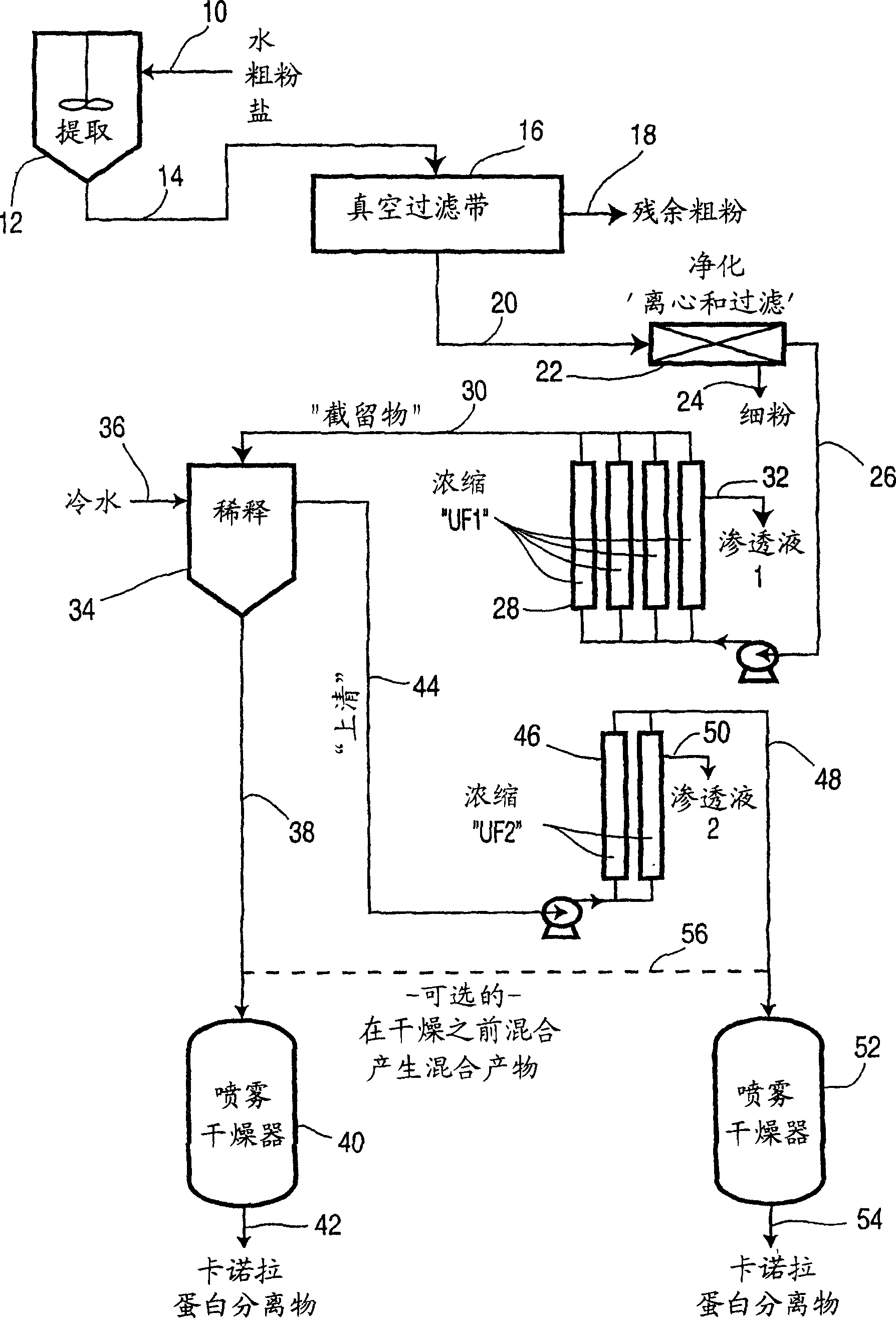

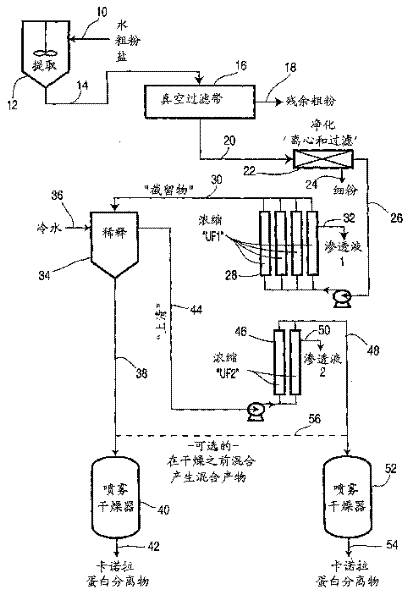

Production of oil seed protein isolate

InactiveCN1523961AProtein composition from vegetable seedsFood membrane processProtein solutionProtein isolate

Oil seed protein isolates, particularly canola protein isolate, are produced at a high purity level of at least about 100 wt % (Nx6.25) by a process wherein oil seed protein is extracted from oil seed meal, the resulting aqueous protein solution is concentrated to a protein content of at least about 200 g / L and the concentrated protein solution is added to chilled water having a temperature below about 15 DEG C. to form protein micelles, which are settled to provide a protein micellar mass (PMM). The protein micelar mass is separated from supernatant and may be dried. The supernatant may be processed to recover additional oil seed protein isolate by concentrating the supernatant and then drying the concentrated supernatant, to produce a protein isolate having a protein content of at least about 90 wt %. The concentrated supernatant may be mixed in varying proportions with at least part of the PMM and the mixture dried to produce a protein isolate having a protein content of at least about 90 wt %.

Owner:BURCON NUTRASCI MB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com