Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Little change in appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

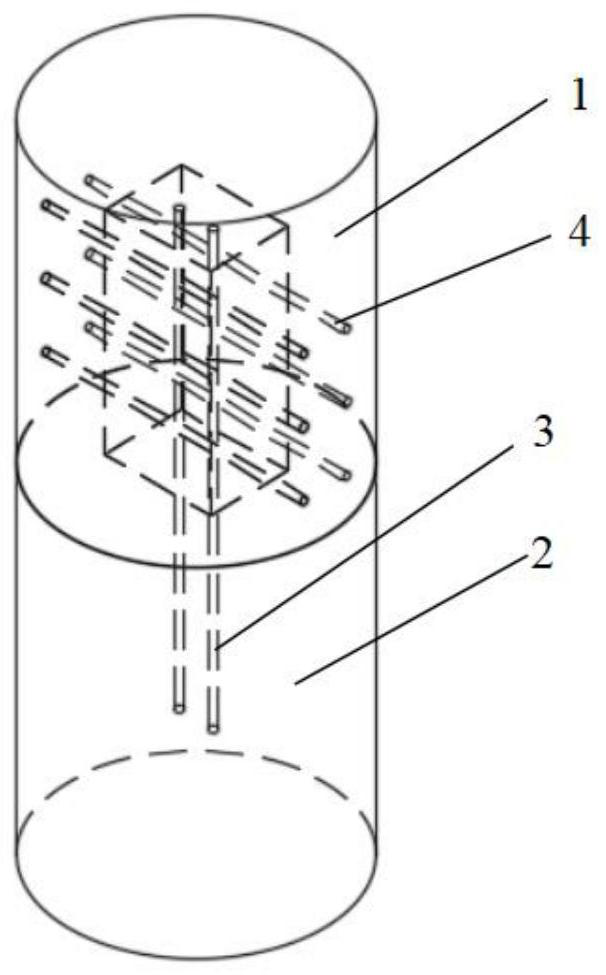

Preparation technology of metal nanometer fiber

InactiveCN105063804AImprove conductivitySuper flexibleInorganic material artificial filamentsFilament/thread formingAir atmosphereElectrospinning

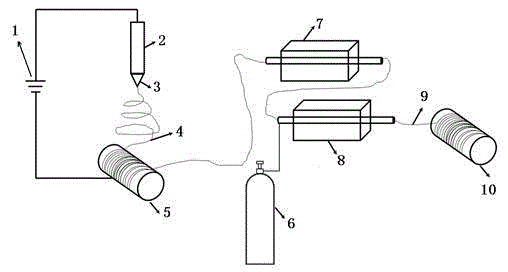

The invention provides a preparation technology of metal nanometer fiber. The preparation technology comprises the following steps: 1) dissolving metal salt, macromoleclar polymer and curing agent in a solvent, obtaining a static spinning liquid; 2) placing the static spinning liquid in a static spinning equipment for spinning, obtaining a jet spinning protofilament, and collecting the jet spinning protofilament in a single fiber mode on a first collection reel; 3) slowly pulling out the jet spinning protofilament on the first collection reel collected in the step 2), placing the jet spinning protofilament in a two stage continuous tunnel furnace for heating and sintering, wherein, a front section is air atmosphere sintering and a back section is a reducing atmosphere sintering; 4) winding and collecting a metal nanometer fiber obtained by sintering in the step 3) in single fiber mode to a second collection reel, and obtaining a metal nanometer fiber. According to the invention, the continuous single metal nanometer fiber of high quality is effectively formed, and the fiber has the ultrafine, ultrasoft and high conductive characteristics.

Owner:SUZHOU MINDOM TECH

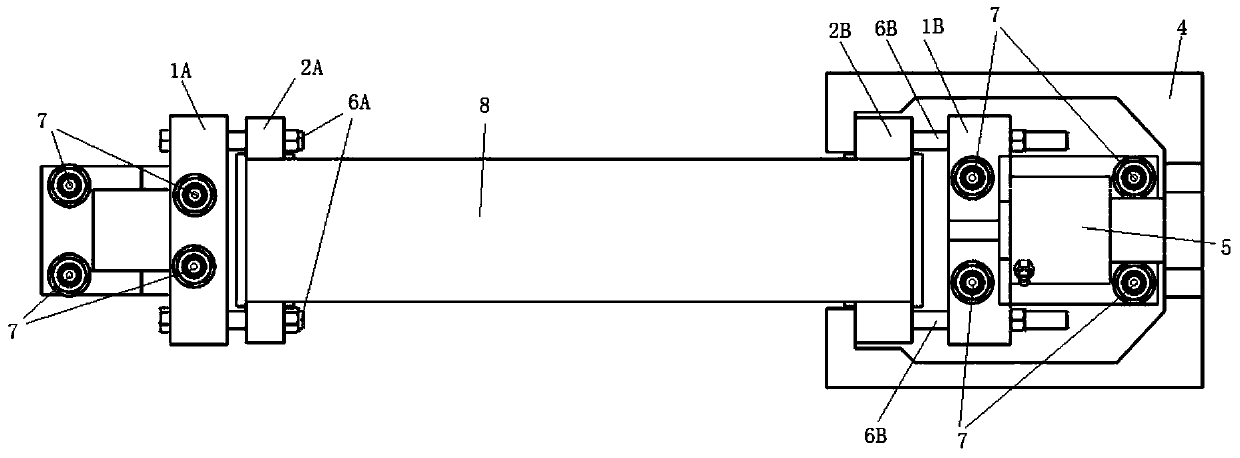

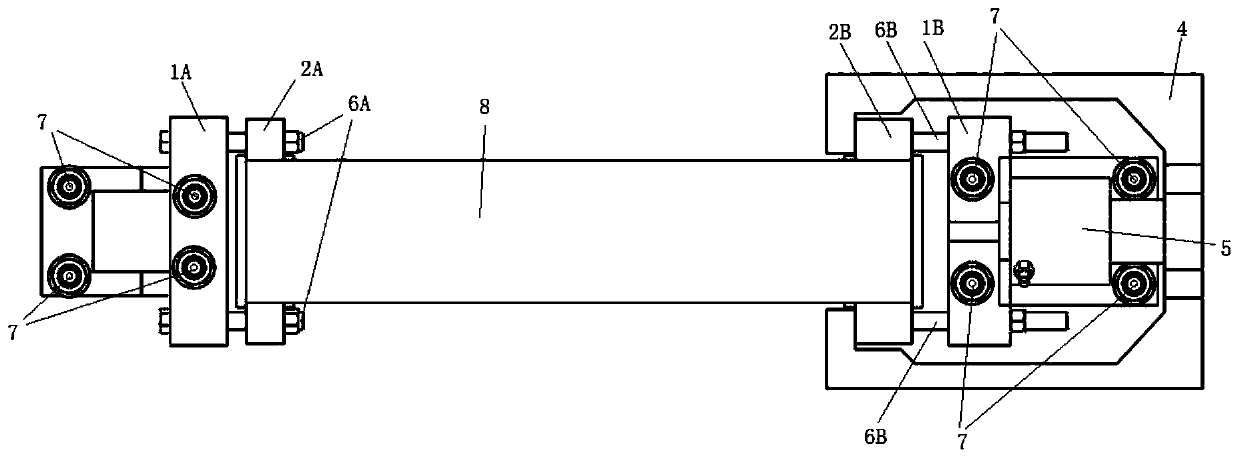

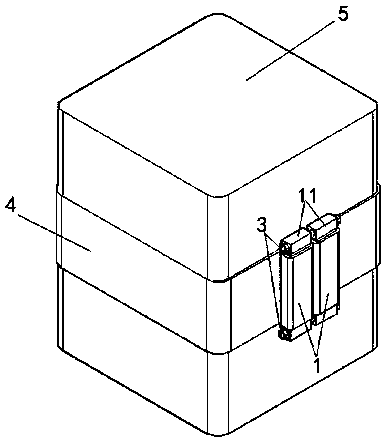

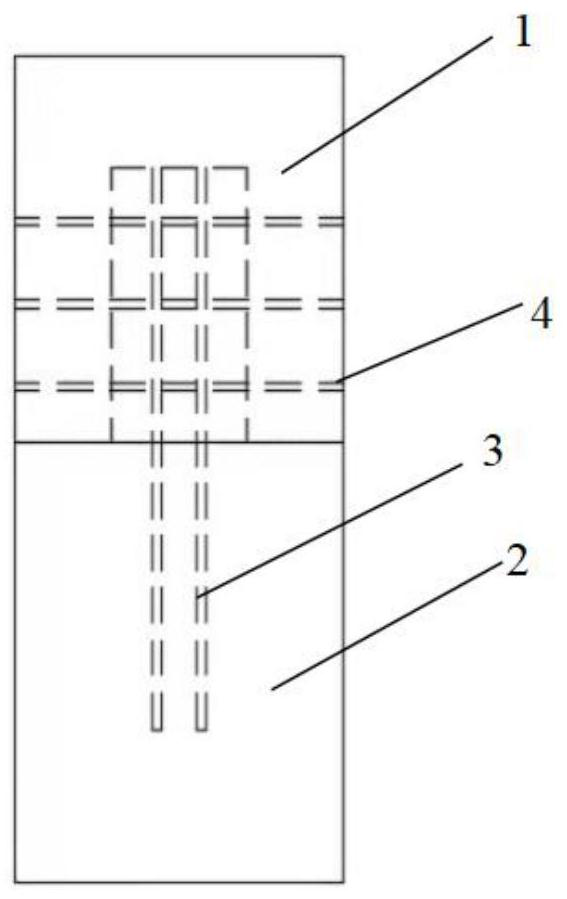

Tensioning and anchoring device for prestressed fiber cloth reinforced beams and construction method of device

ActiveCN108843037APrevent slippageImprove anchoring efficiencyBuilding repairsBuilding material handlingFiberPre stress

