Nubby low-density gel heat-insulation composite material

A composite material and low-density technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of increased thermal conductivity and increased material density, and achieve the effect of not being prone to cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 400ml of ethanol, 55ml of TEOS, and 12ml of water into a 500ml beaker, stir evenly, add HCl ethanol solution dropwise, adjust the pH to 4, stir vigorously for 6 hours, add 1.0g of PAA with a molecular weight of 15 million, and stir well to a homogeneous phase , add 0.05 mol of HF, stir vigorously for 2-3 minutes, airtight and static aging for 6 days, put the wet gel into the kettle, add 50ml of ethanol, and carry out supercritical drying at 270°C under the constant pressure of 12MPa to obtain large pieces Low density airgel composites.

Embodiment 2

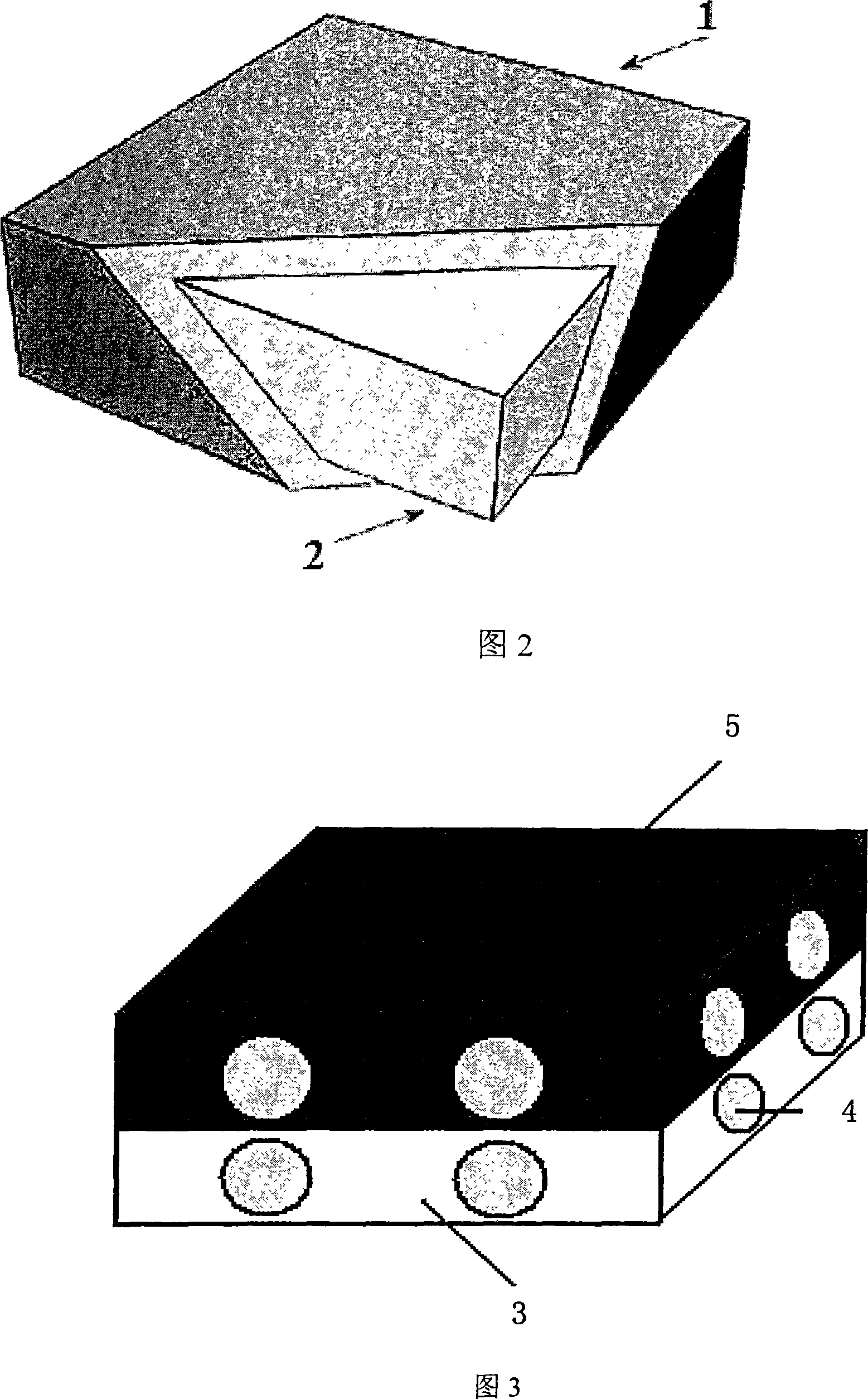

[0027] Fully mix 30 parts by weight of aluminum oxide powder, 60 parts by weight of water glass and 10 parts by weight of sodium fluorosilicate to prepare encapsulation slurry A, and coat the above encapsulation materials on a large low-density 5×2.5mm On the airgel composite material (Example 1), the coating thickness is 0.2mm, and the coating form is shown in Figure 2: put it in an oven at 40°C, cure it for 12 hours, then put it in an oven at 80°C, and dry it for 2 hours to obtain a large Block low-density airgel-encapsulated composites.

[0028] Put the bulk low-density airgel-encapsulated composite into a tube furnace and pass N 2 Gas, raised to 650°C at 1°C / min and calcined for 12 hours, and then cooled naturally to prepare a large low-density, high-temperature heat-insulating airgel-encapsulated composite material.

Embodiment 3

[0030] Fully mix 30 parts by weight of silicon carbide powder, 60 parts by weight of water glass and 10 parts by weight of sodium fluorosilicate to prepare encapsulation slurry B, coat encapsulation slurry A and B according to accompanying drawing 3, and then implement The operation of Example 2, the obtained bulk low-density airgel encapsulation composite material, can obtain the bulk low-density high-temperature heat-insulating airgel encapsulation composite material, the black encapsulation surface of the material is in contact with high temperature, and the white encapsulation surface is in contact with low temperature , can improve the heat insulation effect more effectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com