Polyimide nonwoven fabric and process for production thereof

A manufacturing method, polyimide technology, applied in the field of non-woven fabrics, can solve problems such as insufficient thermal dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

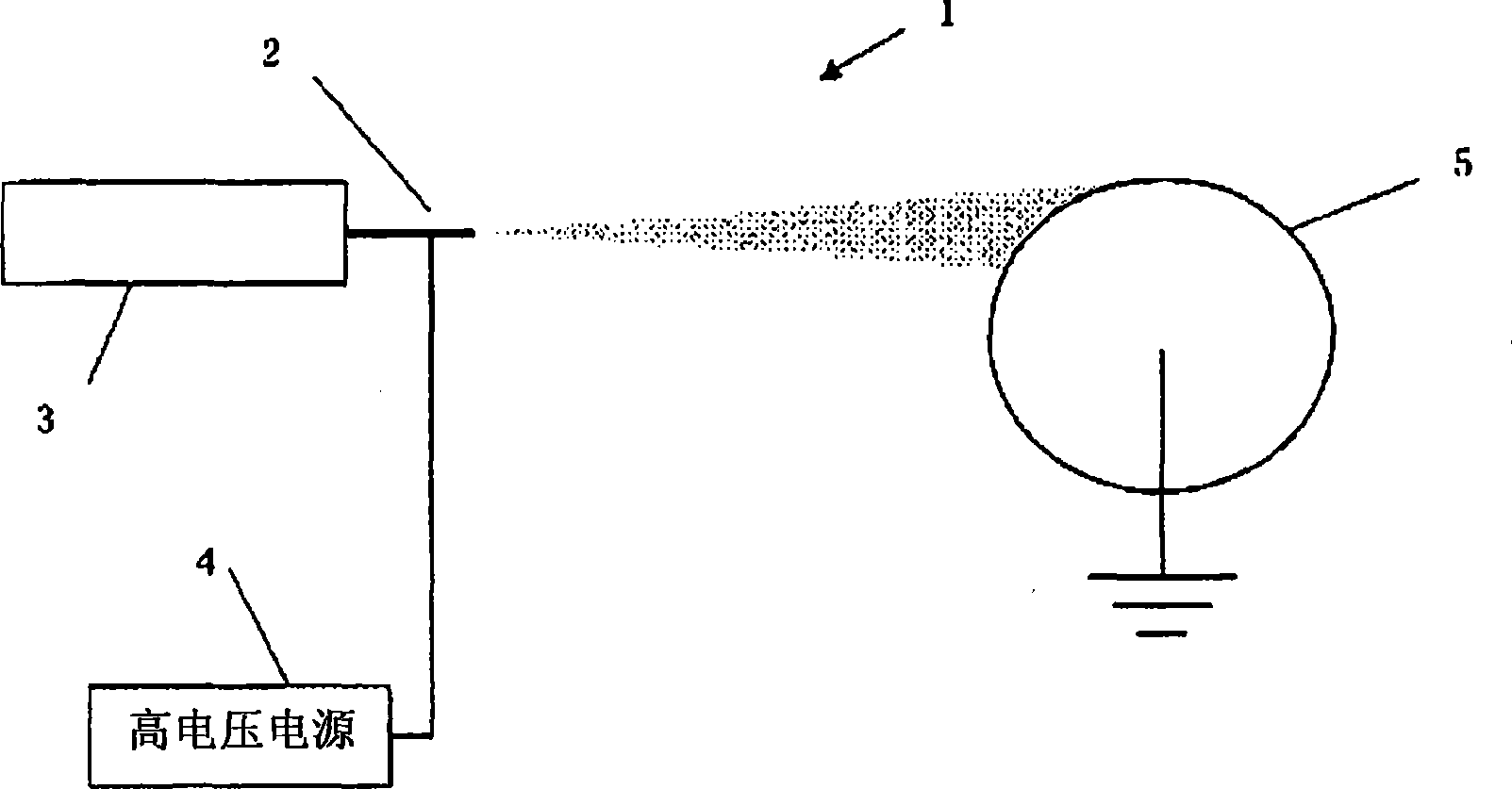

Image

Examples

Embodiment

[0141] The present invention will be described below using examples, but the present invention is not limited by these examples. In addition, the evaluation items in each of the following Examples were implemented according to the method described below.