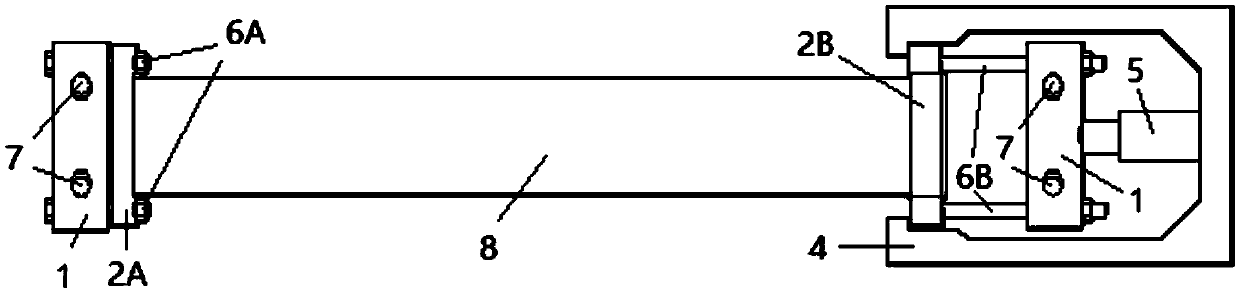

The invention discloses a tensioning and anchoring device for prestressed fiber cloth reinforced beams and a construction method of the device. The device comprises fixed supports, a fixed end anchorage device, a tensioning end anchorage device, clamping pieces, short anchoring screws, long anchoring screws, chemical bolts, fiber cloth, a prestress application frame and a jack, wherein the fixed supports, the fixed end anchorage device and the tensioning end anchorage device are cuboid; the fixed supports are fixed with a to-be-reinforced beam through the chemical bolts; the fixed end anchorage device and the tensioning end anchorage device are connected with the fixed supports through the short anchoring screws and the long anchoring screws respectively; a rectangular through seam allowing the fiber cloth to pass is formed in the fixed end anchorage device; wedge-shaped holes allowing insertion of the clamping pieces are formed in the tensioning end anchorage device, and the clampingpieces are wedged into the wedge-shaped holes, so that clamping of the fiber cloth is realized. The construction method comprises steps as follows: firstly, the anchorage devices are mounted, then thefixed supports are assembled and the anchorage devices are fixed, finally, the prestress application frame and the jack are mounted, and tensioning and anchoring are implemented. The device is reasonable and simple in structure and convenient to operate and can be reused, and the applied prestress is large.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

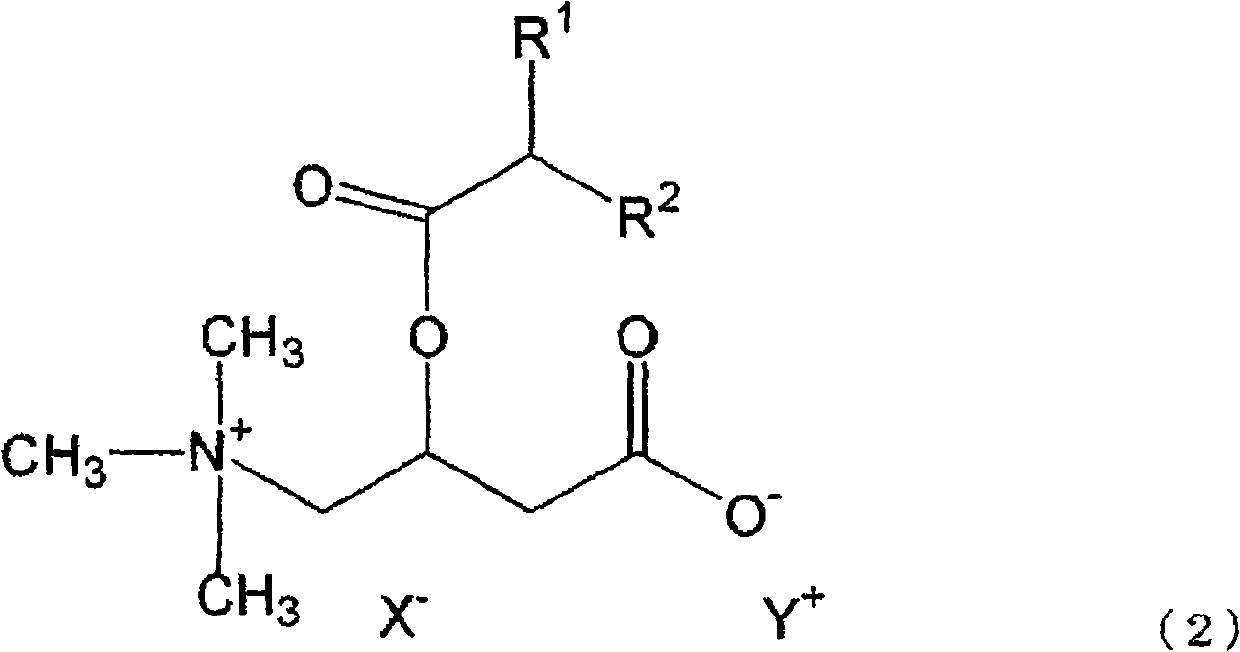

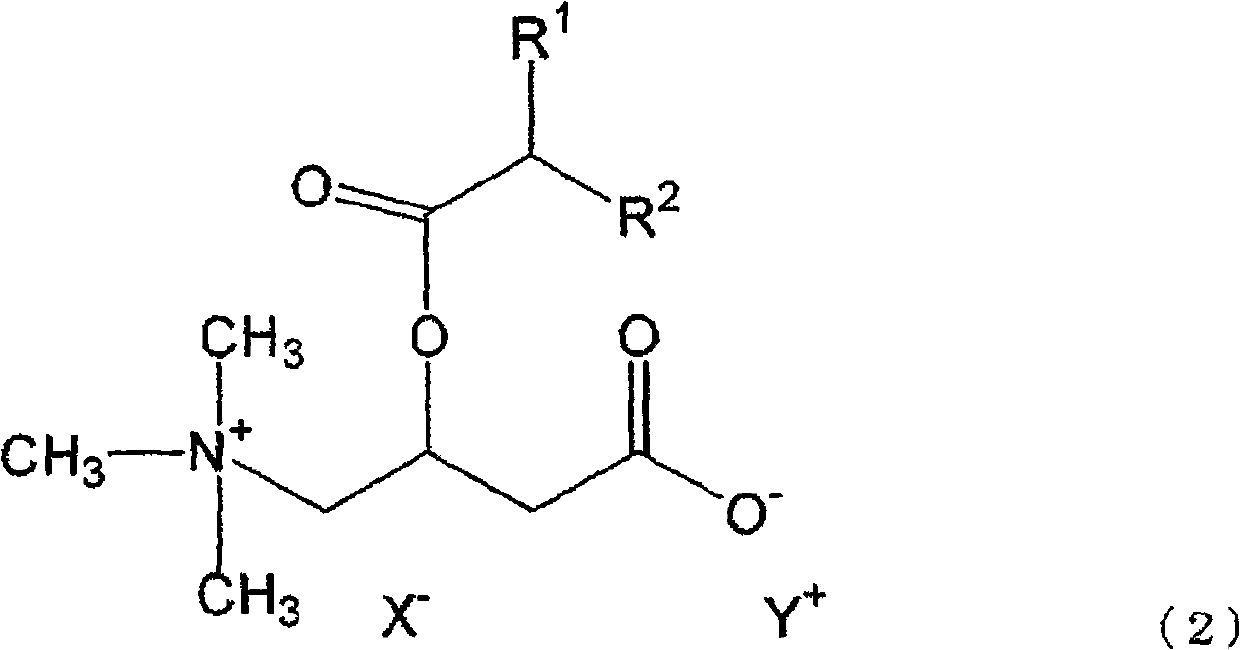

Emulsified skin external preparations and cosmetics

InactiveUS20100273877A1High emulsion stabilityFeel goodCosmetic preparationsBiocidePhotochemistryUnsaturated aliphatic hydrocarbons

An emulsified skin external preparation including 0.01 to 10% by mass of a branched acyl carnitine derivative represented by the following Formula (1) and / or a carnitine derivative salt represented by the following Formula (2), and 0.01 to 20% by mass of a nonionic surfactant:where R1 and R2 are each independently a C1-18 optionally branched, saturated or unsaturated aliphatic hydrocarbon group. In Formula (2), R1 and R2 are the same as in Formula (1), X− is a specific anion and Y+ is a specific cation.

Owner:SHOWA DENKO KK

Conductive foam and fabrication method thereof

ActiveCN105555116AImprove surface activityTight and firm bondNon-macromolecular adhesive additivesMagnetic/electric field screeningPolymer chemistryPolymer

The invention discloses conductive foam and a fabrication method thereof. The conductive foam comprises an elastic body, a bonding layer and a shielding layer, wherein the bonding layer wraps the outer surface of the elastic body, the elastic body, the bonding layer and the shielding layer are sequentially arranged from inside to outside, the shielding layer is provided with a high-molecular polymer film and a metal layer from inside to outside, and a processing agent layer is arranged between the high-molecular polymer film and the bonding layer and used for improving the surface activity of the high-molecular polymer film. With a mode of additionally arranging the processing agent layer, the surface activity of the high-molecular polymer film is improved, the high-molecular polymer film is more tightly and firmly bonded with the elastic body by the bonding layer, a permeating bonding effect is formed between the bonding layer and the high-molecular polymer film, a tiny gap is eliminated, and the high-molecular polymer film is difficult to pop from the elastic body in a high-temperature environment.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

Text detection method

InactiveCN108038486ALittle change in appearanceImprove robustnessCharacter and pattern recognitionNeural architecturesText detectionFeature fusion

The invention discloses a text detection method. The method comprises the steps of extracting an extremal region of a to-be-detected text picture, and filtering the extremal region to obtain candidatecharacter regions; calculating an MSSH feature and a deep convolution feature, and fusing the MSSH feature and the deep convolution feature through an auto-encoder neural network to obtain a fused feature; according to the fused feature, further screening out character regions from the candidate character regions; and combining all the character regions to obtain a final text region. The detection method has very strong robustness; the detection efficiency is high; and a text detection task can be quickly finished.

