High voltage sulphur resistant translation catalyst of CO and preparation method thereof

A sulfur-resistant conversion and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of alkali metal loss and achieve low activation temperature , a wide range of conditions, and high retention rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

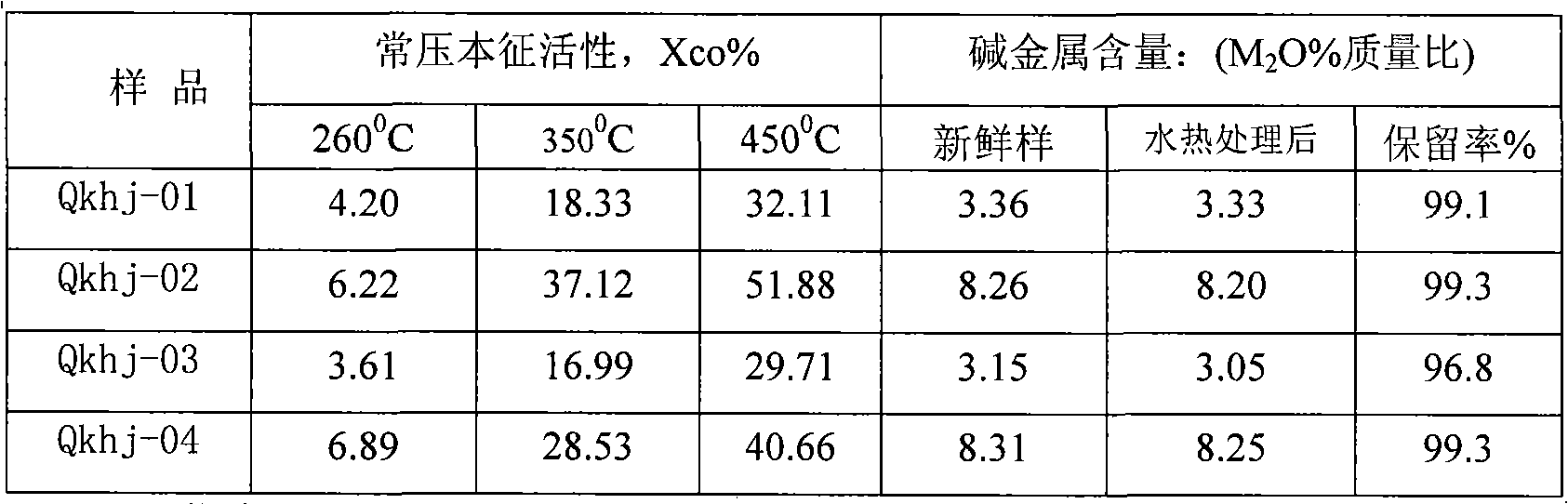

Embodiment 1

[0052] 11g of potassium feldspar was crushed and mixed with 71g of pseudoboehmite and 27g of MgO·Al 2 o 3 Mix evenly, make powdery mixture, above-mentioned mixture is added the mixing solution that is made into by 6g ammonium molybdate and 3.5g cobalt nitrate and mixes beating, and its gained slurry is dried at 400 ℃ so that moisture content reaches 8%, obtains Semi-finished product: after the semi-finished product is pulverized, add 3g of field grass powder and mix evenly, then add 100ml of 10% nitric acid solution, knead it, extrude it, and roast the strip at 500°C for 3 hours to obtain the finished catalyst. The sample number is: Qkhj-01.

Embodiment 2

[0054] 28g potassium feldspar was crushed and mixed with 62g Al(OH) 3 and 18g MgO Al 2 o 3 Mix evenly, make powdery mixture, above-mentioned mixture adds the mixed solution that is made into by 6g ammonium molybdate and 4.6g cobalt nitrate and mixes beating, and its gained slurry is dried at 600 ℃ so that moisture content reaches 4%, obtains Semi-finished product: crush the semi-finished product, add 4g of methyl methacrylate and mix evenly, add 8g of magnesium nitrate solution, knead it, extrude it, and roast the strip at 400°C for 5 hours to obtain the finished catalyst. The sample number is: Qkhj-02.

Embodiment 3

[0056] 11g of kalephine was crushed and mixed with 95g of MgO·Al 2 o 3 Mix evenly to obtain a powdery mixture, which is added to a mixed solution made of 4.2g ammonium molybdate and 3.5g cobalt nitrate for mixing and beating, and the resulting slurry is dried at 170°C so that the moisture content reaches 15%. Obtain a semi-finished product; after the semi-finished product is pulverized, add 3g of grass powder and 1.3g of citric acid and mix evenly, then add 82ml of 20% nitric acid solution, knead it, extrude it, and roast the strip at 300°C for 6 hours That is, the finished catalyst is obtained. The sample number is: Qkhj-03.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com