Soft board base material without glue and preparation method thereof

A soft board substrate and base material technology, applied in circuit substrate materials, chemical instruments and methods, printed circuit manufacturing, etc., can solve the problems of poor dimensional stability, different material properties, poor heat resistance, etc., and achieve mechanical processing performance. Good, easy processing, excellent bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the non-adhesive soft board base material is as follows:

[0053] 1. Corona treatment

[0054] According to the characteristics of PI, under the condition of air cleanliness of 10,000 grades, and in the environment of eliminating static electricity, the polyimide (PI) film with a thickness of 3-50um and a width of 20-1200mm is sent into the corona machine. The surface of the film is subjected to surface corona treatment to improve the adhesion performance of the surface of the base material PI film. During the corona treatment, the control voltage is 5000-20000V, and the corona voltage and current are adjusted until the surface energy of the PI film reaches 50. -55 dyne.

[0055] Wherein, the corona treatment described in the present invention is conventional surface corona treatment.

[0056] 2. Physical vapor deposition treatment

[0057] Send the corona-treated base material PI film into the magnetron sputtering equipment, control the tem...

Embodiment 1

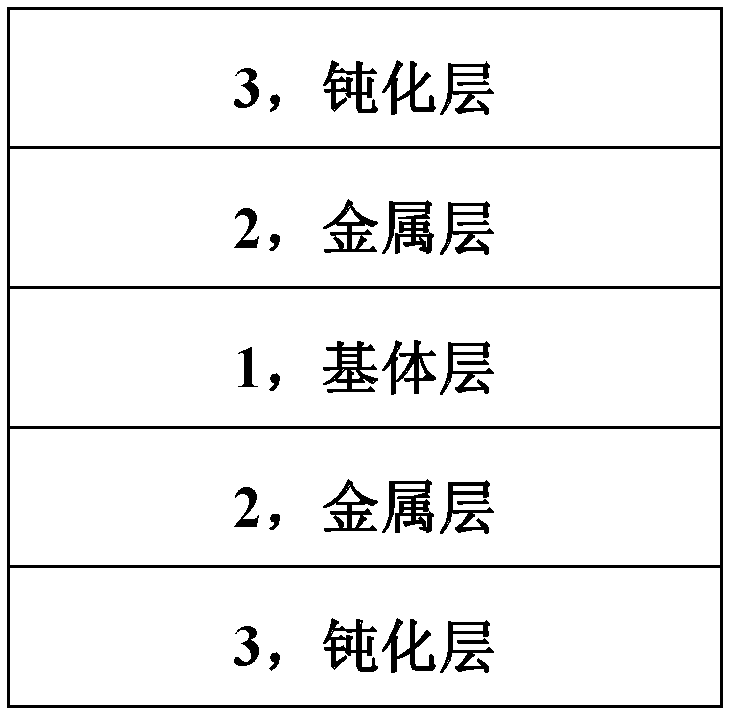

[0068] Example 1 Preparation method of non-adhesive soft board substrate with double-sided metal layer

[0069] 1. Corona treatment

[0070] According to the characteristics of PI, under the condition of air cleanliness of 10,000 grades, and in the environment of eliminating static electricity, the polyimide (PI) film base material with a thickness of 50um and a width of 1200mm is sent into the corona machine, the PI film Surface corona treatment is carried out on both sides (that is, the upper and lower sides) to improve the adhesion performance of the surface of the PI film of the base material. During the corona treatment, the control voltage is 20000V, and the corona voltage and current are adjusted to reach the surface energy of the PI film. Reach 50 dyne.

[0071] Wherein, the corona treatment described in the present invention is conventional surface corona treatment.

[0072] 2. Physical vapor deposition treatment

[0073] Send the PI film of the base material that ...

Embodiment 2

[0084] Example 2 Preparation method of non-adhesive soft board substrate with single-sided metal layer

[0085] 1. Corona treatment

[0086] According to the characteristics of PI, under the condition of air cleanliness of 10,000 grades, and in the environment of eliminating static electricity, the polyimide (PI) film base material with a thickness of 3um and a width of 30mm is sent into the corona machine, the PI film Surface corona treatment is carried out on one side (ie, the upper surface) to improve the adhesion performance of the surface of the PI film of the base material. In the process of corona treatment, the control voltage is 5000V, and the corona voltage and current are adjusted to reach the surface energy of the PI film. Reach 55 dyne.

[0087] Wherein, the corona treatment described in the present invention is conventional surface corona treatment.

[0088] 2. Physical vapor deposition treatment

[0089] Send the PI film of the substrate material treated by s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com