Owner:HOHAI UNIV

Biaxially oriented polyester film for molded part

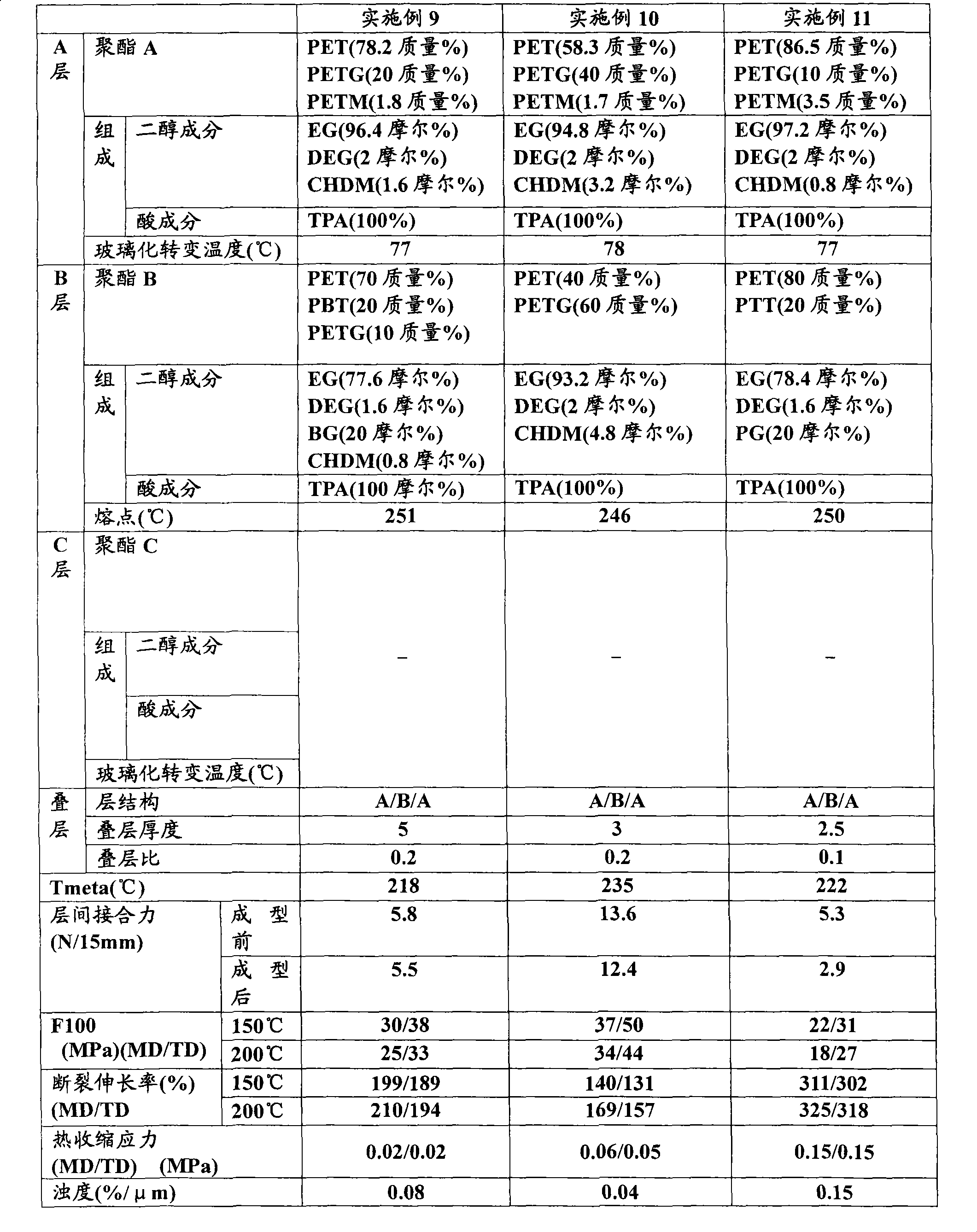

ActiveCN101426646ALittle change in appearanceUniform vapor depositionSynthetic resin layered productsVacuum evaporation coatingPolyesterChemical vapor deposition

To provide a biaxially oriented polyester film, particularly a biaxially oriented polyester film for forming members which is useful as a substrate in producing metallic forming members by metal vapor deposition or as a surface protective film in the forming of decorative sheets. [MEANS FOR SOLVING PROBLEMS] A biaxially oriented polyester film for forming members, which is an at least two-ply laminate constituted of a layer (A) made of a polyester (A) and a layer (B) made of a polyester (B) wherein the interlaminar strength between the layers (A) and (B) is 5 N / 15mm or above and the stress values (F100 values) at 100% elongation in the lengthwise and widthwise directions at 200 DEG C and 150 DEG C are 1 to 50 MPa.

Owner:TORAY IND INC

Application of PMS (potassium methyl silicate) water solution in deacidification and reinforcement of paper

InactiveCN104032623ALittle change in appearanceGood deacidification effectOld paper after-treatmentCelluloseFiber

The invention discloses application of a PMS (potassium methyl silicate) water solution to deacidification and reinforcement of paper. According to the application, a deacidification and reinforcement method comprises the following steps: soaking the paper in a deacidification agent; treating, hanging and airing to complete the deacidification and the reinforcement, wherein the deacidification agent is any one of the PMS water solution and an alcohol water mixing solution. The paper is treated by using a PMS paper deacidification agent, so that the deacidification effect is obvious, and the mechanical property of the paper is well improved. By improving different solvent ratios and concentration ratios, the acid property and the mechanical property of the paper are improved to different extents. Meanwhile, the paper is obvious in hydrophobic performance. According to the characteristics, the water absorption of paper cellulose can be reduced, so that the damage to swelling, degradation and hydrogen-bonding of fibers caused by water is alleviated. The microbiological corrosion degree of the paper is greatly reduced.

Owner:RENMIN UNIVERSITY OF CHINA

Construction method of prestressing force fiber cloth reinforcing column adopting detachable tensioning anchorage device

PendingCN107794849AEasy to holdPrevent slippageBuilding repairsBridge erection/assemblyFiberReinforced concrete

The invention discloses a construction method of a prestressing force fiber cloth reinforcing column adopting a detachable tensioning anchorage device. A prestressing force fiber cloth tensioning andanchoring device adopting a detachable tensioning anchorage device comprises two anchor plates, two clamping plates, two tensioning anchorage devices, two tensioning screw rods, two anchoring screw rods and a fiber cloth. The construction method comprises the following steps of determining a position to be reinforced, performing grinding, performing hole repairing, and coating an epoxy glue layer;then completing the connection of the fiber cloth with the tensioning anchorage devices, as well as the connection of the anchor plates with the clamping plates; wrapping the position to be reinforced and coated with the epoxy glue layer with the connected fiber cloth; screwing the tensioning screw rods to exert prestressing force on the fiber cloth; synchronously screwing the anchoring screw rods to maintain the prestressing force on the fiber cloth; unscrewing big bolts between the tensioning anchorage devices and the clamping plates; and discharging the tensioning anchorage devices and thetensioning screw rods, so that the reinforcing construction of a reinforced concrete pier can be realized. The construction method disclosed by the invention is good in reinforcing effects and convenient to operate; and the tensioning anchorage devices and the tensioning screw rods can be disassembled and repeatedly used, so that the cost is saved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Fingerprint-resistant anti-reflection film

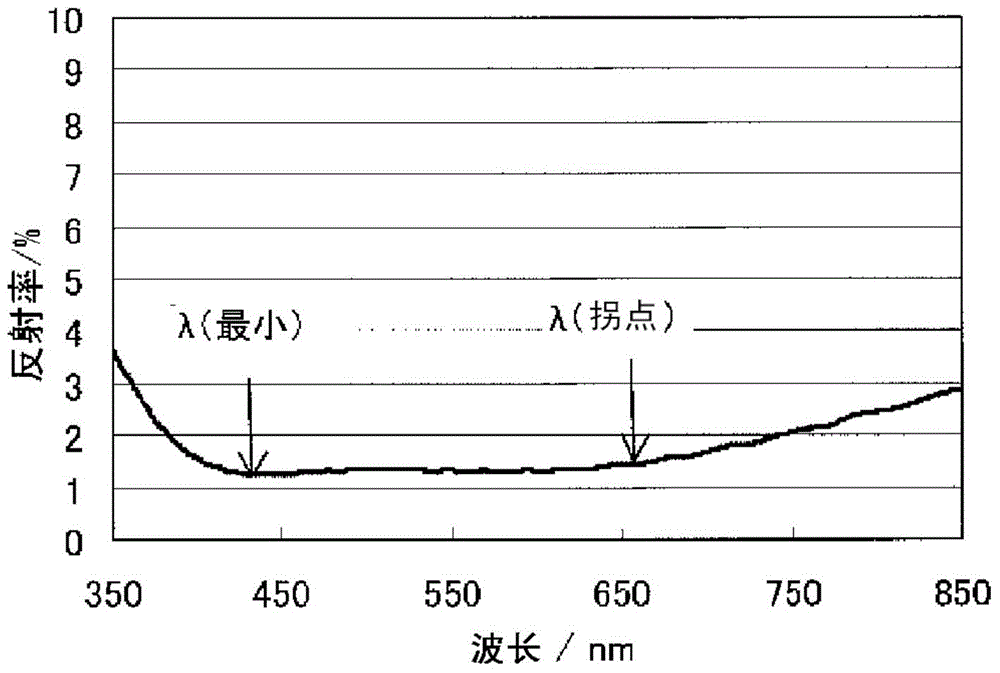

ActiveCN104903755ALittle change in appearanceReduce the amount of adhesionLayered productsCoatingsRefractive indexLength wave

A fingerprint-resistant anti-reflection film having a hard coat layer, a high-refractive-index layer, and a low-refractive-index layer laminated in the stated order on one side of a transparent base film. The refractive index of the high-refractive-index layer is 1.50-1.65, and the film thickness thereof is 130-180 nm. The refractive index of the low-refractive-index layer is 1.36-1.42, and the film thickness thereof is 70-100 nm. The minimum reflectance wavelength (λ(min)) in a wavelength range of 350-850 nm is 350-530 nm, and the wavelength (λ(bend)) at the bending point in the wavelength range of 350-850 nm satisfies the relationship λ(min) < λ(bend). Furthermore, the luminous reflectance of the fingerprint-resistant anti-reflection film is 2.0% or lower, the reflection chroma (C) is less than 6.0, and the reflection color difference (△E) before and after adhesion of sebum soil is less than 7.0.

