Biaxially oriented polyethylene terephthalate film

A technology of polyethylene terephthalate film and polyethylene terephthalate, which is applied in printed circuits, applications, instruments, etc., can solve problems such as thermal dimensional stability and large curling, and achieve Excellent processing adaptability, small curl, and small dimensional change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

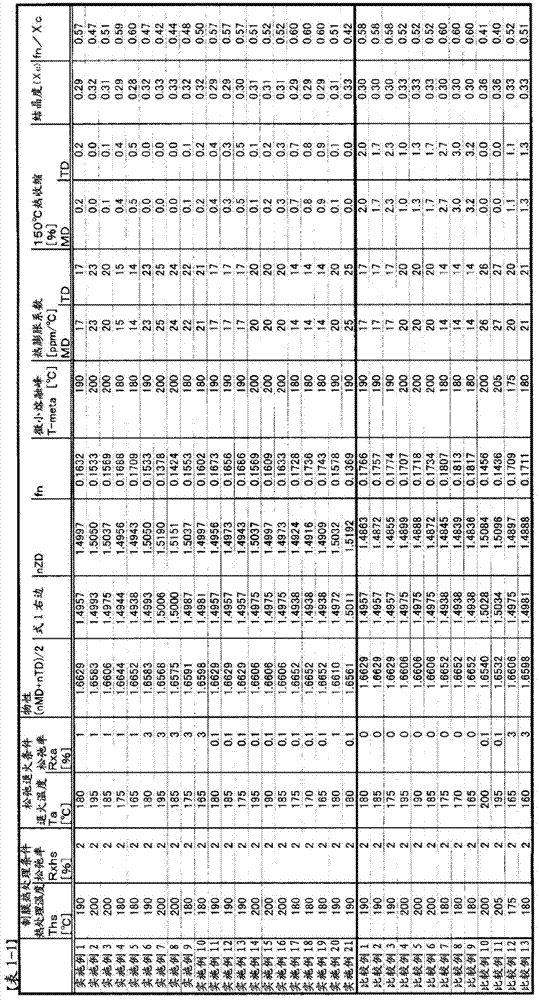

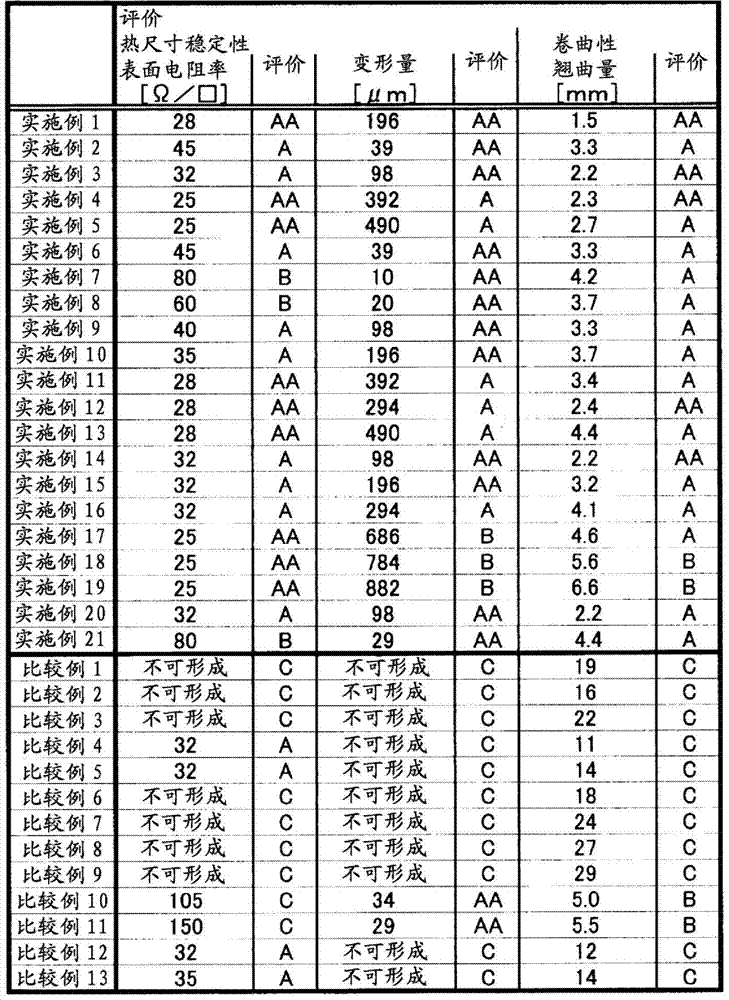

[0135] Embodiments of the present invention will be described based on examples.

reference example 1

[0137] 194 parts by mass of dimethyl terephthalate and 124 parts by mass of ethylene glycol were put into the transesterification apparatus, and the contents were heated to a temperature of 140° C. to dissolve them. Then, stirring the contents, 0.3 parts by mass of magnesium acetate tetrahydrate and 0.05 parts by mass of antimony trioxide were added, and a transesterification reaction was performed while methanol was distilled off at a temperature of 140 to 230°C. Next, 1 part by mass of a 5 mass % ethylene glycol solution of trimethyl phosphate was added (0.05 part by mass as trimethyl phosphate). When an ethylene glycol solution of trimethyl phosphate is added, the temperature of the reaction content decreases. Therefore, stirring was continued until the temperature of the reaction content returned to a temperature of 230° C. while distilling off excess ethylene glycol. In this way, after the temperature of the reaction contents in the transesterification reaction apparatus...

Embodiment 1

[0139] In an extruder heated to a temperature of 280°C, the PET pellet X obtained in Reference Example 1 with an intrinsic viscosity of 0.65 0.65 It was supplied after being dried under reduced pressure at a temperature of 180°C for 3 hours, and introduced into a T-die die under a nitrogen atmosphere. Next, extrude from the T-shaped die in a sheet form to form a molten single-layer sheet, and use an electrostatic application method to carry out close cooling and solidification on a drum that maintains a surface temperature of 25°C to obtain an unstretched single-layer film .

[0140] Next, after preheating the obtained unstretched single-layer film with a heated roll set, perform 4.3-fold MD stretching at a temperature of 88° C., and cool it with a roll set at a temperature of 25° C. to obtain uniaxial stretching. membrane. Both ends of the obtained uniaxially stretched film were introduced into a preheating zone at a temperature of 95° C. in a tenter while being held by cli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Longitudinal stretch ratio | aaaaa | aaaaa |

| Transverse stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com