Soybean protein jelly and preparation method thereof

A technology of soybean protein and jelly, which is applied in the field of soybean protein jelly and its preparation, to achieve the effects of reducing risk, smooth and delicate taste, and soft tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

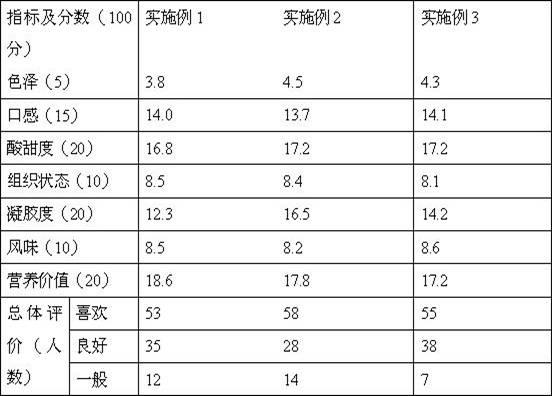

Examples

Embodiment 1

[0027] Embodiment 1 jelly drink formula and preparation process thereof

[0028] Formula (based on 1 ton):

[0029] Acid soluble soybean protein (produced by Pingdingshan Tianjing Plant Protein Co., Ltd.) 45kg

[0030] High fructose syrup 120kg

[0031] Apple juice 50kg

[0032] Agar 7kg

[0033] Citric acid 3kg

[0034] Sodium citrate 2kg

[0035] Apple flavor 2kg

[0036] Water 771kg

[0037] Raw material standard:

[0038] Acid Soluble Soy Protein (ASSP): Protein≥90.0% Fat≤1.0%

[0039] High fructose syrup: F≥42.0%

[0040] Other raw materials are in line with national standards.

[0041] The concrete preparation process of present embodiment soybean protein jelly is as follows:

[0042] 1) ASSP chemical material: At room temperature, slowly add 45kg of acidic soluble soybean protein into the batching tank containing 380kg of water, stir evenly, and then homogenize once under the condition of 15MPa. During the homogenization process, the pressure is guaranteed ...

Embodiment 2

[0051] Example 2 Formula of jelly product and its preparation process

[0052] Formula (based on 1 ton):

[0053] Acid Soluble Soy Protein 40kg

[0054] High fructose syrup 118kg

[0055] Concentrated Orange Juice 60kg

[0056] Agar 5kg

[0057] Carrageenan 3kg

[0058] Citric acid 4kg

[0059] Sodium citrate 2kg

[0060] Orange flavor 1.5kg

[0061] Water 766.5kg

[0062] Raw material standard:

[0063] Acid Soluble Soy Protein (ASSP): Protein≥90.0% Fat≤1.0%

[0064] High fructose syrup: F≥42.0%

[0065] Other raw materials are in line with national standards.

[0066] The concrete preparation process of present embodiment soybean protein jelly is as follows:

[0067] 1) ASSP chemical material: at room temperature, slowly add 40kg of acidic soluble soybean protein into a batching tank of 350kg of water, stir evenly, and then homogenize once under the condition of 15MPa, and keep the pressure constant during the homogenization process. After homogenization, the ...

Embodiment 3

[0076] Example 3 Cup-packed soft jelly formula and its preparation process

[0077] Formula (based on 1 ton):

[0078] Acid Soluble Soy Protein 39kg

[0079] Sucrose 100kg

[0080] Lychee Juice 60kg

[0081] Agar 3.3kg

[0082] Gellan Gum 3kg

[0083] Citric acid 3kg

[0084] Lactic acid 2kg

[0085] Sodium citrate 2.4kg

[0086] Lychee essence 2kg

[0087] Water 785.3kg

[0088] Raw material standard:

[0089] Acid Soluble Soy Protein (ASSP): Protein≥90.0% Fat≤1.0%

[0090] High fructose syrup: F≥42.0%

[0091] Other raw materials are in line with national standards.

[0092] Concrete preparation process of the present invention is as follows:

[0093] 1) ASSP chemical material: at room temperature, slowly add 39kg of acidic soluble soybean protein into the batching tank containing a certain amount of 350kg of water, stir evenly, and then homogenize once under the condition of 15MPa. During the homogenization process, the pressure is guaranteed to be constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com