Waterborne ceramic slurry for lithium ion battery and preparation method of composite separator from waterborne ceramic slurry

A lithium-ion battery, ceramic slurry technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problem of lithium-ion battery safety degradation, reduction of diaphragm strength, thermal stability and puncture resistance, performance is not very good Taking into account and other issues, to achieve the effect of slurry stability, enhanced high temperature safety, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

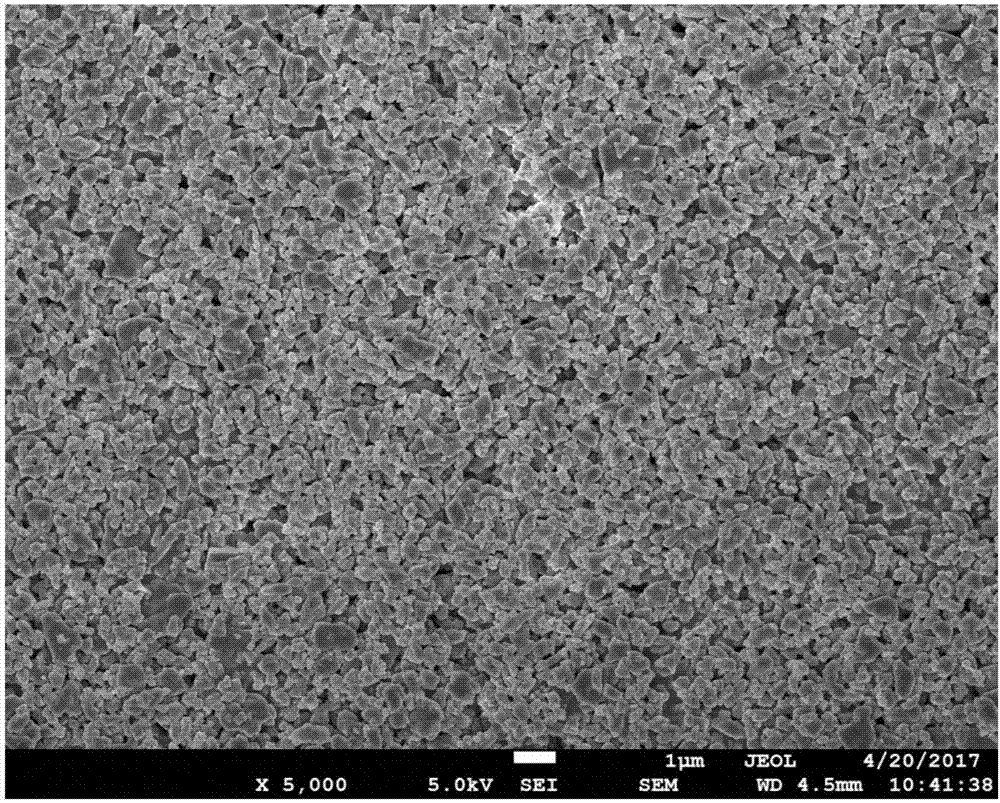

[0025] Example 1: Preparation of Lithium-ion Battery Ceramic Composite Diaphragm

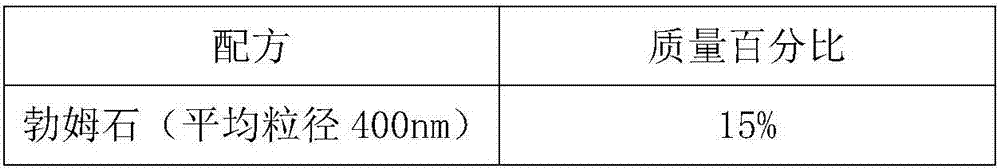

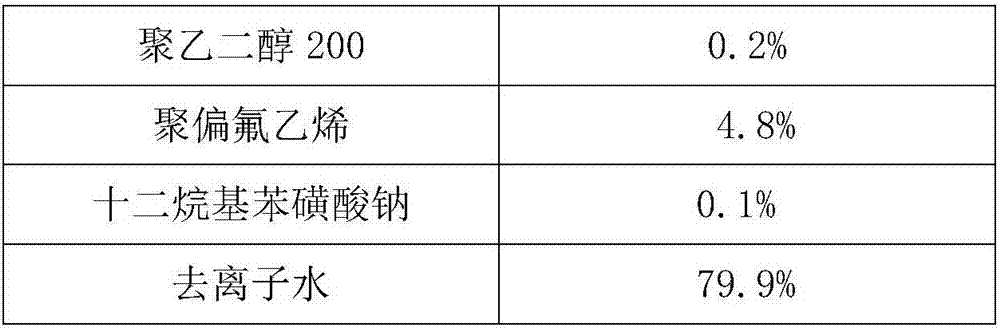

[0026] The mass percentage formula of water-based ceramic slurry is:

[0027]

[0028]

[0029] The preparation process of the water-based ceramic slurry is as follows: a) Add 15% boehmite, 0.2% polyethylene glycol 200 and 79.9% deionized water into the ball mill, set the speed at 2950rpm, and grind for 1 hour to obtain the dispersion I; b ) Pour the dispersion I into a high-speed disperser, add 4.8% polyvinylidene fluoride and 0.1% sodium dodecylbenzenesulfonate, and set the speed at 5000rpm. After dispersing for 2 hours, vacuum defoam for 24 hours, and filter through a 600-mesh stainless steel screen to obtain a water-based ceramic slurry;

[0030] The preparation process of the lithium-ion battery ceramic composite separator is: use a coating machine to evenly coat the water-based ceramic slurry on one side of the polyethylene microporous base membrane with a thickness of 5 μm and an a...

Embodiment 2

[0031] Example 2: Preparation of Lithium-ion Battery Ceramic Composite Diaphragm

[0032] The percentage formula of water-based ceramic slurry is:

[0033] formula

mass percentage

Aluminum oxide (average particle size 400nm)

40%

polyethylene glycol 1000

4%

SBR

5%

1%

Deionized water

50%

[0034] The preparation process of the water-based ceramic slurry is as follows: a) Add 40% alumina, 4% polyethylene glycol 1000 and 50% deionized water into the ball mill, set the speed at 2950rpm, and grind for 1 hour to obtain the dispersion I; b) Pour the dispersion I into a high-speed disperser, add 5% styrene-butadiene rubber and 1% polyoxyethylene lauryl ether, and set the speed at 5000rpm. After dispersing for 2 hours, vacuum defoam for 24 hours, and filter through a 600-mesh stainless steel screen to obtain a water-based ceramic slurry;

[0035] The preparation process of the lithium...

Embodiment 3

[0036] Example 3: Preparation of Lithium-ion Battery Ceramic Composite Diaphragm

[0037] The percentage formula of water-based ceramic slurry is:

[0038] formula

mass percentage

Silica (average particle size 400nm)

20%

5%

Polymethylmethacrylate

0.5%

polyoxyethylene glyceryl ether

0.5%

Deionized water

74%

[0039] The preparation process of water-based ceramic slurry is as follows: a) add 20% silicon dioxide, polyvinylpyrrolidone K15 and 74% deionized water into the ball mill, set the speed at 2950rpm, and grind for 1 hour to obtain dispersion I; b) disperse Liquid I was poured into a high-speed disperser, and 0.5% polymethyl methacrylate and 0.5% polyoxyethylene glyceryl ether were added, and the rotation speed was set at 5000 rpm. After dispersing for 2 hours, vacuum defoam for 24 hours, and filter through a 600-mesh stainless steel screen to obtain a water-based ceramic slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com