Owner:HIGASHIYAMA FILM CO LTD

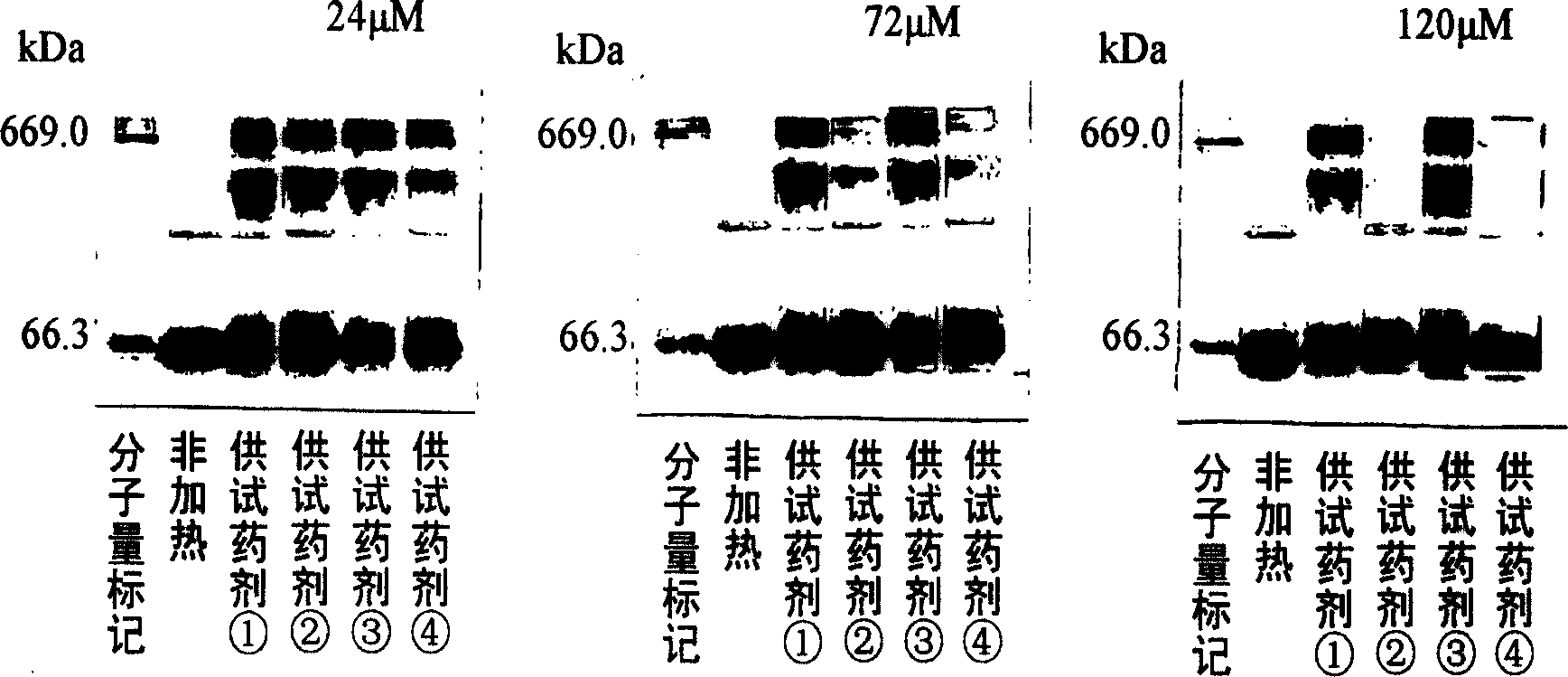

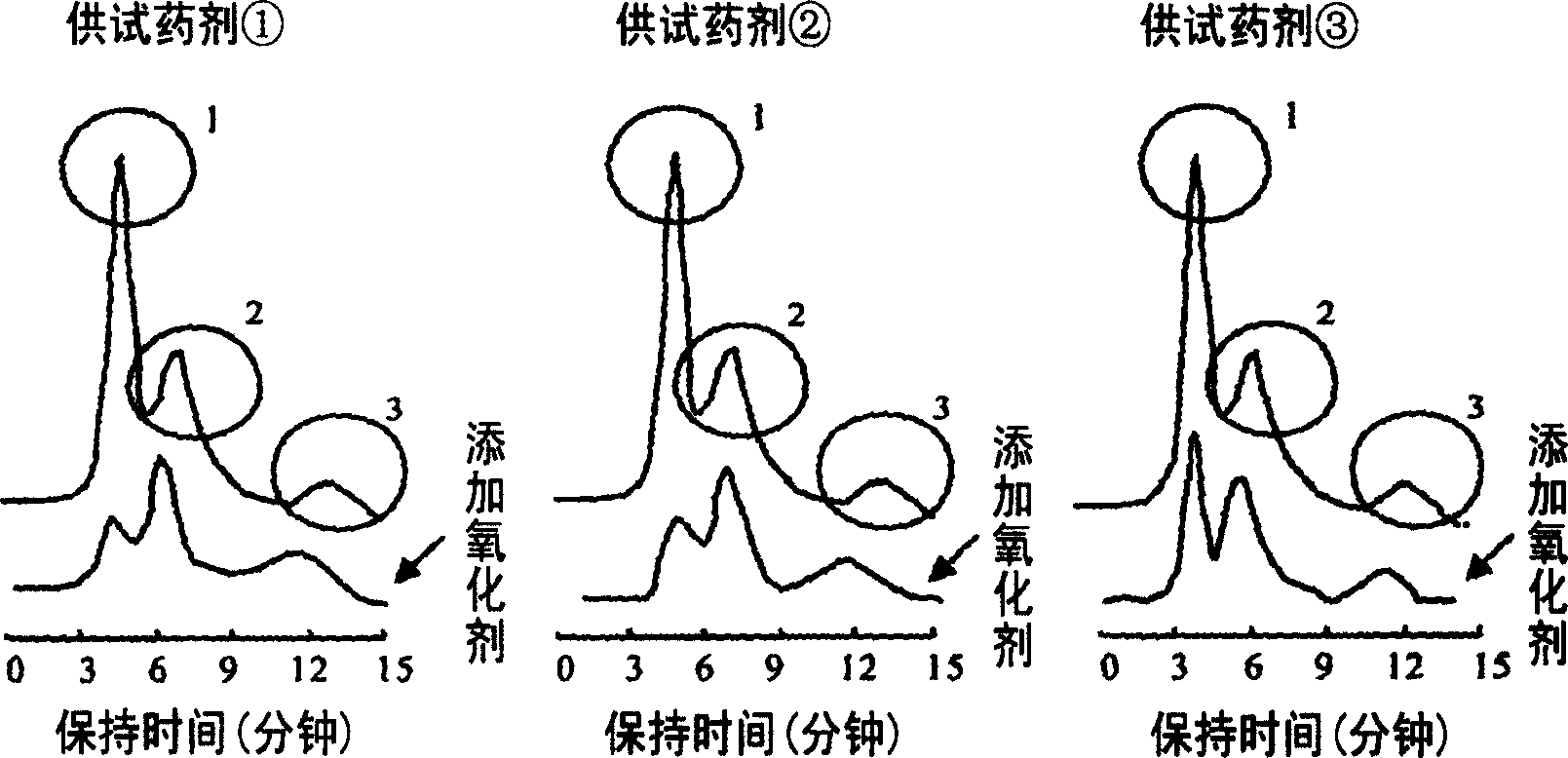

Stabilized albumin preparaions

InactiveCN1638788ALittle change in appearanceImprove stabilityPeptide/protein ingredientsDigestive systemSide effectMedium chain fatty acid

This invention provides albumin preparations with safety and without any risk of side effects, which are free from viruses or contaminating proteins and can be stably stored over a long time while showing neither changes in appearance nor decrease in content. <??>There are provided a stabilized albumin preparation produced by uniformly mixing a medium-chain fatty acid or a salt thereof and a sulfur-containing amino acid or a derivative thereof with an aqueous albumin solution (e.g., a buffer such as phosphate buffer which can be administered as pharmaceutical preparations, injection water, or a physiological saline) and dissolving them therein, and then processing the mixture solution into a formulation suitable for parenteral administration such as an intravenous fluid preparation or an injectable solution, and a stabilization method for an albumin preparation.

