Thermal treatment technology of high-nitrogen stainless bearing steel

A technology of bearing steel and high nitrogen, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as hardness inconsistency, achieve the effect of ensuring dimensional stability, solving deformation problems and crack problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in detail by means of examples.

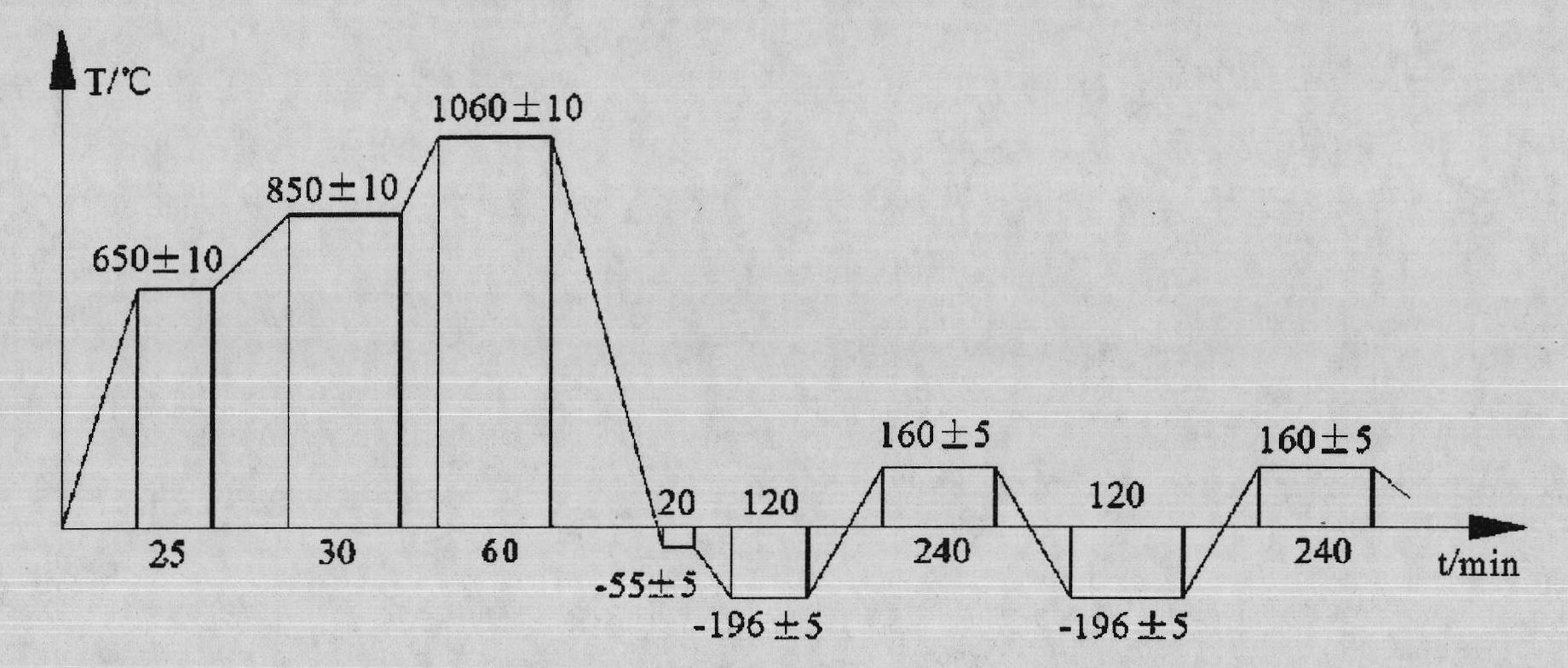

[0021] The heat treatment process of the 40Cr15Mo2VN high-nitrogen stainless bearing steel described in the present invention is: quenching→cold treatment→tempering. Processing equipment includes: ZC 2 -65 vacuum furnace, freezer (model: D-0.8) and tempered oil furnace (model: 130174). Specifically:

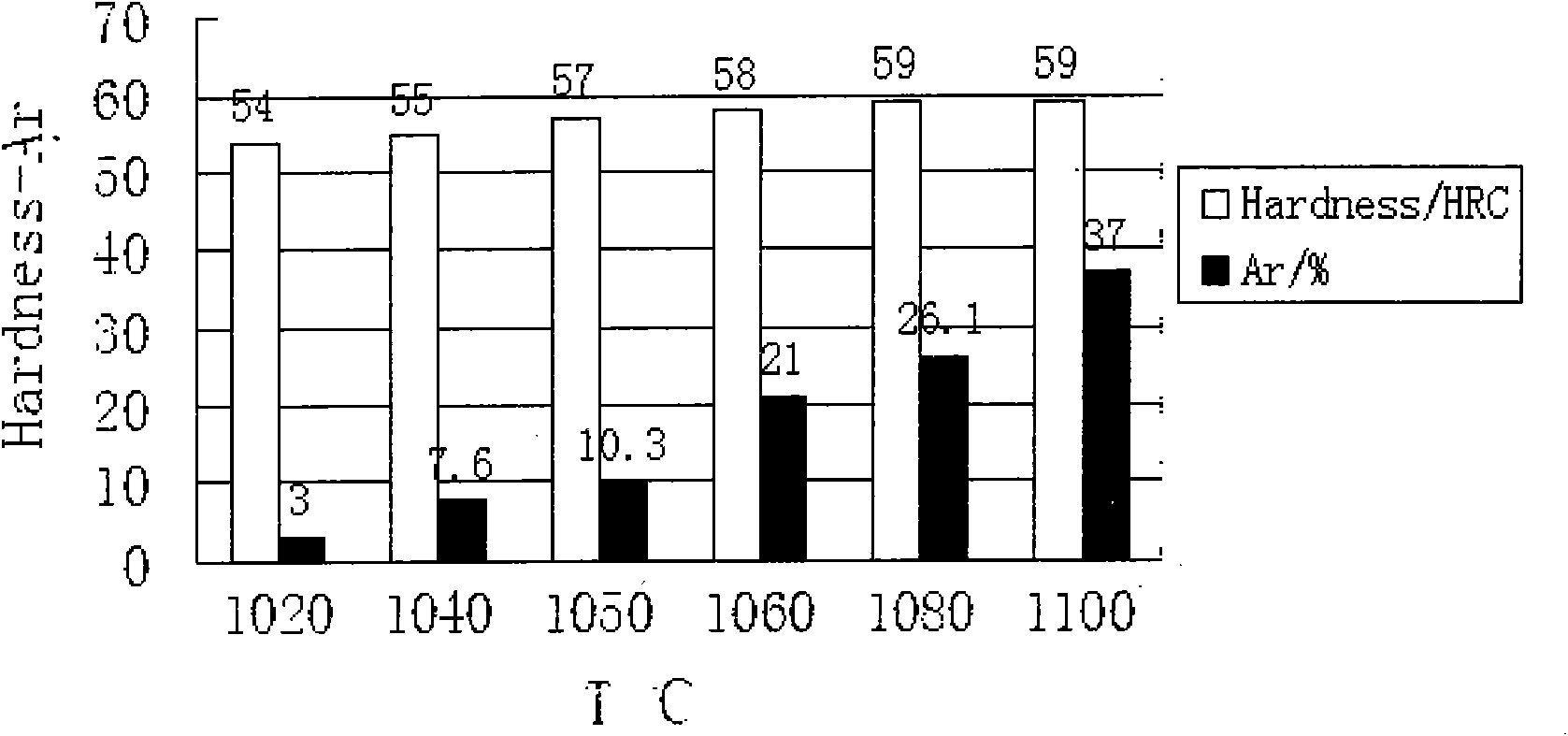

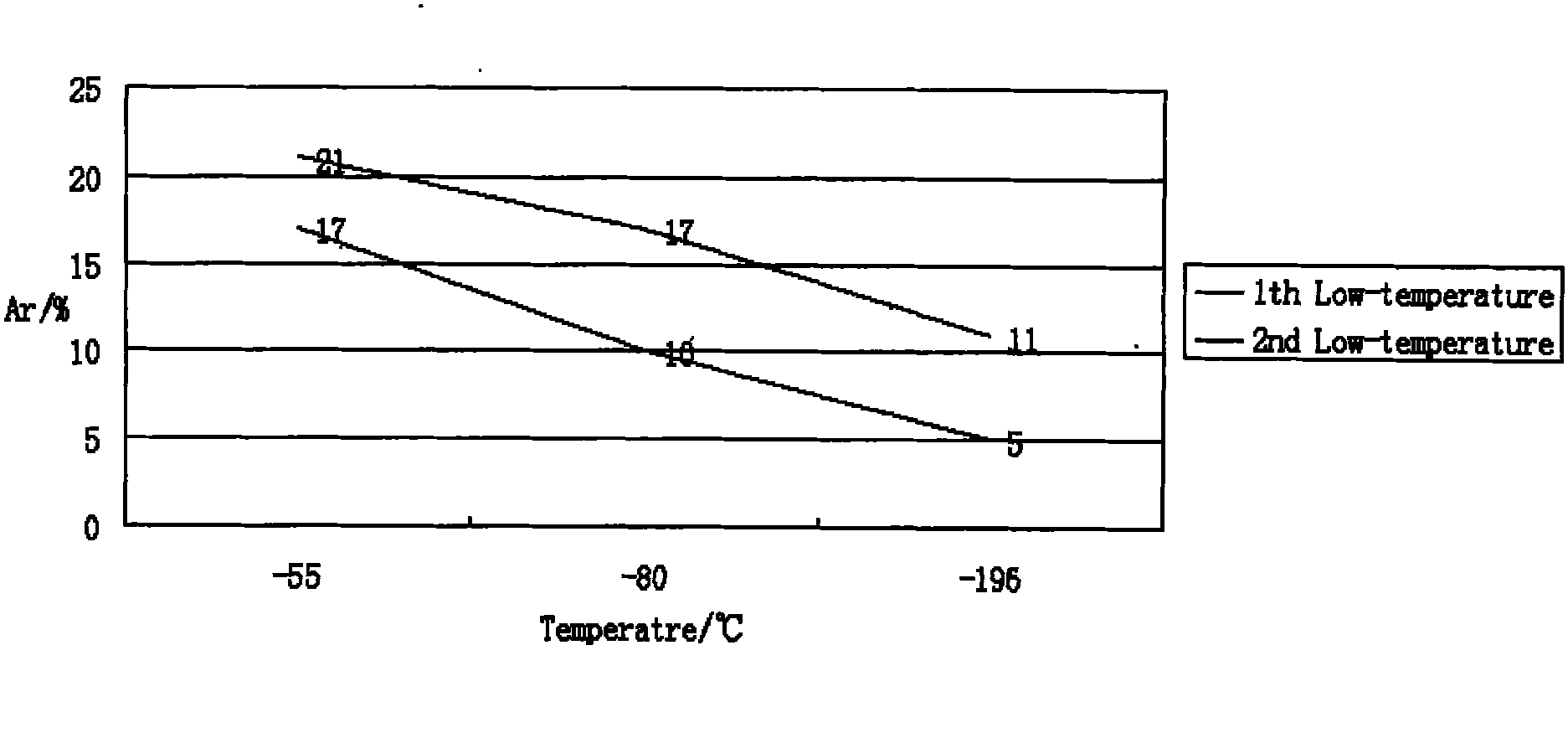

[0022] First use ZC 2 Preheat the 40Cr15Mo2VN workpiece in a -65 vacuum furnace. Preheat once at 650±10°C and 850±10°C. After the temperature rises to 650°C, keep it warm for 25-35 minutes, then continue to heat up to 850°C and keep it warm for 20-45 minutes. After the heat preservation is completed, the temperature is rapidly raised to the quenching temperature; the quenching temperature is 1060±10°C, and the heat preservation is 50-60 minutes; after the quenching and heat preservation is completed, the workpiece is sent from the heating chamber of the vacuum furnace to the oil quenching chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com