Septic tank special material and preparation method thereof

A technology for special materials and septic tanks, which is applied in the field of special materials for septic tanks and its preparation, can solve the problems of difficult processing and poor fluidity of HDPE processing, and achieve the effects of improving processing fluidity, improving compatibility, and preventing biting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

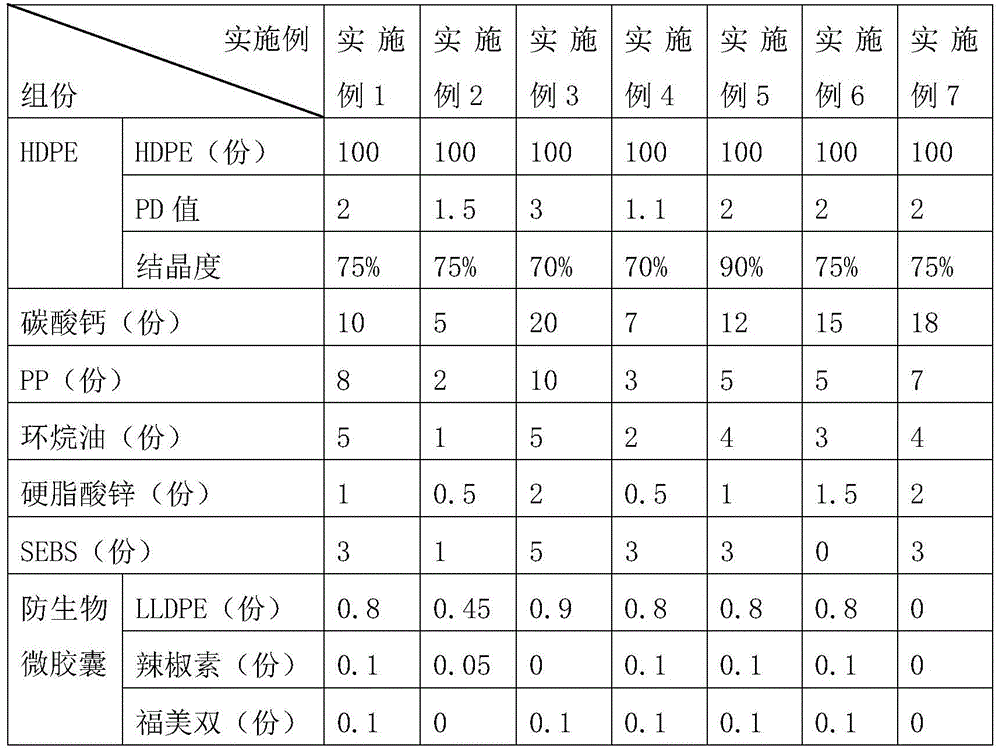

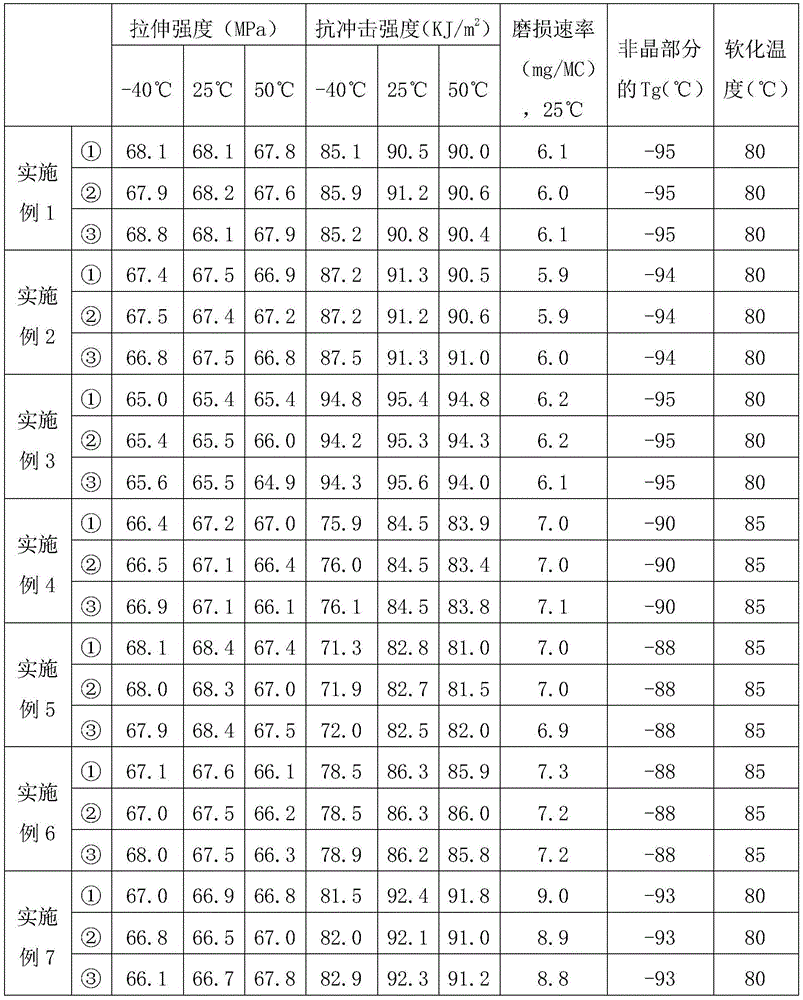

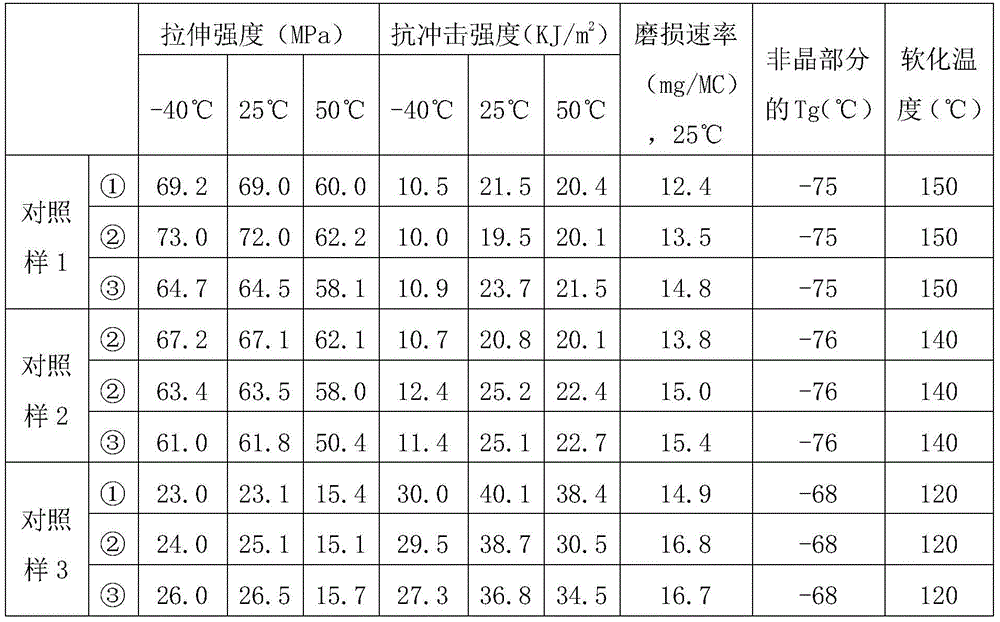

[0031] A special material for septic tanks, its components and parts by weight are as described in Table 1, and it is prepared by the following method:

[0032] S1. Mix HDPE, calcium carbonate, PP, naphthenic oil, zinc stearate and SEBS in the formula, soften and melt at 80-150°C;

[0033] S2, pulverizing the anti-biological agent and spraying it with LLDPE melt, cooling to room temperature to obtain anti-biological microcapsules;

[0034] S3. Add the anti-biological microcapsules obtained in S2 to the melt of S1, and inject to obtain the special material for septic tanks described in this application.

[0035] Table 1 Components and parts by weight statistics of special materials for septic tanks

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com