[0142]

[0143] The solution obtained by dissolving the polymer in N-methyl-2-pyrrolidone was maintained at 30° C. so that the polymer concentration was 0.2 g / dl, and measured using an Ubbelohde viscosity tube.

[0144]

[0145] A scanning electron micrograph (magnification: 5000 times) of the surface of the obtained nonwoven fabric was photographed, and the average value of the fiber diameters measured by n=10 was calculated from the photograph.

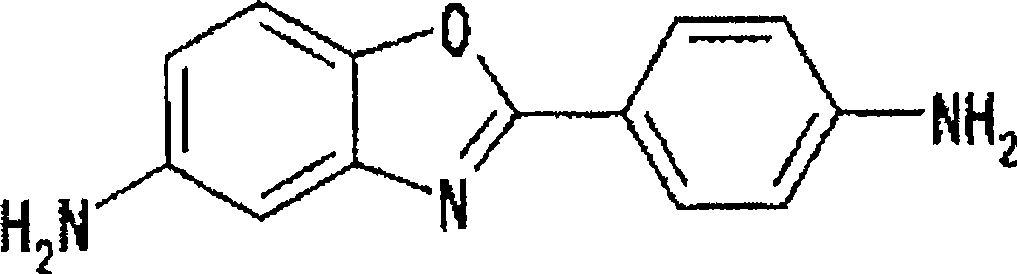

reference example 1

[0147] (Preparation of polyamic acid solution)

[0148] Nitrogen replacement was carried out in a reaction vessel in which the liquid-contacting part of the container equipped with a nitrogen gas introduction tube, a thermometer, and a stirring rod, and the piping for infusion were made of austenite stainless copper SUS3 16L, and then 5-amino-2-( 223 parts by mass of p-aminophenyl) benzoxazole, 4448 parts by mass of N,N-dimethylacetamide, completely dissolved, and then 217 parts by mass of pyromellitic dianhydride was added, at a reaction temperature of 25°C Under stirring for 24 hours, brown viscous polyamic acid solution A1 was obtained. Its ηsp / C was 4.0dl / g.

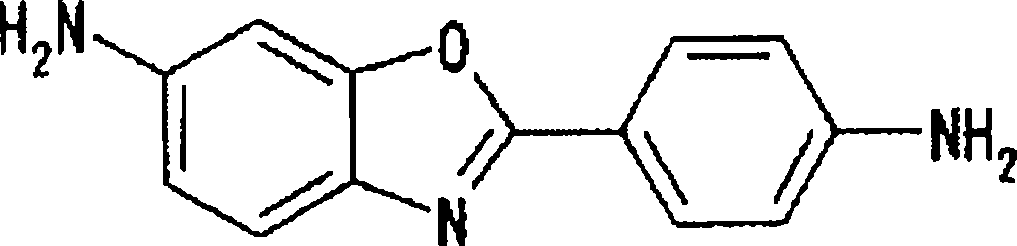

reference example 2

[0150] (Preparation of polyamic acid solution)

[0151] Nitrogen replacement was carried out in a reaction vessel in which the liquid-contacting part of the container equipped with a nitrogen gas introduction tube, a thermometer, and a stirring rod, and the piping for infusion were made of austenite stainless copper SUS3 16L, and then 200 parts by mass of diaminodisulfide was added. Phenyl ether. Next, add 4202 parts by mass of N-methyl-2-pyrrolidone to dissolve it completely, then add 217 parts by mass of pyromellitic dianhydride, and stir at 25°C for 5 hours to obtain a brown viscous poly Amic acid solution B. Its relative viscosity (ηsp / C) was 3.7dl / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com