Zinc-aluminum-silicon-rare earth alloy for hot-dip plating steel tube and preparation method thereof

A rare earth alloy and hot-dip plating technology, which is applied in hot-dip plating process, metal material coating process, coating, etc., to achieve the effects of reducing production costs, inhibiting growth, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

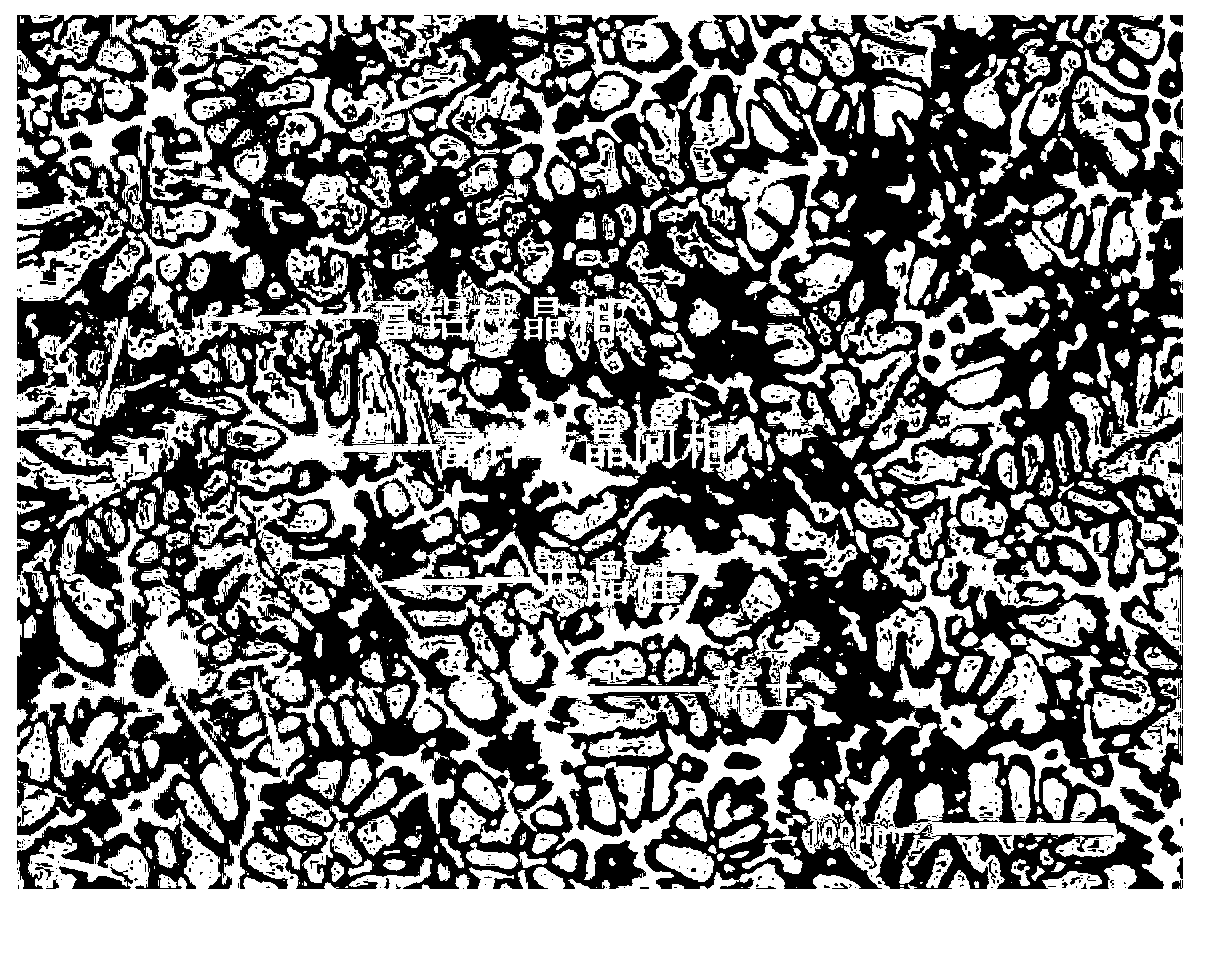

Image

Examples

Embodiment 1

[0032] Preparation method of Zn-30.0wt.%Al-1.5wt%Si-0.6wt.%La alloy

[0033] Step 1: Add zinc ingots accounting for 70.0% of the weight of the Zn-Al alloy into an intermediate frequency induction furnace, raise the temperature to 680°C, add aluminum ingots accounting for 30.0% of the weight of the Zn-Al alloy, melt and stir for 20 minutes; cool down to 620°C And keep it warm for 30 minutes, and cast the ingot into Zn-Al master alloy;

[0034] The second step: select Al-12.0wt.%Si master alloy and Al-10.0wt.%La master alloy as the object of alloying treatment, or prepare the above-mentioned master alloy by the following method.

[0035] 1. Preparation of Al-12.0wt.%Si master alloy

[0036] Put the aluminum ingot accounting for 88.0% of the weight of the Al-Si master alloy into the medium-frequency induction furnace, raise the temperature to 720°C, add a salt covering agent on the surface of the aluminum liquid, and use a bell jar to press the silicon block accounting for 12.0%...

Embodiment 2

[0041] Preparation method of Zn-27.0wt.%Al-1.0wt%Si-0.1wt.%La alloy

[0042] The first and second steps of the alloy preparation method are the same as the example one;

[0043] Step 3: Put the zinc ingot accounting for 9.9067% of the total weight of the alloy and the zinc-aluminum master alloy accounting for 90% of the total weight of the alloy in a medium-frequency induction furnace, raise the temperature to 720°C, add a salt covering agent on the surface of the alloy liquid, and use a clock Press the aluminum-silicon master alloy of 0.0833% of the total weight of the alloy into the alloy liquid, melt and stir to mix evenly; cool down to 650°C, press the aluminum-lanthanum master alloy accounting for 0.01% of the total weight into the molten alloy with a bell jar In the alloy liquid, stir continuously until it is uniform, keep it warm for 30 minutes, remove the slag, and pour it into a metal mold of 300×150mm.

Embodiment 3

[0045] Preparation method of Zn-22.0wt.%Al-1.0wt%Si-0.1wt.%La alloy

[0046] The first and second steps of the alloy preparation method are the same as the example one;

[0047] Step 3: Put the zinc ingot accounting for 26.9067% of the total weight of the alloy and the zinc-aluminum master alloy accounting for 73% of the total weight of the alloy in an intermediate frequency induction furnace, raise the temperature to 720°C, add a salt covering agent on the surface of the alloy liquid, and use a clock Press the aluminum-silicon master alloy of 0.0833% of the total weight of the alloy into the alloy liquid, smelt and stir to mix evenly; cool down to 650°C, press the aluminum-lanthanum master alloy accounting for 0.01% of the total weight of the alloy into the molten alloy with a bell jar In the alloy liquid, stir continuously until it is uniform, keep it warm for 30 minutes, remove the slag, and pour it into a metal mold of 300×150mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com