Method for selectively recovering alum and gallium from alunite concentrate

An alunite and selective technology, applied in the direction of improving process efficiency, etc., can solve the problems of little practical application value, harsh method conditions, long process flow, etc., and achieve the effect of good comprehensive recovery effect, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

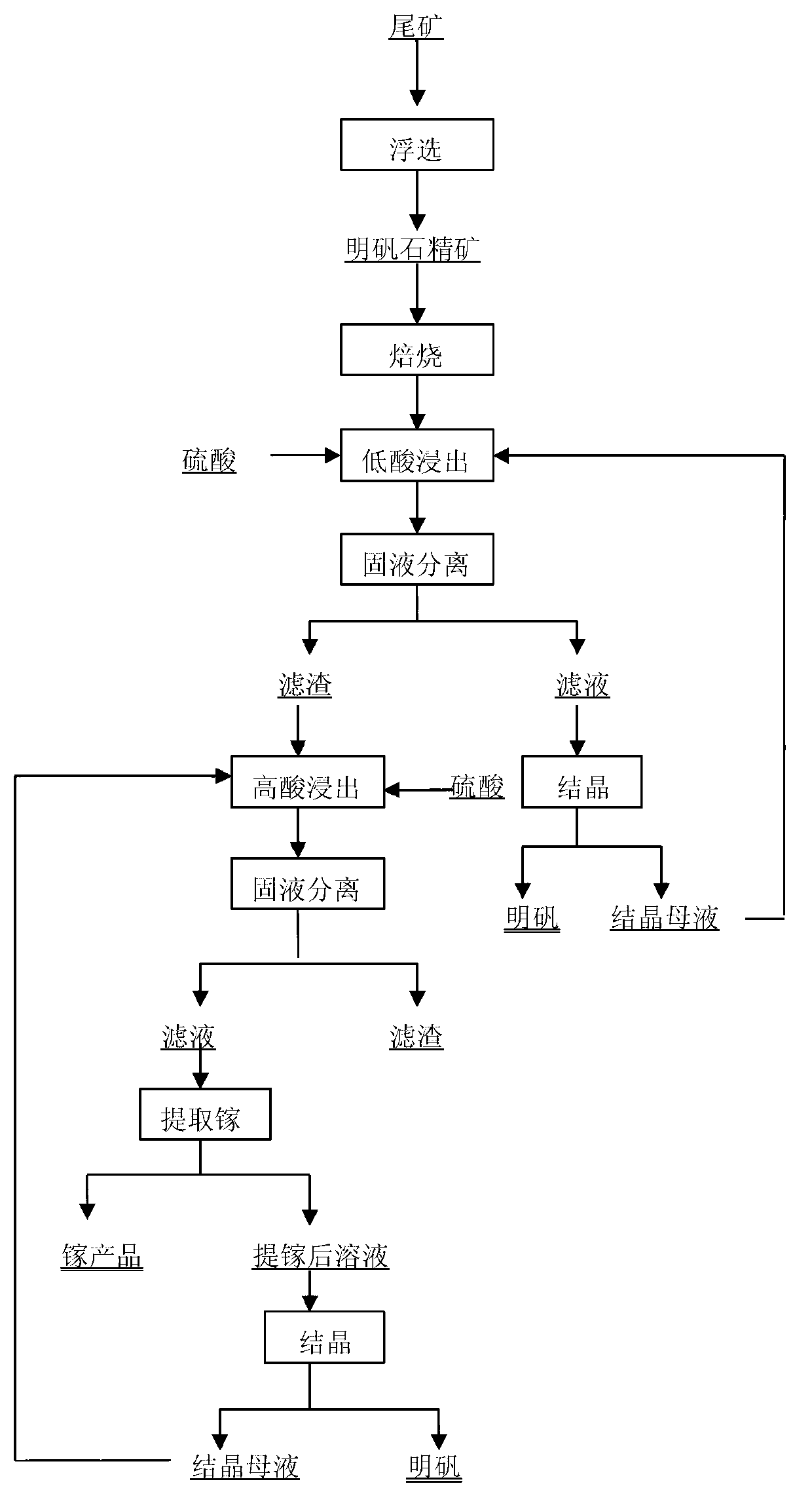

Method used

Image

Examples

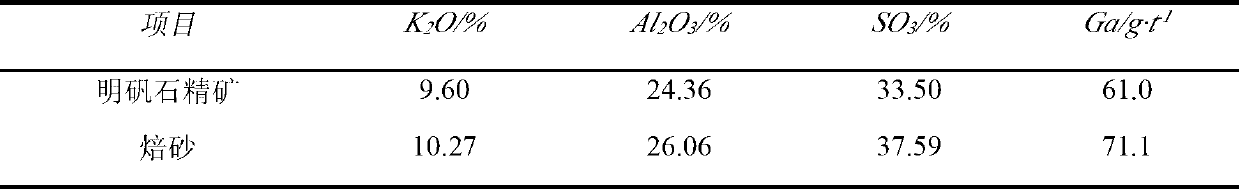

example 1

[0023] Example 1: the alunite concentrate is first placed in a muffle furnace for roasting, and the roasting condition is 400 ° C of temperature and 0.5 hour time; the calcined sand obtained is leached at a low sulfuric acid concentration once, and the primary leaching condition is L / S=4 , temperature 90 ℃, time 0.5 hours, acidity 40g / L, solid-liquid separation after acid leaching is completed, the solution is naturally crystallized to obtain alum product and the mother liquor after crystallization, the crystallized alum is taken out, and the crystallization mother liquor is added to the acidity of 40g / L and returned to For acid leaching of calcined sand, the leaching residue is slurried and then leached at high sulfuric acid concentration. Liquid separation, the filtrate is supplemented with sulfuric acid concentration to 150g / L and then returned to secondary acid leaching. The circulating liquid obtained after 5 cycles of this cycle contains 300mg / L of gallium, and ion exchan...

example 2