Owner:NIPRO CORP

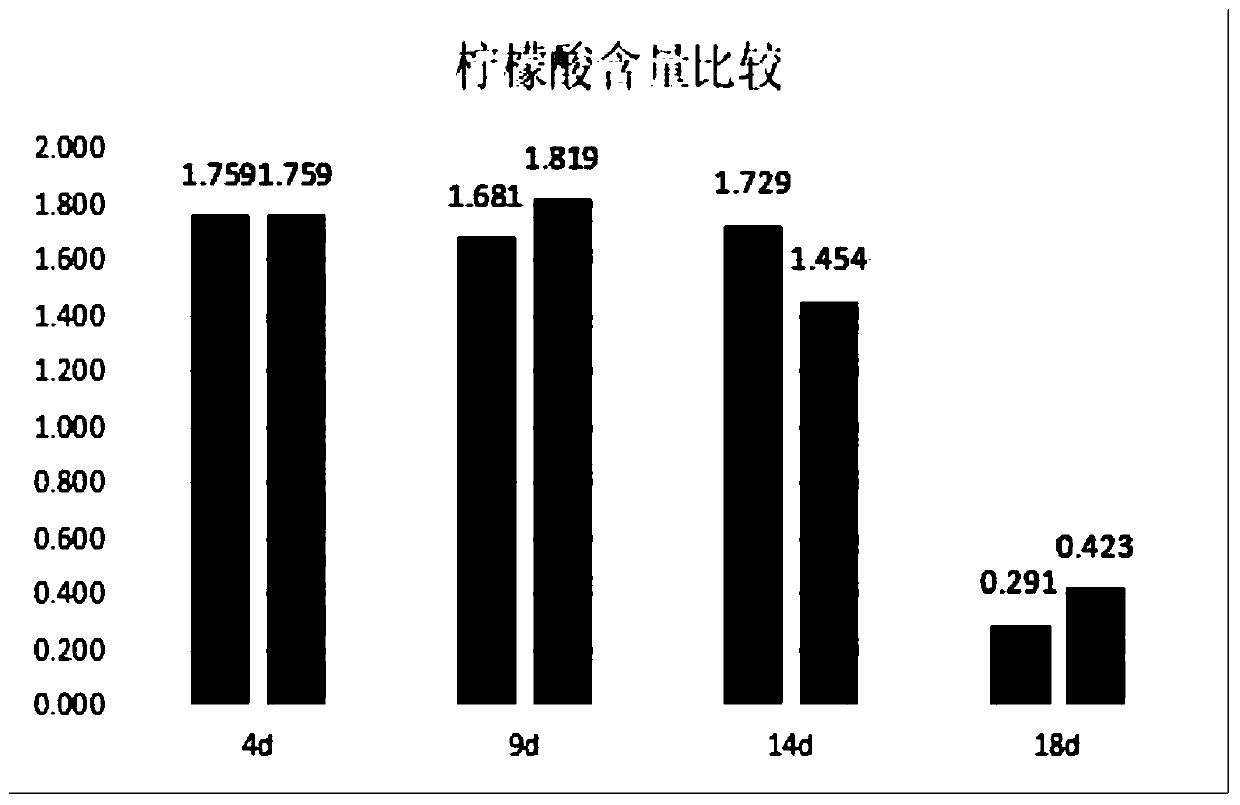

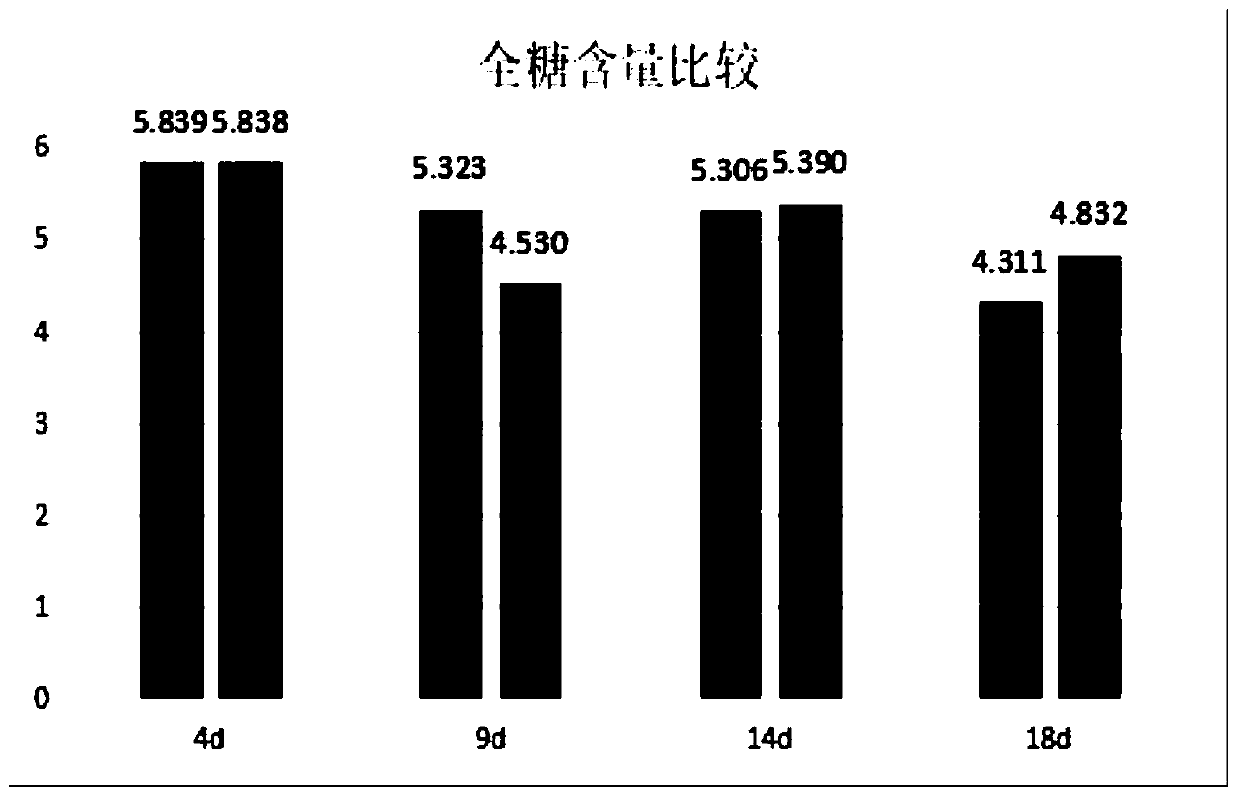

Storage and preservation method of mandarin orange

PendingCN110250263ALittle change in appearanceReduce the degree of oxidationNatural extract food ingredientsFruits/vegetable preservation by coatingChemistryCitrus plant

The invention discloses a storage and preservation method of mandarin orange. The method includes the following steps: (1) pretreatment: soaking picked fresh mandarin orange in a bactericide for 1 minute, taking out, and immediately drying; (2) coating: soaking the pretreated mandarin orange in a film forming agent for 3-5 minutes, taking out, drying the outer skin of the mandarin orange and placing the dried mandarin orange on the surface of the mandarin orange to form a film; (3) placing absorbent paper sprayed with plant essential oil in a nano fresh-keeping bag, placing the mandarin orange with the film on the surface in the step (2) into the fresh-keeping bag, sealing the fresh-keeping bag, and refrigerating at 4-6 DEG C. The method can effectively kill harmful bacteria, spores and other microorganisms on the mandarin orange, prevent the deterioration and decay of the mandarin orange caused by the reproduction of harmful microorganisms, prolong the shelf life and storage period of the mandarin orange, and has far-reaching and positive effects on improving the economic benefits of the citrus planting industry.

Owner:广西壮族自治区农业科学院园艺研究所

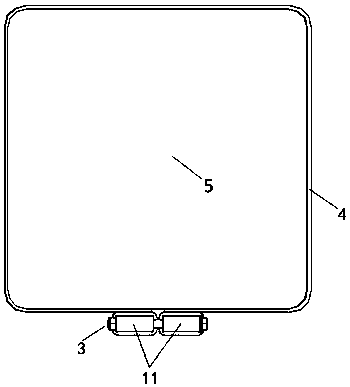

Detachable fiber cloth prestressed tensioning and anchoring device

PendingCN107905126AEasy to removeLow costBuilding repairsBridge erection/assemblyDrill holeEngineering

The invention discloses a detachable fiber cloth prestressed tensioning and anchoring device. The detachable fiber cloth prestressed tensioning and anchoring device comprises two anchoring plates, twoclamping plates, two tensioning anchorage devices, two tensioning screws, two anchoring screws and a fiber cloth. The two ends of the fiber cloth are coated with glue and then wind around the anchoring plates by two circles, the anchoring plates and the clamping plates are fixedly connected through small bolts, and the fiber cloth winds around the anchoring plates the clamping plates by two circles. The anchoring plates, the clamping plates and the tensioning anchorage devices are fixedly connected through large bolts. The tensioning screws penetrate into tensioning screw holes of the tensioning anchorage devices, and the tensioning screws are tightened to apply prestress on the fiber cloth. The surface of the fiber cloth is coated with glue, and then the anchoring screws penetrate into anchoring screw holes in the anchoring plates. The anchoring screws are tightened synchronously so as to keep the prestress on the fiber cloth. After the glue on the fiber cloth is solidified, the large bolts between the tensioning anchorage devices and the clamping plates are loosened, and the tensioning anchorage devices and the tensioning screws are unloaded. According to the detachable fiber cloth prestressed tensioning and anchoring device, the reinforcing effect is good, the structure is simple, and operating is convenient; and the tensioning screws and the tensioning anchorage devices can be detached and reused, and the cost is saved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Construction method for strengthening concrete beam through multi-layer prestressed fiber cloth

ActiveCN110029594AReduce forceImprove anchoring reliabilityBuilding repairsBridge erection/assemblyPre stressFiber

The invention discloses a construction method for strengthening a concrete beam through a multi-layer prestressed fiber cloth. A tensioning and anchoring device of a multi-layer prestressed fiber cloth reinforced beam is arranged, and includes a fixed end support, a tensioning end support, a fixed end anchor, a tensioning end anchor, a clamping piece, an anchoring short screw, an anchoring long screw, a chemical bolt, a fiber cloth, a prestressed applied frame and a jack. Tensioning and anchoring of the fiber cloth are realized by the tensioning and anchoring device of the multi-layer prestressed fiber cloth reinforced beam. According to the construction method, operation is convenient, large prestress can be applied, the multi-layer fiber cloth has uniform stress and the equal length, andmeanwhile, the prestressed applied frame can be reused.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

