Method for manufacturing copper base alloy bearing bush wear-resisting layer

A copper-based alloy and wear-resistant layer technology, applied in the field of surfacing, can solve the problems of low bonding strength, short service life and poor coating performance of the bearing bush coating, and achieve the optimization of the coating structure, the improvement of the bonding strength, and the extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

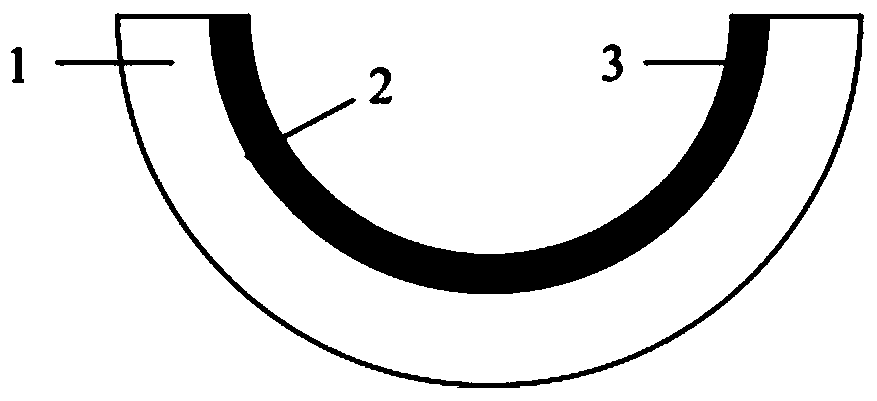

[0018] Specific Embodiment 1: The preparation method of the copper-based alloy bearing wear-resistant layer in this embodiment is carried out according to the following steps:

[0019] 1. Grind the copper alloy bearing bush with fine sandpaper until it appears metallic luster;

[0020] 2. Then use acetone to ultrasonically clean for 5-10 minutes;

[0021] 3. The surface of the bearing bush after cleaning in step 2 is tinned, and the tin water is hung on the surface of the bearing bush;

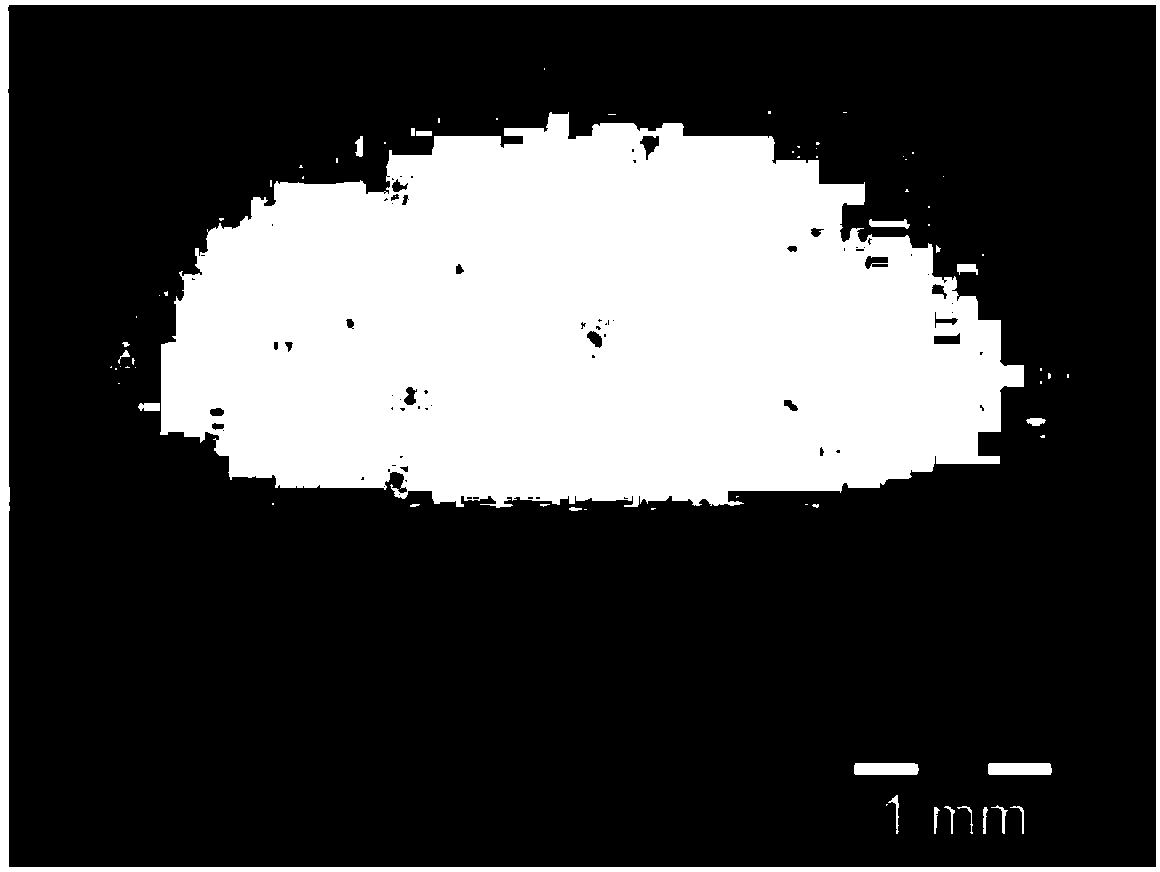

[0022] 4. Under the condition of argon gas protection, use CMT welding machine to surfacing babbitt alloy on the surface of the bearing bush, control the diameter of babbitt alloy welding wire to 1.0~2.0mm, welding current to 40~70A, welding voltage to 10~15V, wire feeding speed 2.0~5.0m / min, welding speed 10~15mm / s, argon gas flow 10~20L / min, babbitt weld layer thickness 2~20mm;

[0023] 5. Adjust the size and flatness of the bearing pad by turning or scraping to complete the preparation of...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is: ultrasonic cleaning with acetone for 5 minutes as described in step 2. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the surfacing welding process described in step 4 is digitally controlled or manually operated using 3D printing control equipment. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com