High-temperature-resistant and oxidation-resistant metal-based self-lubricating composite material and preparation method thereof

A composite material and anti-oxidation technology, which is applied in the field of high temperature corrosion resistance and self-lubrication, can solve the problems of not being able to fully combine self-lubrication and high-temperature oxidation resistance, achieve excellent high-temperature oxidation resistance, improve high-temperature oxidation resistance, and improve aluminum The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, nickel-based alloy Ni-27Cr-11Al-0.5Y (wt.%) is used as the alloy matrix, cerium oxide is used as an antioxidant, eutectic with calcium fluoride / barium fluoride, enamel and aluminum oxide Together, prepare this composite material, its concrete preparation parameter is as follows:

[0047] (1) Enamel micropowder: the formula for smelting enamel glaze is 60wt% of silicon dioxide, 5wt% of diboron trioxide, 10wt% of aluminum oxide, 9wt% of sodium oxide, 7wt% of potassium oxide and 9wt% of zinc oxide. According to the proportion of enamel ingredients, mix various oxides by ball milling at a speed of 320 rpm for 24 hours; heat and smelt at 1500 ° C, and water quench to obtain enamel glaze; planetary ball milling for 100 hours to obtain enamel with a particle size of less than 10 μm Enamel micropowder.

[0048] (2) Powder mixing: the composite material is in accordance with the following composition ratio, nickel-based alloy 72wt%, calcium fluoride / barium f...

Embodiment 2

[0063] The difference from Example 1 is that the high-temperature and oxidation-resistant metal-based self-lubricating composite material consists of 82wt% nickel base alloy, 4wt% calcium fluoride / barium fluoride eutectic (the weight of calcium fluoride and barium fluoride The percentages are 32% and 68%, respectively), enamel 5wt%, aluminum oxide 6wt%, cerium oxide 3wt%.

[0064] After being oxidized at 900°C for 100 hours, the oxidation product of the composite material is aluminum oxide, and the oxidation weight gain is only 0.35 mg / cm 2 , has excellent high temperature oxidation resistance. And the comparison test sample NiCr alloy (the alloy matrix phase selected in the high temperature self-lubricating composite material reported by NASA in the United States), its oxidation product after oxidation is dichromium trioxide, and the oxidation weight gain reaches 2.61mg / cm 2 , and the oxidation rate is 7 times higher than that of the high-temperature-resistant and anti-oxida...

Embodiment 3

[0066] The difference from Example 1 is that the nickel-based alloy composition selected for the preparation of the high-temperature-resistant and anti-oxidation composite material is Ni-8Co-16Cr-12Al-3.5Mo-4Ti (wt.%).

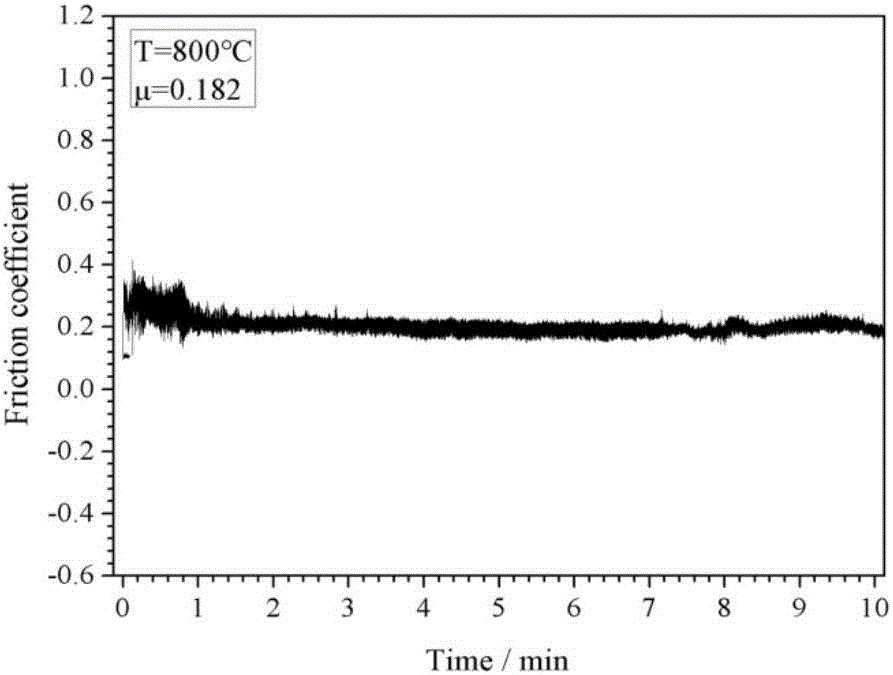

[0067] The friction coefficient curve of the composite material at 800°C is as follows image 3 As shown, the average friction coefficient is only 0.18, and the friction curve is smooth, and the wear amount is 1.9×10 -6 mm 3 / (Nm). And the NiCr-CaF reported in the literature (Surf.Coat.Technol.203(2009) 3058) 2 / BaF 2 -Cr 3 C 2 The high-temperature self-lubricating composite material of the system has a friction coefficient of 0.40 at 800°C and a wear loss of 4.8×10 -6 mm 3 / (Nm). In comparison, the high-temperature-resistant and anti-oxidation metal-based self-lubricating composite material provided by the present invention exhibits excellent comprehensive properties of high-temperature resistance, oxidation resistance and self-lubrication.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com