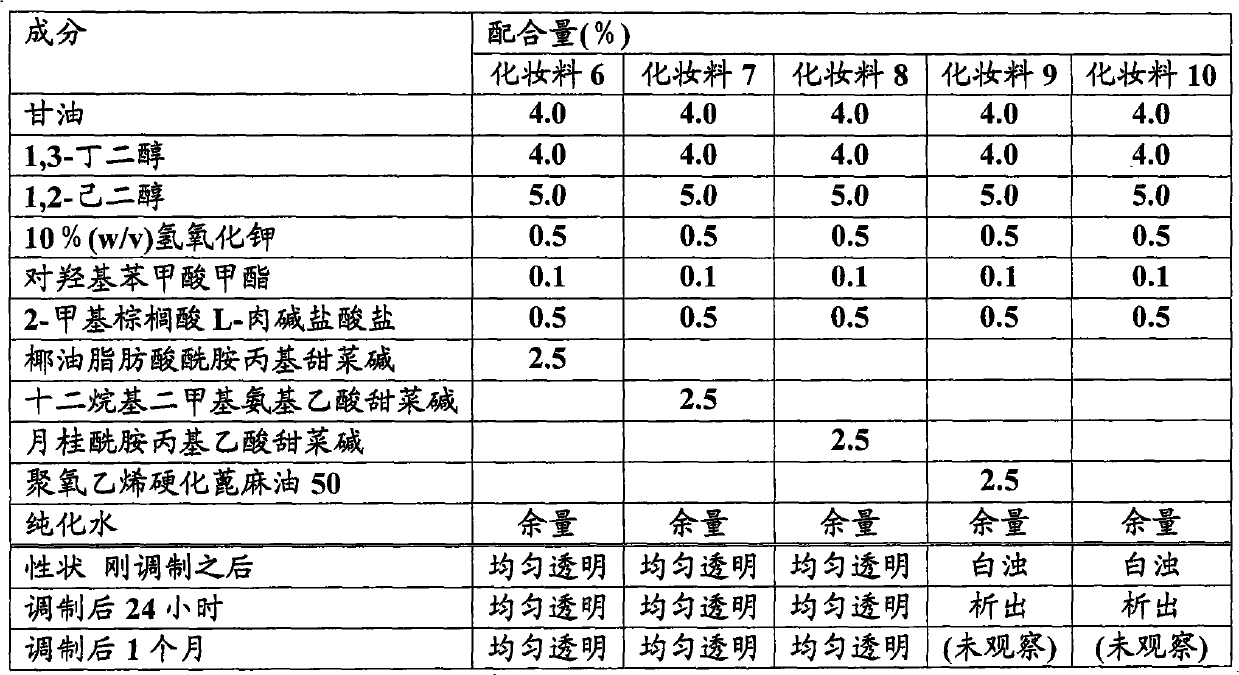

Preparation for external application to skin and cosmetic preparation

InactiveCN101909590AAvoid easy separationFor long-term storageCosmetic preparationsOrganic active ingredientsExternal applicationExcellent preparation

Owner:RESONAC HOLDINGS CORPORATION

Preparation method and application of oil resistant rubber applied under railroad switch

InactiveCN106543504AGood oil resistanceGood value for moneyRail fastenersCost effectivenessTechnical standard

The invention discloses an oil resistant rubber applied under a railroad switch. The oil resistant rubber comprises, by weight, 100 parts of acrylonitrile-butadiene rubber N41 as a big material, 45-65 parts of reinforcing agent and 15-25 parts of anti-wearing agent as middle materials, 4-8 parts of vulcanizing agent, 3-5 parts of accelerant, 1-4 parts of anti-aging agent, 2-4 parts of coupling agent and 1 part of octadecanoic acid as small materials. The invention further provides a preparation method and application of the oil resistant rubber applied under the railroad switch. The oil resistant rubber applied under the railroad switch has the advantages of being good in performance, and high in cost effectiveness. The novel type oil resistant rubber cushion plate applied under railroad switch prepared by using the oil resistant rubber applied under railroad switch can fully meet the railway industry standard TB / T2626-1995 and the high speed railway standard TB / T3395.(1-5) 2015 technical standard, and has little appearance change and stable physical properties, has an oil resistant index more than four times higher than the traditional rubber cushion plate applied under the railroad switch, has an oil absorption rate below 1.53-2.96%, which all prolong the service life of the rubber cushion plate applied under the railroad switch.

Owner:武威复兴华通铁路器材有限公司 +1

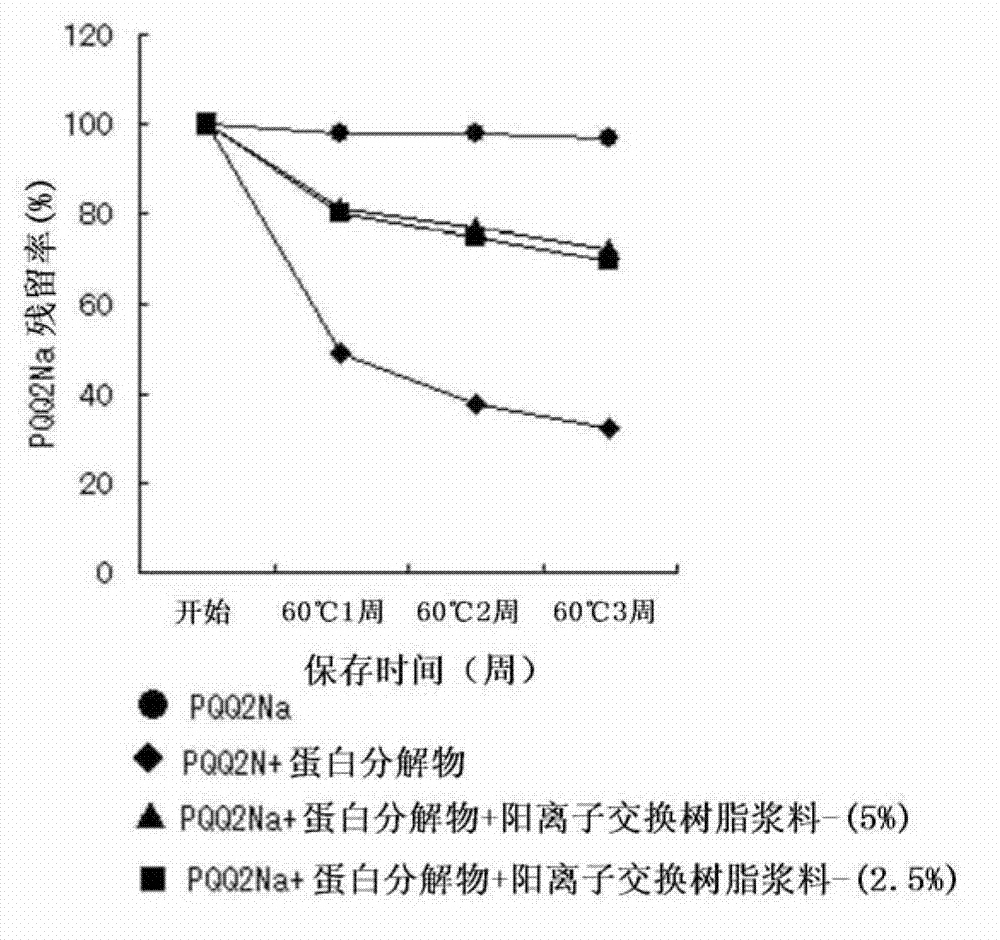

Stabilizing method for external composition

InactiveCN103169626AInhibit appearance changesLittle change in appearanceCosmetic preparationsOrganic active ingredientsQuinoneIon-exchange resin

The present invention provides a stabilizing method for an external composition, wherein ion exchange resin is added in the external composition. Used as the ion exchange resin, if positive ion exchange resin is used, the unstable compound due to existence of the compound selected from a group consisting of compound containing an amino group and amine can be stabilized. The compound can be compound having a carbonyl group, e.g., quinone.