[0024] Example 2: Alumite concentrate is first placed in a muffle furnace for roasting, and the roasting condition is 500 ° C of temperature and 1 hour time; the calcined sand obtained is leached at a low sulfuric acid concentration once, and a leaching condition is L / S=5 , temperature 70 ℃, time 1 hour, acidity 60g / L, solid-liquid separation after acid leaching is completed, the solution is naturally crystallized to obtain alum product and mother liquor after crystallization, the crystalline alum is taken out, and the crystallization mother liquor is added to the acidity of 60g / L and returned to For acid leaching of calcined sand, the leaching residue is slurried and then leached for a second time under high sulfuric acid concentration. The secondary leaching conditions are: L / S=3, temperature 50°C, time 1 hour, acidity 180g / L, and solidification after acid leaching is completed. Liquid separation, the filtrate was supplemented with sulfuric acid concentration to 180g / L and th...

example 3

[0025] Example 3: Alumite concentrate is first placed in a muffle furnace for roasting, and the roasting condition is a temperature of 600 ° C and a time of 2 hours; the obtained calcine is leached at a low sulfuric acid concentration once, and a leaching condition is L / S=6 , temperature 80 ℃, time 1.5 hours, acidity 70g / L, solid-liquid separation after acid leaching is completed, the solution is naturally crystallized to obtain alum product and the mother liquor after crystallization, the crystallized alum is taken out, and the crystallization mother liquor is added to the acidity of 70g / L and returned to For acid leaching of calcined sand, the leaching residue is slurried and then leached at high sulfuric acid concentration. Liquid separation, the filtrate was supplemented with sulfuric acid concentration to 200g / L and then returned to secondary acid leaching. The circulating liquid obtained after 8 cycles of this cycle contained 240mg / L of gallium, and the gallium was extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com