Low temperature baking process of heat conductive corundum-mullite ceramic tile

A technology of mullite and ceramic bricks, which is applied in the field of production and firing of corundum-mullite ceramic bricks with good heat conduction at low temperature, can solve the problems of large energy consumption, achieve the promotion of sintering process, improve the compactness, The effect of superior mechanical properties and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Using kaolin, ball clay, alumina, feldspar, corundum and spodumene as the main raw materials, the chemical composition of corundum-mullite ceramic bricks is shown in Table 2, and the calorific value of the fuel used is shown in Table 3.

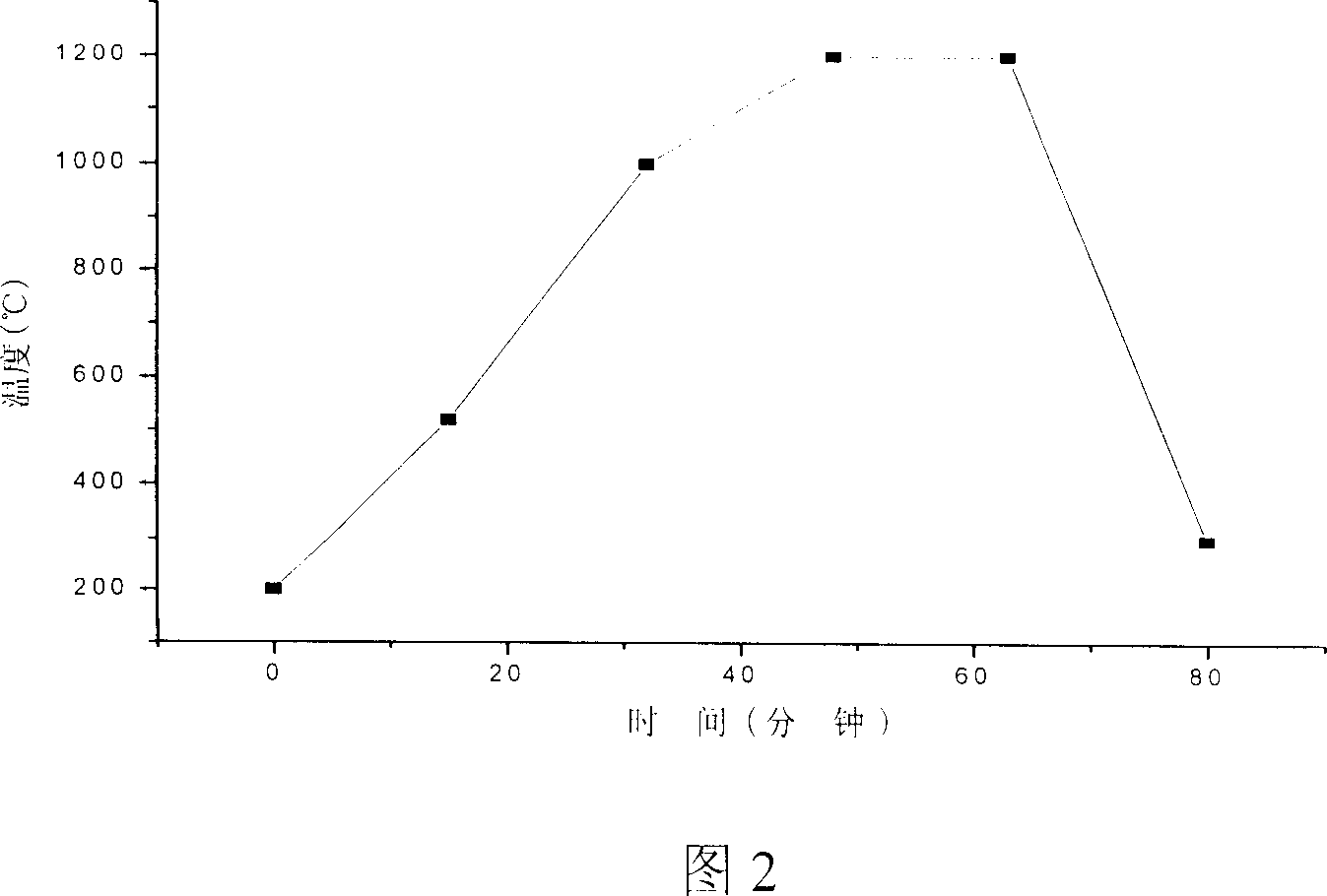

[0047] As shown in Figure 1, it is a process flow diagram of the present invention; Figure 2 is a firing temperature curve of the present invention.

[0048] (1) Raw material processing: including raw material crushing and wet ball milling process, crushing the raw materials, weighing 55.8Kg of raw ball clay, 45.3Kg of kaolin, 33Kg of alumina, 4.3Kg of corundum, 97.8Kg of feldspar, and 13.2kg of spodumene , 27.9Kg of quartz and 34.8Kg of wollastonite are mixed, adding 0.5% sodium tripolyphosphate by weight percentage, then the material is wet ball milled, the ball milling medium is alumina, the ball milling time is 20h, and the moisture content is 31%. The sieve residue is less than 1%, and the fluidity is about 36s in Tu-4 cups.

[0...

Embodiment 2

[0054] Using kaolin, ball clay, alumina, feldspar, corundum and spodumene as the main raw materials, the chemical composition of corundum-mullite ceramic bricks is shown in Table 2, and the calorific value of the fuel used is shown in Table 3. Under the same process conditions and additives, spodumene is used to replace part of feldspar as flux raw material.

[0055] (1) Raw material processing: including raw material crushing and wet ball milling process, crushing the raw material, weighing 50.4Kg of raw material ball clay, 34.8Kg of alumina, 41.1Kg of kaolin, 8.5Kg of corundum, 88.5Kg of feldspar, and 28.2 kg of spodumene , quartz 25.2Kg, wollastonite 31.5Kg, add 0.5% sodium tripolyphosphate by weight percentage, and then carry out wet ball milling to the material, the ball milling medium is alumina, the ball milling time is 22h, and the sieve residue is less than 1%. A mud with a water content of 32% is obtained, and its fluidity is 40 seconds after Tu-4 cups of outflow.

...

Embodiment 3

[0061] With kaolin, ball clay, alumina, corundum, feldspar and spodumene as the main raw materials, the chemical composition of corundum-mullite ceramic bricks is shown in Table 2, and the calorific value of the fuel used is shown in Table 3. Under the same process conditions and additives, spodumene is used to replace part of feldspar as flux raw material, and corundum is added as the main raw material to increase the content of corundum main crystal phase.

[0062] (1) Raw material processing: including raw material crushing and wet ball milling process, crushing raw materials, weighing 46.5Kg of raw materials ball clay, 32.1Kg of alumina, 37.8Kg of kaolin, 24Kg of corundum, 81.9Kg of feldspar, and 26.1Kg of spodumene , 22.8Kg of quartz and 28.5Kg of wollastonite are mixed, adding 0.5% sodium tripolyphosphate by weight percentage, and then the material is wet ball milled, the ball milling medium is alumina, the ball milling time is 24h, and the moisture content is 33%. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com