Nanometer polyamide composition with metal luster and preparation method of nanometer polyamide composition

A technology of polyamide composition and metallic luster, which is applied in the field of nano-polyamide composition and its preparation, can solve the problems of high cost, complex process, and high equipment requirements, and achieve the effect of strong metallic texture, high surface hardness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] 1. Preparation of nano-polyamide masterbatch: the nano-polyamide masterbatch in Examples 1 to 5 of the present invention is a self-made product, and each material component includes polyamide, nanoparticle, silane coupling agent, dispersion aid, anti- Oxygen and other additives are added to the high-mixing equipment, the temperature is controlled at 80-160°C, stirred for 3-15 minutes, and the speed is 500-2000RP / min, the mixed materials are added through the main feeding port of the twin-screw extruder, and the The temperature is 210-280°C, the vacuum is -0.05~-0.08MPa, the rotation speed is 300-500RP / min and other technological conditions, and the granular nano polyamide masterbatch is obtained through twin-screw extruder melt extrusion and granulation.

[0024] 2. The preparation method of the nano-polyamide composition with metallic luster: Weigh each raw material component by weight, and mix the dried polyamide, nano-polyamide masterbatch, dispersion aid and processi...

Embodiment 1

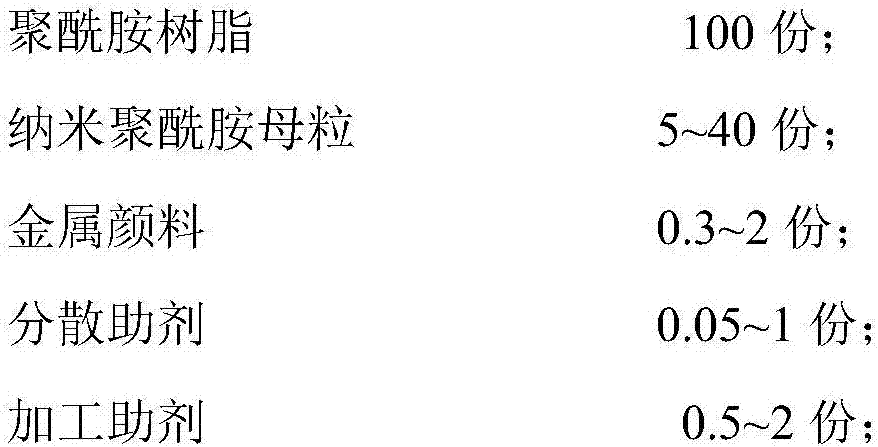

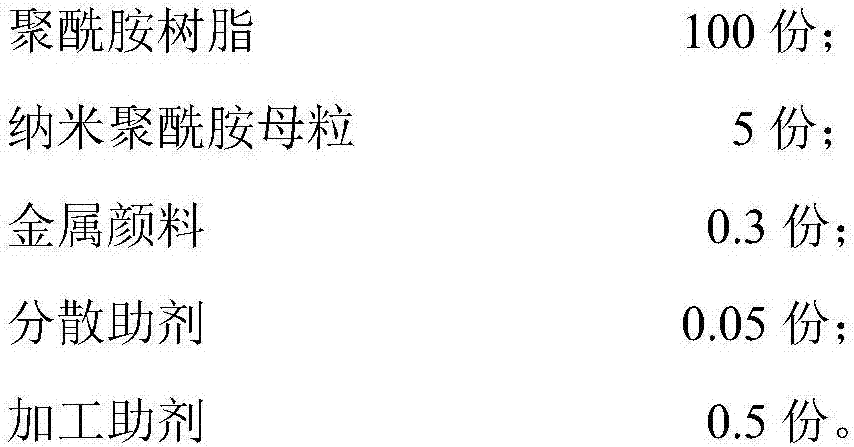

[0026] A nano polyamide composition with metallic luster, which comprises the following raw material components in parts by weight:

[0027]

[0028] Wherein, the polyamide resin is PA6; The content of the nanoparticles in the nano polyamide master batch is 30%wt, wherein the weight ratio of the nanoparticles in the master batch to the dispersing aid in the master batch is 100:5, then the nano polyamide master batch The total amount of nanoparticles in the particle is 1.5 parts, the total amount of dispersing aid is 0.125 parts, and the ratio of the two is 12. The metal pigment is composed of a 3:1 mixture of gold powder and zinc powder with a particle size of 250 μm; the dispersion aid in the nano-polyamide composition and the masterbatch is 0.2 μm carboxyl-terminated core-shell particles; the processing aid includes N , N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, tris(2,4-di-tert-butylphenyl)phosphite mixture, A mixture of sodium iodide and...

Embodiment 2

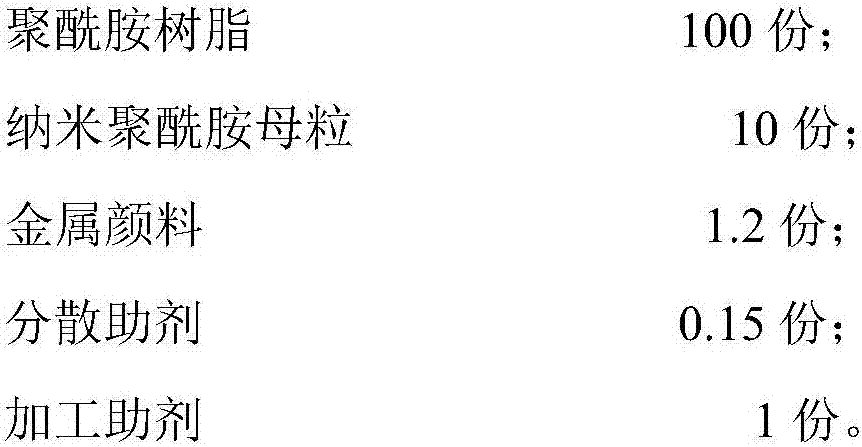

[0030] A nano polyamide composition with metallic luster, which comprises the following raw material components in parts by weight:

[0031]

[0032] Wherein, polyamide resin is PA66; The content of nanoparticle in the nanometer polyamide master batch is 30%wt, wherein the weight ratio of the nanoparticle in the masterbatch and the dispersing aid in the masterbatch is 100:5, then the nanometer polyamide The total amount of nanoparticles in the masterbatch is 3 parts, the total amount of dispersing aid is 0.3 parts, and the ratio of the two is 10. The metal pigment is composed of a 3:1 mixture of gold powder and zinc powder with a particle size of 250 μm; the dispersion aid in the nano-polyamide composition and the masterbatch is 0.2 μm carboxyl-terminated core-shell particles; the processing aid includes N , N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, tris(2,4-di-tert-butylphenyl)phosphite mixture, A mixture of potassium iodide and 2,4-dihy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com