Method for equivalent dialysis through directly adopting membrane treatment

A membrane treatment and direct technology, applied in the field of volume dialysis, can solve the problems of increased treatment cost of acesulfame filtrate, high impurity content of acesulfame potassium, and expensive equipment, so as to save the concentration treatment and recovery process and save steam energy consumption. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of method that the present invention proposes directly adopts membrane treatment equivalent dialysis, comprises the following steps:

[0019] S1: Store the filtrate of acesulfame-K in the filtrate storage tank, which is the original solution;

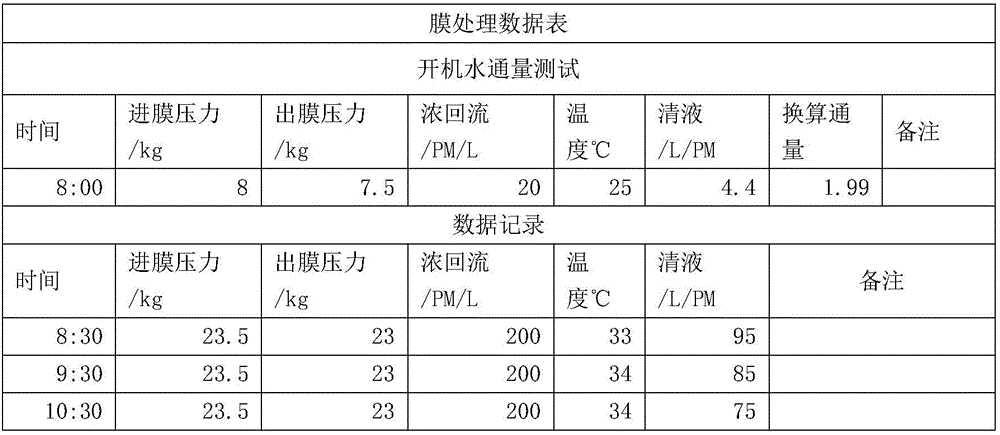

[0020] S2: Preset the temperature of the filtrate storage tank to 38°C, turn on the hot water circulation system outside the filtrate storage tank, raise the temperature of the raw liquid in the filtrate storage tank to the preset temperature, and set the membrane inlet pressure in the membrane equipment to 23.5kg, The membrane outlet pressure is 23kg. After the temperature of the raw liquid reaches the preset temperature, the outlet valve of the filtrate storage tank and the inlet valve of the membrane equipment are opened, so that the raw liquid enters the membrane equipment, and then permeates and concentrates through the membrane system in the membrane equipment. The organic membrane with a medium molecular weight of 1...

Embodiment 2

[0026] A kind of method that the present invention proposes directly adopts membrane treatment equivalent dialysis, comprises the following steps:

[0027] S1: Store the filtrate of acesulfame-K in the filtrate storage tank, which is the original solution;

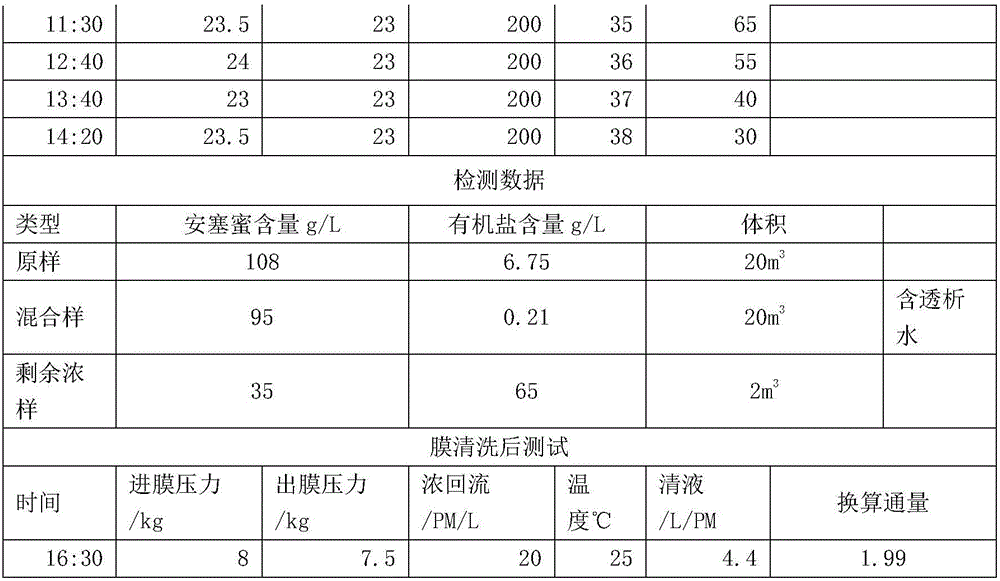

[0028] S2: Preset the temperature of the filtrate storage tank at 37°C, turn on the hot water circulation system outside the filtrate storage tank, raise the temperature of the raw liquid in the filtrate storage tank to the preset temperature, and set the equal pressure of the membrane inlet and outlet membrane in the membrane equipment After the raw liquid temperature reaches the preset temperature, open the outlet valve of the filtrate storage tank and the inlet valve of the membrane equipment, so that the raw liquid enters the membrane equipment, and then permeates and concentrates through the membrane system in the membrane equipment. The molecular weight in the membrane system is The organic membrane of 800 is permeat...

Embodiment 3

[0034] A kind of method that the present invention proposes directly adopts membrane treatment equivalent dialysis, comprises the following steps:

[0035] S1: Store the filtrate of acesulfame-K in the filtrate storage tank, which is the original solution;

[0036] S2: Preset the temperature of the filtrate storage tank at 32°C, turn on the hot water circulation system outside the filtrate storage tank, raise the temperature of the raw liquid in the filtrate storage tank to the preset temperature, and set the equal pressure of the membrane inlet and outlet membrane in the membrane equipment. After the raw liquid temperature reaches the preset temperature, open the outlet valve of the filtrate storage tank and the inlet valve of the membrane equipment, so that the raw liquid enters the membrane equipment, and then permeates and concentrates through the membrane system in the membrane equipment. Permeate through the organic membrane of 1200, and the membrane clear liquid flows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com