Owner:ROHTO PHARM CO LTD

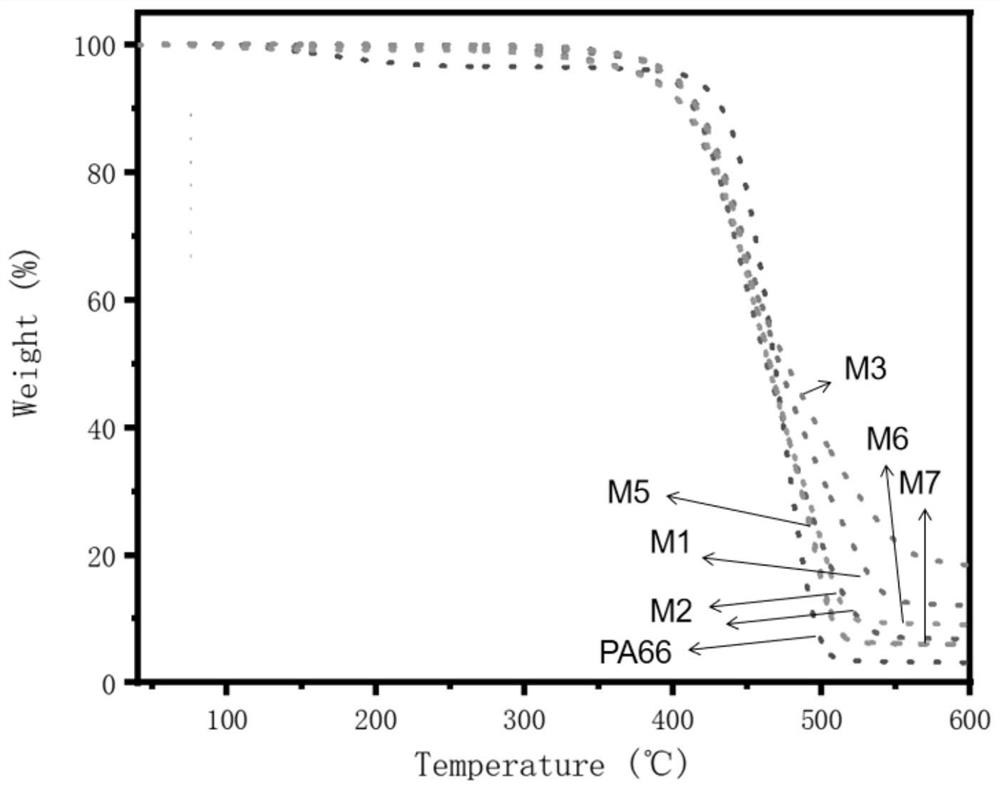

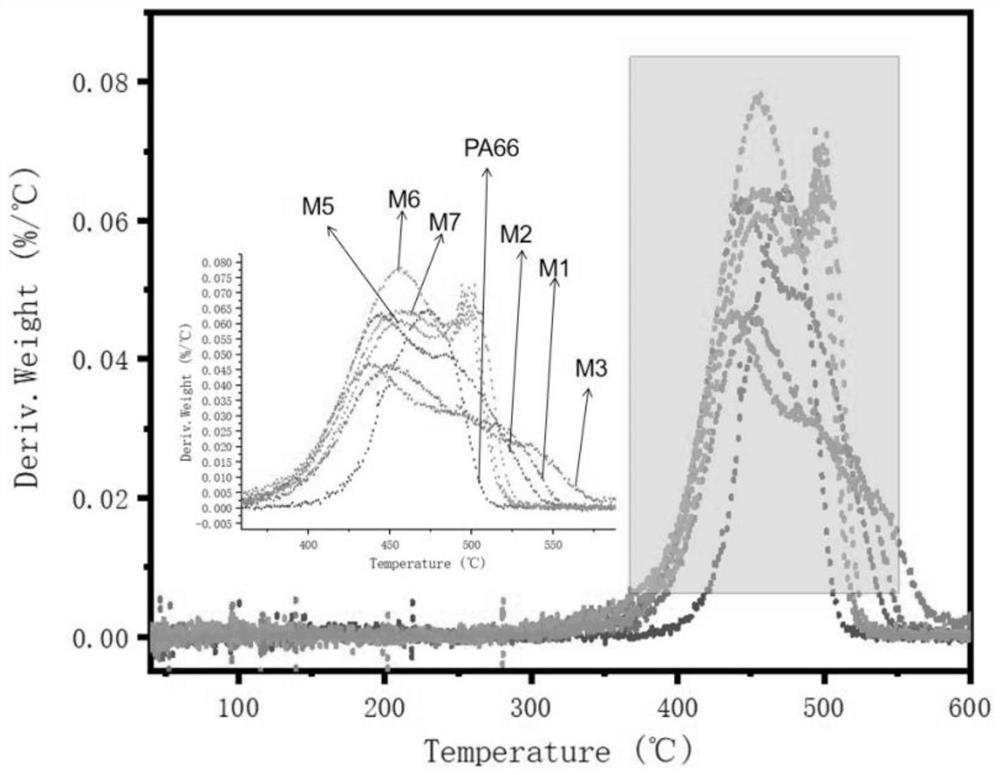

Low-filling efficient synergistic flame-retardant nylon 66 and preparation method thereof

PendingCN114133734AImprove mechanical propertiesSolve the problem of mechanical performance degradationAluminium hydroxideAntioxidant

The invention belongs to the technical field of modified nylon materials, and particularly relates to low-filling efficient synergistic flame-retardant nylon 66 and a preparation method thereof. The low-filling efficient synergistic flame-retardant nylon 66 comprises the following components in parts by mass: 88-92 parts of nylon 66; 6.5 to 10 parts of a composite flame retardant; 0.1 to 0.2 part of a dispersant; 0.1 to 0.2 part of an antioxidant; 0.7 to 3 parts of an inorganic nano filler; wherein the composite flame retardant comprises the following components in parts by mass: 2-4 parts of aluminum hypophosphite; 0 to 1 part of hexaphenoxy cyclotriphosphazene; 1 to 3 parts of aluminum diethyl hypophosphite; 0-2 parts of ammonium polyphosphate; 0 to 3.5 parts of nano aluminum hydroxide; and 0-2 parts of magnesium oxide. The inorganic nano filler comprises nano silicon dioxide with the particle size of 10-50nm, montmorillonite and nano aluminum oxide. The flame-retardant nylon 66 at least comprises one or more of the composite flame retardant and the inorganic nano filler, when the adding amount of the composite flame retardant is 10% or below, the flame-retardant level of the prepared flame-retardant nylon 66 can reach the UL94 V-0 level, and the tensile strength and the impact strength of the prepared flame-retardant nylon 66 are greatly improved.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

Emulsion preparation for external application to skin and cosmetic

InactiveCN101909591AGood touchLittle change in appearanceOrganic active ingredientsCosmetic preparationsEmulsionExternal application

Disclosed is an emulsion preparation for external application to skin, which contains a branched acylcarnitine and has excellent emulsion stability. Also disclosed is a cosmetic preparation. Specifically disclosed is an emulsion preparation for external application to skin, which is characterized by containing 0.01-10% by mass of a carnitine derivative represented by Formula (1) and / or a carnitine derivative salt represented by Formula (2) and 0.01-20% by mass of a nonionic surfactant. In Formula (1), R1 and R2 independently represent an optionally branched, saturated or unsaturated aliphatic hydrocarbon group having 1-18 carbon atoms. In Formula (2), R1 and R2 are as defined in Formula (1); X- represents a specific anion; and Y+ represents a specific cation.

Owner:SHOWA DENKO KK

Glasses with adjustable reflection structure

InactiveCN104834110AGood rear sight adaptabilityGood appearance changeOptical partsVisual field lossUses eyeglasses

Owner:ZHEJIANG OCEAN UNIV

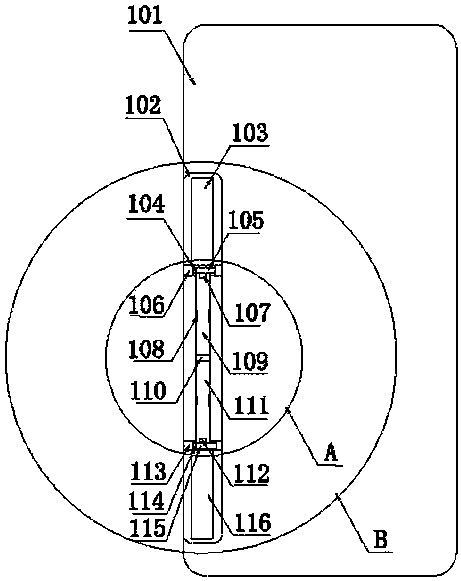

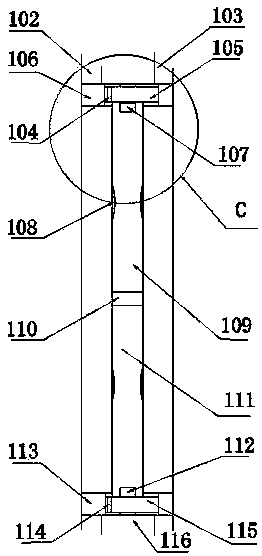

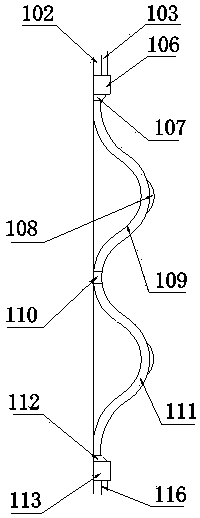

Tensioning and anchoring device for multi-layer pre-stressed fiber cloth reinforced beam

ActiveCN110029593AImprove reliabilitySolve the problem of unequal lengthBridge erection/assemblyBridge strengtheningFiberPre stress

The invention discloses a tensioning and anchoring device for a multi-layer pre-stressed fiber cloth reinforced beam. The tensioning and anchoring device comprises a fixing end supporting seat, a tensioning end supporting seat, a fixing end anchorage, a tensioning end anchorage, clamping sheets, an anchoring long screw rod, an anchoring short screw rod, chemical bolts, fiber cloths, a pre-stress applying frame and a jack; each of the fixing end supporting seat and the tensioning end supporting seat is a T-shaped body, each of the fixing end anchorage and the tensioning end anchorage is in a cuboid shape, the fixing end supporting seat and the tensioning end supporting seat are fixed to a to-be-reinforced beam through the chemical bolts, the fixing end anchorage is connected with the fixingend supporting seat through the anchoring short screw rod, and the tensioning end anchorage is connected with the tensioning end supporting seat through the anchoring short screw rod; and the fiber cloths are clamped by the two clamping sheets, thus the fiber cloths are wedged into a wedge-shaped through seam in the tensioning end anchorage, and thus the fiber cloths are anchored. The tensioningand anchoring device is simple in structure and convenient to operate, the multiple layers of the fiber cloth are subjected to force evenly, the high prestress can be applied, and the pre-stress applying frame can be repeatedly used.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Poly(vinyl alcohol) based film

InactiveCN100462392CLittle change in appearanceGood solubility in cold waterAbsorbent padsBandagesSolubilityHigh humidity

A polyvinyl alcohol film which dissolves in water at 20 DEG C. within 10 minutes and has an alpha / beta ratio of not more than 10 wherein alpha is a storage modulus of the film at 20 DEG C. in a dry atmosphere and beta is a storage modulus of the film at 20 DEG C. and 80% RH, and which has an excellent cold water solubility and an excellent durability such that the change in appearance of the film under high humidity is slight and the lowering of the cold water solubility is slight even if the film is stored for a long term.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

