Preparation technology of metal nanometer fiber

A kind of metal nano-technology, preparation process, applied in fiber treatment, fiber chemical characteristics, chemical post-treatment of rayon, etc., can solve problems such as sticking, and achieve the effect of less modification, small appearance change, and high environmental tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

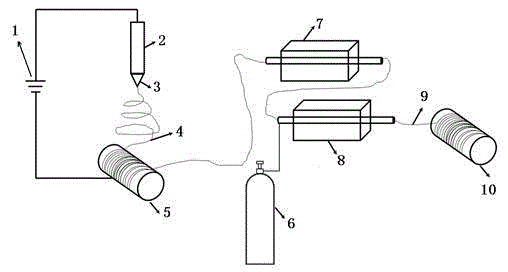

Image

Examples

Embodiment 1

[0037] Step (1) First prepare the electrospinning solution, take 8 grams of polyvinyl alcohol, 5 grams of polyethylene glycol, and 2 grams of polyvinylpyrrolidone dissolved in 60 grams of water and ethanol mixed solvent, then add 5 grams of copper acetate, 3 grams of After the copper nitrate was completely dissolved and evenly stirred, 0.2 g of isocyanate curing agent was added and the stirring was continued until it was completely uniform, and then placed for use.

[0038] Step (2) Electrospinning the spinning solution obtained in step (1) at a voltage of 10kV and an outflow rate of spinning solution of 0.01 ml / min. On the collection reel, the reel speed is 2 revolutions / minute. like figure 2 Shown is the scanning electron microscope (SEM) image of the copper salt polymer protofilament fibers obtained by electrospinning.

[0039] Step (3) Slowly pull out the raw silk fibers on the collection reel in step (2) in the form of individual fibers, then pass through the front-sta...

Embodiment 2

[0041] Similar to the process of Example 1, but in step (1), all polymers are adjusted to: 10 grams of polyethylene glycol, 2 grams of polyvinyl alcohol; the solvent is changed to pure water, and the amount is 60 grams; the metal salt is replaced by 3 grams of cobalt acetate, 3 grams of cobalt nitrate, and 2 grams of cobalt chloride; in step (2), the electrospinning voltage was adjusted to 8 kV, and the flow rate of the spinning solution was 0.02 ml / min; other conditions remained unchanged.

[0042] Figure 4 That is the SEM image of the finally obtained cobalt nanofibers.

Embodiment 3

[0044] Similar to the process of Example 1, but in step (1) all polymers are adjusted to: 9 grams of polyvinyl alcohol, 1 gram of polyvinyl pyrrolidone, and 1 gram of water-based acrylate; the solvent is changed to pure water, and the dosage is 55 grams The metal salt is replaced with 5 grams of silver nitrate, 3 grams of palladium chloride, and 0.5 grams of palladium acetylacetonate; the curing agent is changed to urea, and the dosage is 0.8 grams; the electrospinning voltage is adjusted to 9kV in step (2), and the flow rate of the spinning solution It was 0.015 ml / min; the rest of the conditions were unchanged.

[0045] Figure 5 It is the SEM image of the prepared silver-palladium alloy nanofibers with super soft properties. It can be seen from the figure that this alloy fiber has superior flexibility and excellent bending resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com