Composite diaphragm, preparation method thereof and lithium ion battery

A technology of composite diaphragm and composite base material, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems that it is difficult to completely prevent the penetration of nanomaterials, and achieve improved safety, charge and discharge performance, and good thermal dimensions. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

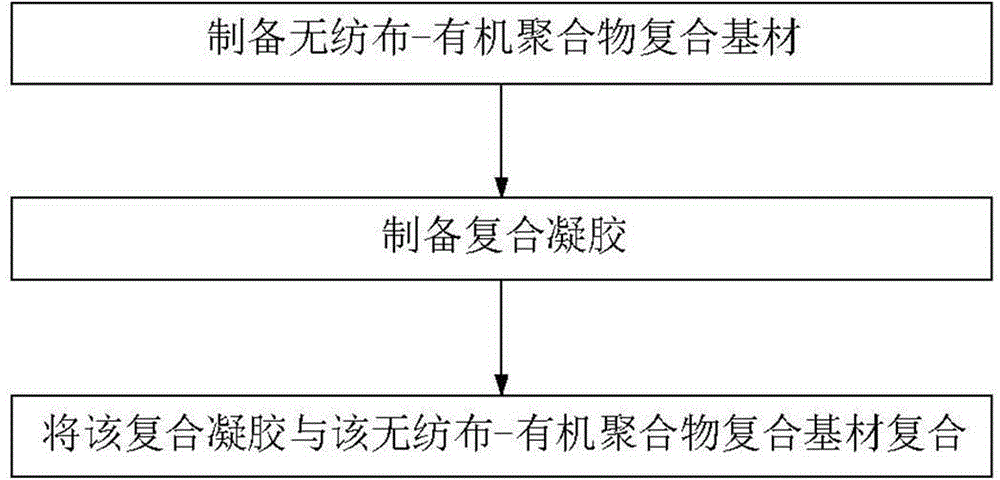

[0024] see figure 1 , the embodiment of the present invention provides a preparation method of a composite diaphragm, which includes the following steps:

[0025] S1, preparing non-woven fabric-organic polymer composite substrate;

[0026] S2, preparing a composite gel; and

[0027] S3, compounding the composite gel with the non-woven fabric-organic polymer composite substrate.

[0028] First, the step S1 is introduced. The non-woven fabric-organic polymer composite substrate contains the following two components: 1) non-woven fabric and 2) polymer monomers containing alkenyl groups and alkoxysilanes containing alkenyl groups. A cross-linked polymer formed by copolymerization under the action of a catalyst and a cross-linking agent. The nonwoven fabric is a nanofiber nonwoven fabric used in lithium-ion battery separators. Preferably, the heat-resistant temperature of the non-woven fabric is greater than 200°C, specifically polyimide nanofiber non-woven fabric, polyethylene...

Embodiment

[0085] Soak the polyimide nanofiber non-woven fabric in the modification solution for 5 minutes, take it out, and dry it at 80° C. to obtain the non-woven fabric-organic polymer composite substrate. The components of the modification solution are: 10 parts of vinyltriethoxysilane, 80 parts of methyl methacrylate, 10 parts of diethylene glycol divinyl ether, 1 part of benzoyl peroxide, 5000 Parts of ethyl acetate (mass ratio).

[0086] Mix 10 mL of tetrabutyl titanate with 100 mL of isopropanol to form a first solution. Mix deionized water and 80 mL of isopropanol to form a second solution, and add hydrochloric acid to the second solution to make the pH value 3-4. The molar ratio of deionized water to tetrabutyl titanate is 4:1. The first solution was mixed with the second solution and heated at 45°C to form a titanium sol solution. The titanium sol solution was heated to 58° C., vinyltriisopropoxysilane and MMA monomer were added to the titanium sol solution, and uniformly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com