Filter material and purpose thereof

A technology of filter material and filter surface, applied in the direction of filtration separation, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of difficult control of fiber ratio, increased pulse times, low air permeability, etc., to achieve excellent dust collection efficiency, heat Good dimensional stability, good dimensional stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

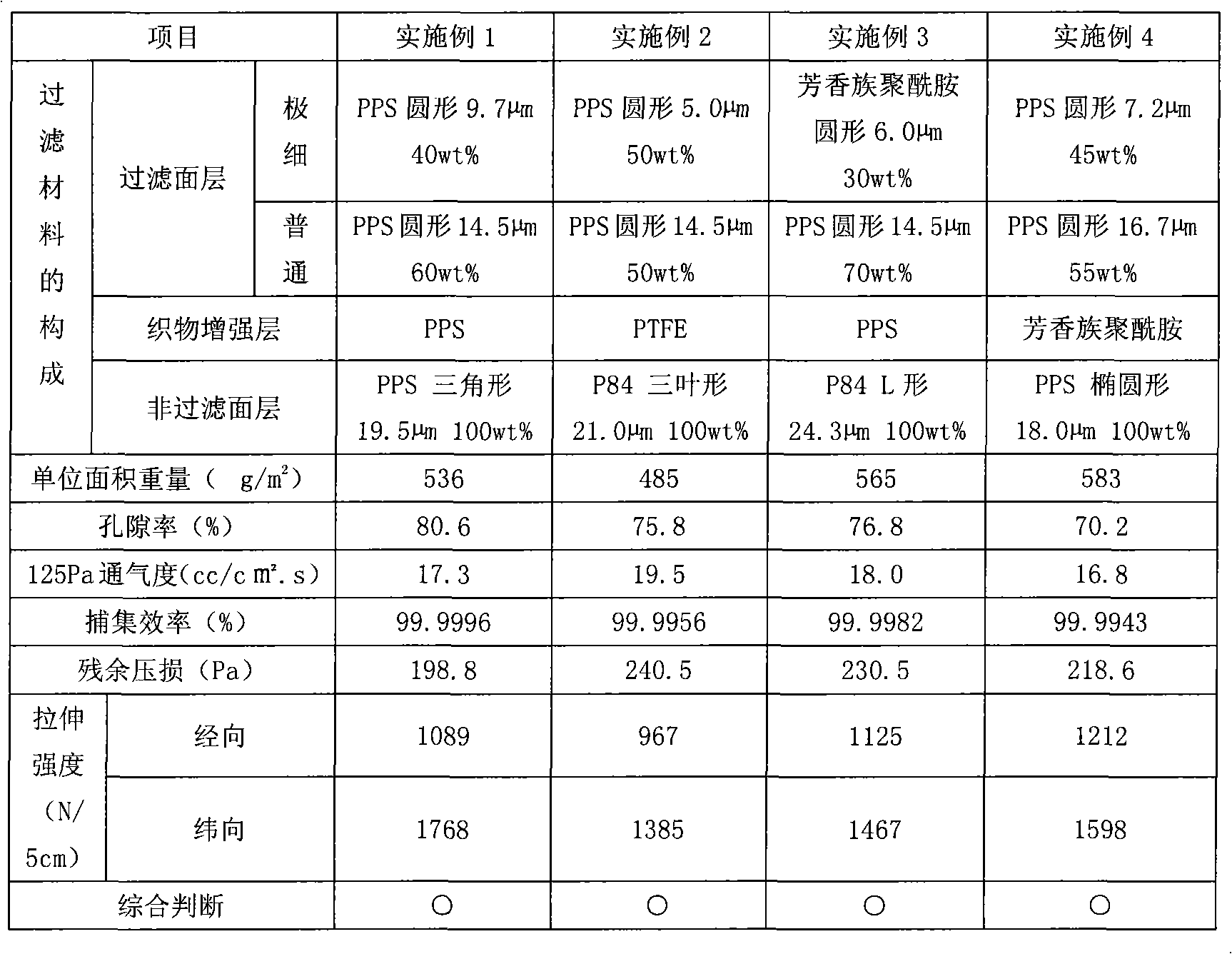

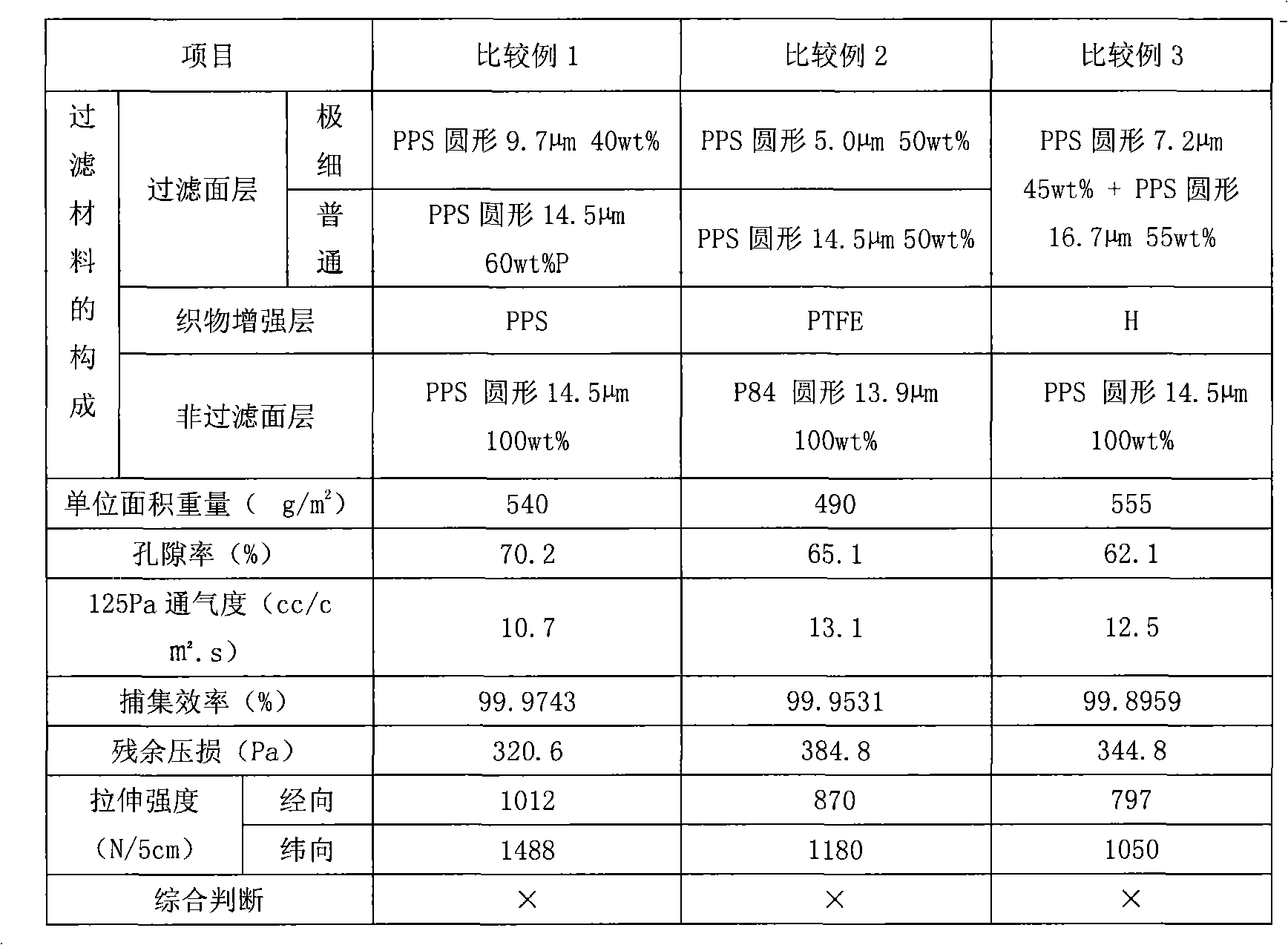

Embodiment 1

[0044] Using PPS short fibers with an average diameter of 13.8μm and a length of 51mm to make a plain weave fabric with a warp density of 38 / 2.54cm and a weft density of 15 / 2.54cm as the fabric reinforcement layer, which is used as the fiber net on the side of the filter surface. The ultra-fine PPS fiber with an average diameter of 9.7μm and a length of 51mm and an ordinary PPS fiber with an average diameter of 14.5μm and a length of 51mm are used at 198g / m 2 The superfine fiber web and the ordinary fiber web formed by laminating and carding the cotton according to the weight of 40wt% and 60wt% respectively. The fiber web that constitutes the non-filter surface side is 198g / m 2 A laminated fiber web with an average diameter of 19.5μm and a length of 51mm is a fiber web formed by opening and carding 100wt% of short fibers with an average diameter of 19.5μm and a length of 51mm. Layer, ordinary fiber mesh layer, fabric reinforcement layer, and non-filter surface fiber web layer ar...

Embodiment 2