Construction method for strengthening reinforced concrete pier column by using prestressed fiber fabrics

PendingCN108487086ALittle change in appearanceEffective anchoringBridge erection/assemblyBridge strengtheningRebarReinforced concrete

The invention discloses a construction method for strengthening a reinforced concrete pier column by using prestressed fiber fabrics. A prestressed fiber fabric strengthening device is arranged. The prestressed fiber fabric strengthening device comprises two jacket plates, two wedge sheets, two threaded rods and fiber fabrics; the fiber fabrics are wound on the wedge sheets for two circles; the wedge sheets wound with the fiber fabrics are inserted into wedge sheet grooves in bodies of the jacket plates; the fiber fabrics are wound on the jacket plates for two circles; and the other ends of the fiber fabrics are treated by using the same mode. The fiber fabrics connected with the jacket plates and the wedge sheets surround the strengthened reinforced concrete pier column for one circle. Threaded rod holes in jacket plate anchoring heads at the upper and lower ends of the two jacket plates are aligned with each other; the two threaded rods penetrate into the threaded rod holes in the jacket plate anchoring heads; and the two threaded rods are synchronously tightened to apply prestress to the fiber fabrics so as to finish reinforcing construction to the reinforced concrete pier column. The prestressed fiber fabric strengthening device used by the construction method for strengthening the reinforced concrete pier column by using the prestressed fiber fabrics has the advantages ofsimple structure, convenient construction method operation and high implementing efficiency.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Seabuckthorn freeze drying method

PendingCN110089554ALittle change in appearanceReduce lossesFruits/vegetable preservation by irradiation/electric treatmentFood dryingChemistryFreeze dry

The invention discloses a seabuckthorn freeze drying method. The method includes the following steps: (1) pretreatment: washing the seabuckthorn, draining the water, performing ultraviolet irradiation, and after refrigeration, rotating the material by a rotating sieve; (2) pre-freezing: cooling the pretreated seabuckthorn to -35 to -40 DEG C, and then maintaining for 2 to 3 hours; (3) sublimationdrying: firstly maintaining at 3 to 4 hours at -30 to -35 DEG C and 70 to 90 Pa; then maintaining for 2 to 3 hours at -24 to -28 DEG C and 30 to 50 Pa; then maintaining at 22 DEG C and 25 Pa for 6h; finally, continuously keeping the pressure of 25 Pa and heating to 30 DEG C, and completing the freeze drying; and (4) performing analytical drying. The method provided by the invention is carried outby pre-treatment of ultraviolet irradiation and rotary sieve rotation on seabuckthorn, and is carried out in stages during sublimation drying, the loss of nutrients in seabuckthorn by traditional freeze-drying is significantly reduced, the appearance and shape of seabuckthorn are small, and the utilization rate of raw materials is high.

Owner:青海青藏高原健康科技有限公司

Production method of nutritional gluten

ActiveCN112244142AGreat tasteImprove appearance unevennessClimate change adaptationVegetable proteins working-upBiotechnologyGluten

The invention provides a production method of nutritional gluten, which comprises the following steps: (1) kneading dough; (2) washing the dough; (3) dehydrating; (4) beating the dough to produce gluten with mixed variable-speed; (5) rough gluten is molded; (6) rapidly molding with a high-temperature in a first-zone; (7) boiling in a second-zone; (8) boiling in a third-zone; (9) cooling with water; (10) secondary shaping; and (11) forming by hand tearing. Compared with traditional gluten, the gluten produced through the method provided by the invention is remarkably improved in nutrition and taste, can be directly heated for eating or matched with seasonings for eating according to personal taste, can also be used as a food material for eating after cooking such as frying, baking, deep-frying and stir-frying, and is widely suitable for daily diet and accompaniment.

Owner:河南飞天生物科技股份有限公司

Beer rich in red wine polyphenols and preparation method of beer

The invention relates to a beer rich in red wine polyphenols. The beer contains the red wine polyphenols. When drinking the beer rich in red wine polyphenols disclosed by the invention, a drinker can enjoy beer flavor and can also obtain health benefits of improving heart and blood vessels, reducing blood pressure and the like at the same time. Besides, a preparation method of the beer disclosed by the invention is simple and convenient; and the prepared beer does not have great appearance changes, the taste of the prepared beer is basically the same as that of an ordinary beer, the mouth feel is not influenced, and the most original flavor of the beer can be retained.

Owner:李安国

Ancient building wooden column reinforced through tenon-and-mortise embedded steel bar pier connection

PendingCN113073869ANot easy to rustIncrease lateral stiffnessStrutsBuilding repairsMortise and tenonArchitectural engineering

The invention provides an ancient building wooden column reinforced through tenon-and-mortise embedded steel bar pier connection. The ancient building wooden column comprises a log column and a new pier connection column, the new pier connection column comprises a new column body and a tenon-and-mortise joint, the tenon-and-mortise joint is arranged on the upper part of the top of the new column body in the vertical direction, a mortise opening is formed in the lower bottom face of the log wooden column, the tenon-and-mortise joint is inserted into the mortise opening in the section of the log column, the log column and the pier connection new column are connected together through a mortise and tenon joint and are reinforced through a set of parallel self-tapping screws in the horizontal direction. On the premise that the bearing capacity of the wooden column is guaranteed, the appearance of the log column is not changed much, and the log column is not prone to being affected by the environment.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Multi-purpose telescopic loop antiskid mobile phone back shell

InactiveCN105227718ALittle change in appearanceReasonable structureTelephone set constructionsComputer hardwareHuman–computer interaction

The invention provides a multi-purpose telescopic loop antiskid mobile phone back shell, comprising a function support plate, a telescopic loop bar a, a telescopic loop bar b, a telescopic jam bar a and a telescopic jam bar b, a loop is formed by retracting and arching, a finger can hold the loop for a long time more easily after easily and freely sleeving in the loop, and meanwhile, a thumb can better operate a mobile phone or a tablet computer screen. In addition, the loop formed by the telescopic loop bar a, the telescopic loop bar b, the telescopic jam bar a and the telescopic jam bar b can be used as a supporting frame, thereby saving trouble and being convenient. The loop formed by the telescopic loop bar a, the telescopic loop bar b, the telescopic jam bar a and the telescopic jam bar b can being stretched in parallel, so as not to affect the call use, storage and beautiful appearance of the mobile phone, and a mounting support of the loop is integrally designed, embedded, mounted and fixed on the mobile phone back shell, a jacket or a tablet computer back cover, so that the loop is firmer and safer.

Owner:于卫华

A tensioning and anchoring device for beams reinforced with multi-layer prestressed fiber cloth

ActiveCN110029593BImprove reliabilitySolve the problem of unequal lengthBridge erection/assemblyBridge strengtheningFiberEngineering

The invention discloses a tensioning and anchoring device for multi-layer prestressed fiber cloth reinforced beams. Including fixed end support, tension end support, fixed end anchor, tension end anchor, clip, anchor long screw, anchor short screw, chemical bolts, fiber cloth, prestressing frame and jack. The fixed-end support and the tension-end support are T-shaped, and the fixed-end anchor and the tension-end anchor are in the shape of a cuboid. The fixed end support and tension end support are fixed to the beam to be strengthened by chemical anchor bolts. The anchor at the fixed end is connected with the support at the fixed end through a short anchor screw. The tension end anchor is connected with the tension end support through the anchoring long screw rod. The fiber cloth is clamped by two clips and wedged into the wedge-shaped through-slit in the tension end anchor to realize the anchoring of the fiber cloth. The tensioning and anchoring device of the present application is simple in structure, easy to operate, and the multi-layer fiber cloth is evenly stressed, and high prestress can be applied, and the prestress applying frame can be used repeatedly.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Non-bearing concrete component reinforcement repair method

InactiveCN107386675AReinforced surface with high unidirectional tensile strengthHigh elastic modulusBuilding repairsDiseaseCarbon fibers

The invention discloses a non-bearing concrete component reinforcement repair method. The method comprises the process steps in sequence of: paying-off positioning, fracture indication treatment, drilling, drilling cleaning, reinforcement derusting, steel bar embedding glue preparation, chemical steel bar embedment, primary curing, surface leveling, adhesive stirring, primer brushing, carbon fiber cloth reinforcement, secondary curing, appearance surface finishing, and detection. The chemical steel bar embedment and carbon fiber reinforcement technologies are applied to reinforce the fracture diseases of non-bearing concrete components to solve one technical difficulty perplexed for a long time in the architectural cultural heritage protection. The advanced technology is applied to prevent wrong actions of disassembly and abandon of disease components and loss of history information, so that fractured components can be reused, the history information is preferably retained, the destruction of a traditional reinforcement method to the building style can be solved, and more purposes are achieved.

Owner:陈亦文

Application of Potassium Methyl Silicate Aqueous Solution in Deacidification and Strengthening of Paper

InactiveCN104032623BLittle change in appearanceGood deacidification effectOld paper after-treatmentCelluloseFiber

The invention discloses application of a PMS (potassium methyl silicate) water solution to deacidification and reinforcement of paper. According to the application, a deacidification and reinforcement method comprises the following steps: soaking the paper in a deacidification agent; treating, hanging and airing to complete the deacidification and the reinforcement, wherein the deacidification agent is any one of the PMS water solution and an alcohol water mixing solution. The paper is treated by using a PMS paper deacidification agent, so that the deacidification effect is obvious, and the mechanical property of the paper is well improved. By improving different solvent ratios and concentration ratios, the acid property and the mechanical property of the paper are improved to different extents. Meanwhile, the paper is obvious in hydrophobic performance. According to the characteristics, the water absorption of paper cellulose can be reduced, so that the damage to swelling, degradation and hydrogen-bonding of fibers caused by water is alleviated. The microbiological corrosion degree of the paper is greatly reduced.

Owner:RENMIN UNIVERSITY OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com