Acrylic and fleece coarse gauge weft knitting double-napped shell fabric and production method thereof

A manufacturing method and a technology of thick gauge, which are applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of good warmth retention, inability to provide a sense of wool, and low-cost fleece fabrics, so as to achieve full suede and improve Soft touch, good touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An acrylic and wool thick-gauge weft-knitted double-sided fleece fabric. The polyester elastic yarn is used as the ground yarn, and the high-shrinkage acrylic / wool / fine-denier acrylic fiber blended yarn is used as the terry yarn. A weft-knitted double-sided fleece fabric made from single-sided terry fabric woven on a weft-knitting terry machine and finished after napping.

[0018] Wherein, the count of the polyester elastic yarn is 150D / 96F, the blending ratio of the high-shrinkage acrylic / wool / fine denier acrylic fiber blended yarn ranges from 30 to 40 / 10 / 50 to 60, and the blended yarn count is 20 ~30 N / 2.

Embodiment 2

[0020] A method for manufacturing acrylic fiber and wool thick gauge weft-knitted double-sided fleece fabric, using polyester elastic yarn as ground yarn, high shrinkage acrylic fiber / wool / fine denier acrylic fiber blended yarn as terry yarn, through thick gauge single The single-face terry fabric woven on the face circular weft-knitting terry machine is made after the napping step.

[0021] Wherein, the count of the polyester elastic yarn is 150D / 96F, the blending ratio of the high-shrinkage acrylic / wool / fine denier acrylic fiber blended yarn ranges from 30 to 40 / 10 / 50 to 60, and the blended yarn count is 20 ~30 N / 2.

[0022] Wherein, the manufacturing method specifically includes the preparation process in sequence: yarn preparation, weft knitting, pretreatment, presetting, dyeing, napping, and setting.

[0023] Wherein, in the weft knitting process, the weaving tension of the pile yarn is controlled at 18-22g.

[0024] Wherein, the napping treatment process is specifica...

specific example

[0026] 150D / 96F polyester elastic yarn as ground yarn, 24 N / 2 High-shrinkage acrylic / wool / fine-denier acrylic fiber blended yarn is terry yarn, and the blending ratio is 35 / 10 / 55, and the reverse-wrapped terry fabric is woven on a 30-inch single-sided weft-knitting terry machine with a gauge of 8, The braiding tension is 20g.

[0027] The rough fabric goes through a post-finishing process of pretreatment, dyeing, light napping on the surface, heavy carding, low shearing, and shaping, and finally becomes a double-faced fleece fabric.

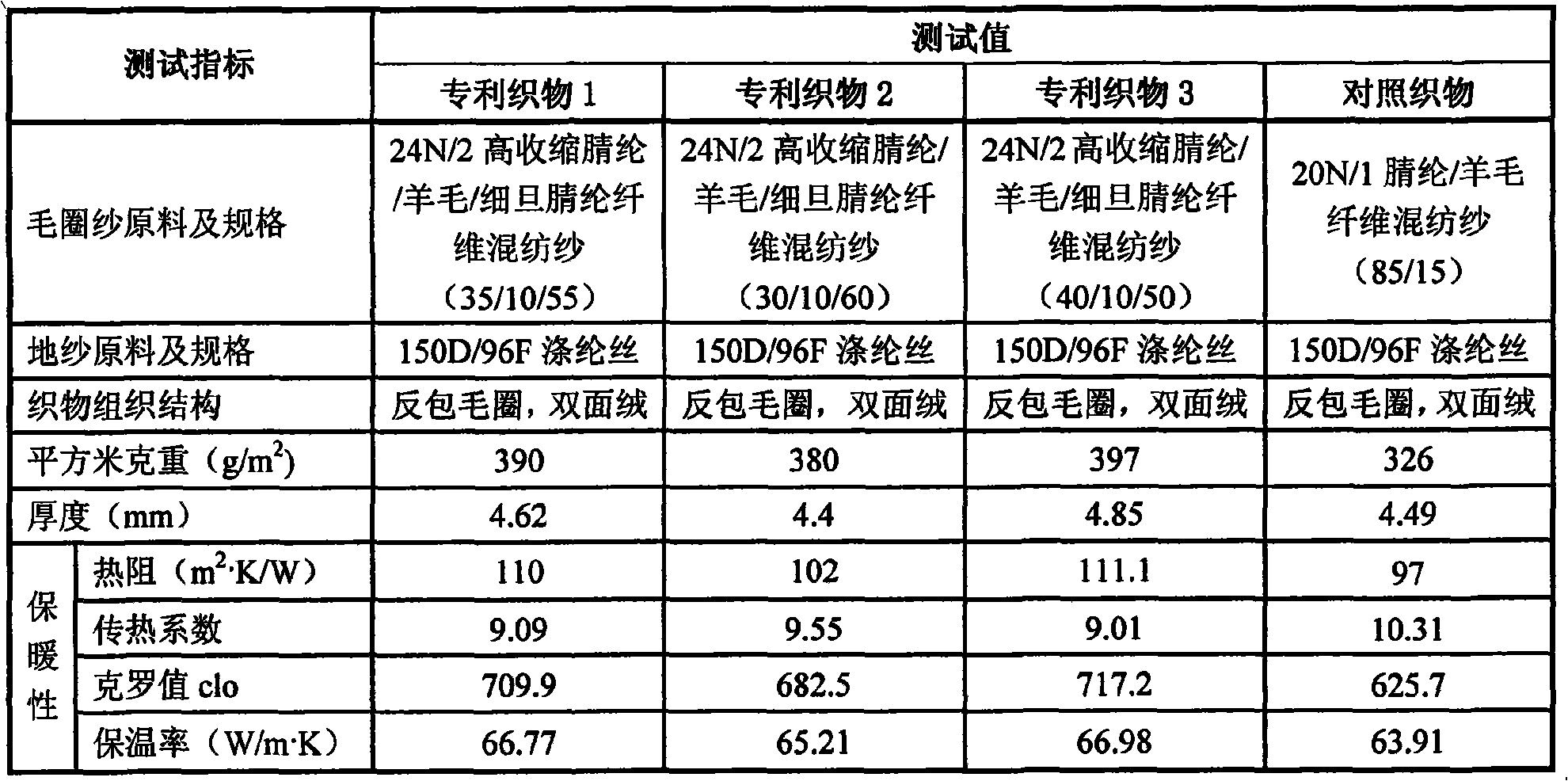

[0028] Shown in table 1 is on the No. 8 terry machine, the double-faced fleece fabric prepared by using the high-shrinkage acrylic / wool / fine-denier acrylic fiber blended yarn and special technology described in this patent and the conventional acrylic / wool blended The parameters and performance comparison results of fabrics with the same structure prepared by yarn and conventional technology can be seen from the table that the finished product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com