[0046] Using PTFE filament fibers with an average diameter of 202.2μm, a plain weave fabric with a warp density of 33 strands / 2.54 cm and a weft density of 33 strands / 2.54 cm is used as the fabric reinforcement layer. The fiber mesh on the side of the filter surface is the average diameter The ultra-fine PPS fiber with 5.0μm and the length of 51mm and the ordinary PPS fiber with the average diameter of 14.5μm and the length of 76mm are 180g / m 2 The unit area weight of the fiber web is respectively laminated, and the ultra-fine fiber web and ordinary fiber web formed by opening and carding the cotton according to the weight of 50wt% and 50wt% respectively. The fiber web constituting the non-filter surface is 180g / m 2 The weight per unit area of the laminated fiber web, the fiber web is 100wt% of P84 trilobal cross-section short fibers with an average diameter of 21.0μm and a length of 51mm to open and card the fiber web, and then according to the extremely fine After the fiber w...

Embodiment 3

[0048] Using PPS short fibers with an average diameter of 13.8μm and a length of 51mm to make a plain weave fabric with a warp density of 30 / 2.54cm and a weft density of 13 / 2.54cm as the fabric reinforcement layer, as the fiber net that constitutes the filter surface. The ultra-fine aromatic polyamide fiber with an average diameter of 6.0μm and a length of 51mm and a common PPS fiber with an average diameter of 14.5μm and a length of 76mm are combined at 220g / m 2 The unit area weight is 30wt% and 70wt% of the ultrafine fiber web and ordinary fiber web formed by opening and carding respectively. The fiber web constituting the non-filter surface is 220g / m 2 The fiber web is laminated with 100wt% of short fibers with an average diameter of 24.3μm and a length of 64mm with a P84L cross-section. The fiber web is formed by opening and carding. After the mesh layer, the ordinary fiber mesh layer, the fabric reinforcement layer, and the non-filter surface fiber mesh layer are laminated i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com