Ceramic large board ground glaze and preparation method thereof

A bottom glaze and ceramic technology, applied in the field of ceramic tiles, can solve problems such as high production costs, reduced economic benefits, and low yield, and achieve good antifouling and chemical corrosion resistance, strong controllability of process parameters, and high production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

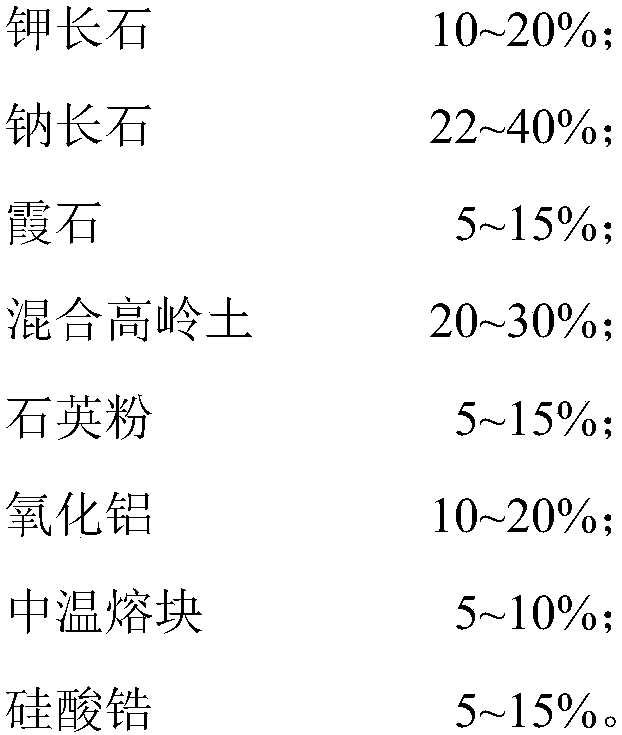

[0026] A ceramic slab base glaze, the high-temperature firing temperature of which is 1185-1215°C, comprising the following components in terms of raw material weight percentage:

[0027]

[0028] Wherein, the potassium feldspar is K 2 O content accounts for the feldspar raw material of 7%; The albite is Na 2 Feldspar raw material with O content of 13%; the mixed kaolin is a mixture of raw kaolin and calcined kaolin with a weight ratio of 1:3; Al in the nepheline is by mass percentage 2 o 3 Content is 20%, K 2 O content is 8%, Na 2 The O content is 5%; SiO is calculated by mass percentage in the medium temperature frit 2 The content is 60%, Al 2 o 3 The content is 10%; the base glaze includes the following main chemical components in terms of mass percentage: 22% Al 2 o 3 , 65% SiO 2 , 0.01% Fe 2 o 3 , 0.9% CaO, 0.1% MgO, 0.99% K 2 O, 1% Na 2 O, 0.6% TiO 2 , 5.4% ZrO 2 , 4% loss on ignition.

[0029] Preparation:

[0030] 1) Put each component into the glaz...

Embodiment 2

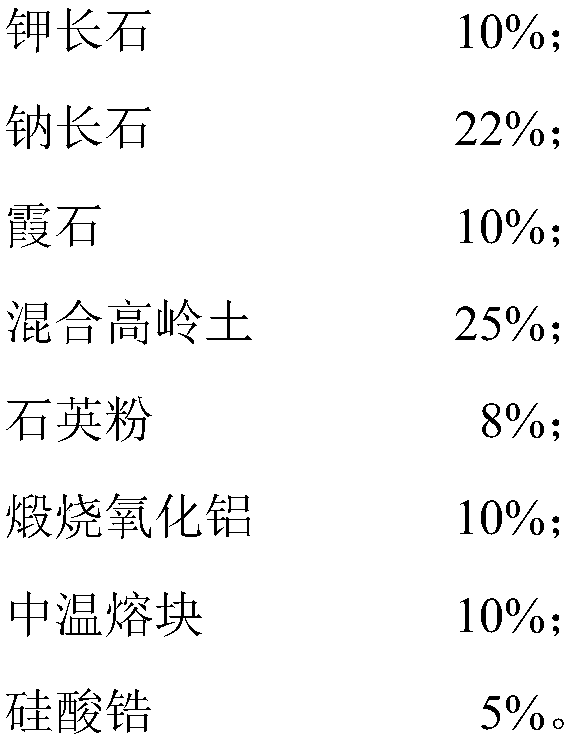

[0033] A ceramic slab base glaze, the high-temperature firing temperature of which is 1185-1215°C, comprising the following components in terms of raw material weight percentage:

[0034]

[0035] Wherein, the potassium feldspar is K 2 O content accounts for the feldspar raw material of 14%; The albite is Na 2 Feldspar raw material with O content of 7%; the mixed kaolin is a mixture of raw kaolin and calcined kaolin with a weight ratio of 1:3; Al in the nepheline is by mass percentage 2 o 3 Content is 30%, K 2 O content is 1%, Na 2 The O content is 10%; SiO is calculated by mass percentage in the medium temperature frit 2 The content is 75%, Al 2 o 3 The content is 2%; the base glaze includes the following main chemical components in terms of mass percentage: 29.25% Al 2 o 3 , 50% SiO 2 , 0.45% Fe 2 o 3 , 0.1% CaO, 0.1% MgO, 0.5% K 2 O, 1% Na 2 O, 0.6% TiO 2 , 10% ZrO 2 , 8% loss on ignition.

[0036] Preparation:

[0037]1) Put each component into the glaz...

Embodiment 3

[0040] A ceramic slab base glaze, the high-temperature firing temperature of which is 1185-1215°C, comprising the following components in terms of raw material weight percentage:

[0041]

[0042] Wherein, the potassium feldspar is K 2 O content accounts for the feldspar raw material of 10%; The albite is Na 2 Feldspar raw material with O content of 10%; the mixed kaolin is a mixture of raw kaolin and calcined kaolin with a weight ratio of 1:3; Al in the nepheline is by mass percentage 2 o 3 Content is 25%, K 2 O content is 4%, Na 2 The O content is 8%; SiO is calculated by mass percentage in the medium temperature frit 2 The content is 70%, Al 2 o 3 The content is 8%; the base glaze includes the following main chemical components in terms of mass percentage: 25% Al 2 o 3 , 55% SiO 2 , 0.2% Fe 2 o 3 , 0.7% CaO, 0.4% MgO, 1.5% K 2 O, 8% Na 2 O, 0.3% TiO 2 , 4% ZrO 2 , 4.9% loss on ignition.

[0043] Preparation:

[0044] 1) Put each component into the glaze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com