Method for producing alum by utilizing alunite

Alum stone and alum technology, applied in the field of alum production by utilizing alum stone, can solve problems such as unreasonable roasting process, influence on alum crystallization rate, long alum production cycle, etc., and achieve the effects of shortening production cycle, short roasting time and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

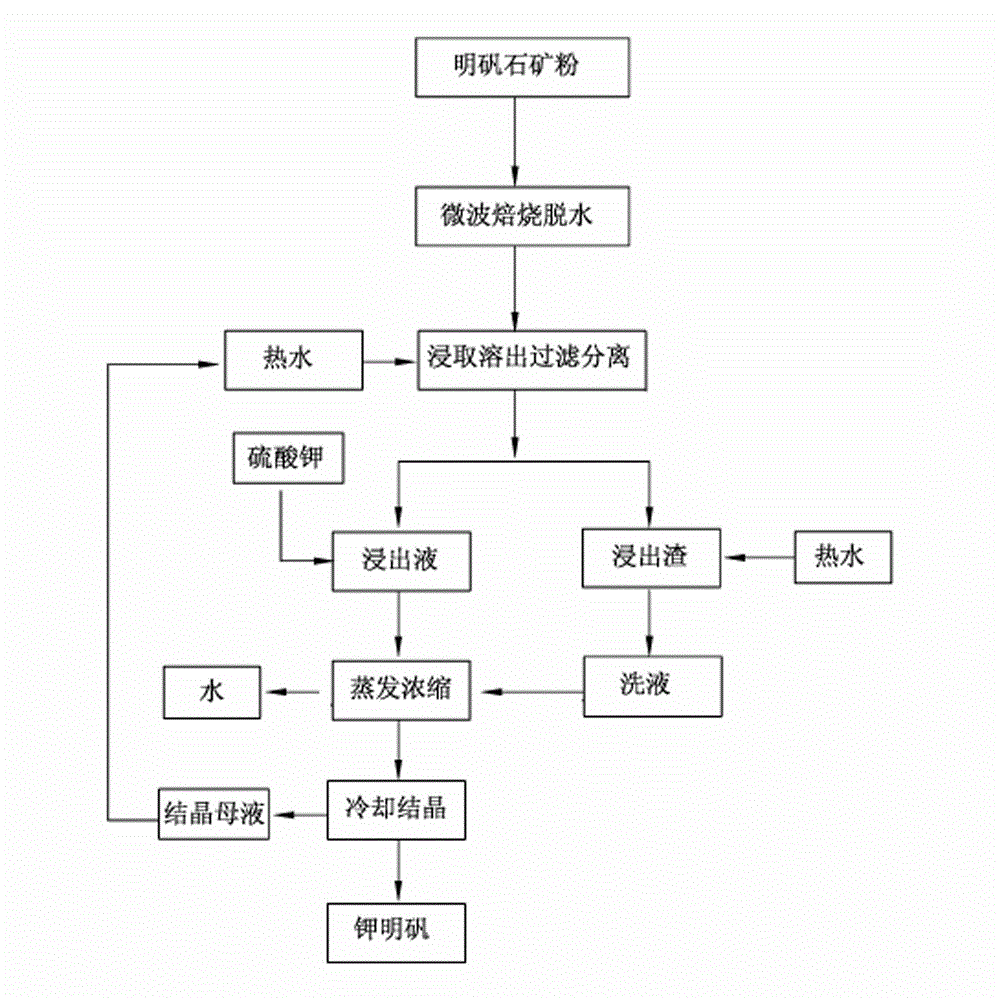

Method used

Image

Examples

Embodiment 1

[0040] The specific implementation of this embodiment includes the following steps:

[0041] (1), choose alunite mineral powder:

[0042] Alunite ore is crushed, ground or floated to obtain alunite concentrate. The ore grade is 50-65%, and the fineness of ore powder is 80-200 mesh (0.175-0.074mm).

[0043] (2) Mineral powder microwave roasting dehydration:

[0044] The ore powder is roasted and dehydrated with microwave thermal equipment, the microwave frequency is 2450MHz, the microwave output power is 1.0-5.0KW, the microwave radiation time is 10-60min, the dehydration rate of ore clinker is 95-99%, and the decomposition rate is 2-5 % , A1 2 o 3 The dissolution rate is 90-95%.

[0045] (3) Sulfuric acid solution leaching and dissolution, filtration and separation:

[0046] The dehydrated alunite (clinker) is leached and dissolved with sulfuric acid solution, heat-preserved and filtered, solid-liquid separation, the leached residue is washed with hot water, and the was...

Embodiment 2

[0051] The steps of this embodiment are the same as in Embodiment 1. Select alunite concentrate from flotation (alunite A1 in the ore 2 o 3 16.53%, dickite A1 2 o 3 12.56 %, Total A1 2 o 3 29.09%). The fineness of mineral powder is about 200 mesh (0.074mm). The amount of alunite mineral powder is 100 grams, and the mineral powder is dehydrated by microwave roasting, and the microwave radiation time is 30 minutes. Dehydrated alunite (clinker) with 40ml of sulfuric acid (98%), heated 500g of water, heated for leaching and leaching, the leaching and leaching temperature was 100°C, and the leaching and leaching time was 2.0h. Insulation filtration, solid-liquid separation. The leaching residue is washed with hot water, and the washing liquid is incorporated into the leaching liquid. Add 42 grams of potassium sulfate to the leaching solution, and stir to dissolve. The leaching solution is heated, evaporated and concentrated until the concentration of the alum stock soluti...

Embodiment 3

[0053] The steps and experimental conditions of this example are the same as in Example 2. Potassium sulfate was not added in the leaching solution, and 142 grams of potassium alum / aluminum sulfate were obtained, including 40 grams of potassium alum. The crystallization mother liquor is recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com